Titanium dioxide suspension for chinlon polymerization and preparation method thereof

A technology of titanium dioxide and suspension, which is applied in the field of nylon preparation, can solve the problems of short switching period of melt filter, decreased spinnability of slices, and decreased heat exchange efficiency, and achieves less impact, stable pressure difference, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

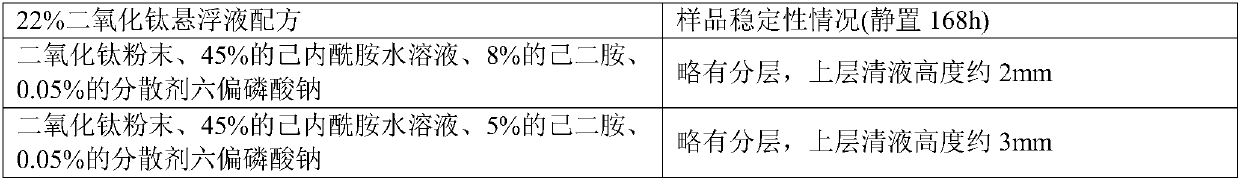

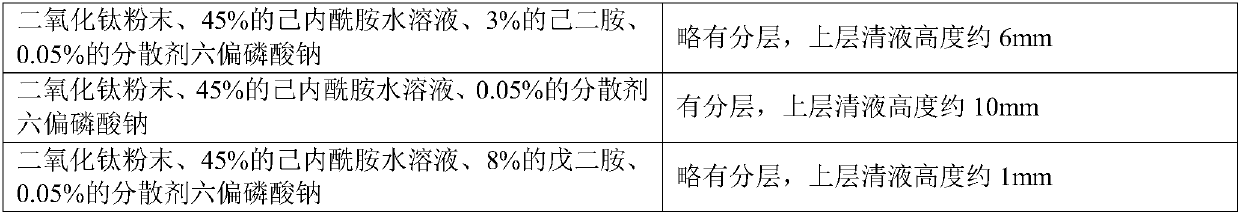

Embodiment 1

[0025] Mix titanium dioxide powder, caprolactam aqueous solution with a mass fraction of 45%, and hexamethylenediamine with a caprolactam mass ratio of 8% in a mixer to make a 22% titanium dioxide suspension, which is centrifuged, ground and prepared for nylon polymerization production After 40 days of use, the temperature difference between the inside and outside of the upper section of the polymer tube is 1.7°C, the fouling of the polymer tube has improved significantly, and the spinnability of the slices is good. The above-mentioned titanium dioxide suspension for nylon polymerization was sampled and left to stand for 78 hours, and no delamination was observed.

Embodiment 2

[0027] Titanium dioxide powder, mass fraction is 45% caprolactam aqueous solution, and caprolactam mass ratio is 5% hexamethylenediamine, sodium hexametaphosphate is 0.05% dispersant and mixes in mixer, makes 22% titanium dioxide suspension, After centrifugation, grinding and blending, it is used for nylon polymerization production. According to production tracking, the pressure of the melt filter is stable during the production process. After 40 days of use, the temperature difference between the inside and outside of the upper section of the polymerization tube is 1.6°C, and the spinnability of the slices is good. The above-mentioned titanium dioxide suspension for nylon polymerization was sampled and left to stand for 90 hours, and no delamination was seen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com