Patents

Literature

52results about How to "Guaranteed imaging accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

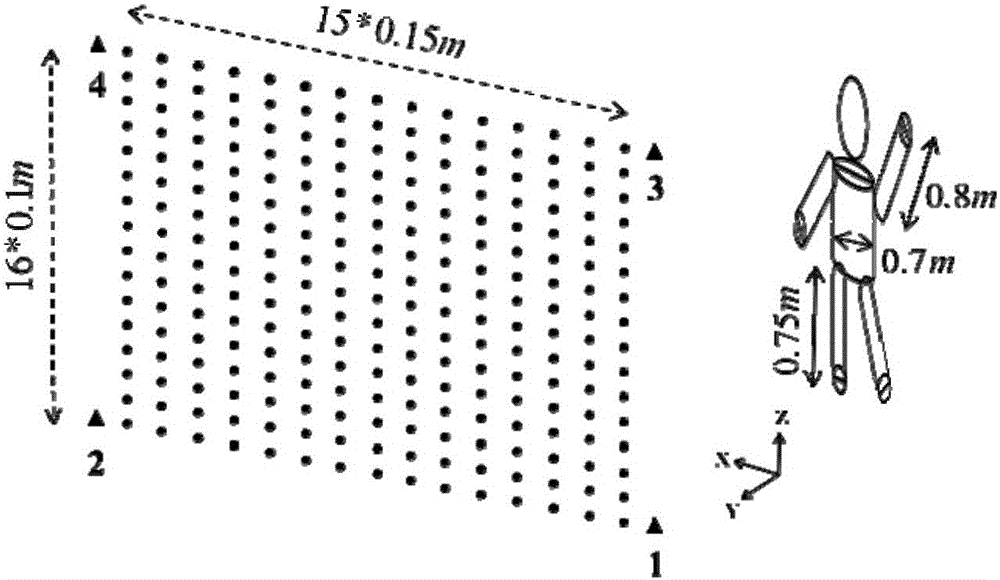

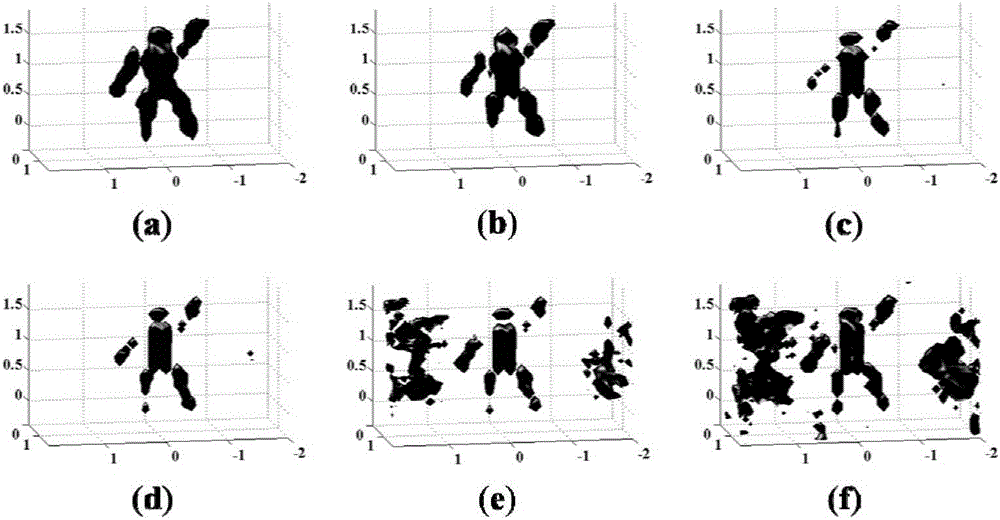

Microwave associated imaging radar amplitude-phase error correction method based on auxiliary array elements

ActiveCN105044693AImprove calibration efficiencyHas rotation invariant propertiesWave based measurement systemsPhysicsWave shape

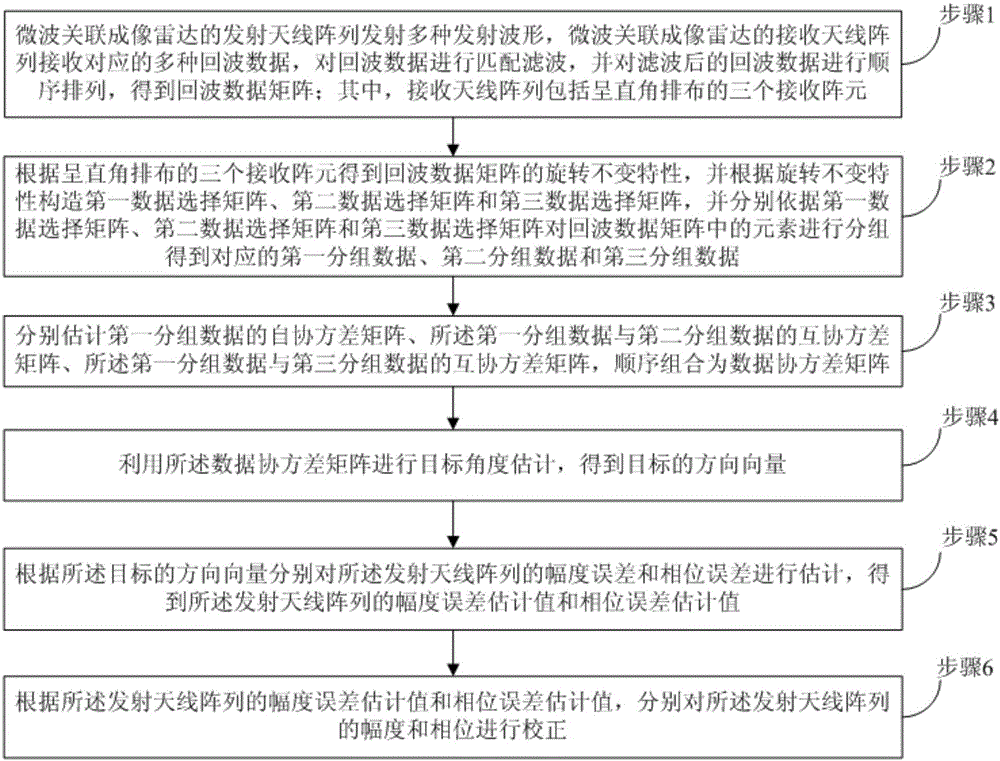

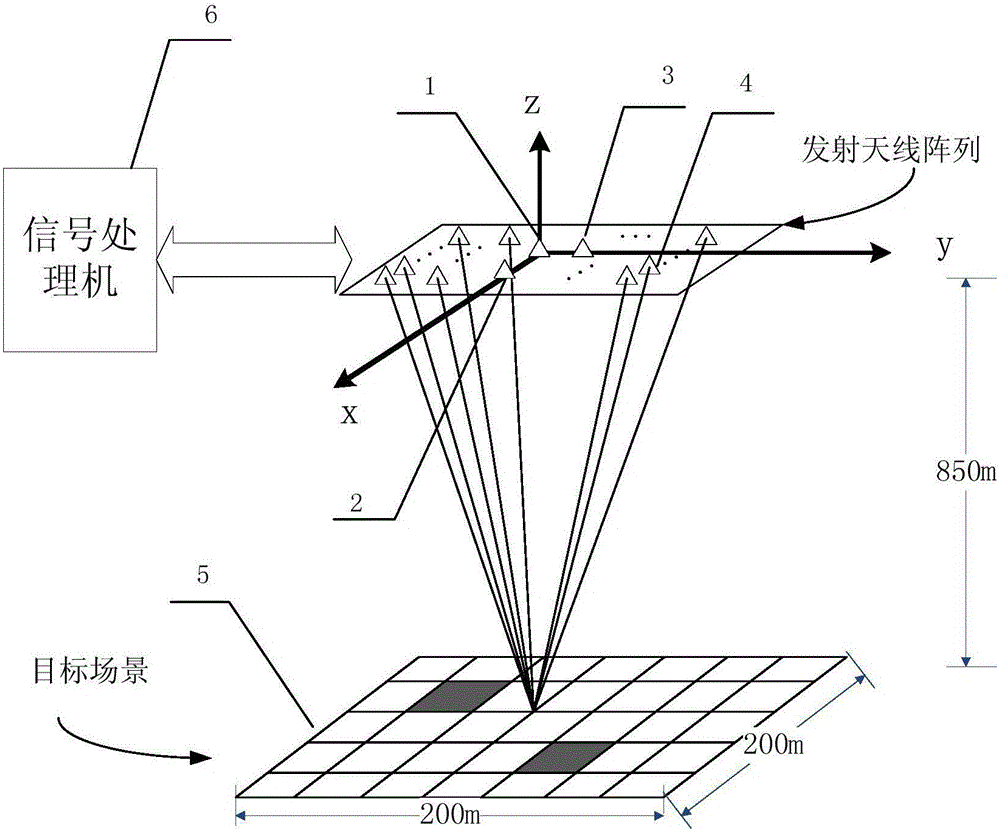

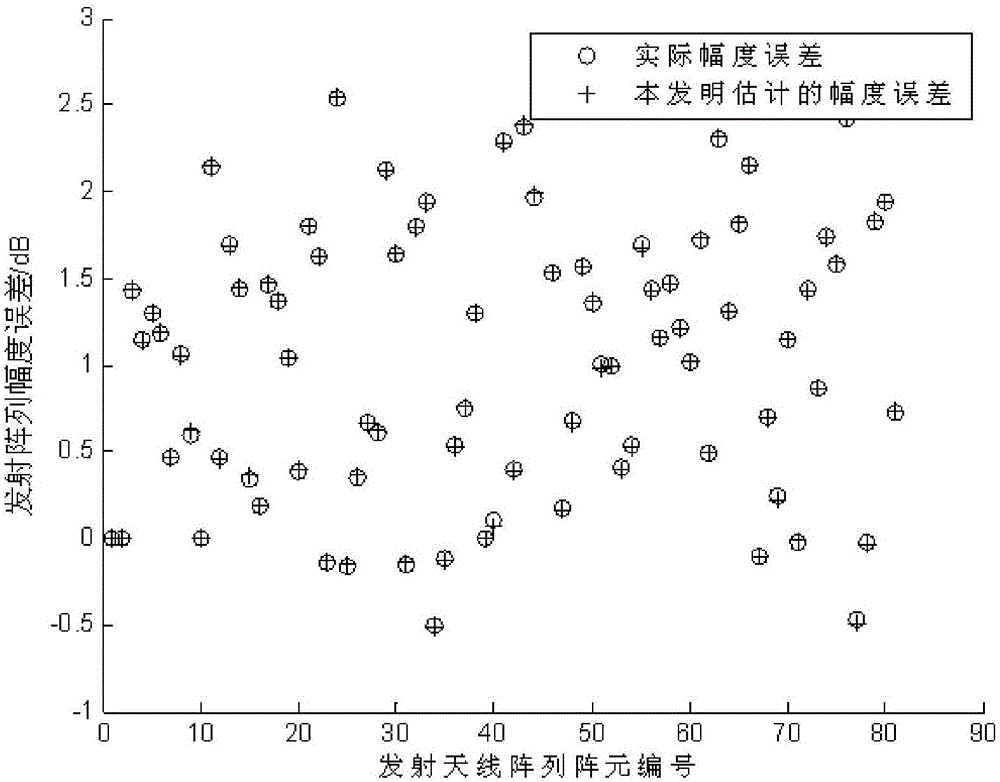

The invention provides a microwave associated imaging radar amplitude-phase error correction method based on auxiliary array elements so as to estimate a microwave associated imaging radar amplitude-phase error and then obtain a relatively ideal time and space radiation field by compensation on the amplitude-phase error. The method comprises the steps that step 1: a microwave associated imaging radar transmitting antenna array transmits multiple types of waveforms, corresponding multiple types echo data are received by a receiving antenna array, matched filtering is performed on the echo data, and the obtained echo data matrixes are orderly arranged; step 2: the elements in the echo data matrixes are grouped; step 3: a data covariance matrix is estimated; step 4: target angle estimation is performed so that a target direction vector is obtained; step 5: the amplitude error and the phase error of the transmitting antenna array are estimated respectively so that corresponding error estimation values are obtained; and step 6: the amplitude and the phase of the transmitting antenna array are respectively corrected according to the amplitude error estimation value and the phase error estimation value of the transmitting antenna array.

Owner:XIDIAN UNIV

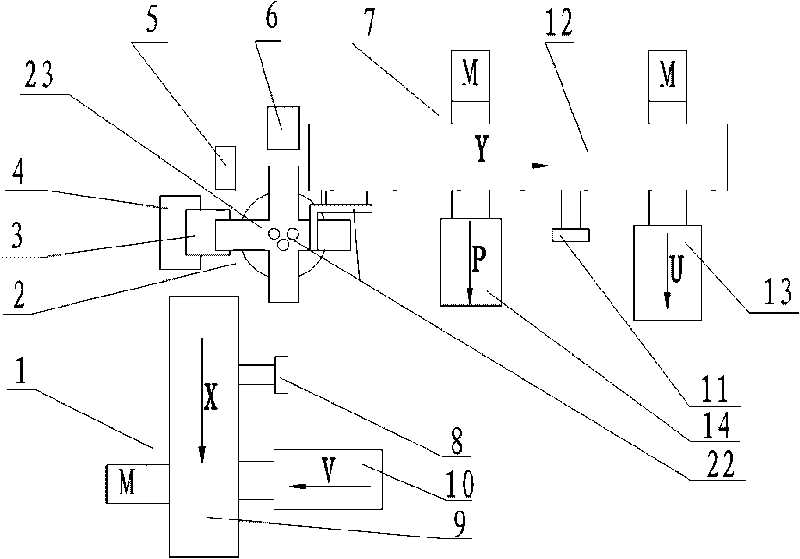

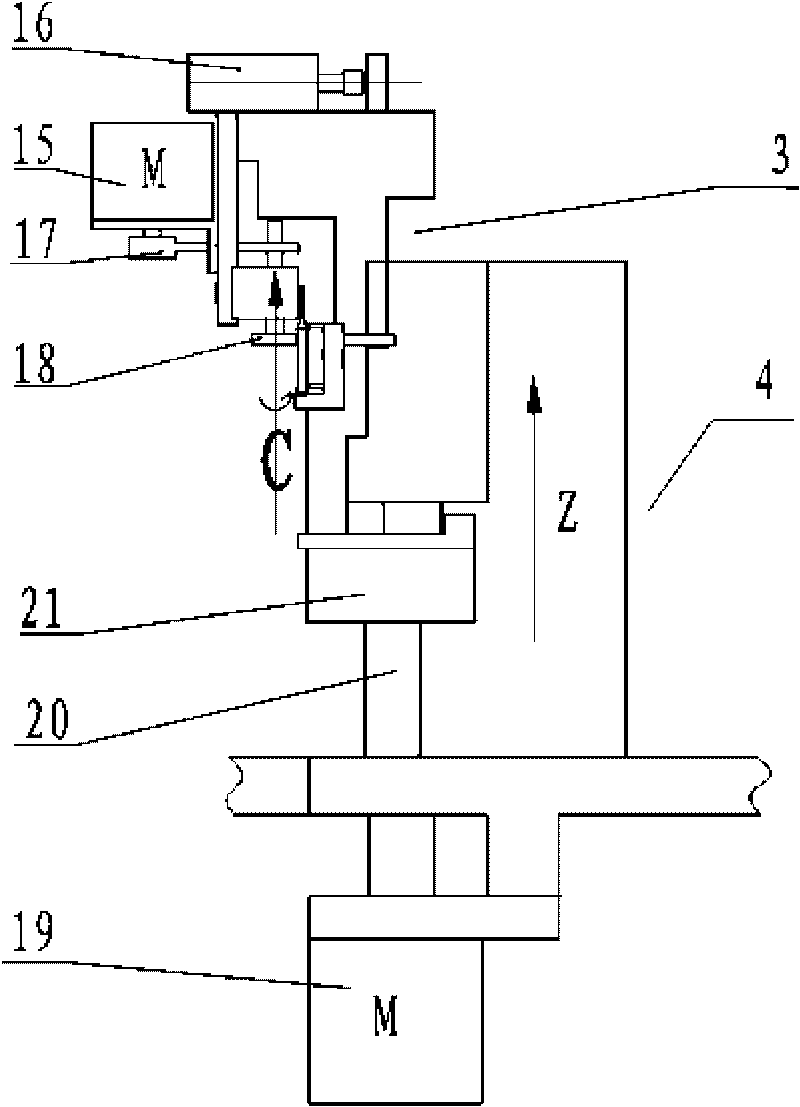

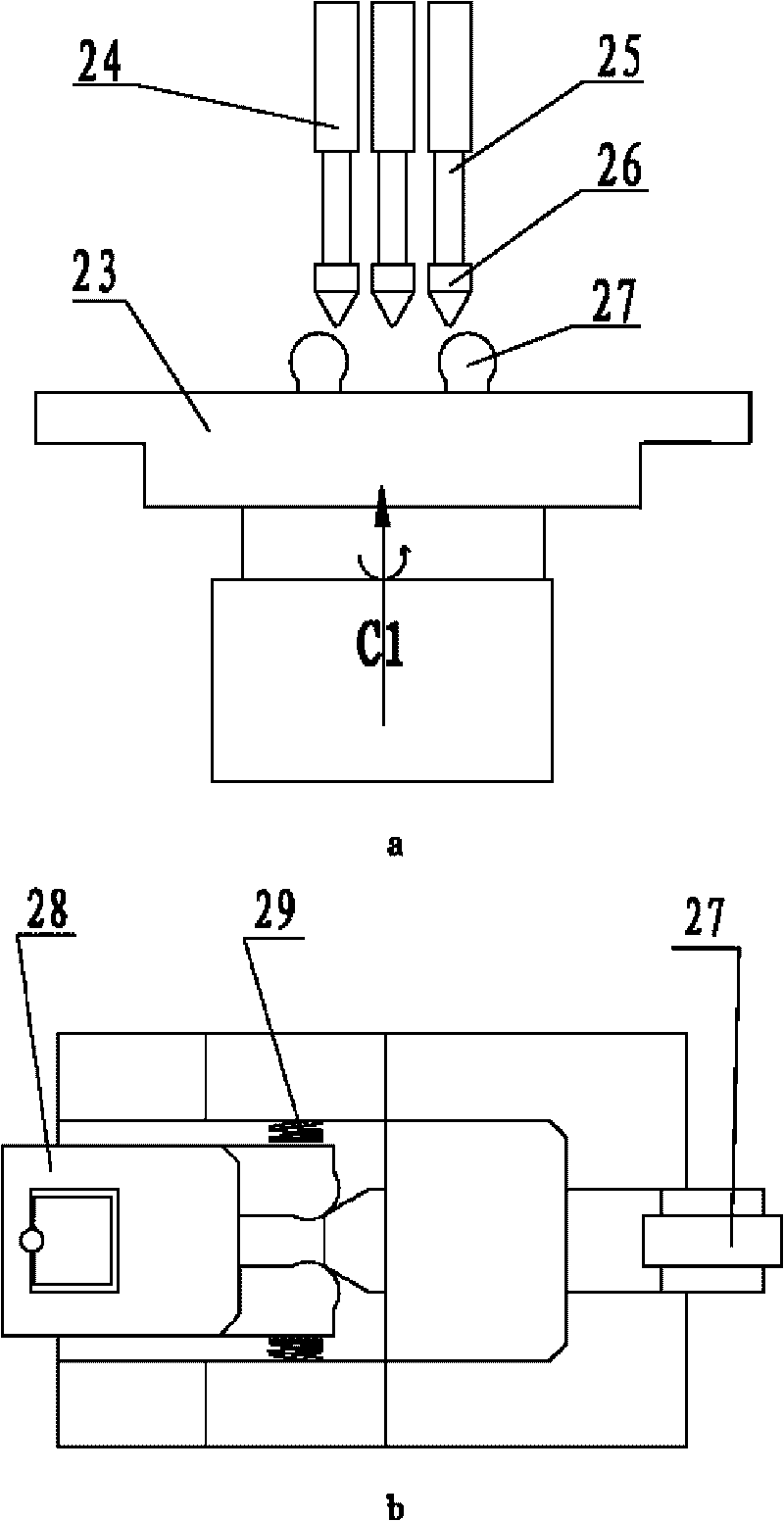

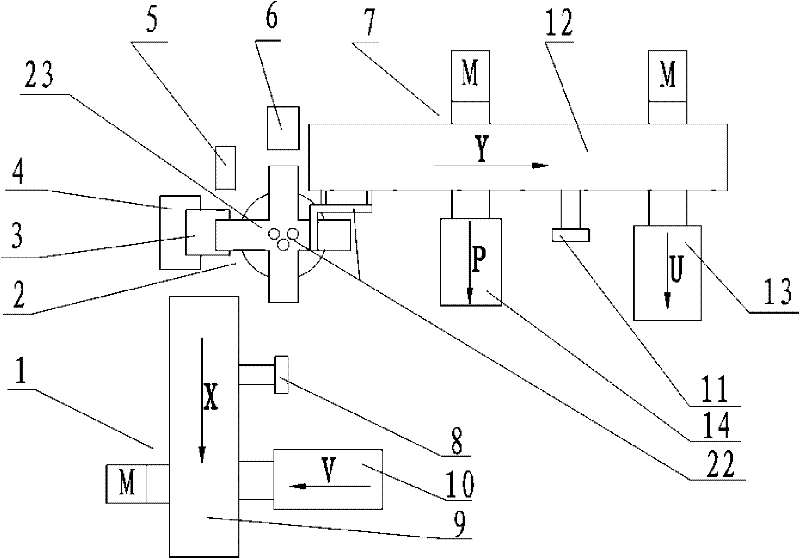

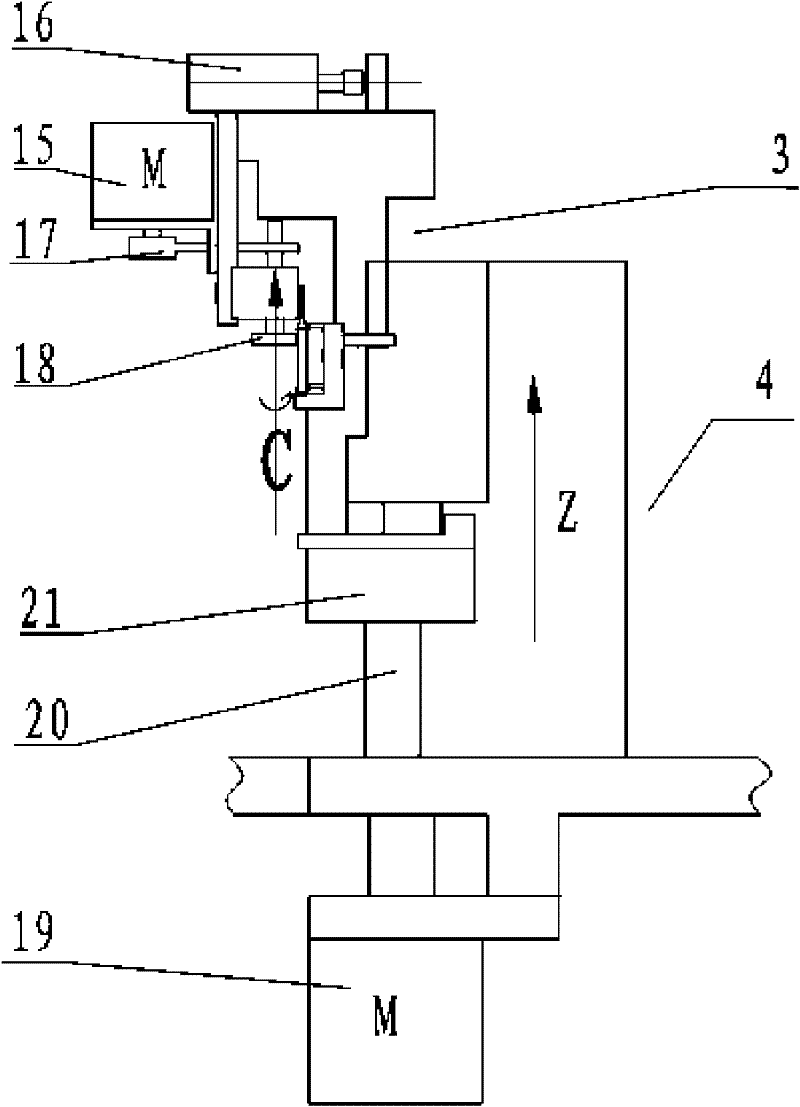

Full-automatic quality detection device of micro drill point for drilling PCB

InactiveCN101706256AReal-time precise axial positioning heightGuaranteed stabilityUsing optical meansImaging qualityEngineering

The invention relates to a full-automatic quality detection device of a micro drill point for drilling a PCB in the technical field of tool detection, which comprises a feeding mechanism, a rotary worktable, a micro drill rotary mechanism, a height adjusting mechanism, a vision detection device and a discharging mechanism, wherein the feeding mechanism, the rotary worktable and the discharging mechanism are respectively and correspondingly arranged at a feeding station, a rotary station and a discharging station of a working platform, the micro drill rotary mechanism and the height adjusting mechanism are sequentially arranged at the side face of the rotary table, the vision detection device is arranged at a vision detection station of the working platform, the feeding station and the rotary station are arranged at the same side, the discharging station and the feeding station are positioned at two ends of the working platform, and the vision detection station and the discharging station are positioned at the same side. The micro drill rotary mechanism and the height adjusting mechanism can enable a micro drill to simultaneously realize the circumferential rotation and the axial real-time precise adjustment, can fine adjust the axial positioning height of the micro drill in real time, and ensure the imaging quality of a blade surface and the measurement precision of geometric parameters.

Owner:SHANGHAI JIAO TONG UNIV

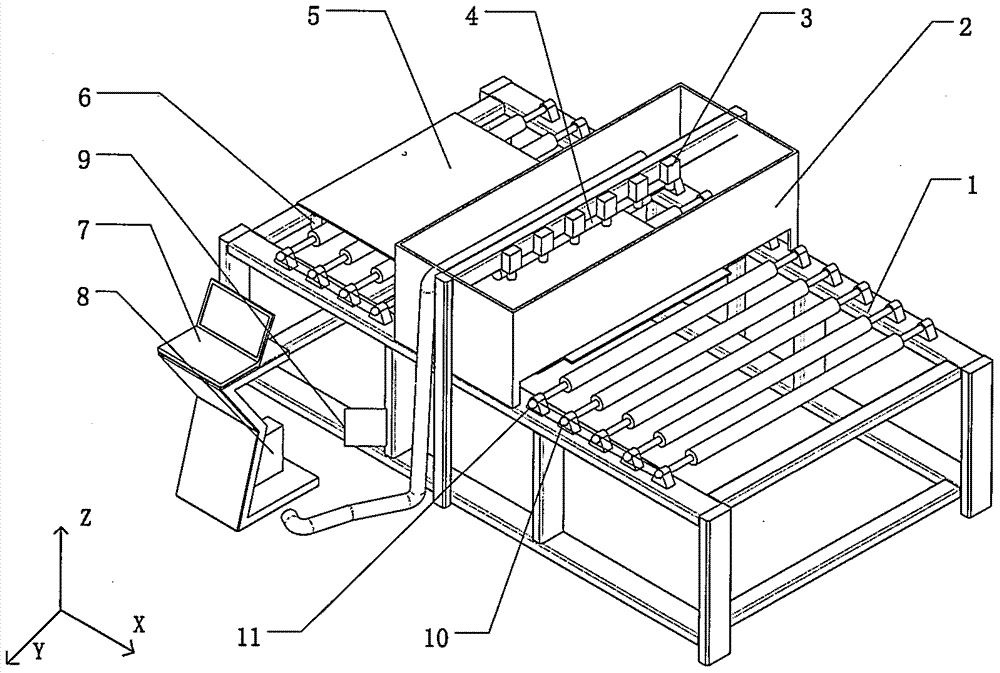

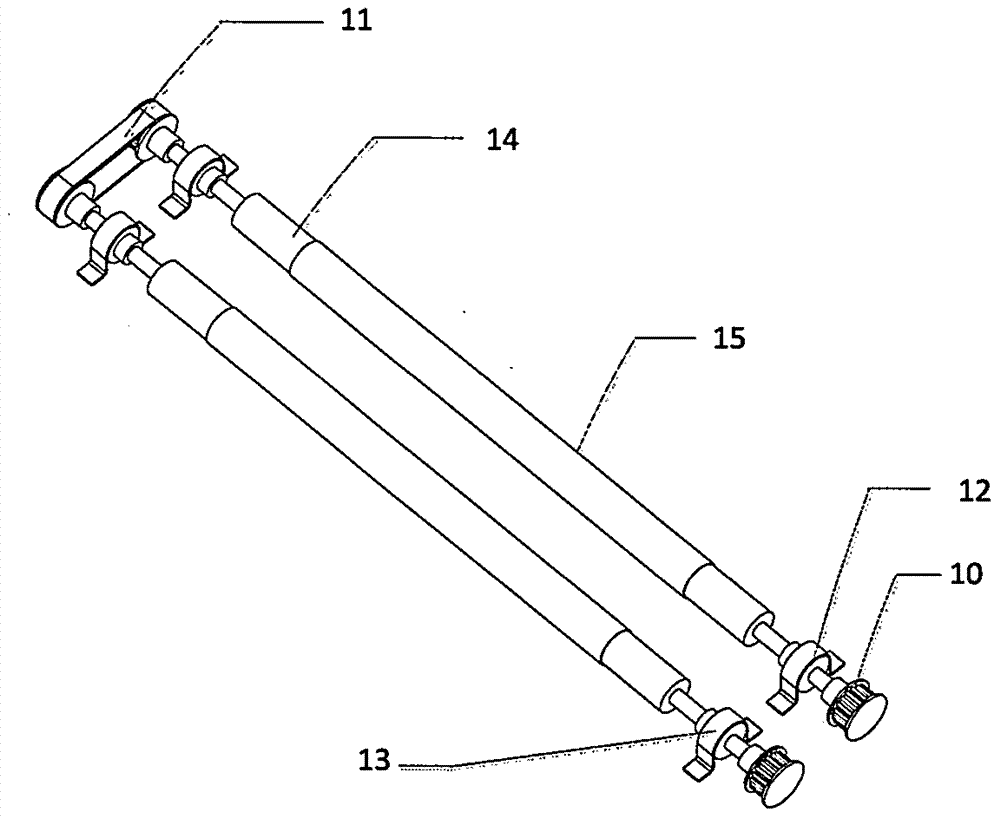

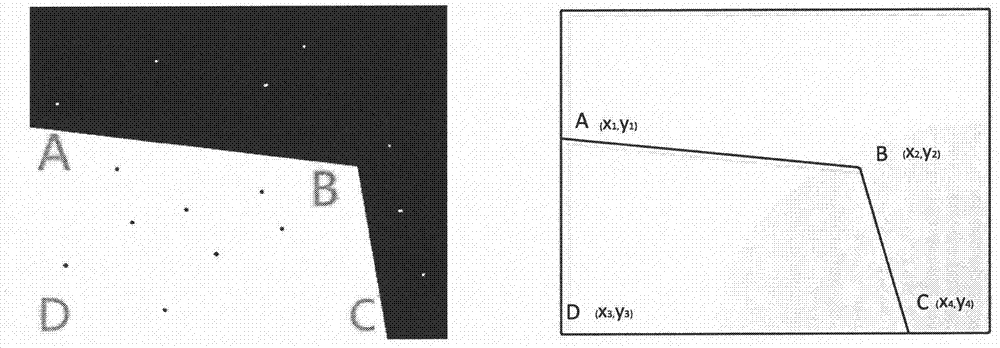

Painted glass defect detection device based on area-array camera parallel-acquisition system

InactiveCN106896115ADetection adaptationEliminate distractionsMaterial analysis by optical meansImaging processingComputer module

The present invention designs a painted glass defect detection system based on a CCD area array camera, aiming at the current situation that glass manufacturers generally use artificial methods to detect defects on painted glass. It consists of a mobile stage, 5 CCD area array cameras with lenses, 1 strip-shaped red light scanning light source, network cables, switches, host computers, and corresponding fixed facilities. It is mainly divided into two modules, one is the glass image The acquisition module, the second is the glass image processing module, and the two modules are connected through the network. The processing program uses the edge finding operator to judge the glass area and extract statistical defect information.

