Device for controlling pressure difference between forming department and hot-cutting department of glass substrate

A glass substrate and control device technology, applied in glass forming, glass forming, glass manufacturing equipment, etc., can solve problems such as the influence of pressure difference, the change of the position of the iron sheet, and the stability of the product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

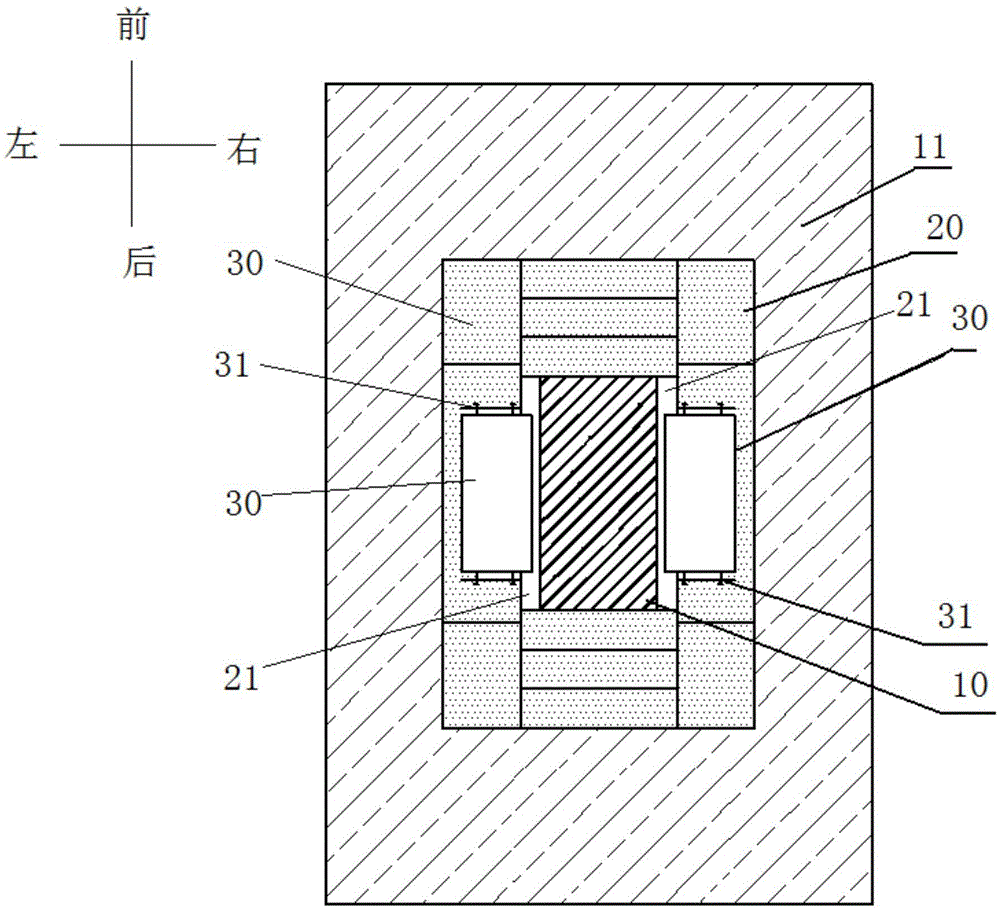

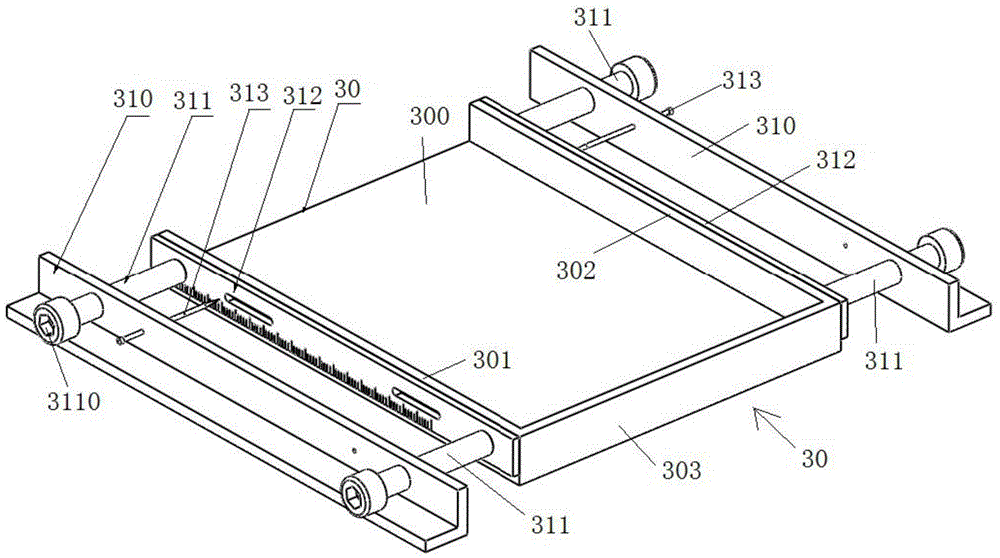

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a pressure difference control device between the glass substrate forming room and the heat-cutting room, which includes the forming room and the heat-cutting room separated by a partition board 11, the partition board 11 is formed with mounting holes, and the annealing furnace 10 penetrates Through the mounting hole and spaced apart from the mounting hole to form an annular gap surrounding the annealing furnace 10. The pedal 20 is used to partially seal the annular gap, and between the pedal 20 and the annealing furnace 10 are formed on the left and right sides of the annealing furnace 10, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com