Final-stage channel flow measuring method and device

A flow measurement device and flow measurement technology, which are used in the detection of fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., which can solve the problems of inconvenient automatic monitoring and management, inability to continuously measure, and poor accuracy. Achieve the effect of improving efficiency and measurement accuracy, improving flow detection accuracy, and small measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

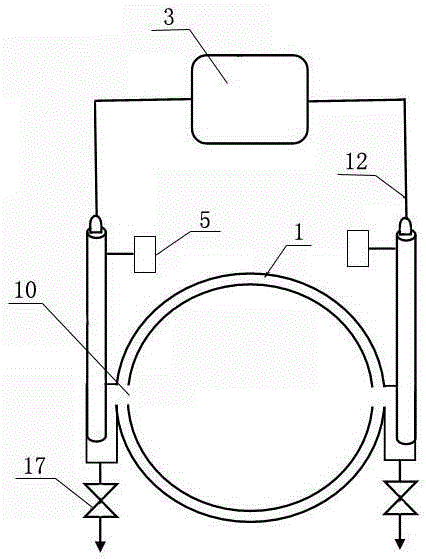

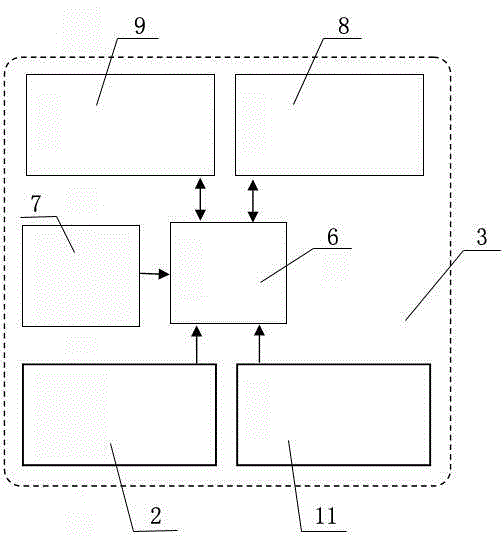

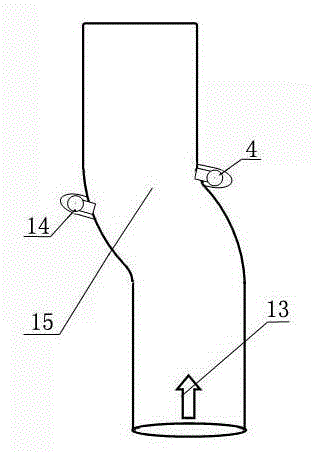

[0046] Embodiment one, with reference to the attached figure 1 , 2 , 3, the main pipeline 1 is a pipeline with an S-shaped curved structure 15, and the pressure-taking points of the two pressure sensors on the main pipeline are respectively arranged on the inner side and the outer side corresponding to the bending point of the main pipeline; The pressure taking points on the side are respectively provided with pressure pipes to communicate with the pressure taking points. The two pressure pipes are respectively the inner pressure pipe 4 and the outer pressure pipe 14. The two pressure sensors are pressure sensor one 2 and pressure sensor two 11 respectively. Sensor 1 2 matches the inner pressure tube 4, pressure sensor 2 11 matches the outer pressure tube 14; the pressure on the inside and outside of the bending point of the main pipeline is taken from the inner pressure tube to the pressure sensor 1, and the outer pressure tube is led to the pressure sensor 2 .

Embodiment 2

[0047] Embodiment two, referring to the attached figure 1 , 2 4. The main pipeline 1 is a pipeline with two S-shaped curved structures. The main pipeline is a V-shaped structure 16 as a whole. The bending point of the V-shaped structure is located at the bottom apex of the V-shaped structure. Two pressure sensors are on the main pipeline The pressure-taking points of the pressure sensor are respectively set on the inner side and the outer side corresponding to the bottom apex of the V-shaped structure of the main pipeline, that is, the pressure-taking point of the pressure sensor matches the middle part of the bend of the main pipeline. At the pressure taking points on both sides of the main pipeline, pressure pipes are respectively provided to communicate with the pressure taking points. The two pressure pipes are the inner pressure pipe 4 and the outer pressure pipe 14 respectively, and the two pressure sensors are pressure sensor one 2 and pressure sensor respectively. Two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com