Owner:SHANGHAI UNIV

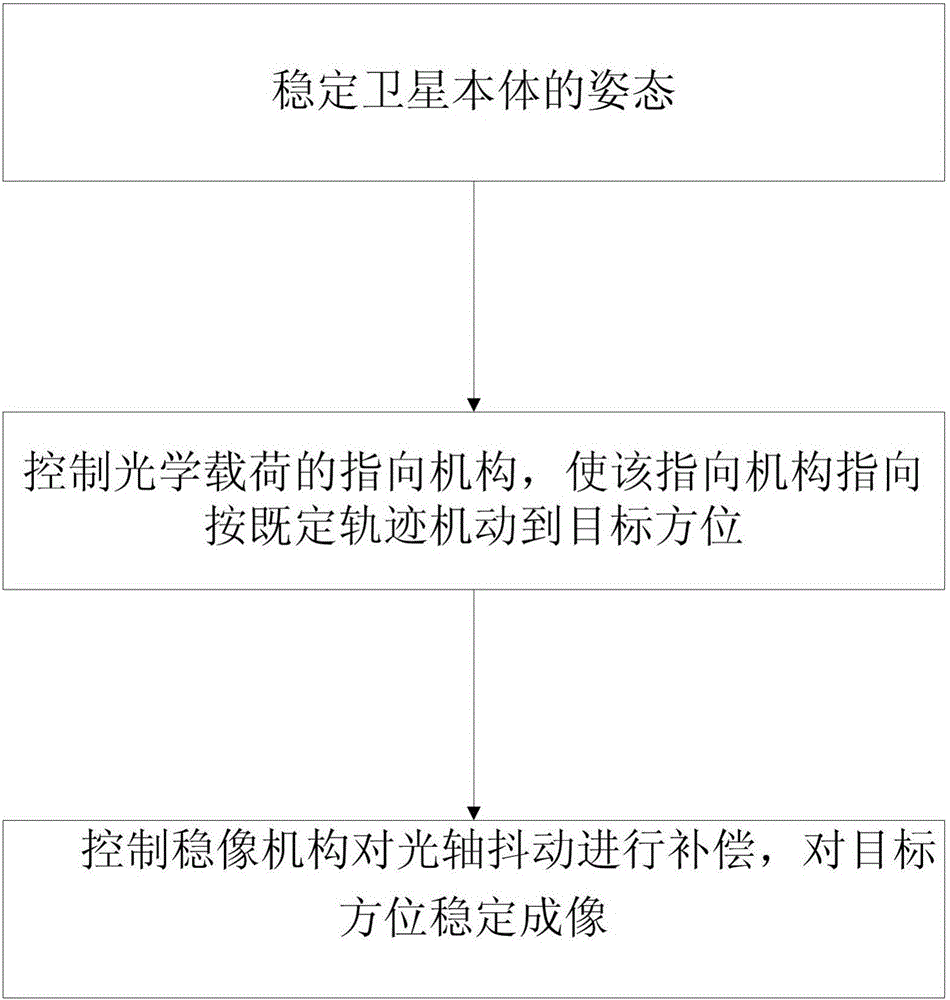

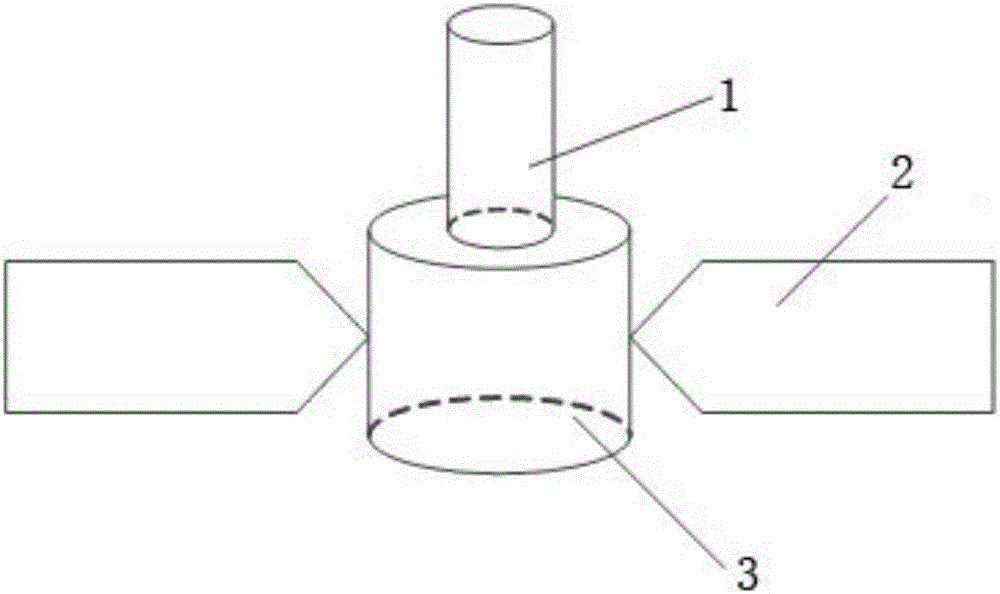

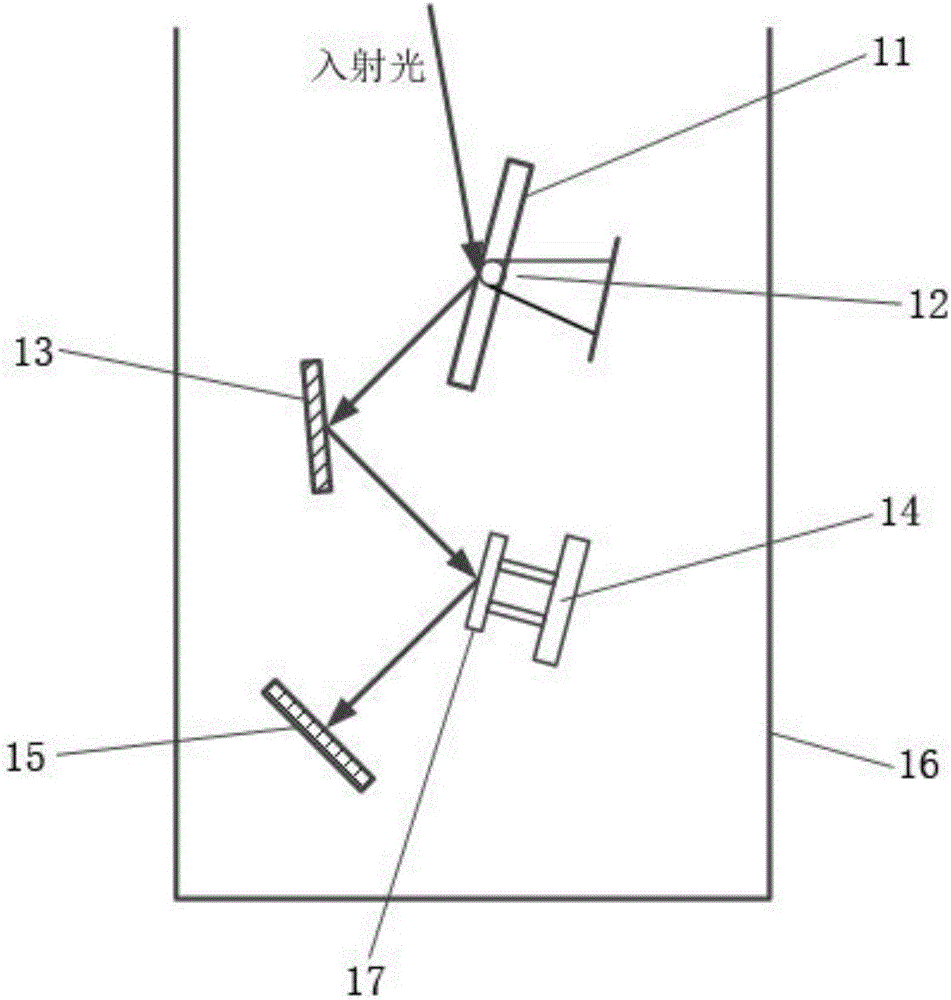

Smooth and steady pointing maneuvering control method for satellite optical load

InactiveCN105867435AReduce size and massFast maneuvering speedControl using feedbackSpacecraft guiding apparatusElectricityOptical axis

The invention relates to a smooth and steady pointing maneuvering control method for a satellite optical load. The method comprises the following steps that 1, the attitude of a satellite body is stabilized; 2, a pointing mechanism of the optical load is controlled to enable pointing mechanism pointing orientation to be maneuvered to a target orientation along a set track; 3, an image stabilizing mechanism is controlled to carry out compensation on optical axis shaking, and the target orientation is stably imaged. The smooth and steady pointing maneuvering control method for the satellite optical load has the following advantages that 1, compared with the satellite body, the pointing mechanism is small in mass and size, high in maneuvering speed and little in energy consumption, and the image stabilizing mechanism is driven by a piezoelectric material, is wide in bandwidth and can effectively carry out compensation on control errors of the pointing mechanism and inhibit optical axis shaking; in addition, in the load optical axis maneuvering process, the stability is high, little pointing shaking is generated, the track is smooth, and the target orientation precision and stability are high; smooth and steady pointing maneuvering is provided for the optical load, and the imaging precision during maneuvering is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

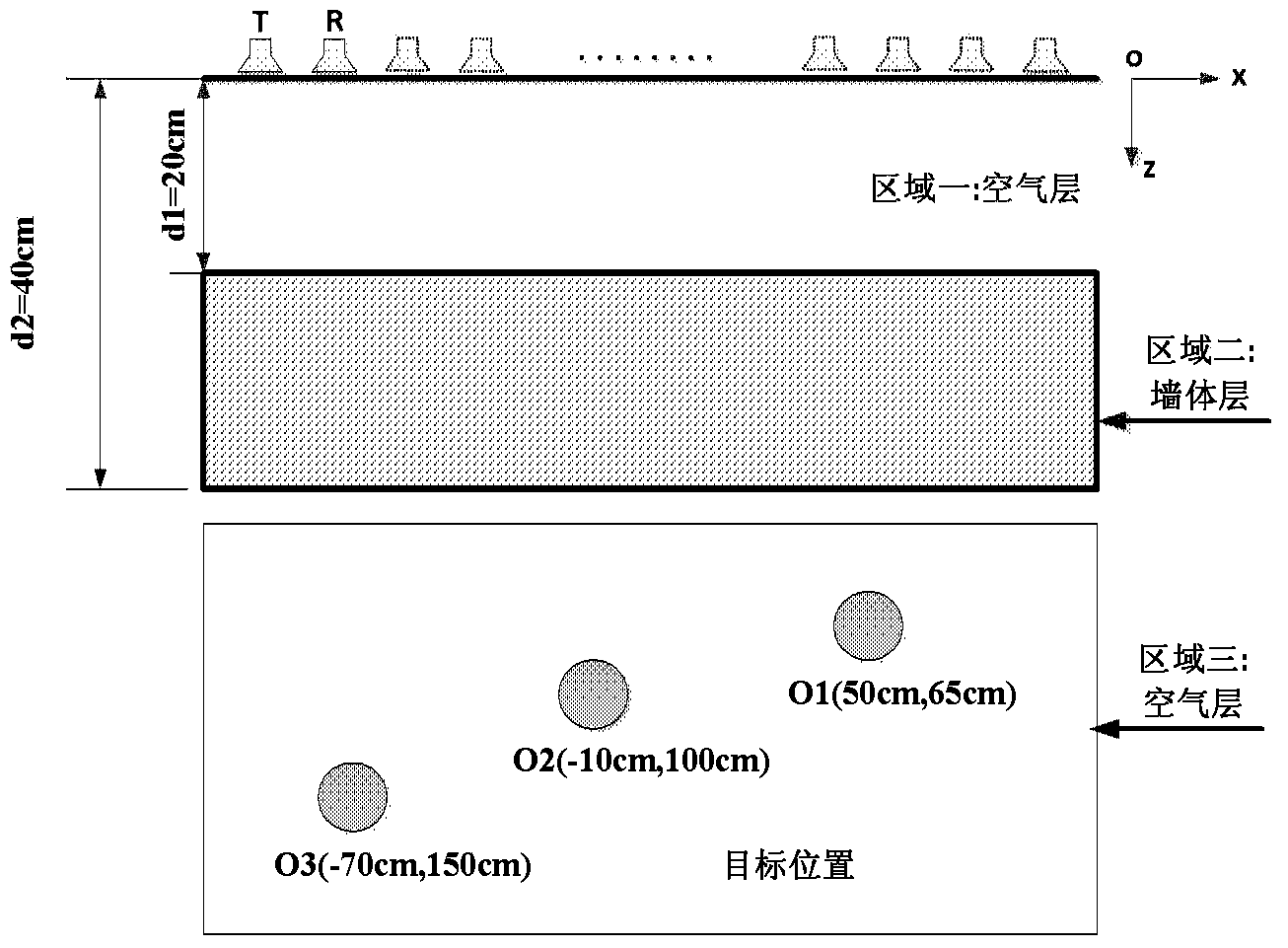

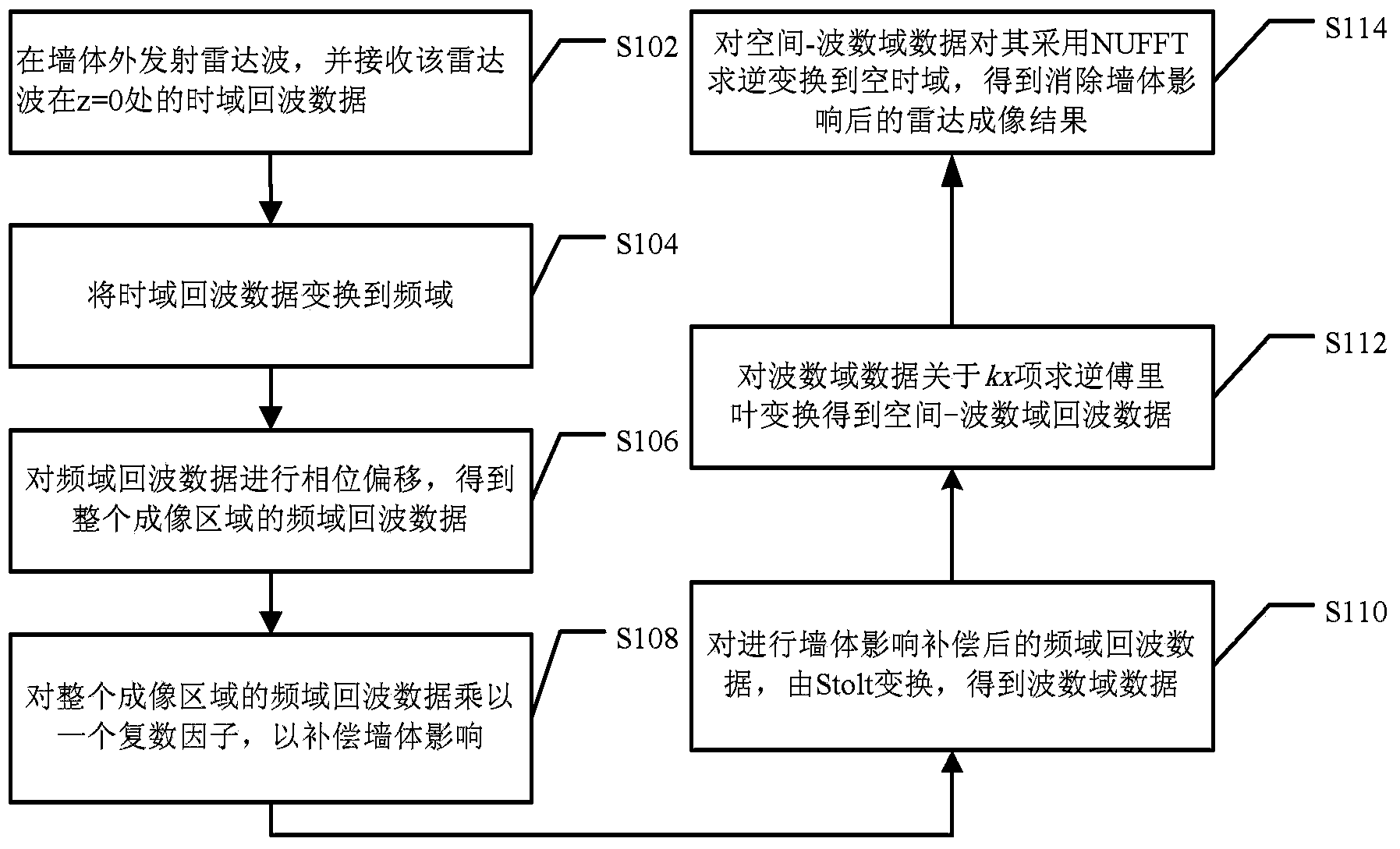

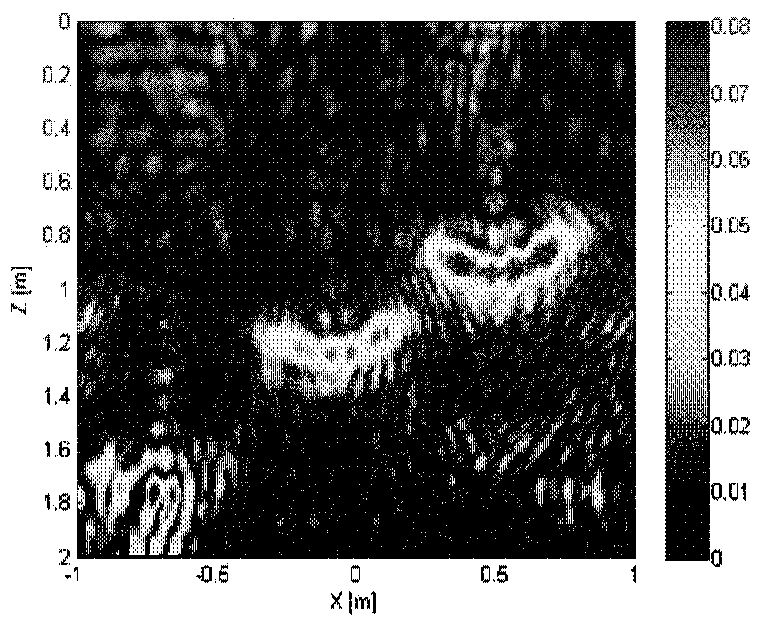

Through-the-wall radar imaging method

ActiveCN103675810AGuaranteed imaging accuracySmall amount of calculationRadio wave reradiation/reflectionPhysical modelFrequency domain

The invention provides a through-the-wall radar imaging method. According to the method, in a radar imaging processing process, spectral data is multiplied by a wall compensation factor; the compensation factor uses an accurate physical model and takes interaction between an electromagnetic wave and a wall into account; and accordingly, an impact of the wall on an imaging position is eliminated, and the imaging accuracy is ensured. In addition, since the elimination of the impact of the wall is in a frequency domain and only multiplication is used, and compensation factor calculation does not need solving a nonlinear equation, the calculation amount is quite small.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

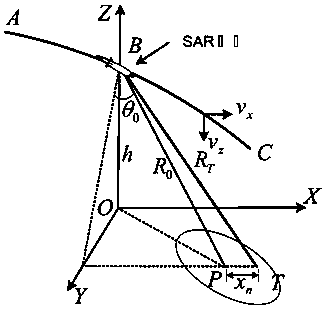

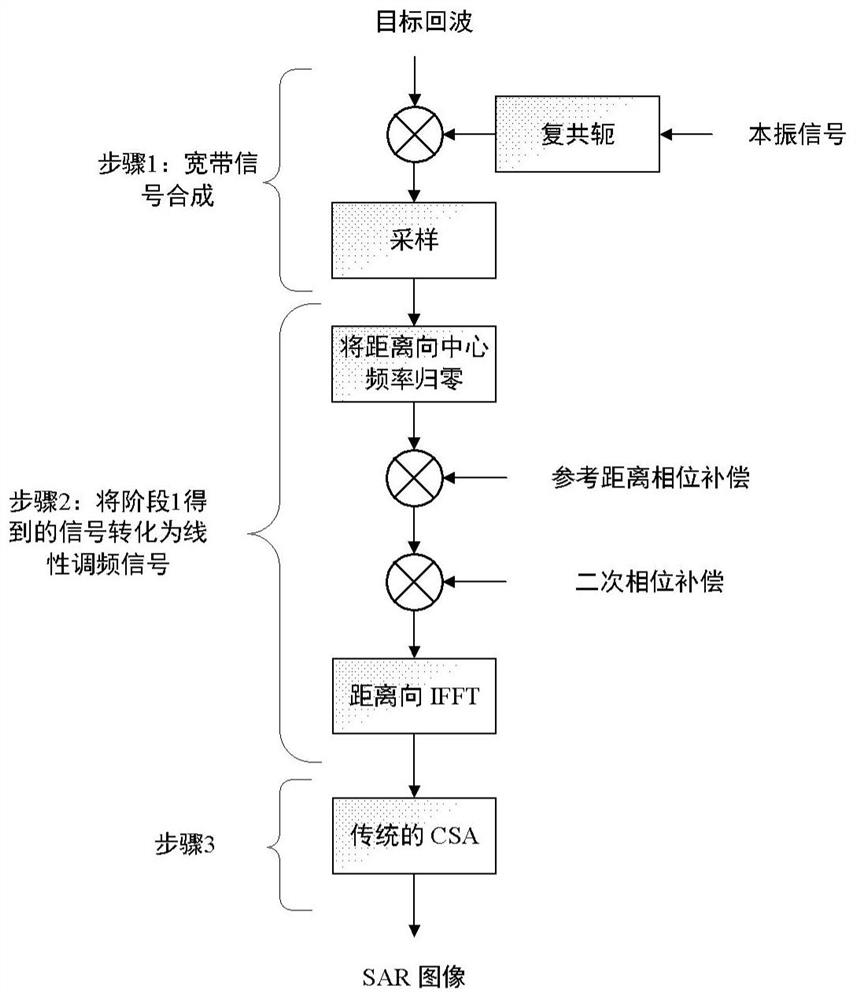

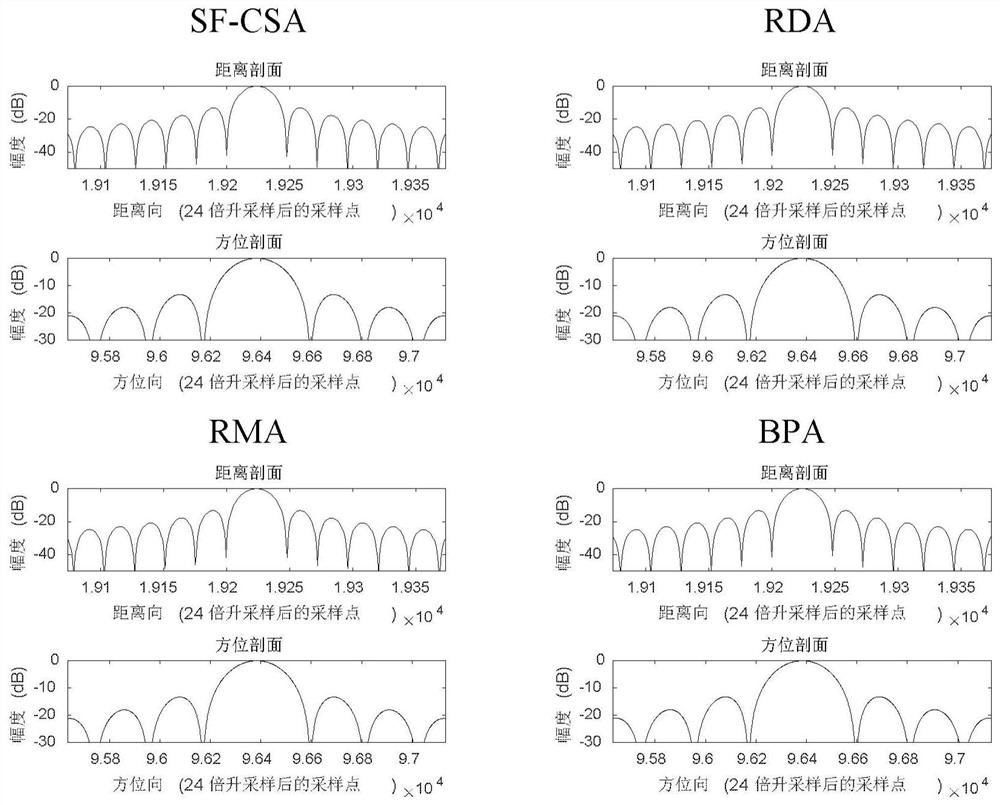

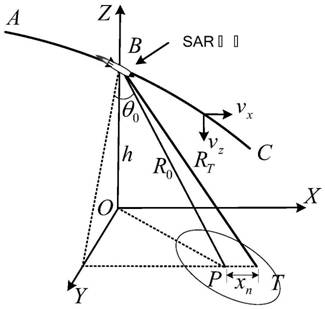

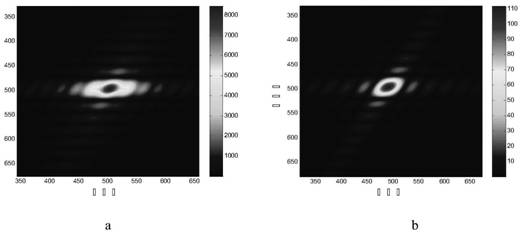

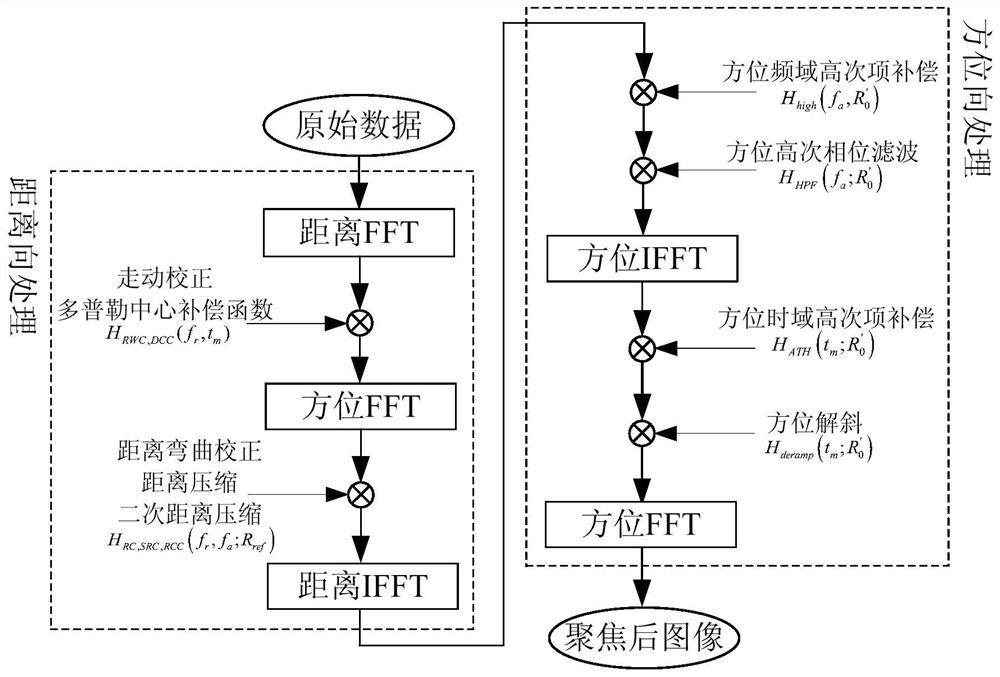

SAR imaging method

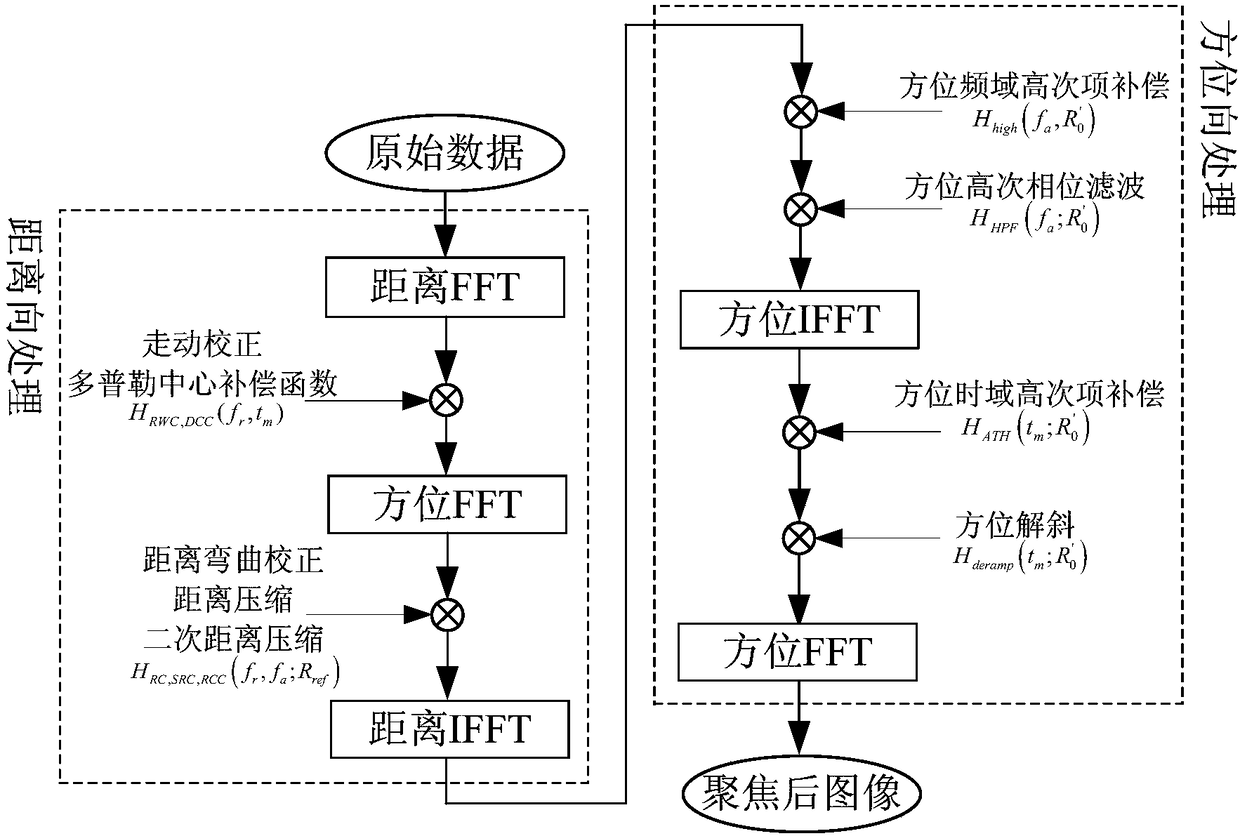

ActiveCN108061890AFast imagingGuaranteed imaging accuracyRadio wave reradiation/reflectionTime domainFrequency modulation

