Voltage stabilizing device for glue coating and developing equipment and glue coating and developing equipment

A technology of glue developing and voltage stabilization device, which is applied in the fields of optomechanical equipment, microlithography exposure equipment, photolithography process exposure device, etc. Longer service life, reduced rework rate, stable uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

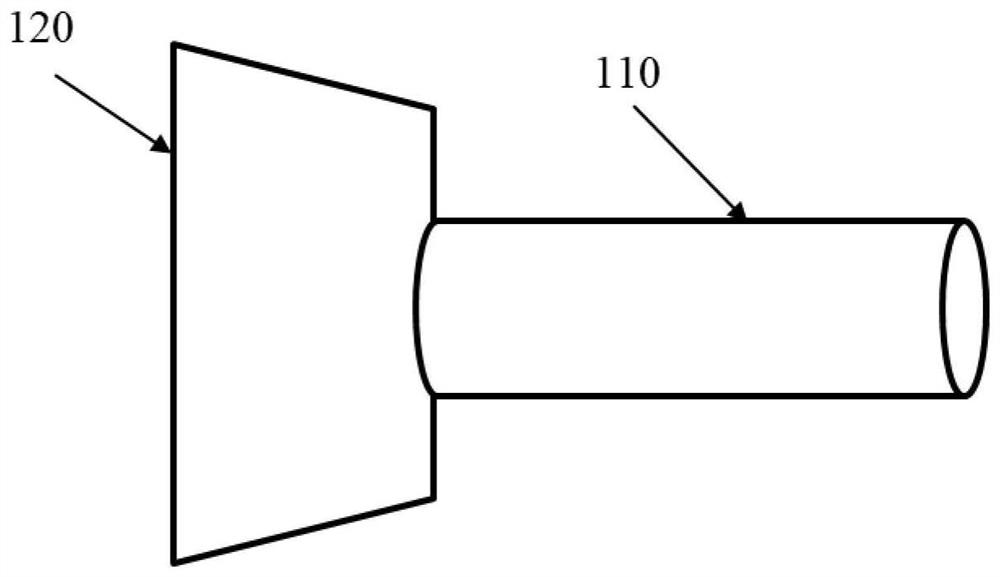

[0047] The diversion port 120 is disposed at the air inlet end 131 of the wind tunnel 110, and communicates with the through hole 130. the guide

[0049] The limiting port 114 is disposed on the side wall of the through hole 130 close to the air inlet end 131 (ie the wind tunnel).

[0050] The piston 112 is located on the side of the limiting port 114 close to the air inlet end 131, and the piston 112 and

[0051] The spring 116 is arranged on the side of the limiting port 114 away from the air inlet end 131, and the spring 116 is ring-shaped.

[0052] The crank 117 and the crank connecting rod 118 are arranged on a side of the spring 116 away from the air inlet end 131.

[0053] When the piston 112 is in contact with the limit opening 114 (ie, the through hole 130 is closed), the spring 116 is in the

[0054] The propeller 113 is arranged at one end of the bearing 111 close to the air outlet end 132, and the propeller

[0057] In a stable state, the crank 117 and the bearing 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com