The invention proposes an SAR imaging method, and the method comprises the steps: carrying out the collection of SAR data, range direction compensation, azimuth frequency domain high-order term compensation, azimuth frequency domain high-order phase filtering, azimuth time domain high-order term compensation and azimuth inclination correction, and obtaining an image after focusing. The method is used for aperture data processing, gives consideration to the frequency modulation rate space variant caused by the range envelope and azimuth target position at the same time on the basis of the high-order approximate two-dimensional spectrum, employs a frequency domain high-order phase filtering method for solving, effectively improves the imaging speed, and can meet the requirements of real-timeimaging on the basis that the imaging precision is guaranteed.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

High resolution radar fast imaging method based on generalized reflectivity model

InactiveCN105842689AImprove imaging effectGuaranteed imaging accuracyRadio wave reradiation/reflectionImaging processingDual transformation

The invention discloses a high resolution radar fast imaging method based on a generalized reflectivity model. According to the invention, the conventional radar imaging Bonn approximation model can be extended, and the anisotropic characteristic of the target and the characteristic of the target having different action effects on the signals of different frequency bands can be added to the model; the model is closer to the actual signal model, and the radar imaging effect can be enhanced, and the good foundation can be laid for realizing the high resolution radar imaging; by using three sparse characteristics of the target generalized reflectivity, the radar imaging system can be divided into the sub-apertures or sub-frequency bands for the approximation calculation; according to the system function characteristics, the imaging area can be divided into a series of sub-imaging areas, and then the imaging speed can be greatly accelerated; by adopting the dual transformation, the conventional radar imaging problem can be changed into the image processing problem based on the physical mechanism. The radar imaging precision can be guaranteed, and the radar imaging speed can be accelerated, and therefore the technical problem of the inability of realizing the large-scale high-resolution radar real-time imaging can be effectively solved.

Owner:PEKING UNIV

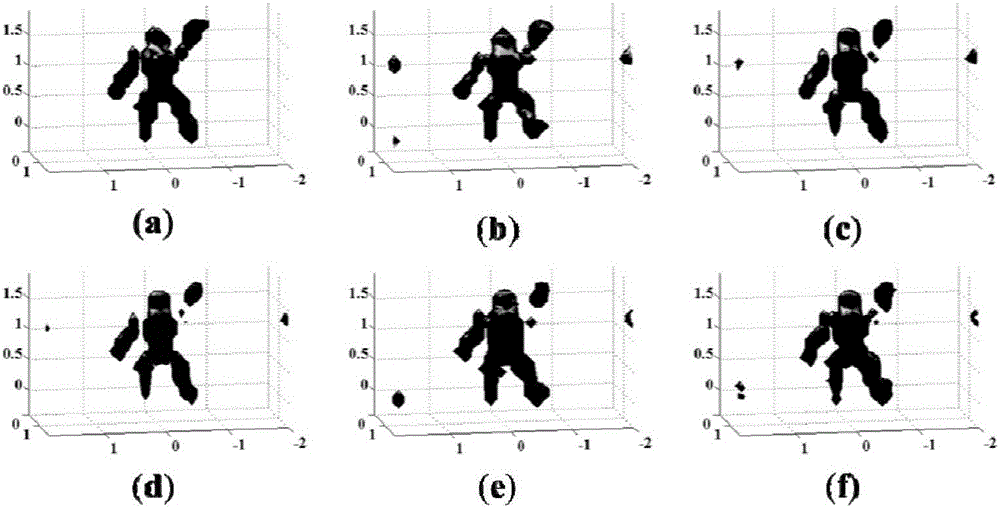

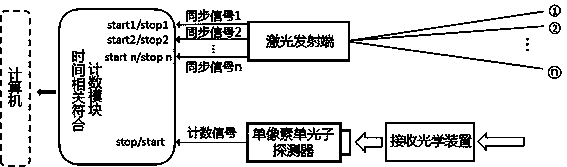

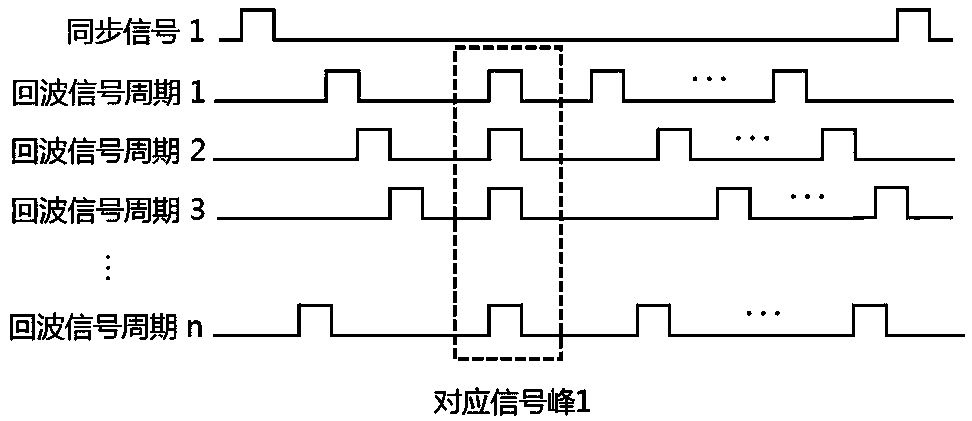

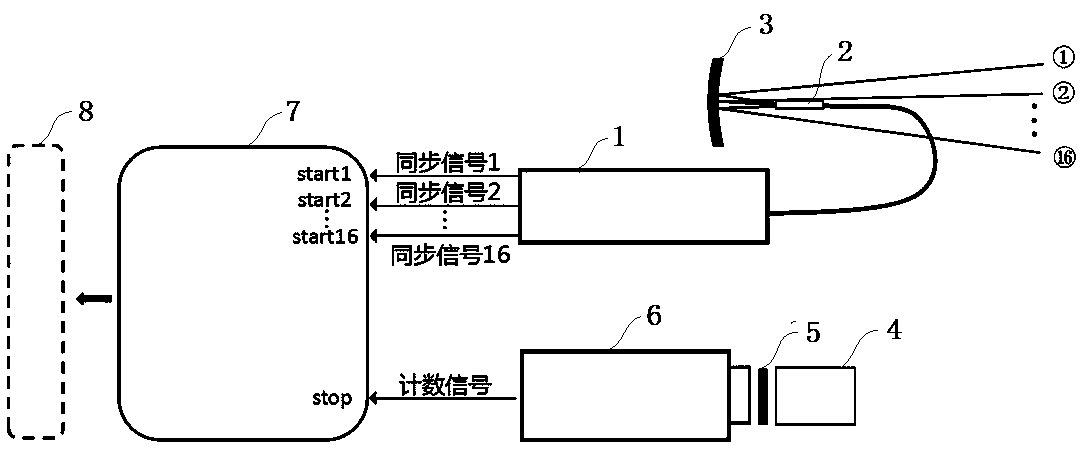

Multi-beam photon counting laser imaging method

ActiveCN109521438AGuaranteed imaging accuracySimplified detection structureElectromagnetic wave reradiationMultiplexingLaser imaging

The invention discloses a multi-beam photon counting laser imaging method. The method comprises the following steps: a laser transmitting device generates multi-beam laser pulses to scan an imaging target; meanwhile, synchronous signals of the multi-beam laser pulses are transmitted to a time-dependent single-photon coincidence counting module; a single-pixel single-photon detector is used for detecting an echo signal and transmitting a counting signal to the time-dependent single-photon coincidence counting module; and the time-dependent single-photon coincidence counting module analyzes andobtains the flight time of the multi-beam laser pulses so as to solve the distance of each scanning position on the imaging target, thereby constructing a three-dimensional image of the imaging target. The method has the advantages that: multi-beam multiplexing detection can be realized at a detection end by using only one single-pixel single-photon detector by adopting multi-beam laser pulses with mutually random phases and unequal repetition frequencies as scanning laser, so that the detection structure is simplified while the imaging precision is ensured, and the equipment cost is reduced.

Owner:EAST CHINA NORMAL UNIV

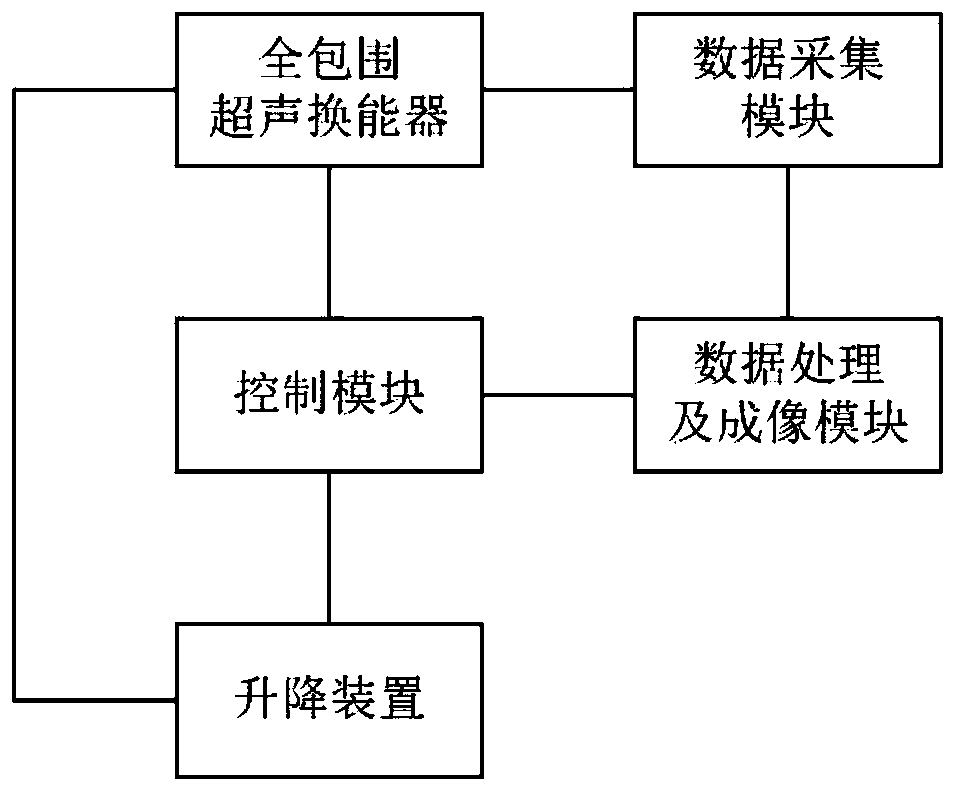

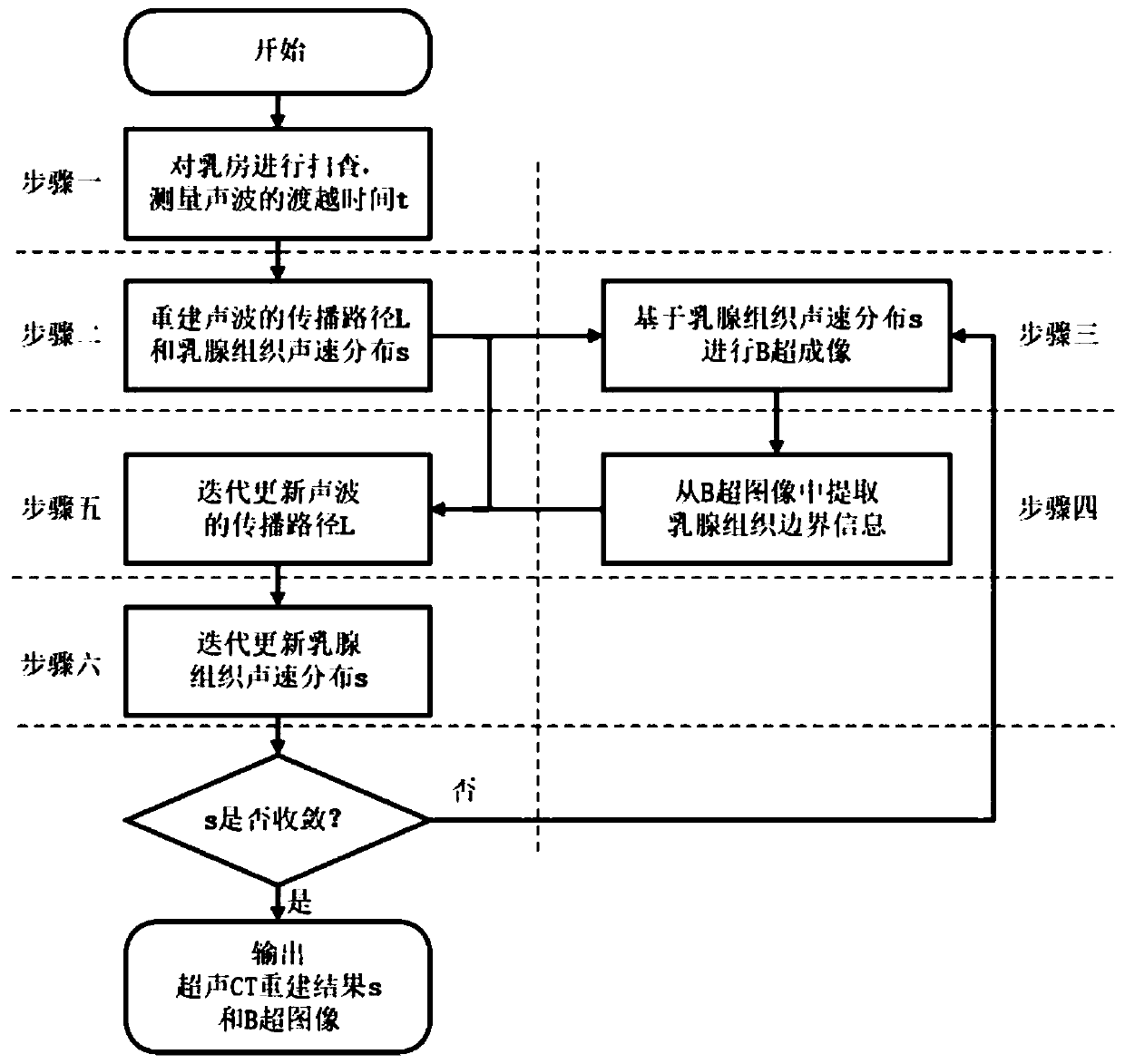

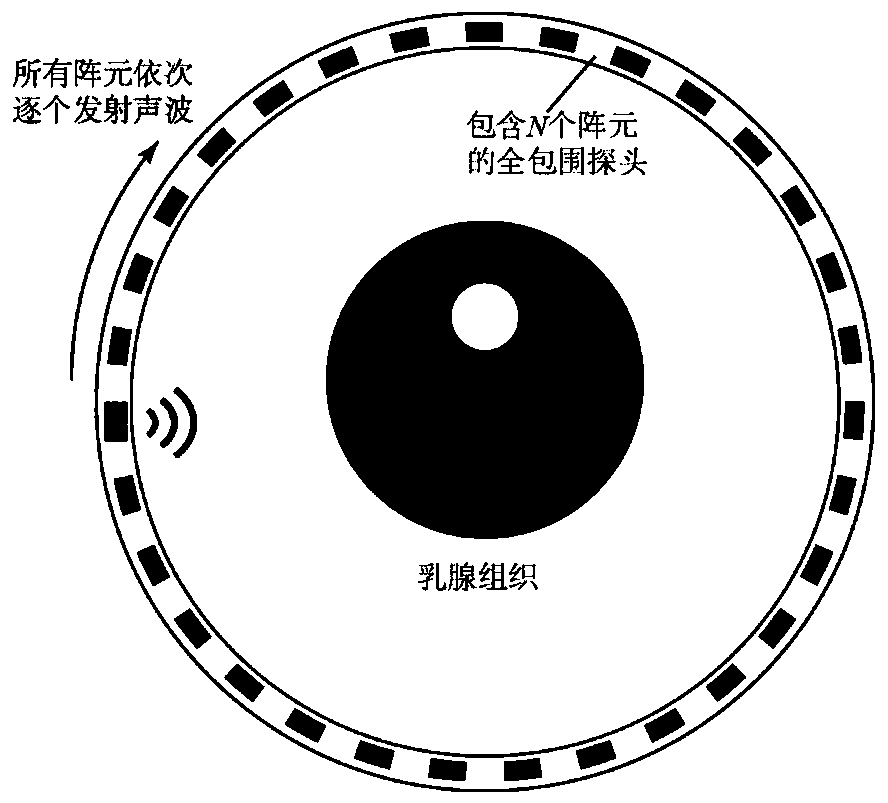

Ultrasonic CT imaging system based on improved ray tracing method

ActiveCN110772281AGuaranteed imaging accuracyClear boundariesOrgan movement/changes detectionInfrasonic diagnosticsUltrasonic imagingSound wave

The invention relates to an ultrasonic CT imaging system based on an improved ray tracing method. The ultrasonic CT imaging system comprises a full-enclosed ultrasonic transducer, a signal acquisitionmodule and a data processing and imaging module. When a processor in the data processing and imaging module executes computer programs stored in a memory, an implementation method comprises the following steps that human organs are scanned based on the full-enclosed ultrasonic transducer, and the transit time of sound waves is measured; the initial sound velocity distribution of a target is reconstructed; B-mode ultrasound imaging is conducted based on the sound velocity distribution of the target; the boundary information of organic tissues is extracted from B-mode ultrasound images; propagation paths of the sound waves are updated iteratively; and the sound velocity distribution of the target is updated iteratively. Compared with a traditional imaging scheme, while the ultrasonic CT imaging accuracy is ensured, the calculation amount is reduced, the reconstruction speed is improved, and the accuracy of the B-mode ultrasound images and the edge definition in an ultrasonic CT imagingresult are improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

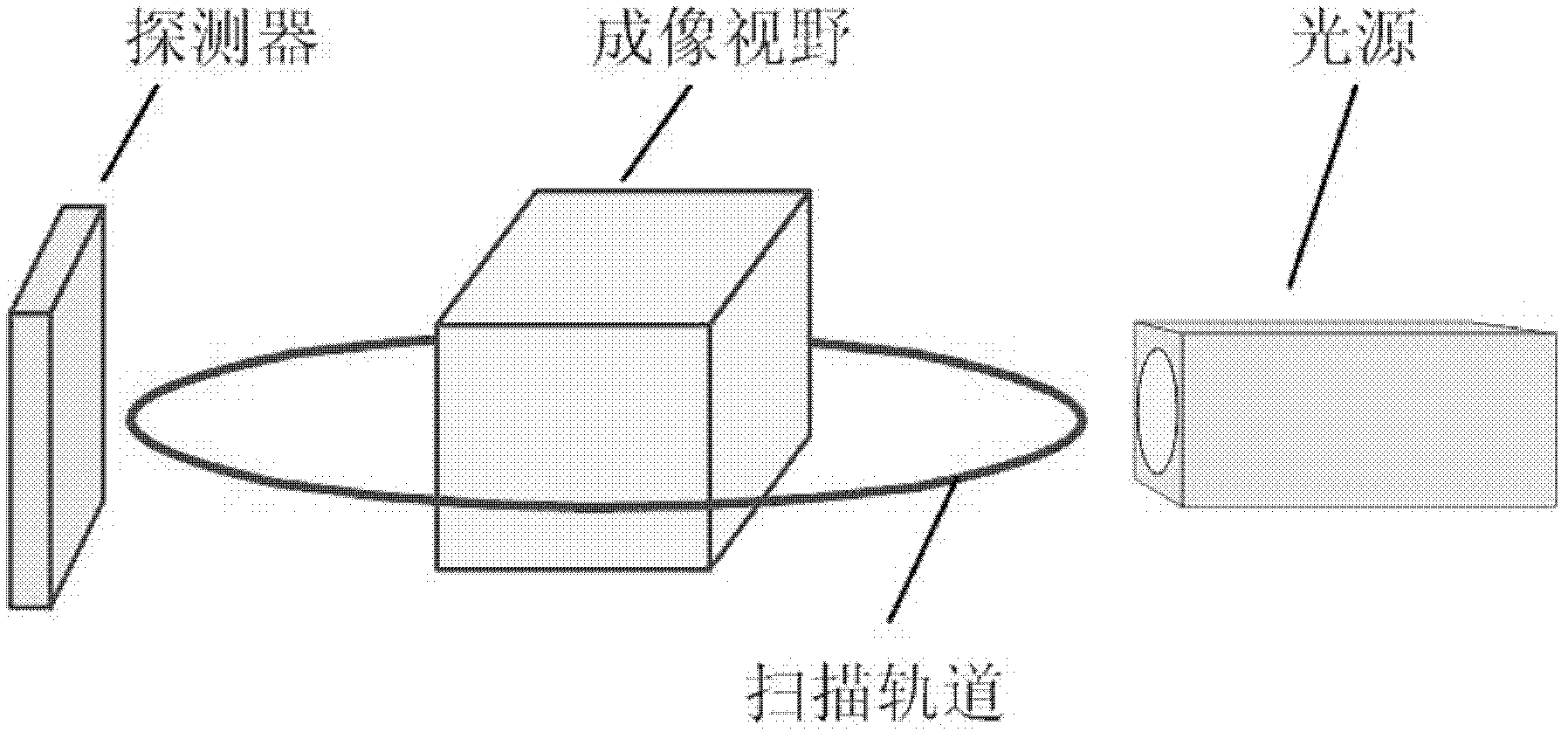

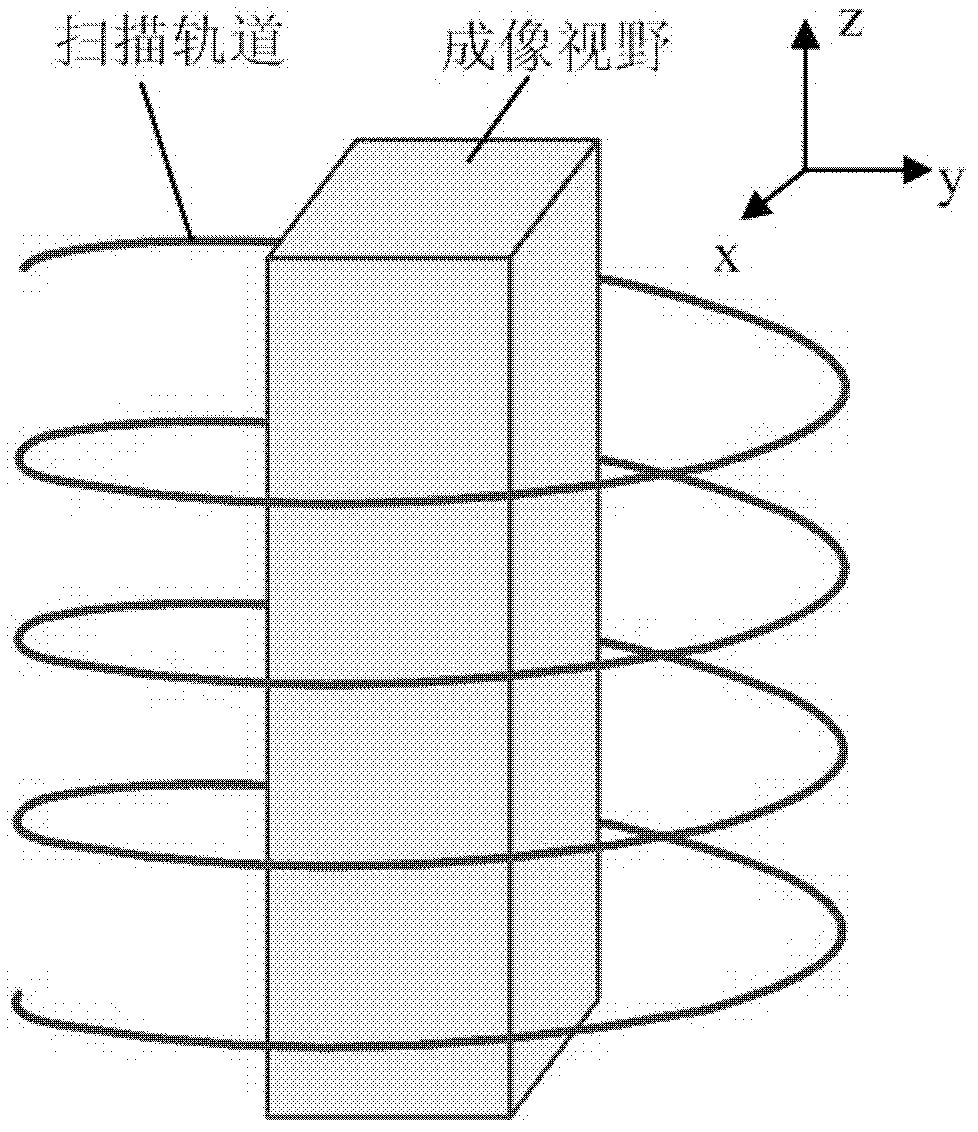

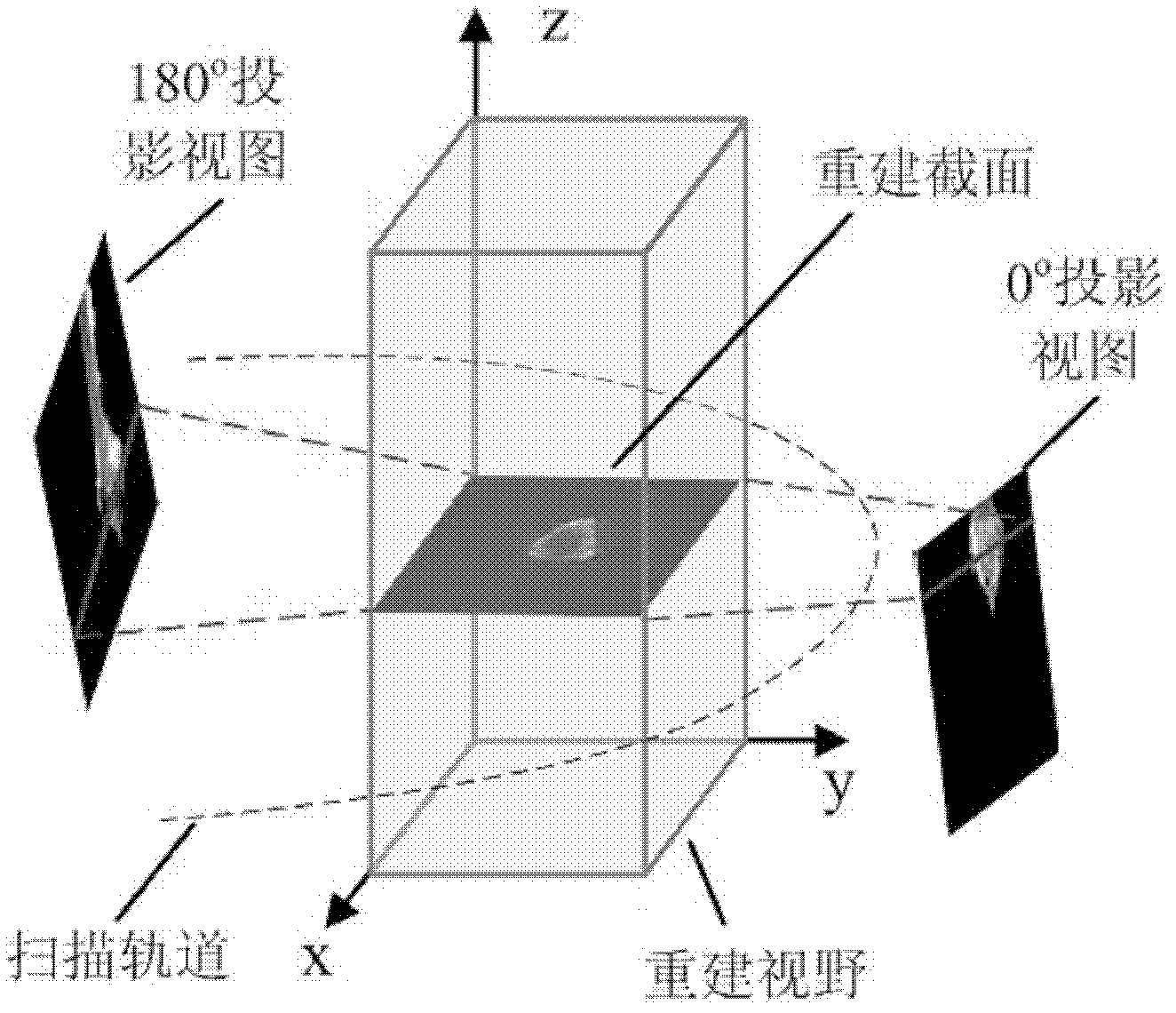

Optical projection tomography method based on helical scanning track

ActiveCN102599887ARealize 3D reconstructionGuaranteed imaging accuracyDiagnostic recording/measuringSensorsOptical projection tomographyHelical scan

The invention discloses an optical projection tomography method based on a helical scanning track. The projection data obtained by an optical projection tomography (OPT) system in a helical scanning manner is rearranged to be transformed to a series of sinusoidal projection images scanned in a circular track, and the sinusoidal projection images are reconstructed, so as to obtain a sample three-dimensional fault structure. The optical projection tomography method provided in the embodiment of the invention can be used for effectively expanding the view of the optical projection tomography, in particular to the imaging view for long and thin objects.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

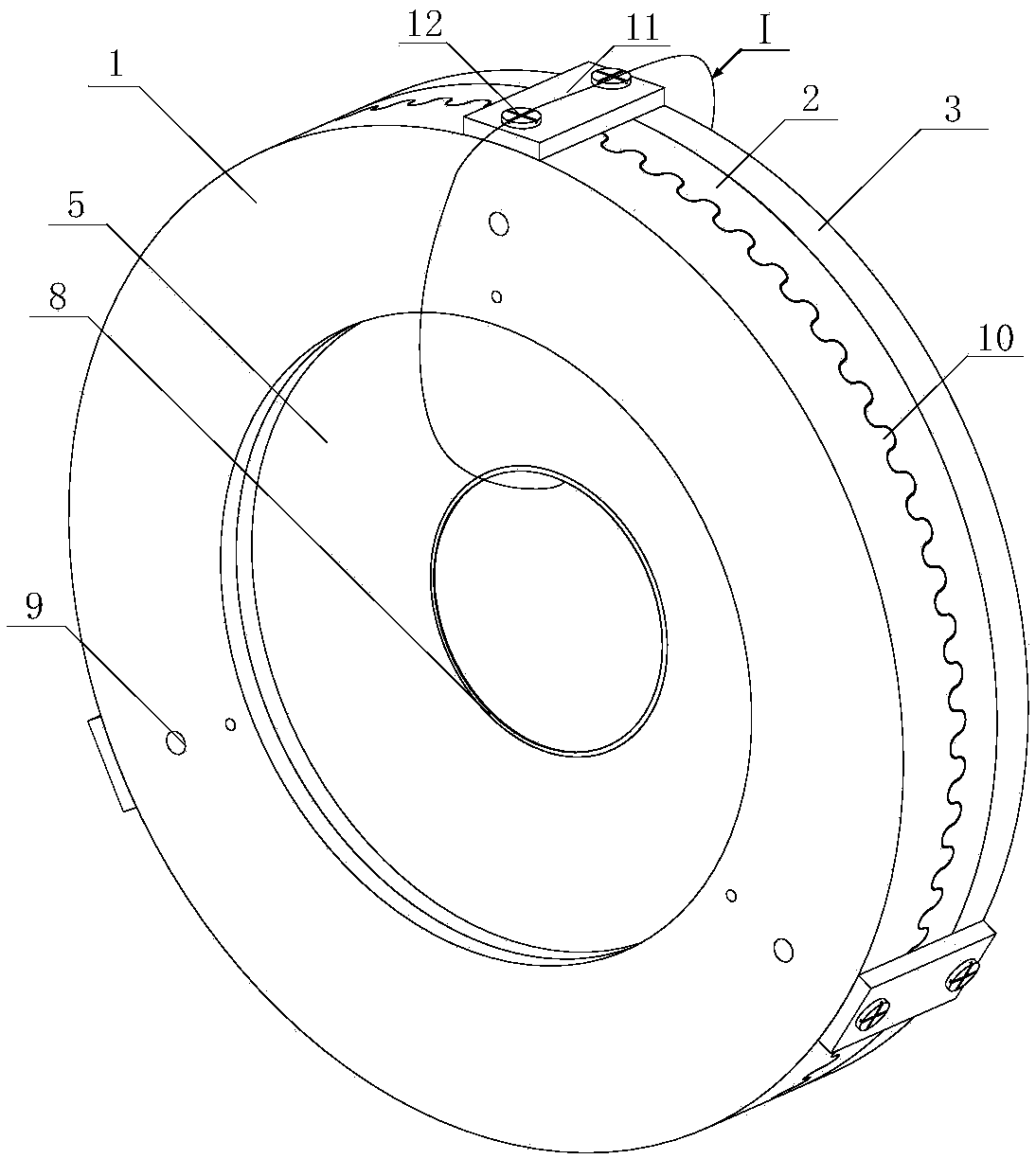

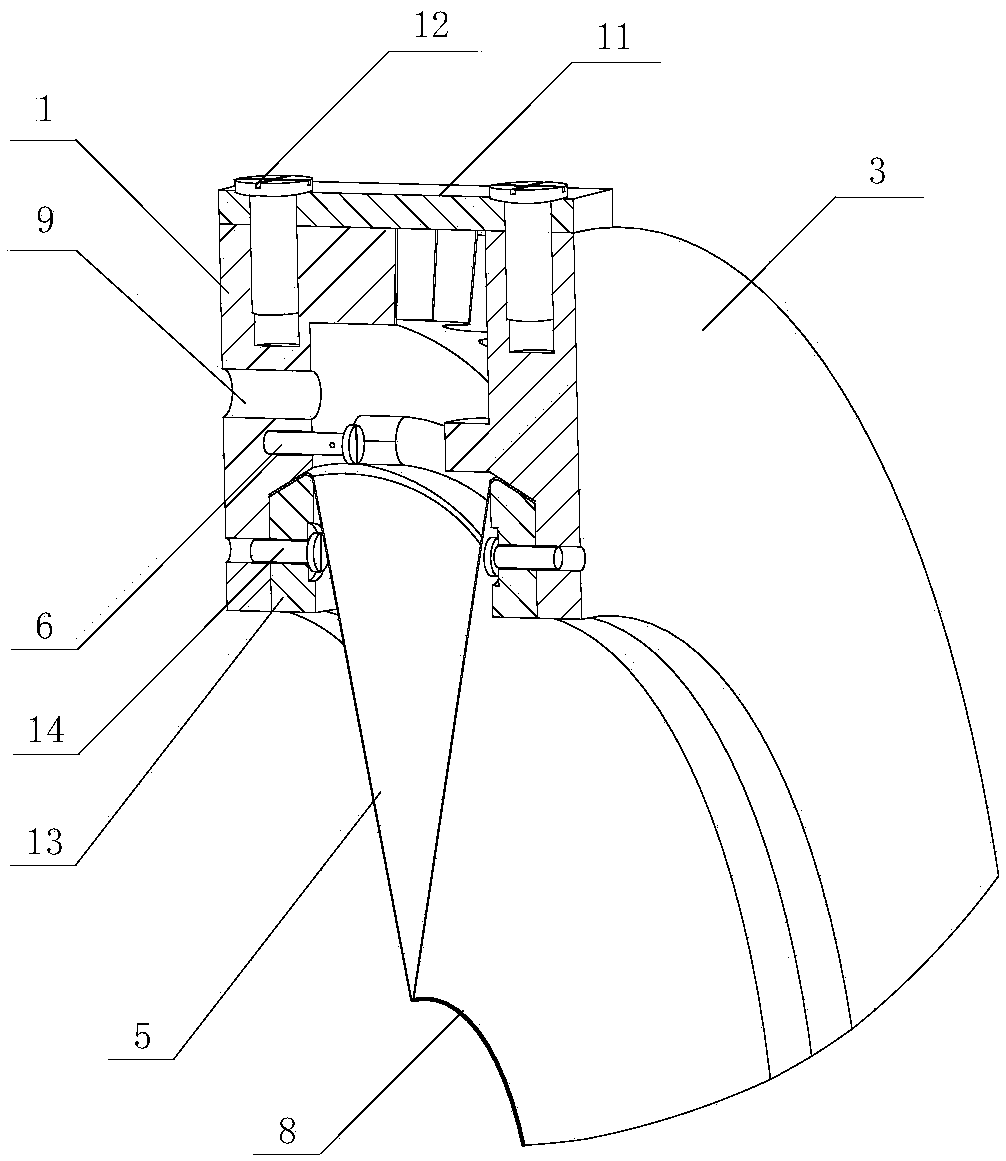

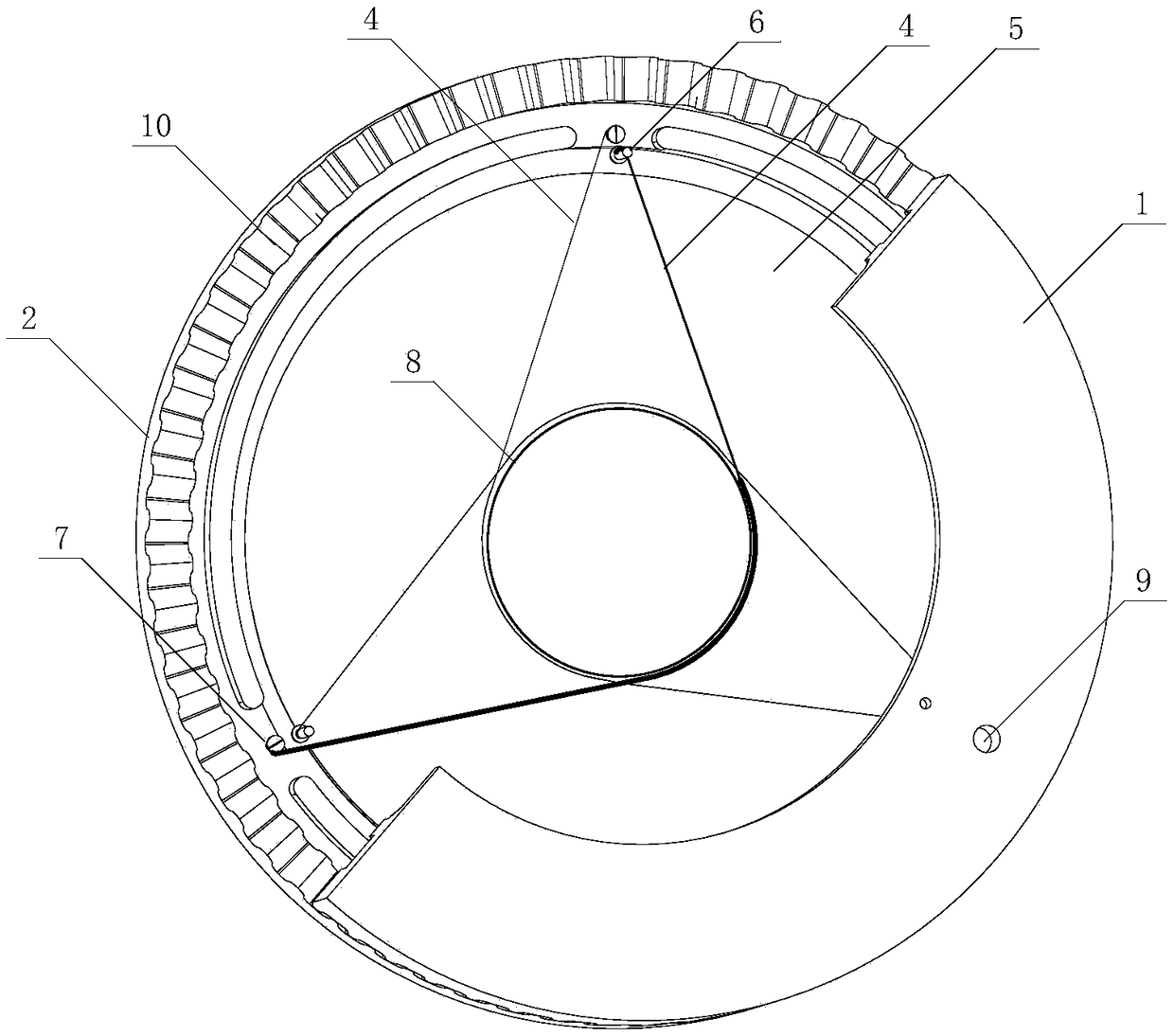

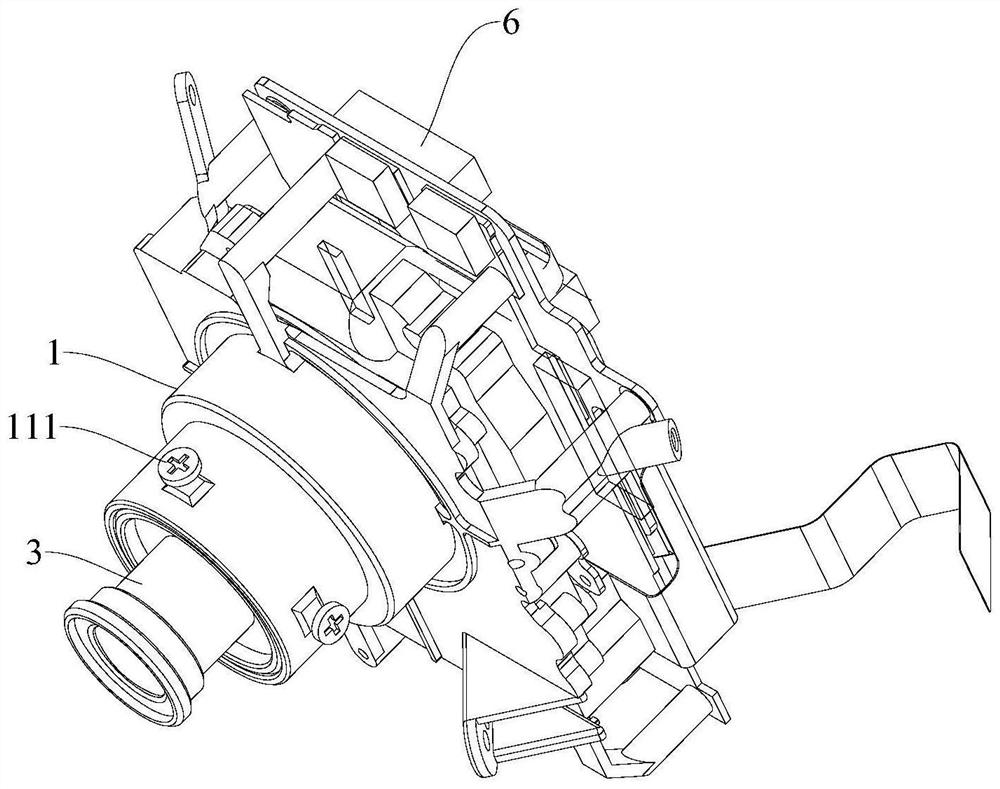

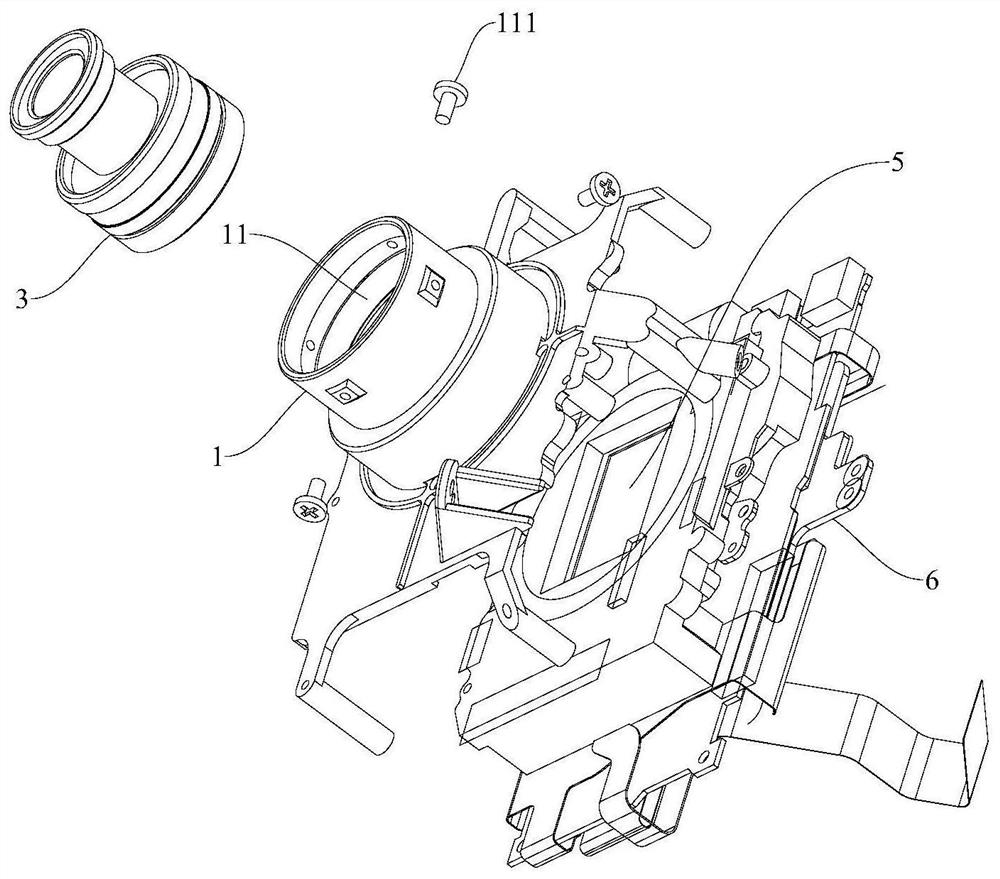

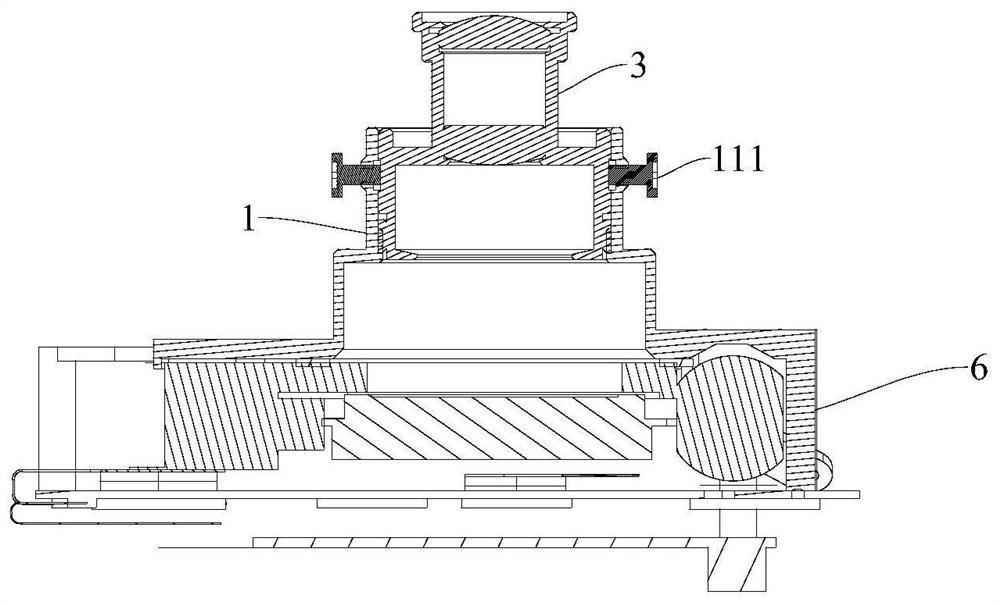

A dimmable aperture device

PendingCN109143724APrecise adjustment of the center positionAvoid offsetCamera diaphragmsEngineering

Owner:SHANDONG UNIV OF TECH

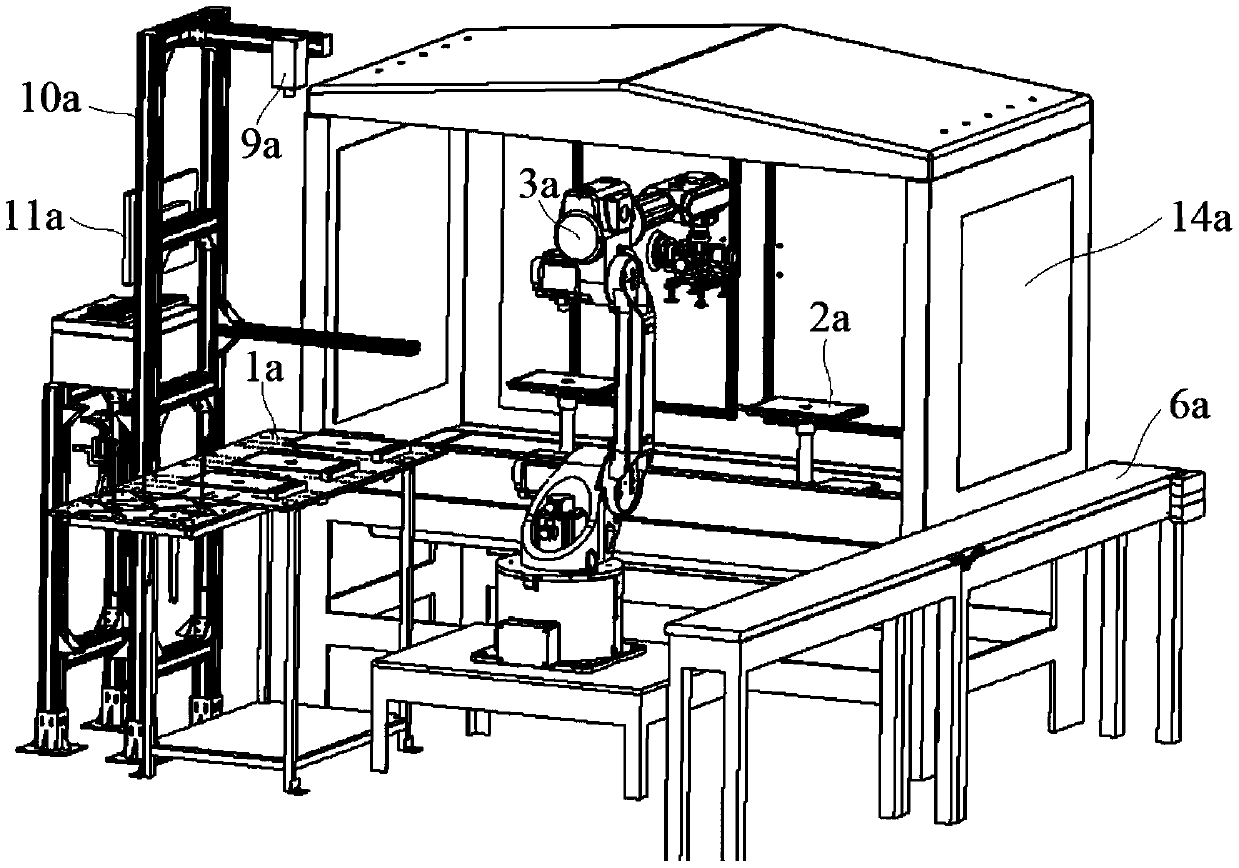

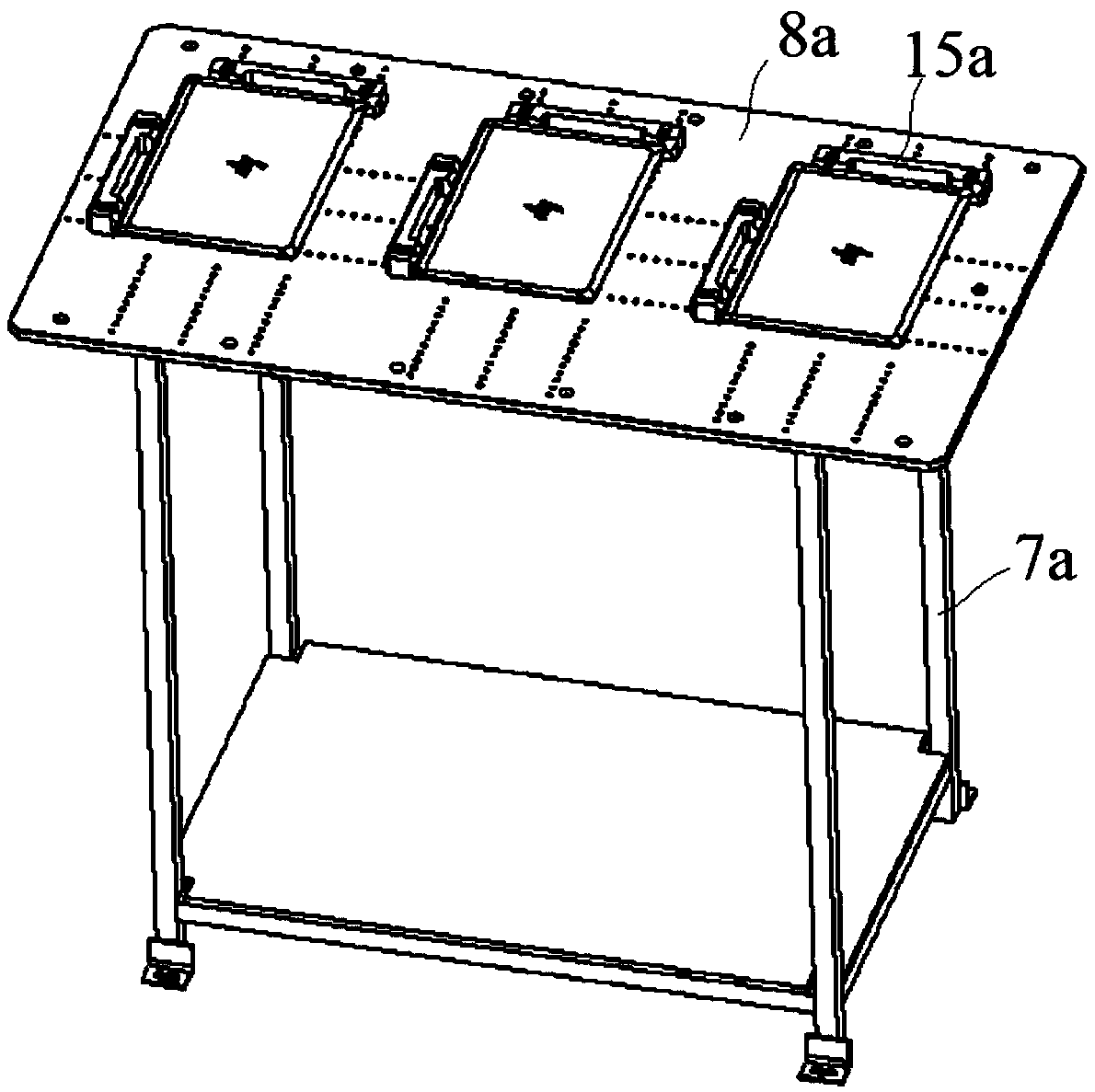

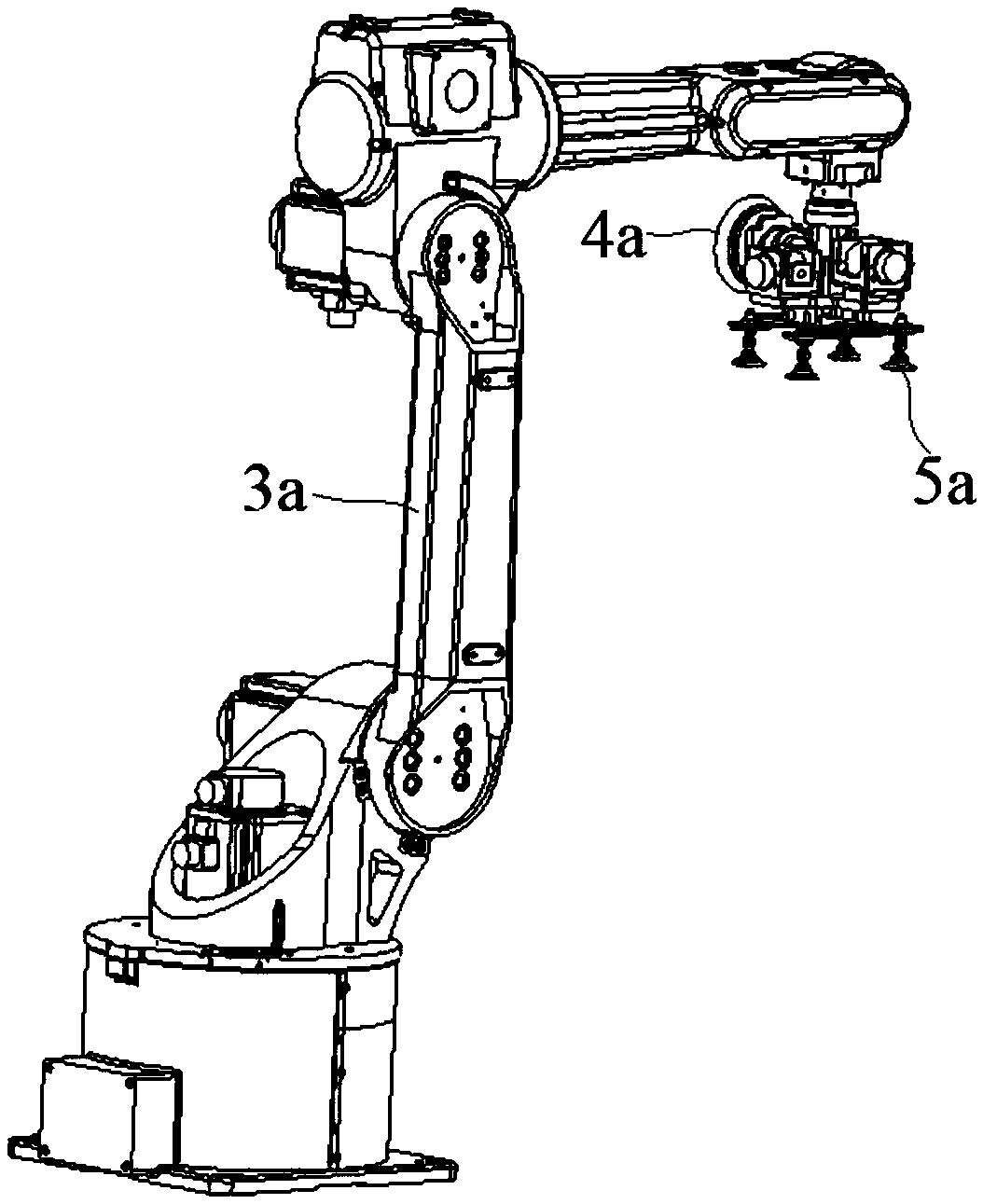

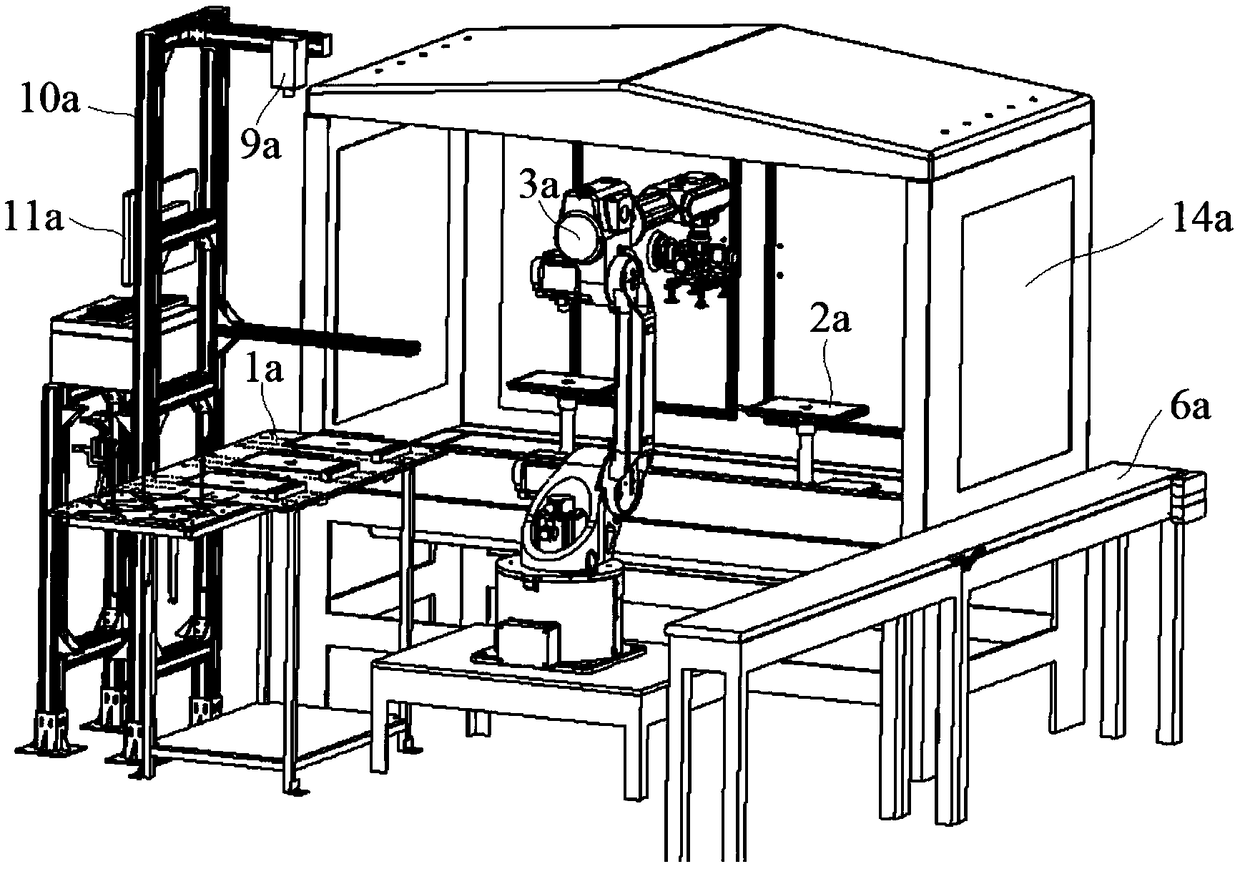

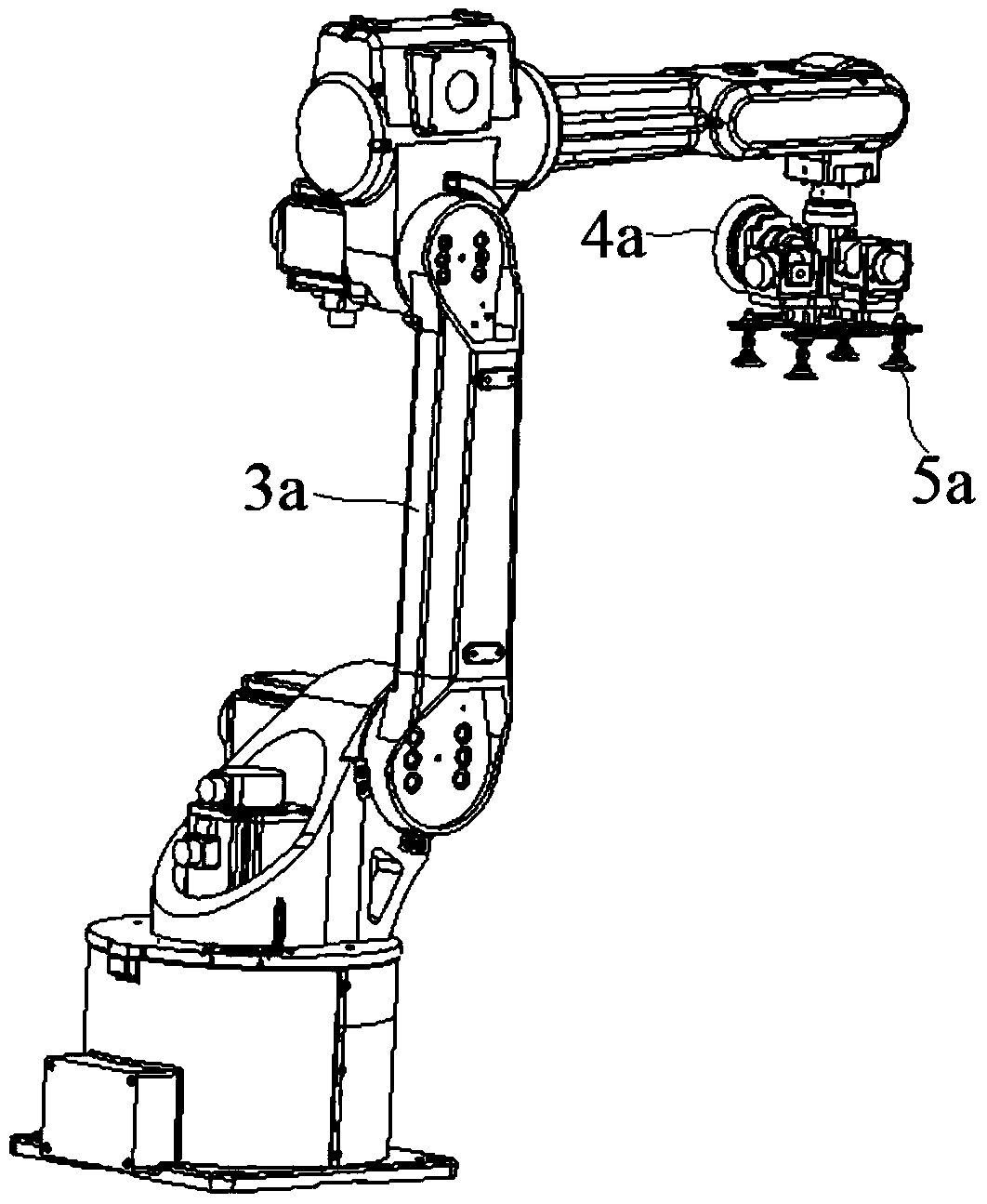

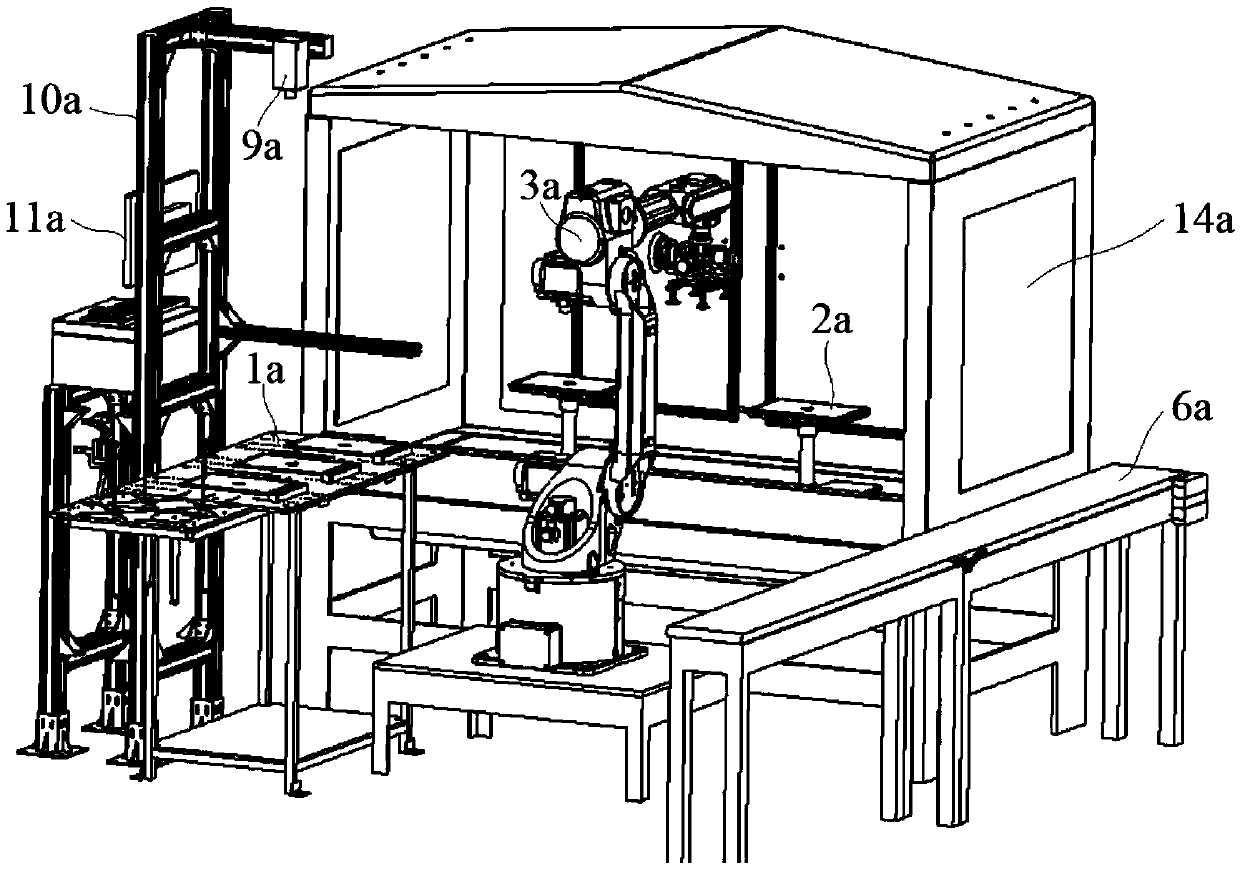

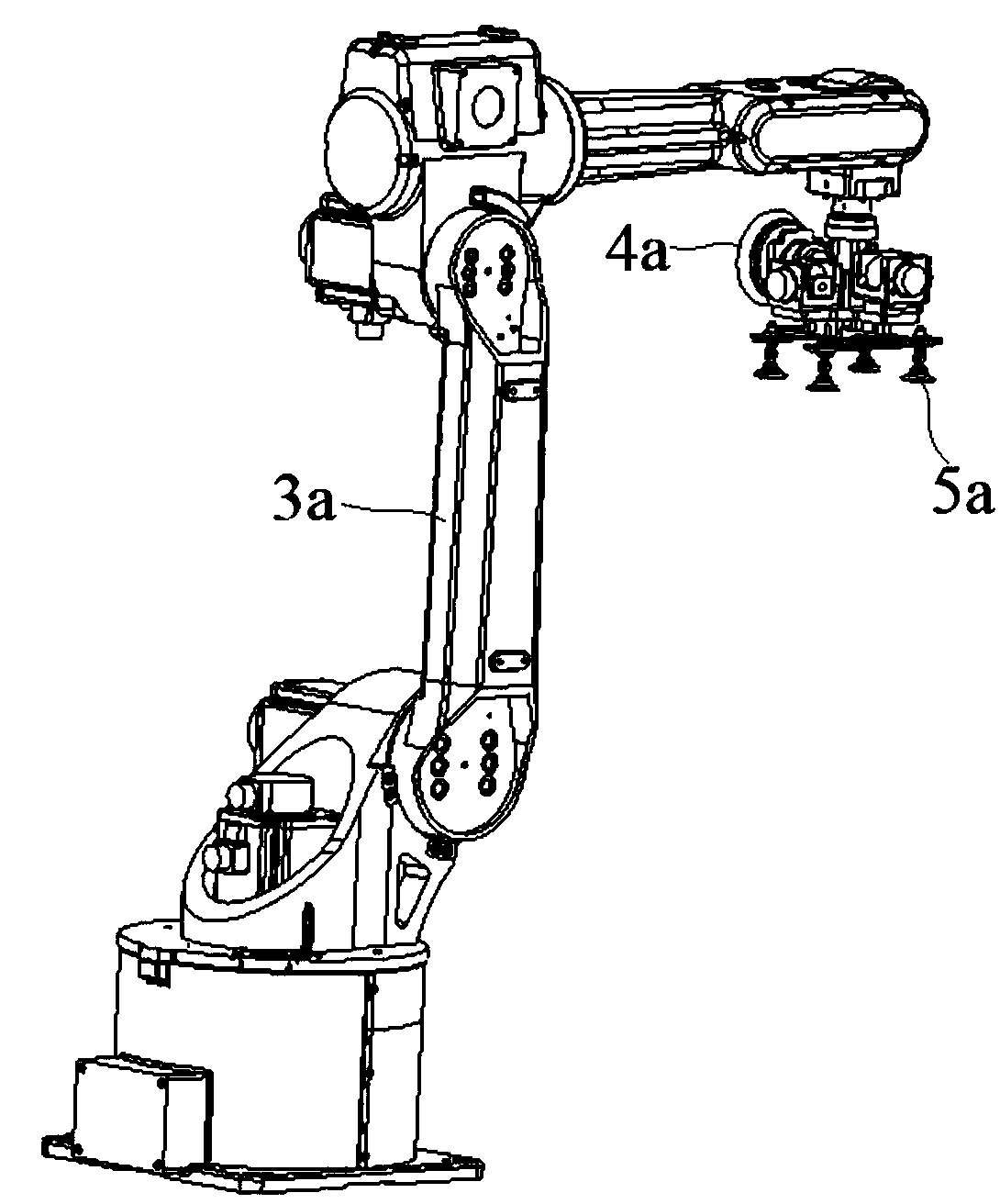

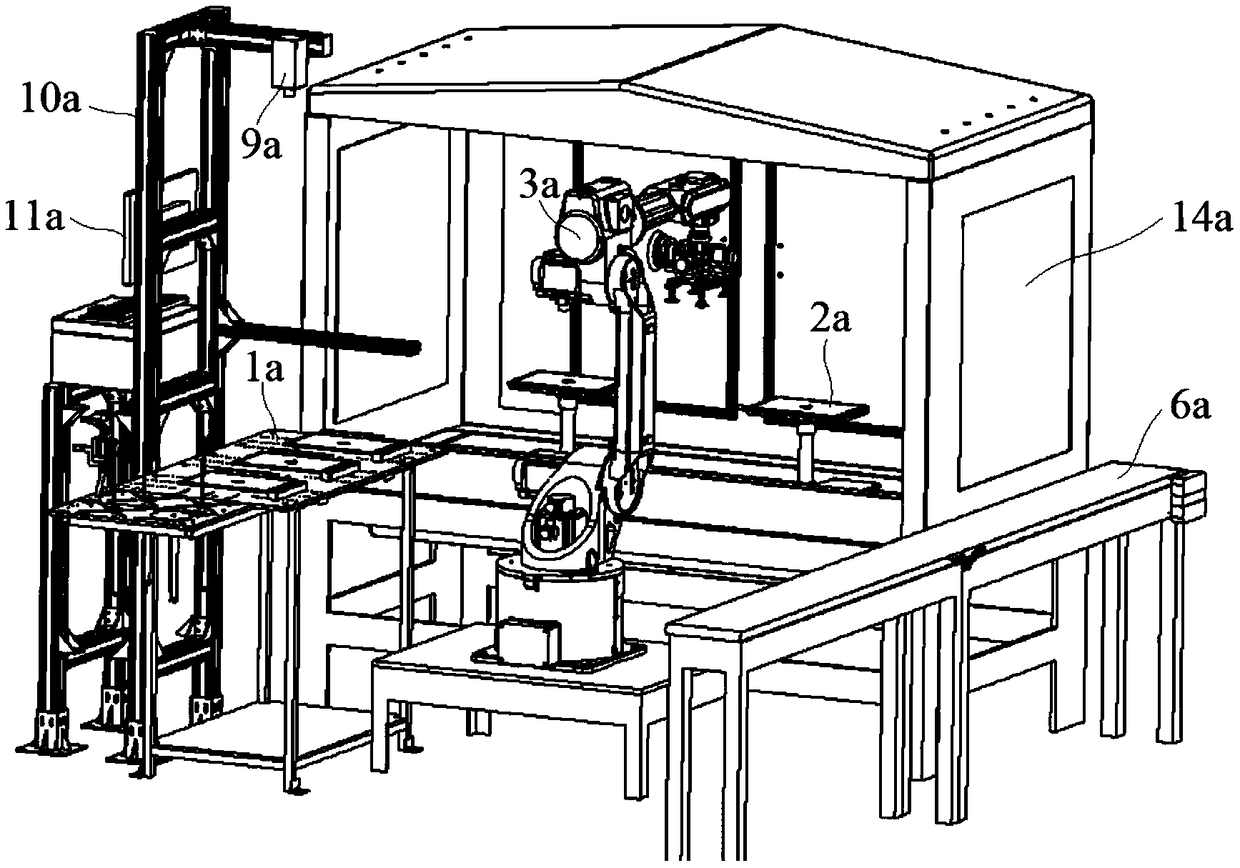

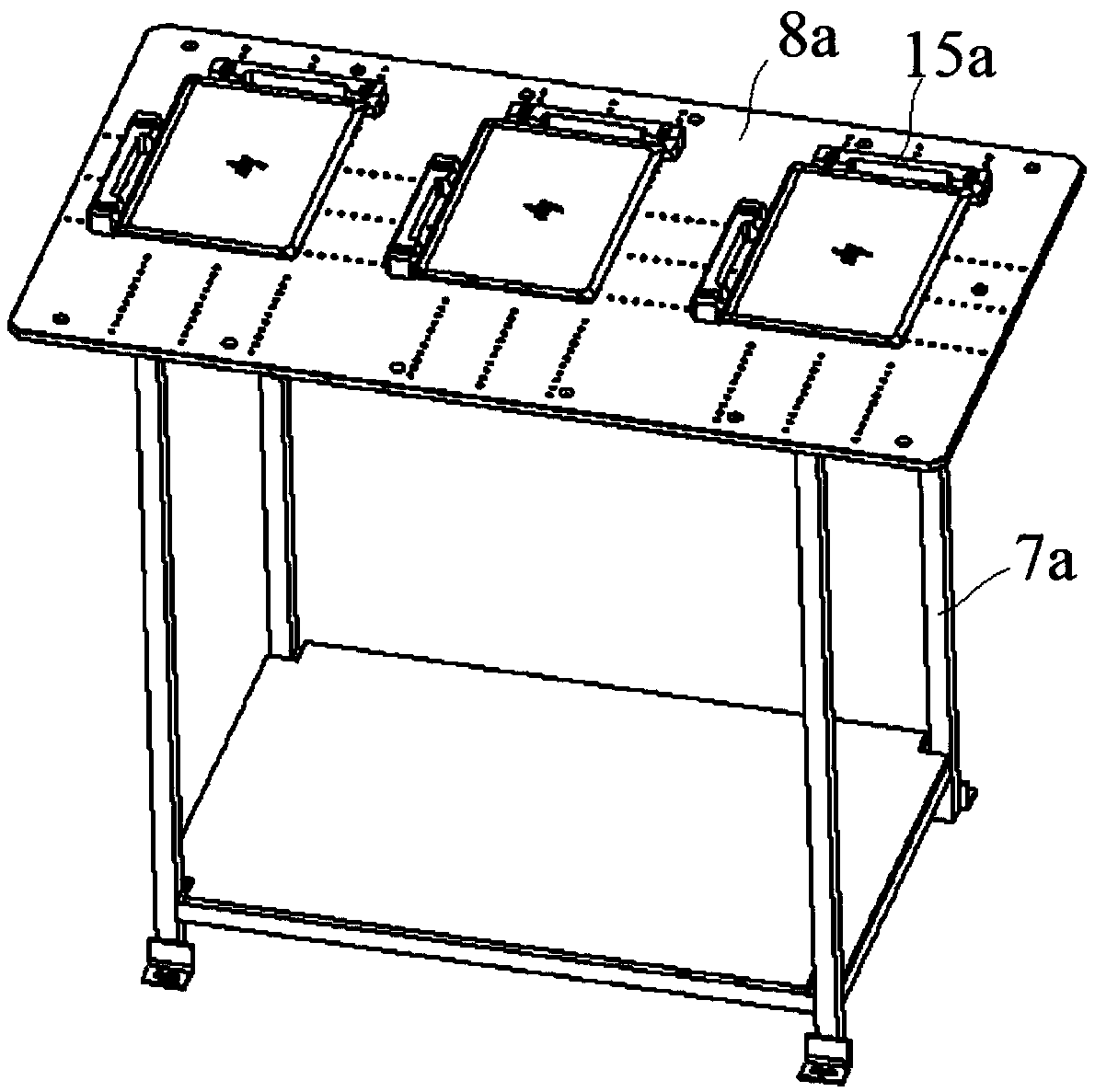

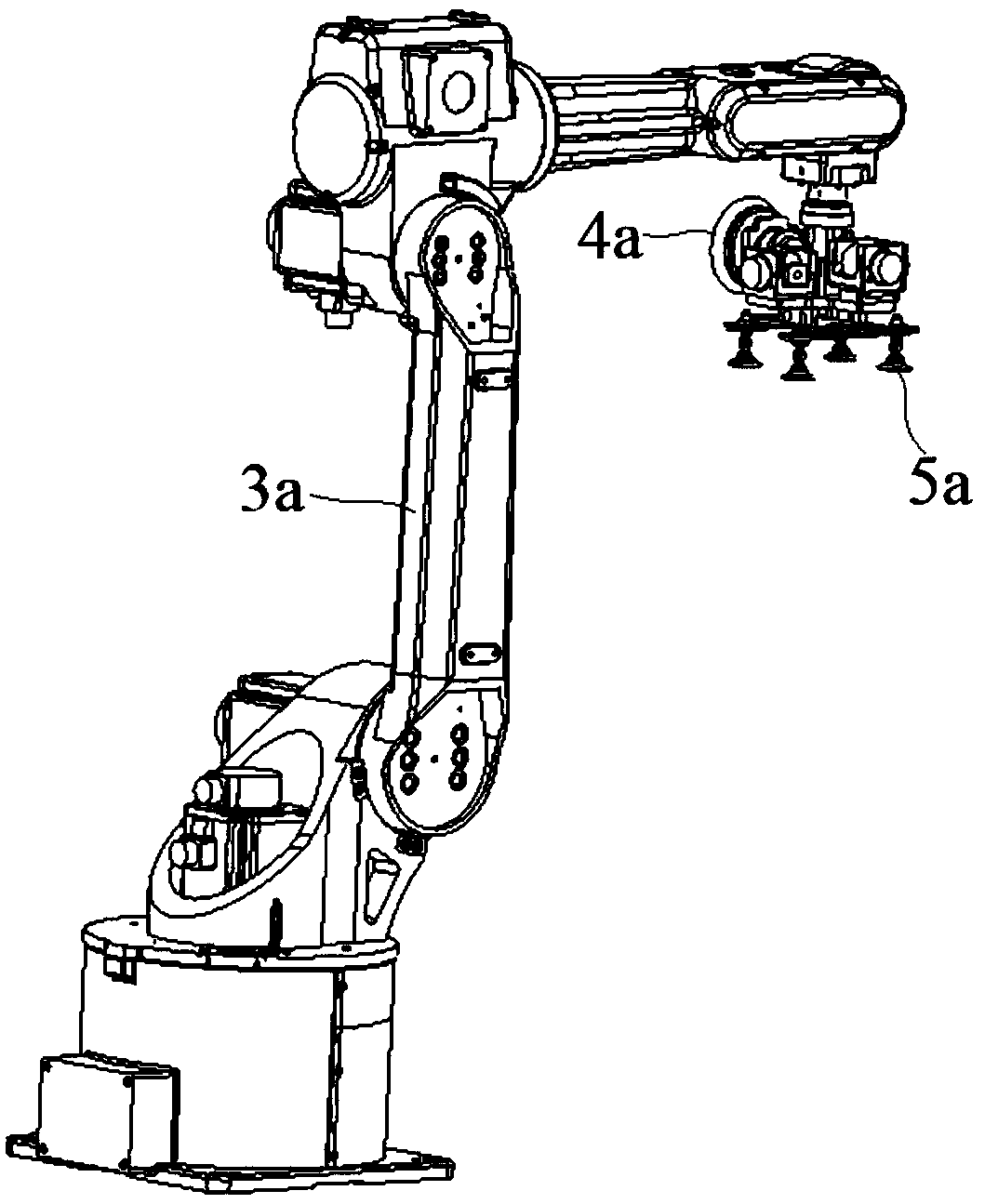

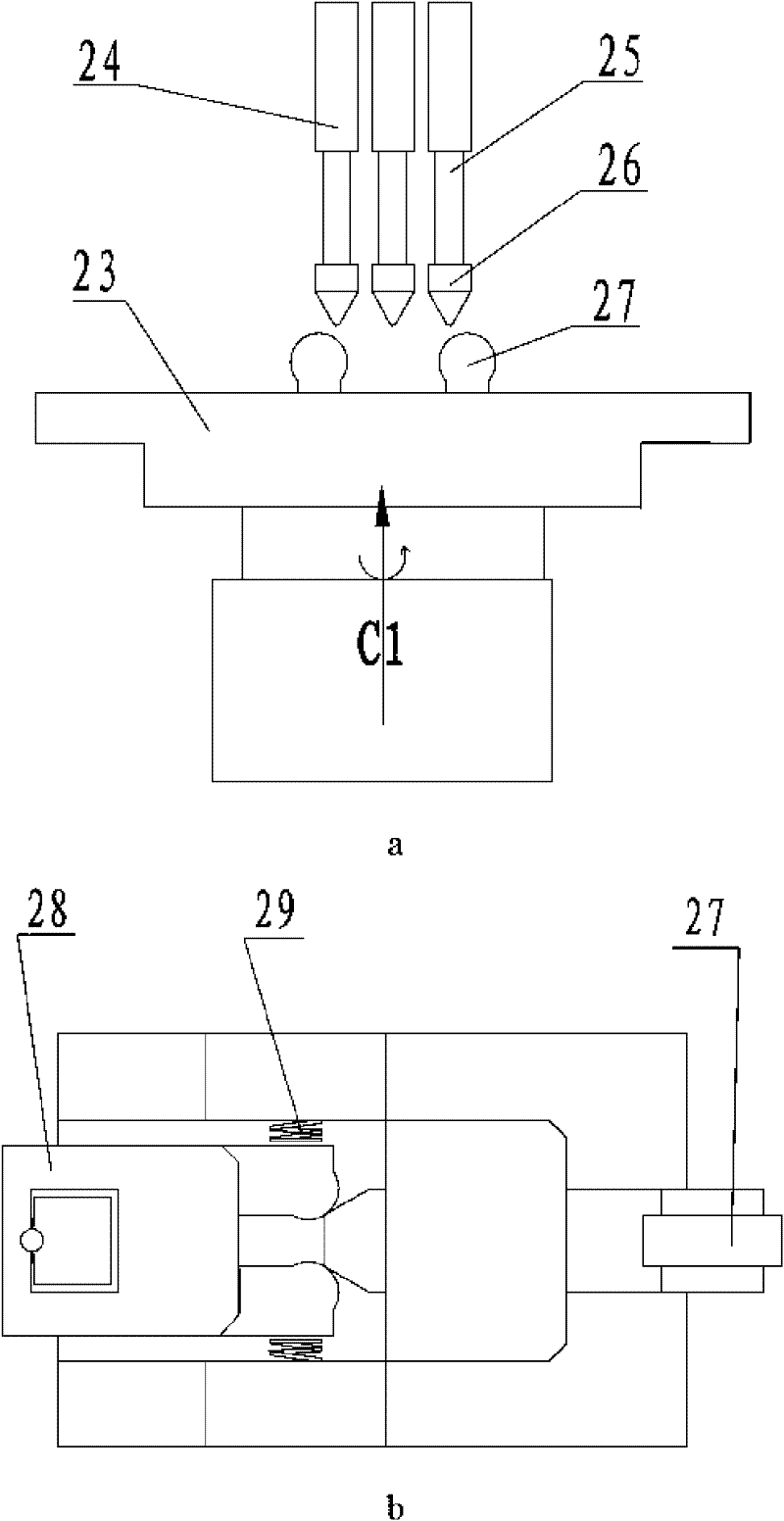

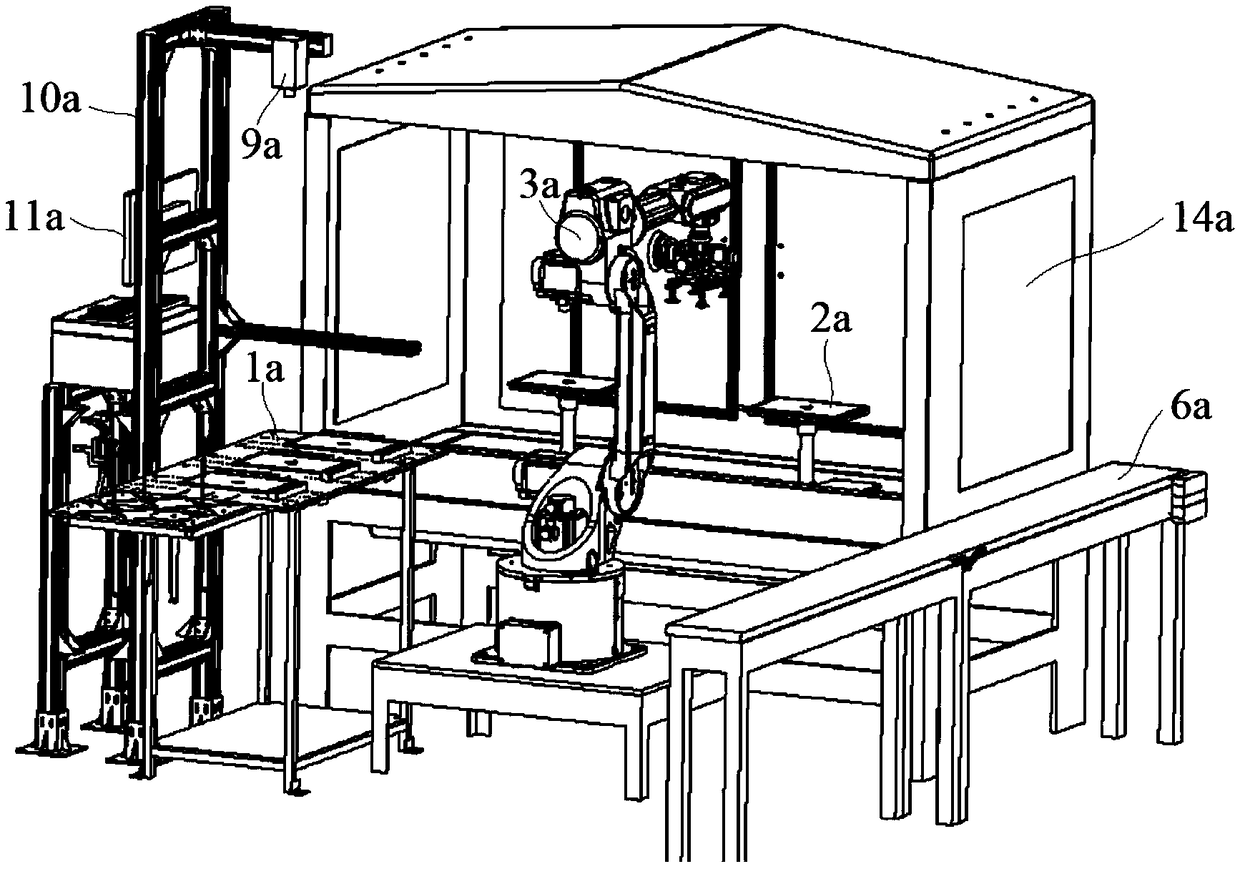

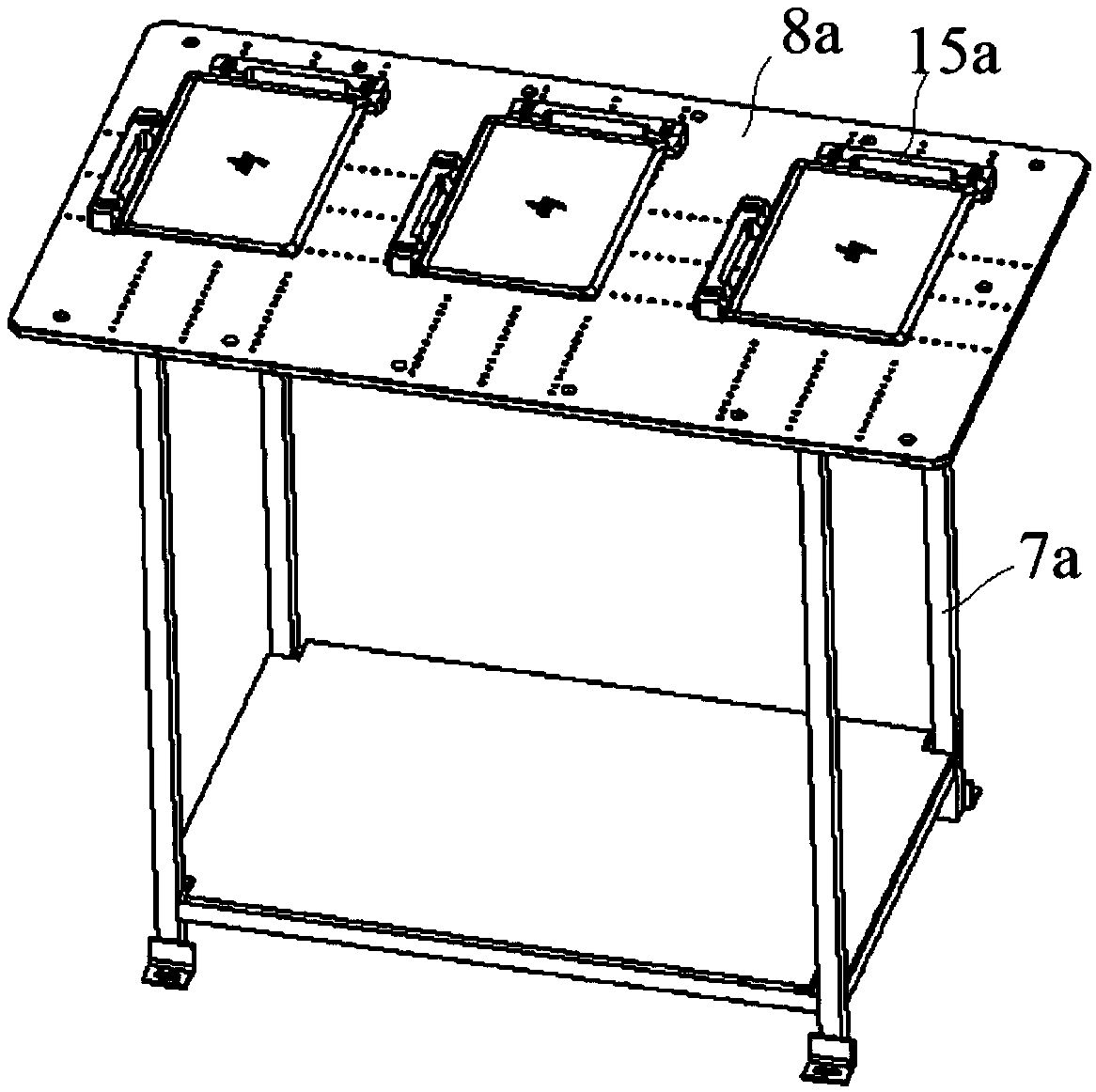

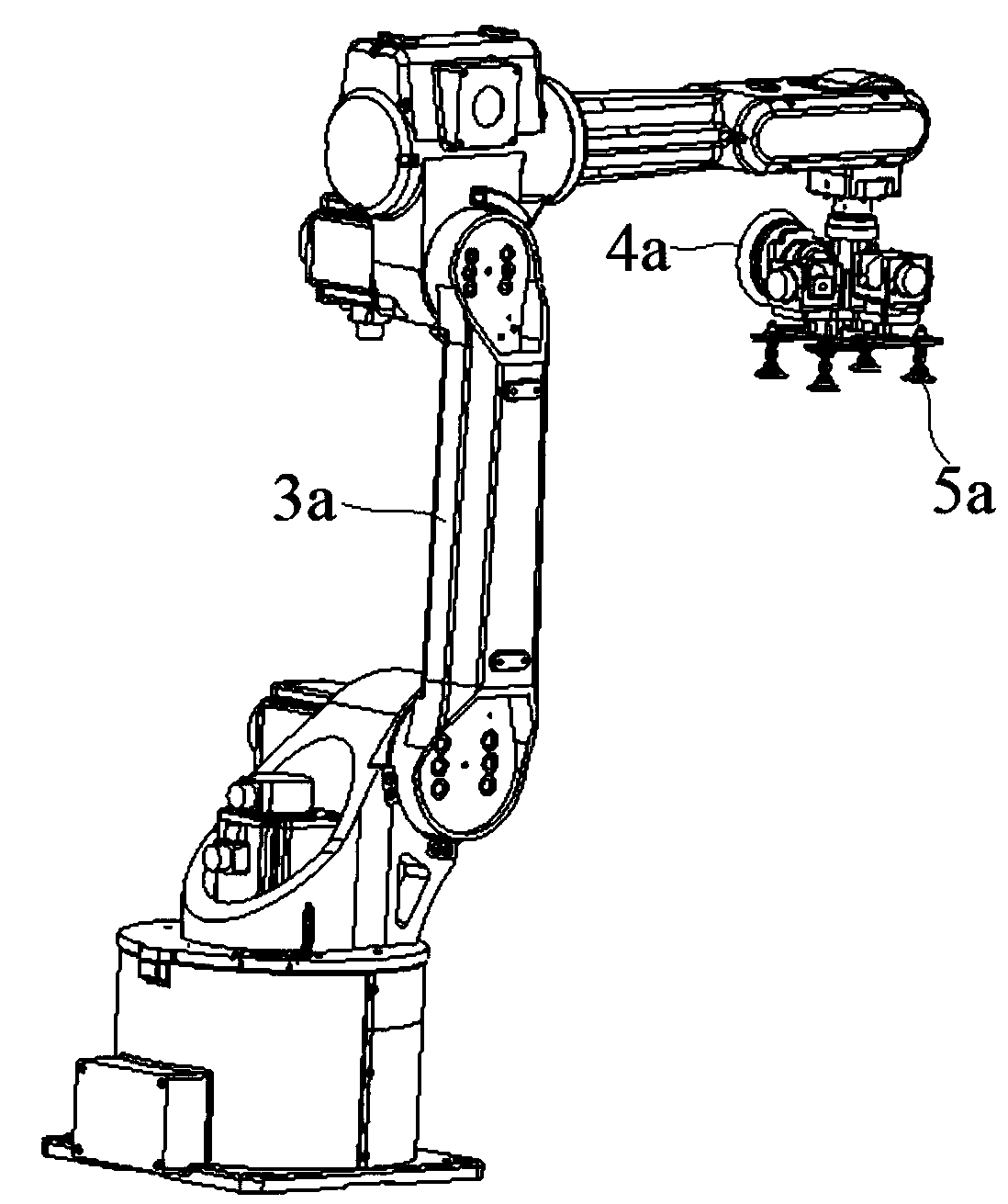

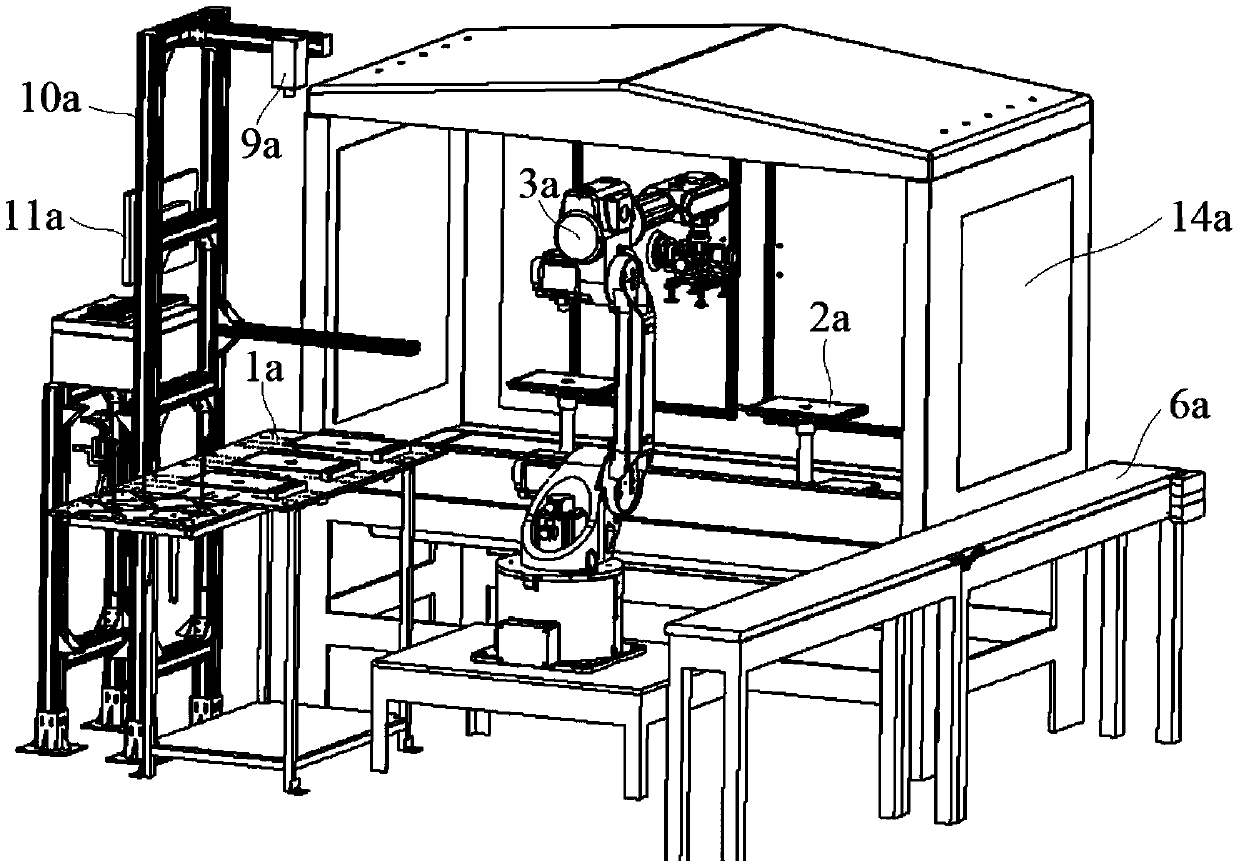

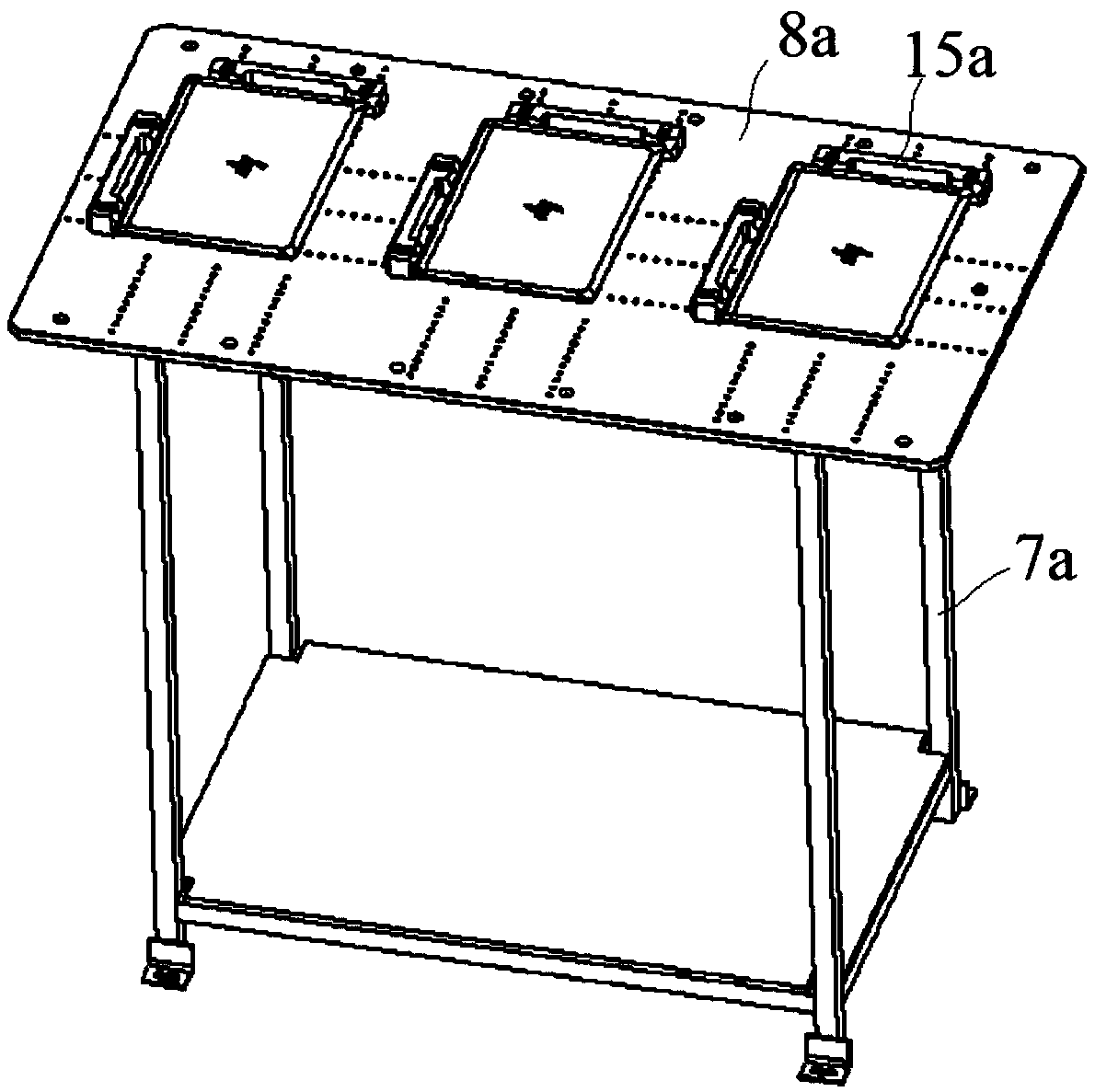

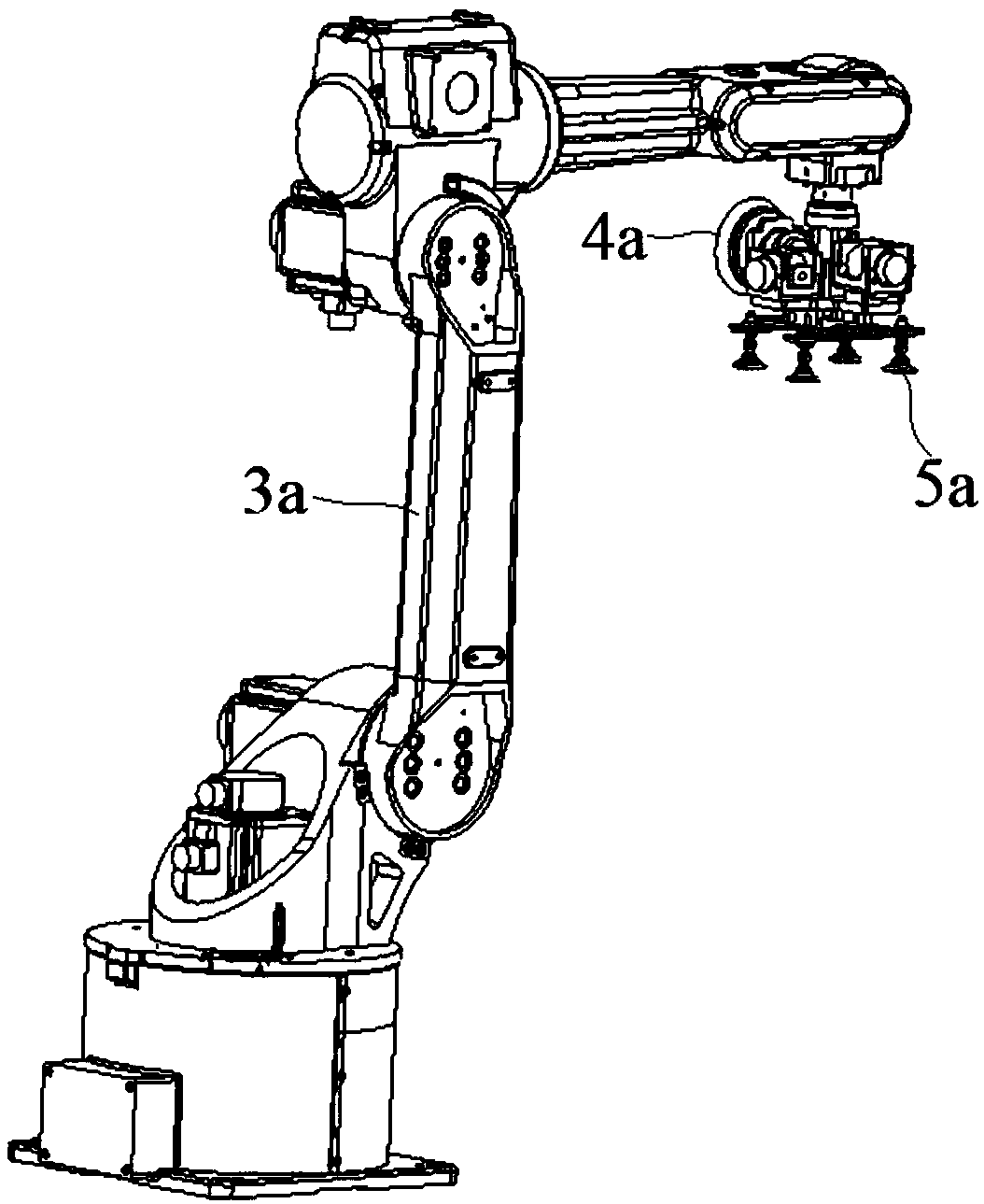

Automatic machining mechanism for notebook computer shell

InactiveCN109623567ASave materialReduce grinding time and processProgramme-controlled manipulatorGrinding carriagesEngineeringRubber ring

The invention discloses an automatic machining mechanism for a notebook computer shell. The automatic machining mechanism comprises feeding supports, polishing supports, a plurality of mechanical arms, a polishing head and a material-conveying clamp, the polishing head and the material-conveying clamp are mounted at and connected with end joints of the mechanical arms correspondingly, and the feeding supports and the polishing supports are arranged in the circumferential directions of the mechanical arms correspondingly; and a rubber ring is mounted at the tail end of a lower shaft part in a sleeving mode, a bearing is arranged in a shell part of a rotating shell, a sealing washer is arranged on the lower part of the bearing, an annular gasket is arranged on the lower part of the sealing washer, a washer is mounted on a lower shaft part of a core body in a sleeving mode and embedded into a through hole in the upper surface of a lower bearing seat, and the upper surface of the washer ishigher than the upper surface of the lower bearing seat. According to the automatic machining mechanism for the notebook computer shell, the situation that a rotating head is stuck when downward-pressing force is excessively large can be prevented, flexible rotation of the rotating head is ensured, through eccentric arrangement that the rotating head and the core body for driving the rotating head to rotate have different axes, a polishing trajectory is not left in the polishing process, and the elaborate degree of polishing is increased.

Owner:苏州丰川电子科技有限公司

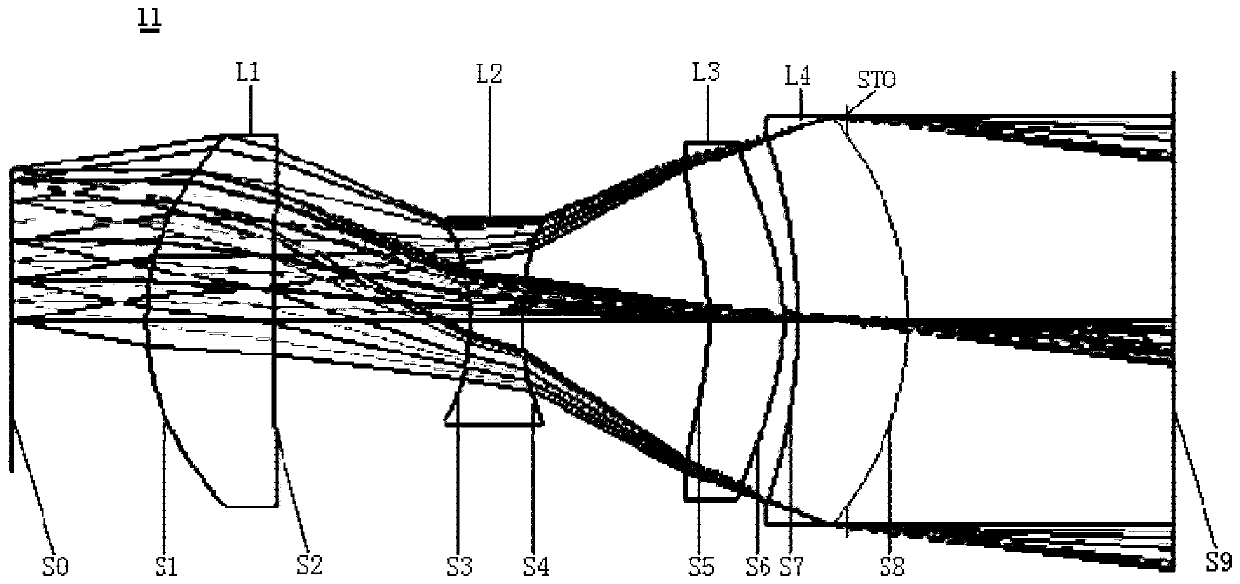

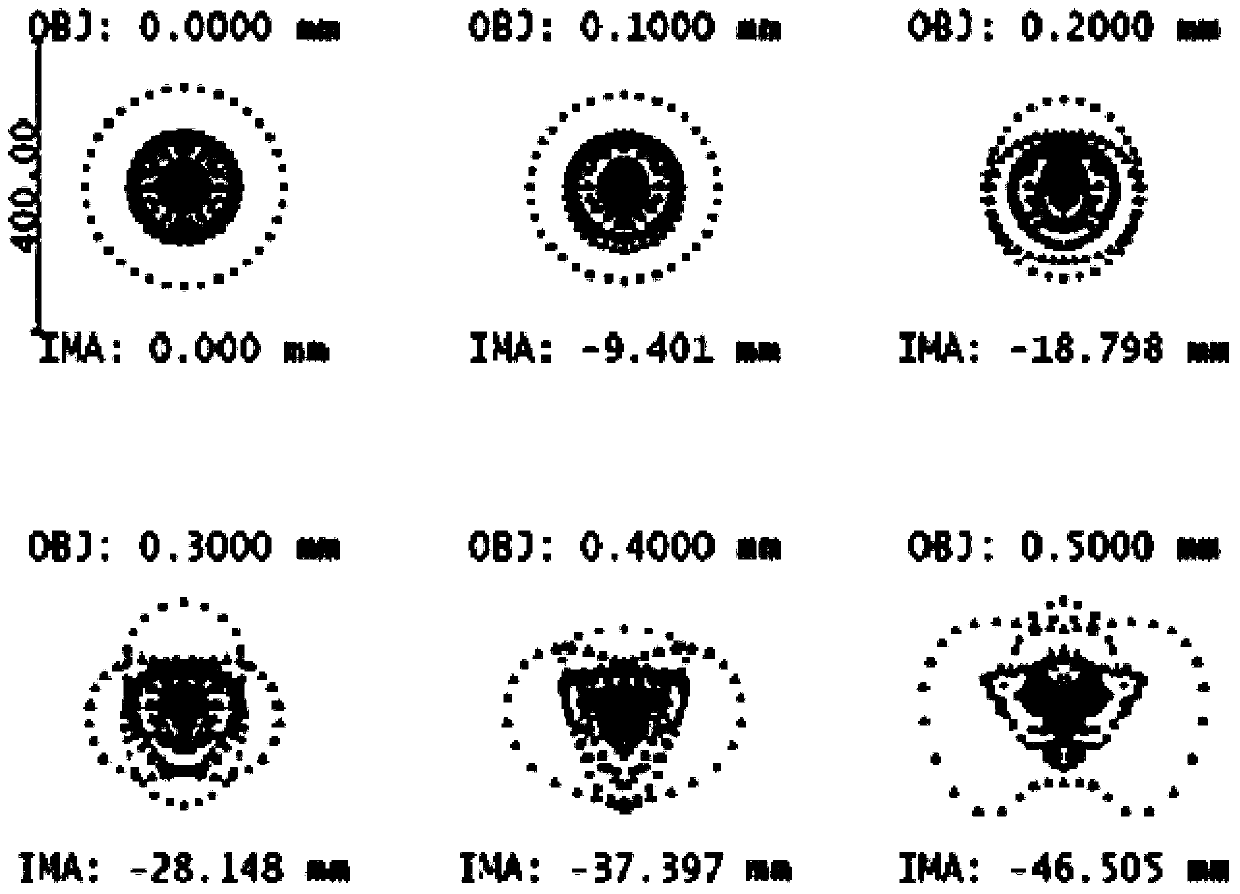

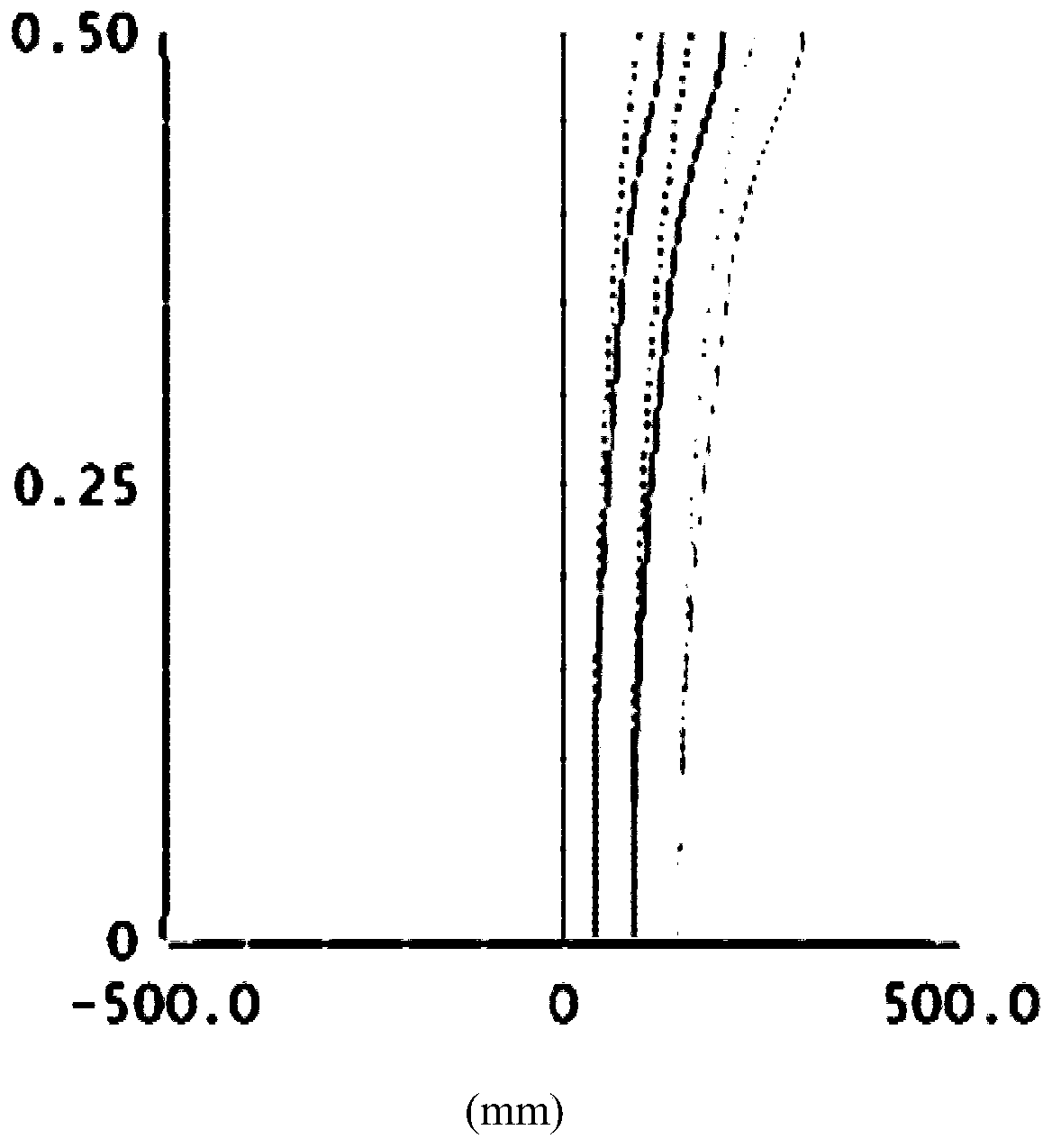

Collimating lens, laser module, depth camera and electronic device

InactiveCN110275180ANo errorGuaranteed imaging accuracyTelevision system detailsColor television detailsOptoelectronicsSurface type

The invention discloses a collimating lens, a laser module, a depth camera and an electronic device. The collimating lens sequentially comprises a first lens with positive focal power, a second lens with negative focal power, a third lens with positive focal power and a fourth lens with positive focal power from an object side to an image side. The object side surface and the image side surface of the first lens are convex surfaces. The object side surface and the image side surface of the second lens are concave surfaces. The object side surface of the third lens is a concave surface, and the image side surface of the third lens is a convex surface. The object side surface of the fourth lens is a concave surface, and the image side surface of the fourth lens is a convex surface. The first lens, the second lens and the third lens are all plastic lenses, the fourth lens is a glass lens, and the object side surfaces and the image side surfaces of the first lens to the fourth lens are aspheric surfaces. The collimating lens, the laser module, the depth camera and the electronic device effectively control the change of focal lengths at different temperatures through the matching design of the surface types and materials of the first to fourth lenses, thereby guaranteeing the imaging precision of depth images at different temperatures.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

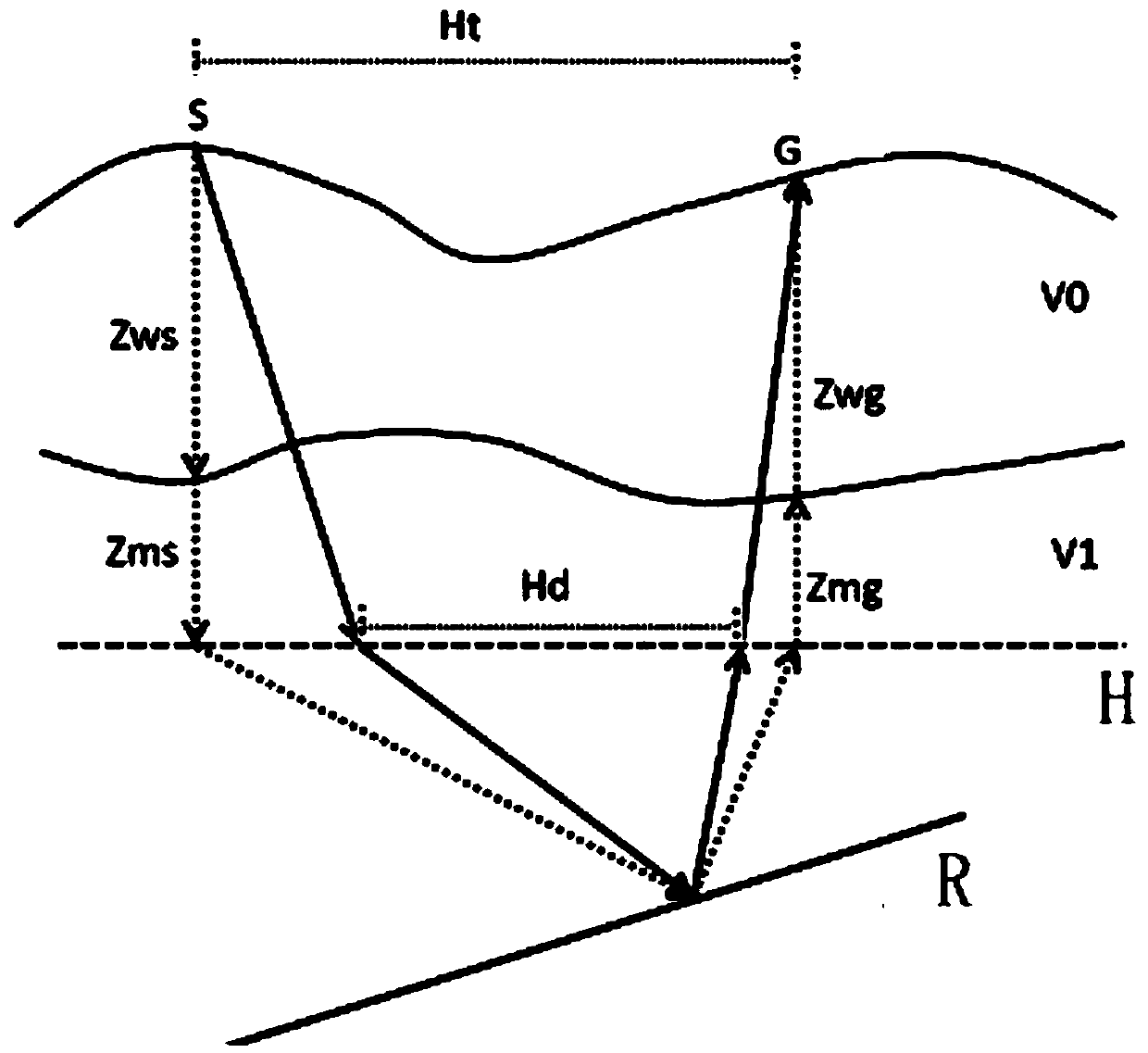

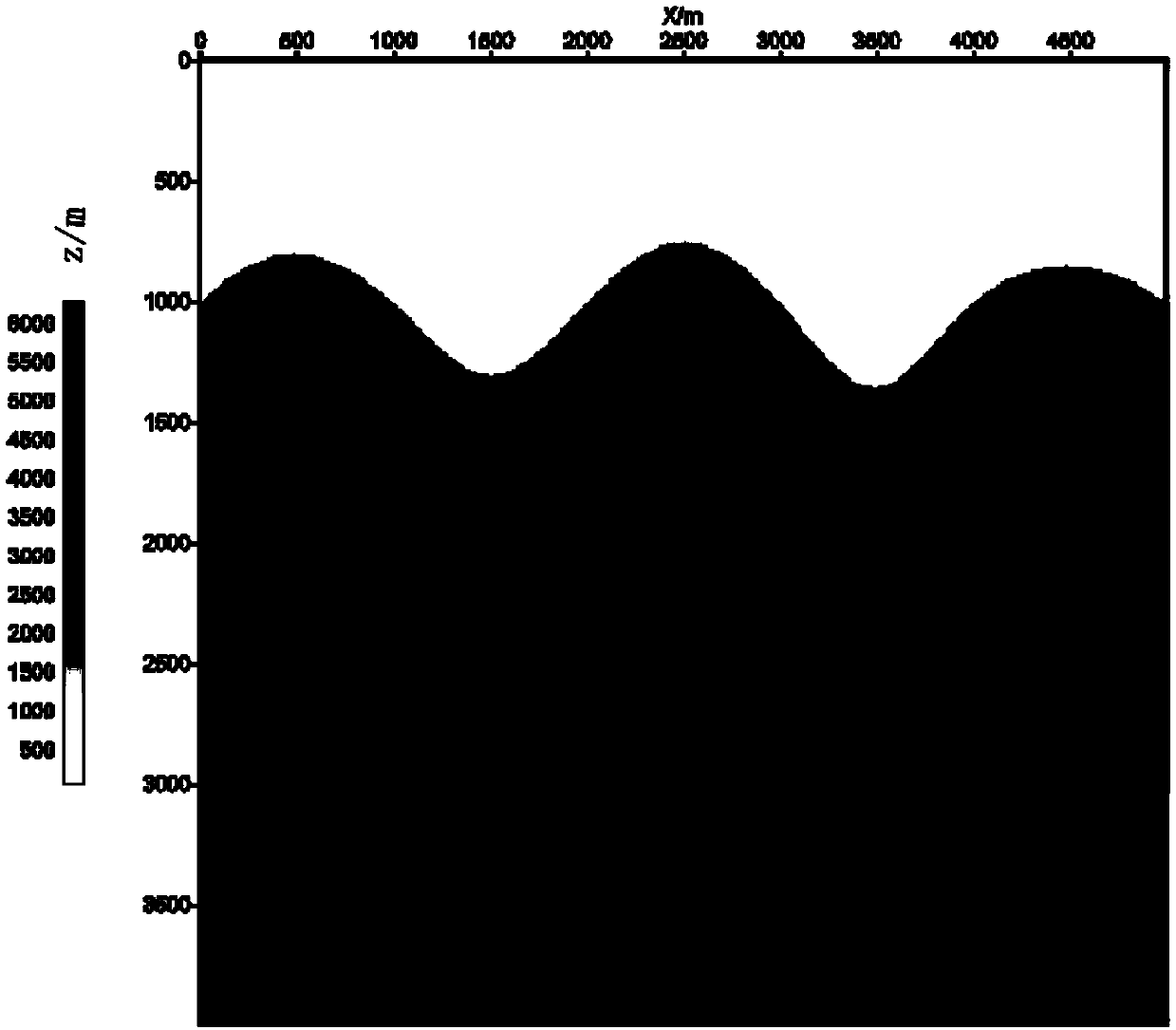

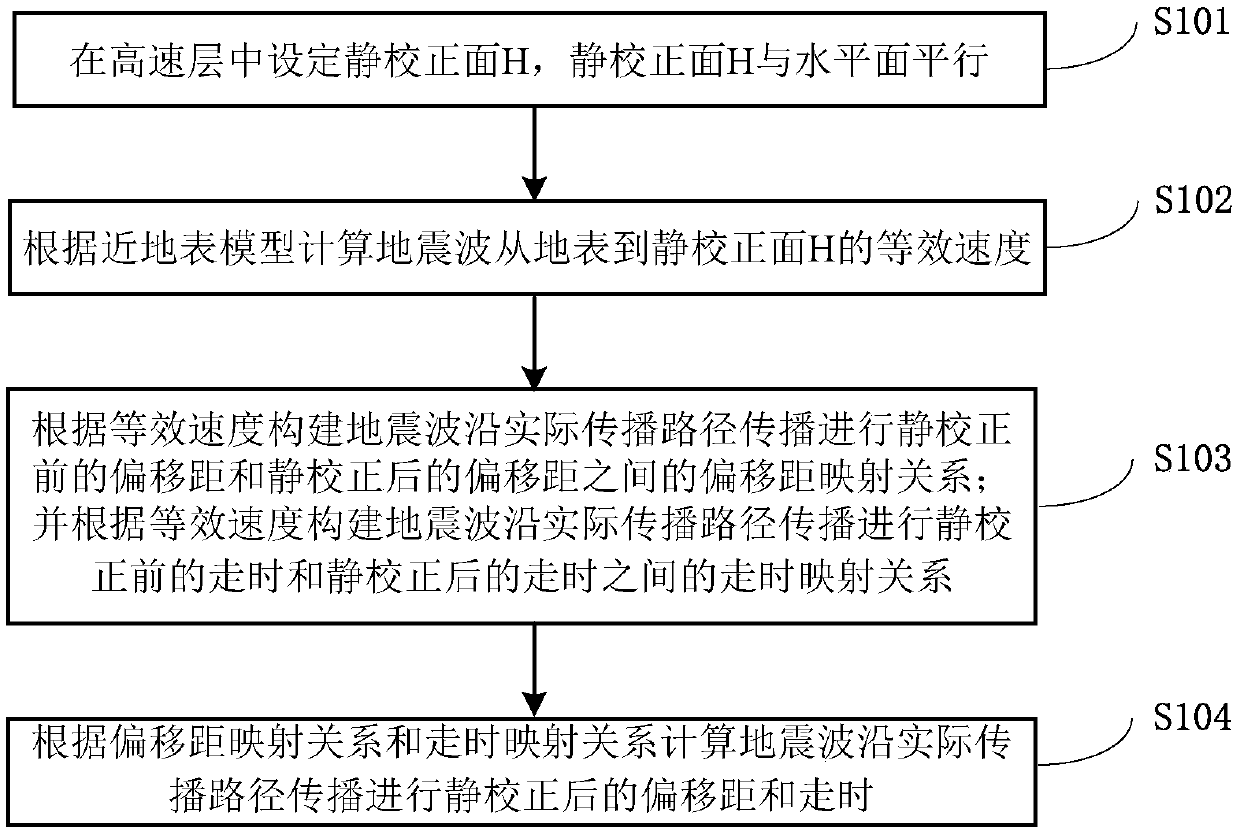

Non-surface consistency static correction method based on equivalent speed

InactiveCN110858003AAvoid precision errorsAccurate space-time distance relationshipSeismic signal processingSeismic wavePhysics

The invention discloses a non-surface consistency static correction method based on equivalent speed and belongs to the field of seismic exploration. The method comprises the following steps that: theequivalent speed of seismic waves transmitted from the ground to a static correction surface H is calculated according to a near-surface model; an offset distance mapping relation between an offset distance before static correction and an offset distance after static correction under the condition of the transmission of seismic waves along an actual propagation path is constructed according to the equivalent speed, and a travel time mapping relation between travel time before static correction and travel time after static correction under the condition of the transmission of the seismic wavesalong the actual propagation path is constructed according to the equivalent speed; and the offset distance and travel time of the seismic waves under the condition of the transmission of seismic waves along the actual propagation path are calculated according to the offset distance mapping relation and the travel time mapping relation. With the non-surface consistency static correction method based on the equivalent speed adopted, precision errors caused by the vertical transmission of seismic waves assumed by conventional static correction are avoided. Compared with the conventional staticcorrection, the method has higher precisions, can better keep an accurate space-time distance relation, and meanwhile can better guarantee subsequent imaging precision.

Owner:CHINA PETROLEUM & CHEM CORP +1

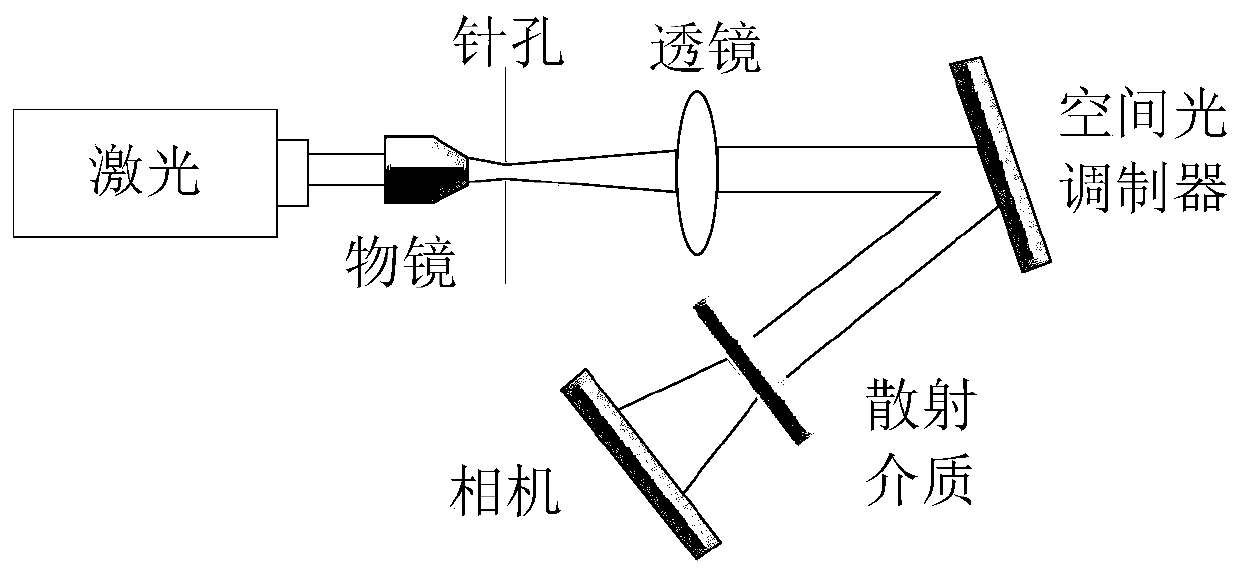

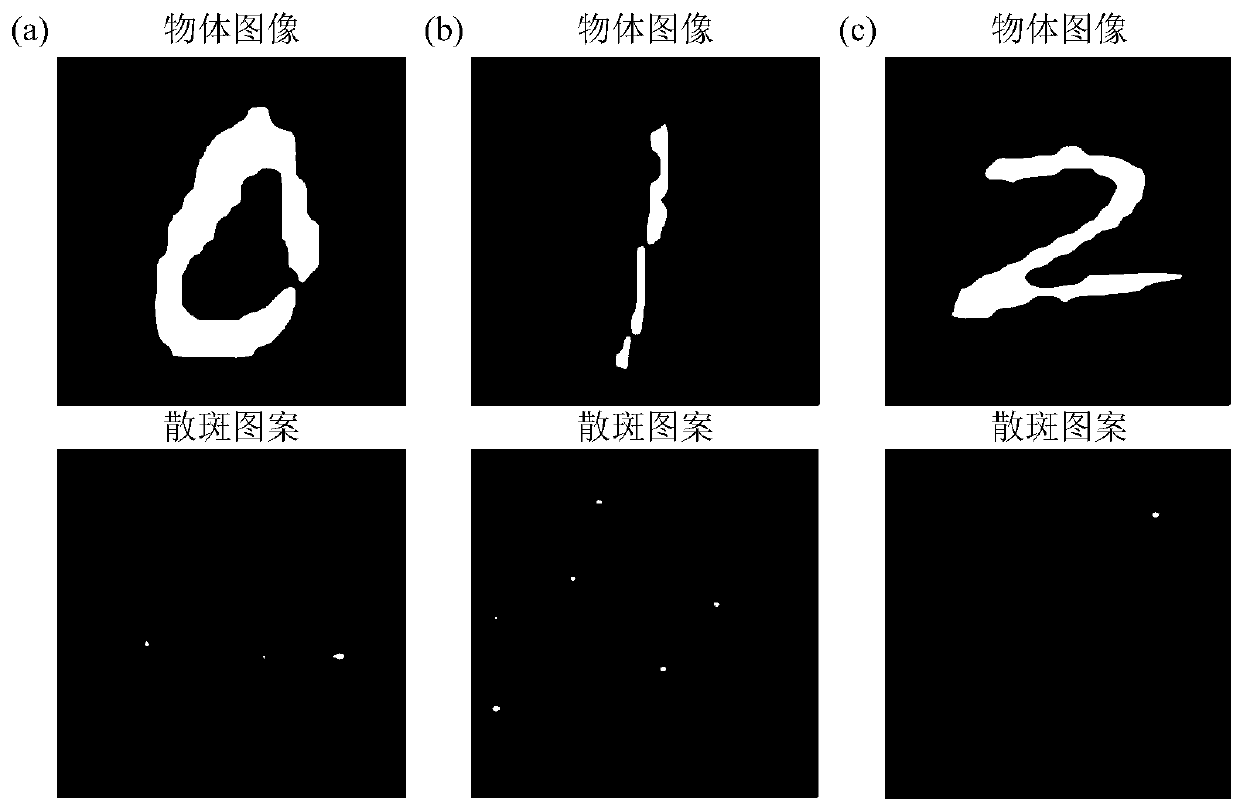

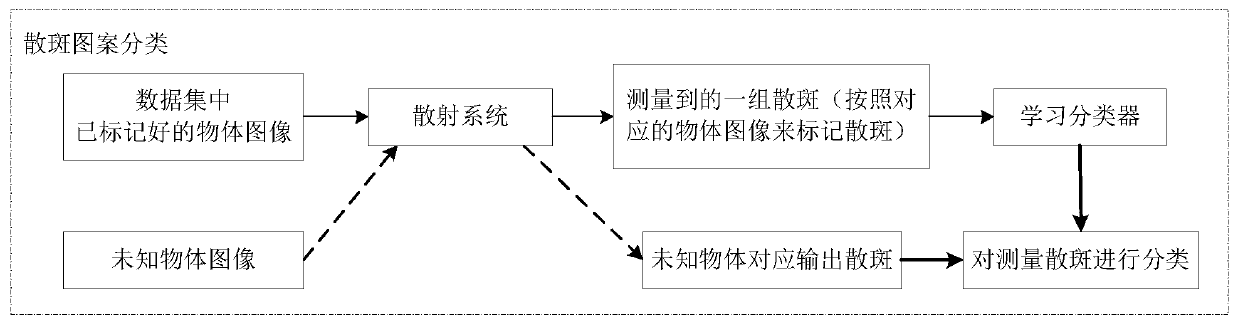

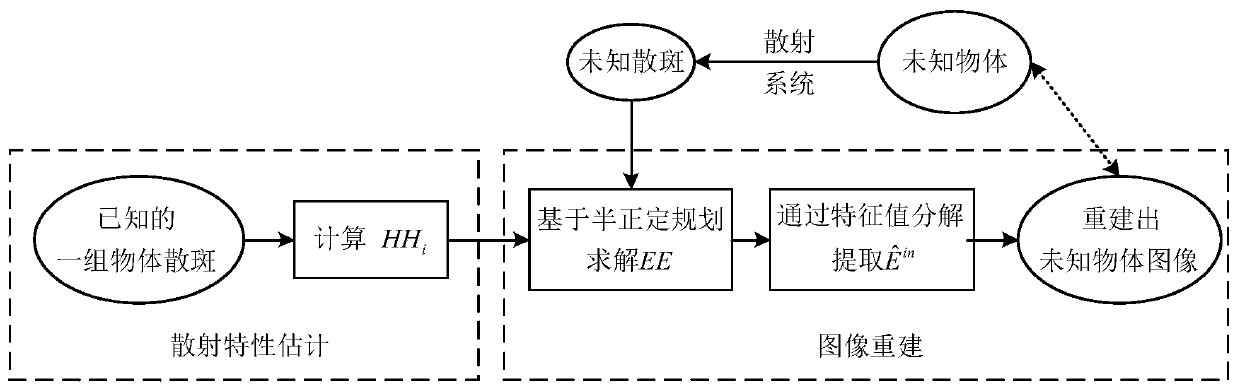

Scattering medium imaging method and system based on machine learning

ActiveCN110823812AScattering medium imaging implementationImproving Imaging Accuracy2D-image generationCharacter and pattern recognitionScattering functionComputer graphics (images)

The invention provides a scattering medium imaging method and system based on machine learning. The method comprises a speckle classification step of carrying out the classification on unknown speckles based on known objects for measured speckles corresponding to an unknown object to obtain a classification result, and an image reconstruction step of selecting known speckles and objects of a corresponding type to learn an inverse scattering function corresponding to a scattering medium according to the obtained classification result, and then performing image reconstruction of the unknown object on the unknown speckles according to the inverse scattering function to realize scattering medium imaging. According to the invention, the imaging precision and efficiency in the presence of the scattering medium are improved, and the imaging precision is ensured while the efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

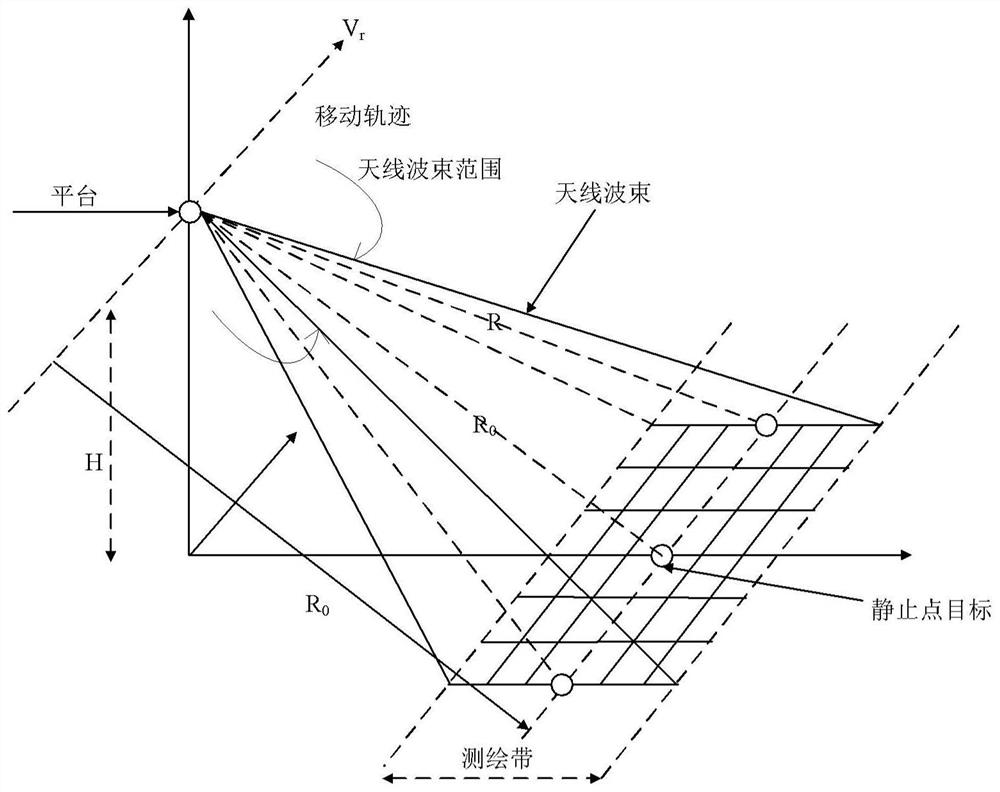

Efficient terahertz stepping frequency synthetic aperture radar imaging method

ActiveCN112731392AGuaranteed imaging accuracyFast imagingRadio wave reradiation/reflectionHigh resolution imagingSynthetic aperture radar

The invention discloses an efficient terahertz stepping frequency synthetic aperture radar imaging method. The method comprises the following steps: processing a terahertz stepping frequency synthetic aperture radar echo signal to obtain a frequency domain synthetic broadband signal; and converting the distance direction signal of the frequency domain synthetic broadband signal into a linear frequency modulation signal; and processing the distance direction signal into the linear frequency modulation signal by using a CS algorithm to obtain a synthetic aperture radar imaging result. According to the invention, on the premise of ensuring the imaging precision, the imaging speed is improved, and real-time high-resolution imaging is carried out on a target. According to the method, the traditional CSA is improved, the defect that the traditional CSA can only be applied to a linear frequency modulation system radar is overcome, and a new algorithm suitable for THz stepping frequency SAR imaging is provided. Compared with other imaging algorithms, the calculation amount is smaller, and the cost is lower when the method is put into practical application.

Owner:AEROSPACE INFORMATION RES INST CAS

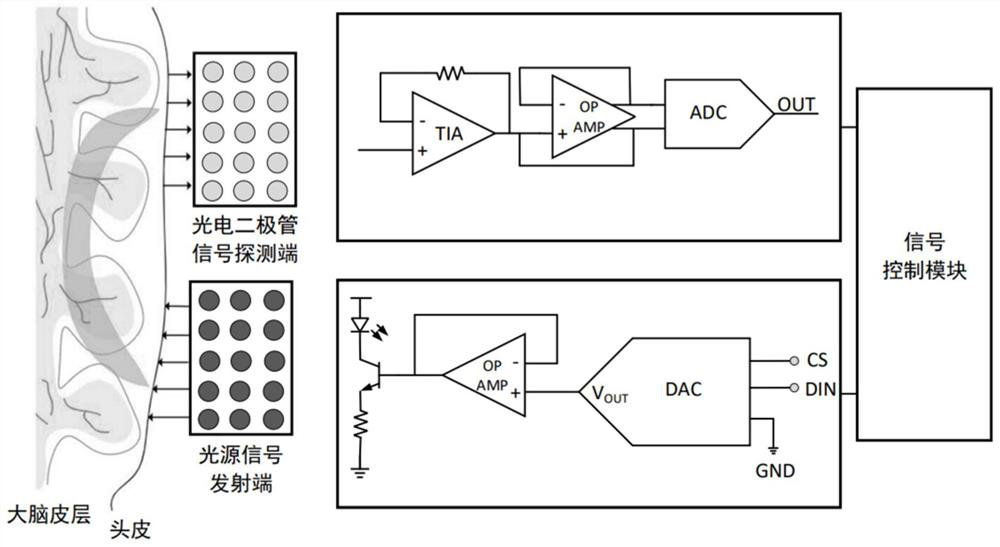

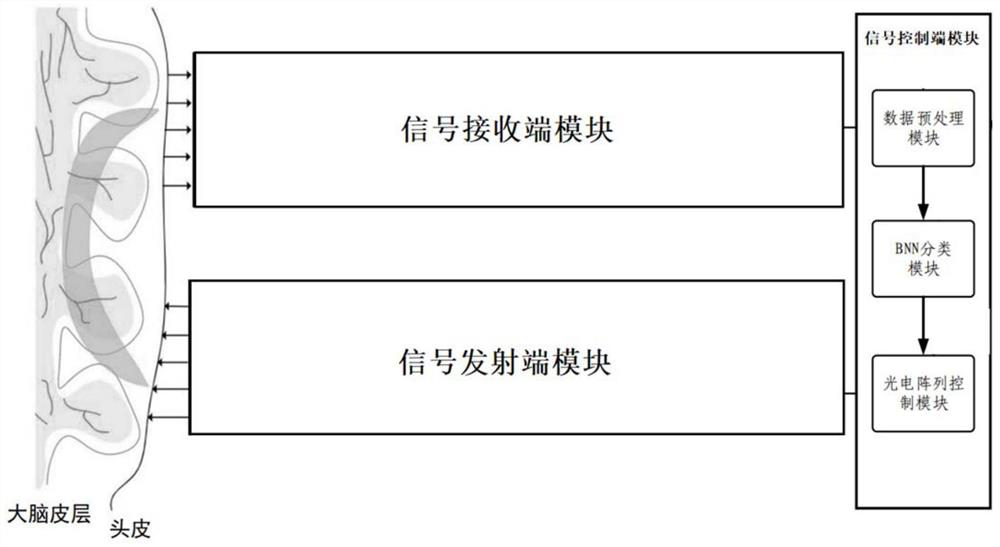

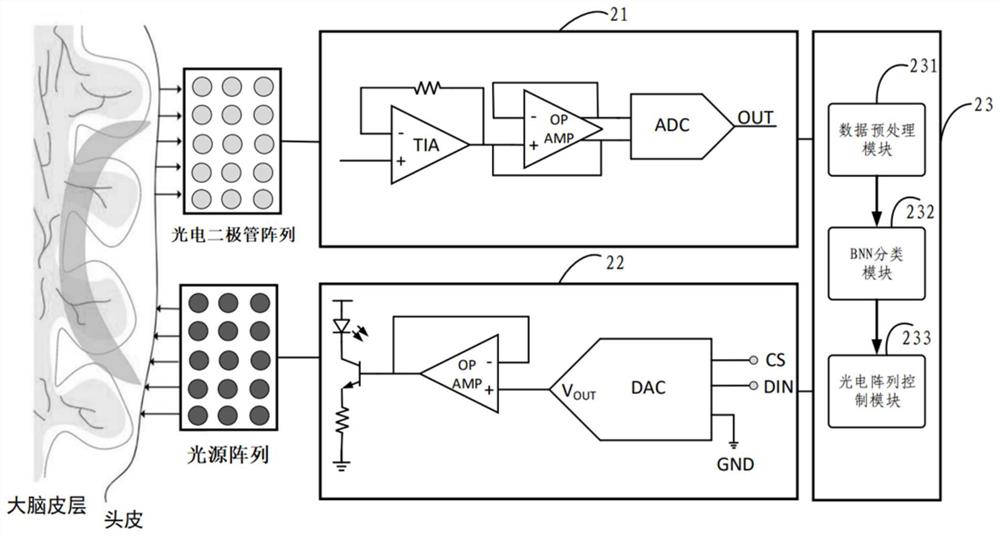

Near infrared spectrum brain function imaging system and imaging signal sampling method

PendingCN113633262AGood battery performanceReduce power consumptionMedical imagingDiagnostics using spectroscopyLight sourceImaging Signal

The invention provides a near infrared spectrum brain function imaging system. The near infrared spectrum brain function imaging system comprises a signal transmitting end module, a signal receiving end module and a signal control end module, wherein the signal transmitting end module is used for generating a near-infrared light source signal; the signal receiving end module is used for converting a near-infrared light signal reflected by the cerebral cortex into a digital signal to realize imaging; and the signal control end module adaptively adjusts working arrays in the signal transmitting end module and the signal receiving end module. Meanwhile, the invention provides a near-infrared spectrum brain function imaging signal acquisition method which comprises the step of adaptively adjusting the working arrays in the signal transmitting end module and the signal receiving end module through the signal control end to obtain a digital signal output by the signal receiving end. On the premise that the imaging precision and the manufacturing cost are guaranteed, meanwhile, the advantages of good battery performance, low power consumption and high data imaging precision are achieved.

Owner:嘉兴知芯电子科技有限公司 +3

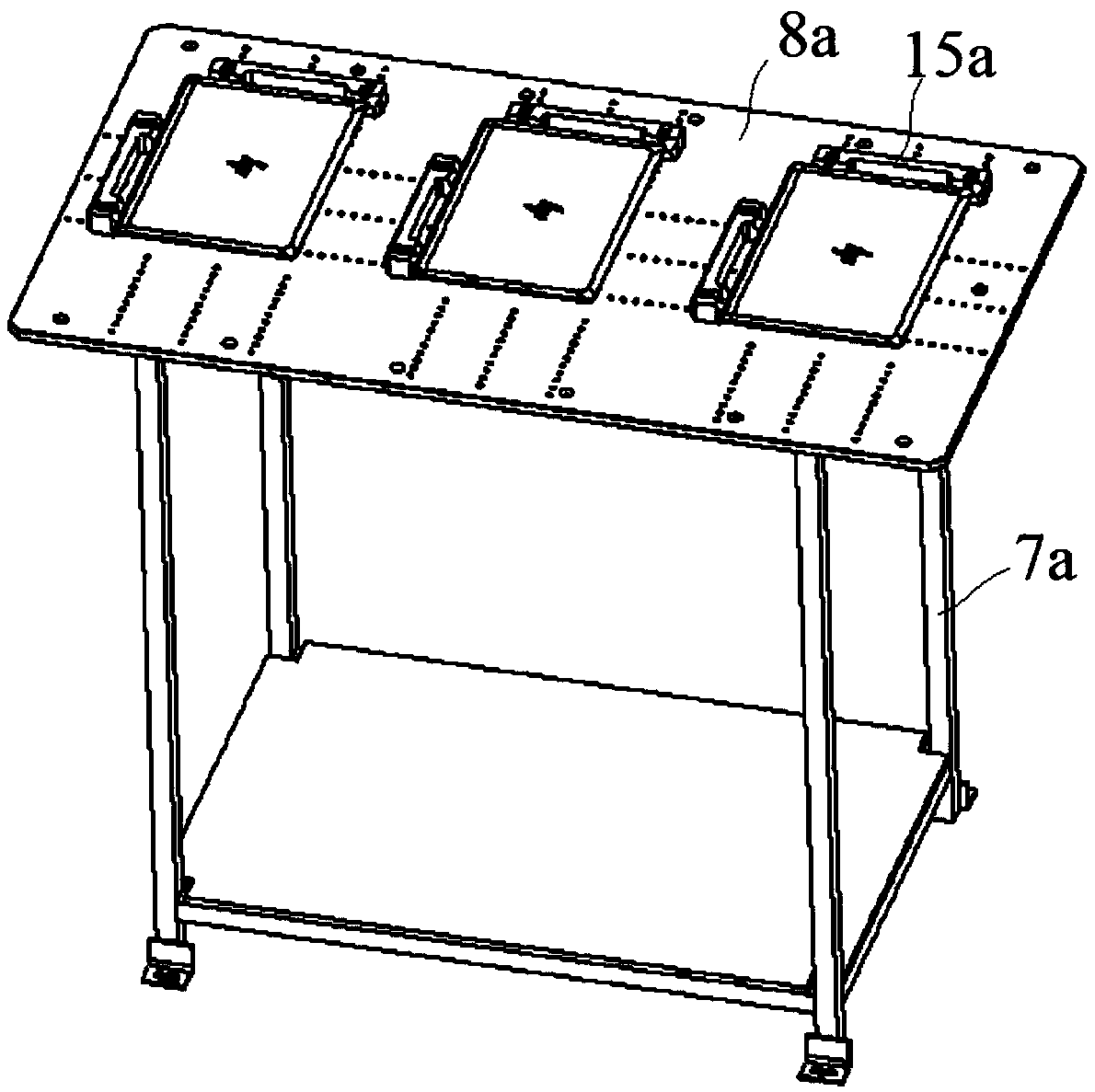

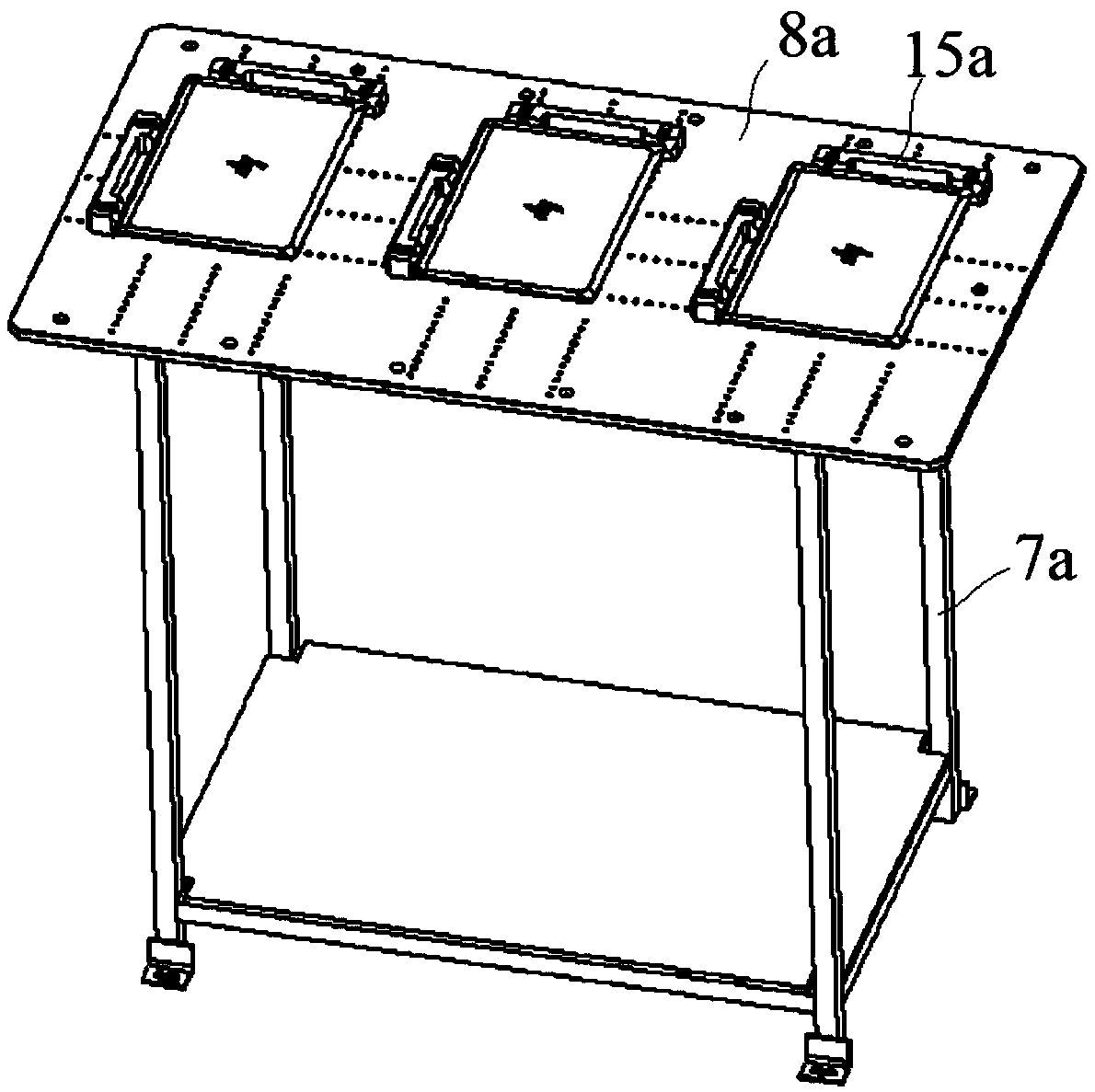

Surface treatment device for notebook-computer shell

PendingCN109382728AGuaranteed imaging accuracyGuaranteed accuracyGrinding carriagesGrinding machinesL-shellClosed state

The invention discloses a surface treatment device for a notebook-computer shell. The surface treatment device comprises a feeding support, a polishing support, multiple mechanical arms, a polishing head and a transporting clamp, wherein the polishing head and the transporting clamp are connected with tail end nodes of the mechanical arms respectively, and the feeding support and the polishing support are circumferentially arranged along the mechanical arms; the feeding support comprises a supporting frame and a feeding table installed on the supporting frame, multiple blade grooves are formedin a core body at equal intervals in the circumferential direction, and driving blades are embedded into the blade grooves respectively; an air inlet and an air outlet are formed in an outer shell, the air inlet is communicated with a first cavity, and the air outlet is communicated with the second cavity. As an air pipe installing base and an air pipe are arranged on the surface treatment devicefor the notebook-computer shell, the air inlet and an air outlet in the outer shell can be in the closed state, it is completely isolated that liquid used in the polishing process enters a shell fromthe air inlet or the air outlet, the service life of the polishing head is prolonged, the cost is saved, and the production efficiency is improved.

Owner:苏州丰川电子科技有限公司

High precision machining apparatus used for electronic equipment outer shell

InactiveCN109605212ASave materialShorten the timeGrinding feed controlGrinding feedersElectric equipmentElectron

The invention discloses a high precision machining apparatus used for an electronic equipment outer shell. The high precision machining apparatus used for the electronic equipment outer shell comprises a feeding supporting seat, a polishing supporting seat, a plurality of mechanical arms, a polishing head and a material conveying clamping fixture, the polishing head and the material conveying clamping fixture are correspondingly connected with the tail end nodes of the mechanical arms in an installing mode, the feeding supporting seat and the polishing supporting seat are arranged in the circumferential direction of the mechanical arms, the feeding supporting seat comprises a supporting frame and a feeding table installed on the supporting frame, the tail-end nodes of the mechanical arms are connected with an installing seat, the polishing head and the material conveying clamping fixture are installed on the installing seat, an air outlet communicates with a second cavity body, the lower end of a core body is connected with a rotating shell, the central axes of the installing seat, a bearing and a rotating head coincide, and the central axis of the rotating head does not coincide with the central axis of the core body. According to the high precision machining apparatus used for the electronic equipment outer shell, vacuum adsorption of a workpiece is realized through an adsorption hole and an adsorption line groove, the accurate position and stability of the workpiece are ensured in the polishing process, the situations of offset and the like in the polishing process are avoided, and the polishing accuracy and stability are ensured.

Owner:苏州丰川电子科技有限公司

High-precision automatic polishing machine

ActiveCN109500718ASave materialShorten the timeGrinding carriagesPolishing machinesRubber ringWater vapor

The invention discloses a high-precision automatic polishing machine. The high-precision automatic polishing machine comprises a material loading support seat, polishing support seats, a plurality ofmechanical arms, polishing heads and material conveying fixtures, wherein the polishing heads and the material conveying fixtures are installed and connected to tail end joint points of the mechanicalarms correspondingly, the material loading support seat and the polishing support seats are arranged in the circumferential direction of the mechanical arms correspondingly, the material conveying fixtures are suction cup mechanisms, the suction cup mechanisms comprise installation plates and a plurality of suction cups connected to the corresponding installation plates, each polishing head comprises an outer shell body, an inner shell body, a core body and a rotating head, the inner shell body is located inside the corresponding outer shell body, the core body is rotatably arranged inside the corresponding inner shell body, the rotating head is installed and connected to the corresponding core body, each polishing head is further provided with an air pipe installation seat installed to the corresponding outer shell body, and each air pipe installation seat comprises an air inlet portion and an air outlet portion. According to the high-precision automatic polishing machine, by means of the arrangements of rubber rings, sealing pad rings and pad pieces, the sealing effect of the lower portions of the polishing heads is enhanced layer by layer, water vapor and liquid can be effectively prevented from entering the shell bodies, components inside the shell bodies are protected, and the service life of the high-precision automatic polishing machine is prolonged.

Owner:苏州丰川电子科技有限公司

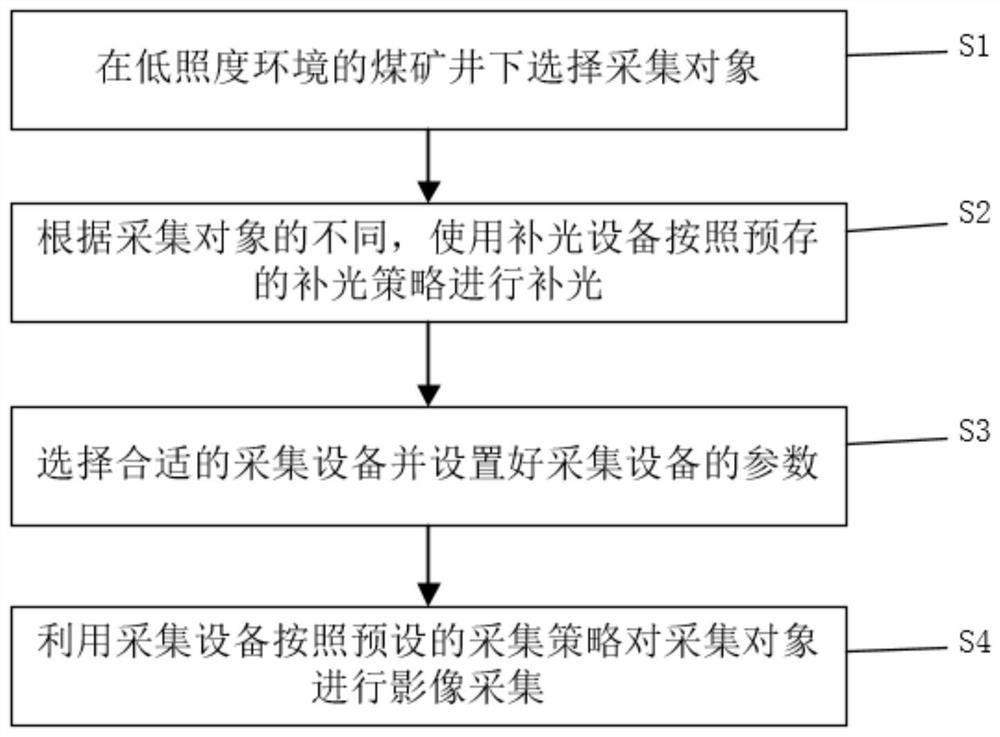

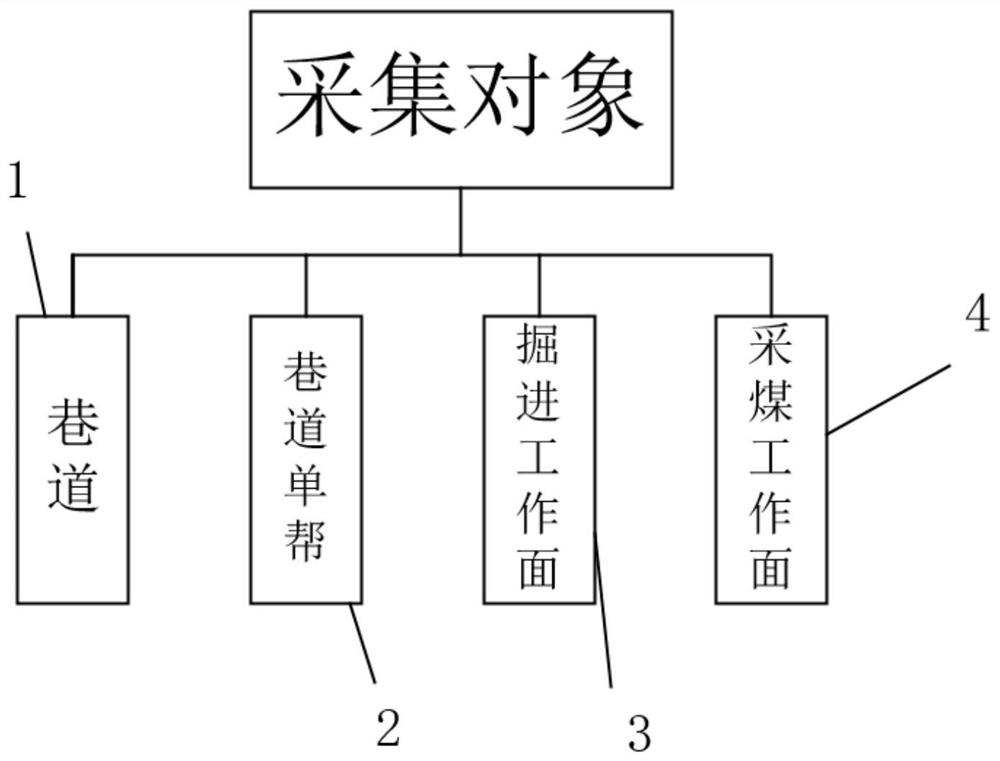

Coal rock geological image high-precision acquisition method applied to low-illumination environment

ActiveCN113607137AAvoid ineffective workGuaranteed imaging accuracyPicture taking arrangementsEnergy saving control techniquesIlluminanceMining engineering

The invention relates to the field of mineral exploration, and discloses a coal rock geological image high-precision acquisition method applied to a low-illumination environment. A cold and warm light imaging mechanism is adopted to carry out targeted light supplement on each acquisition object in a coal mine, and acquisition equipment is utilized to carry out image acquisition on each acquisition object according to a preset acquisition strategy. The method can acquire a high-precision coal rock geological image and ensure the safe operation of mineral work.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

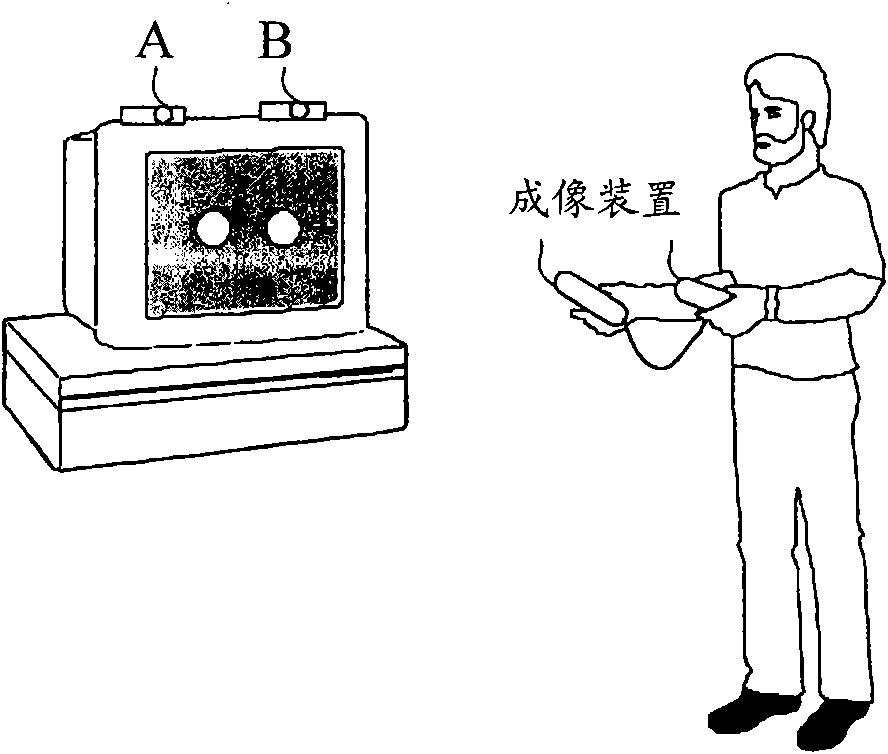

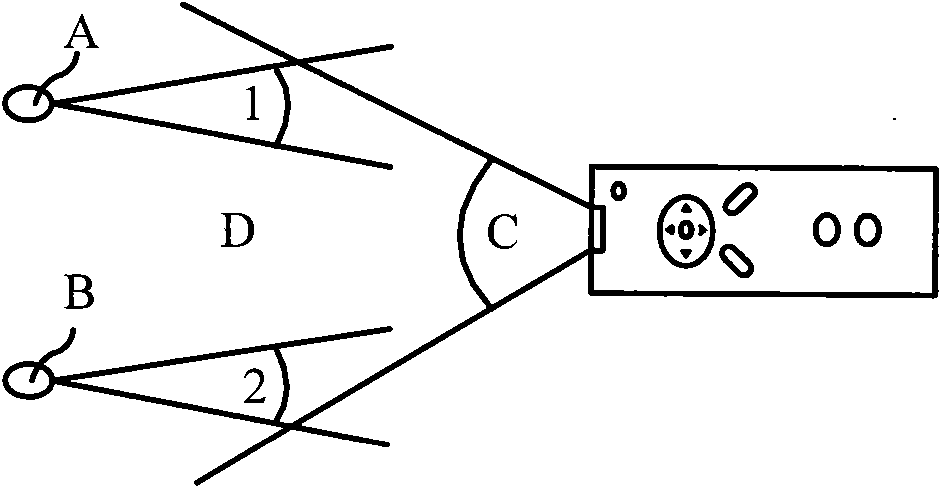

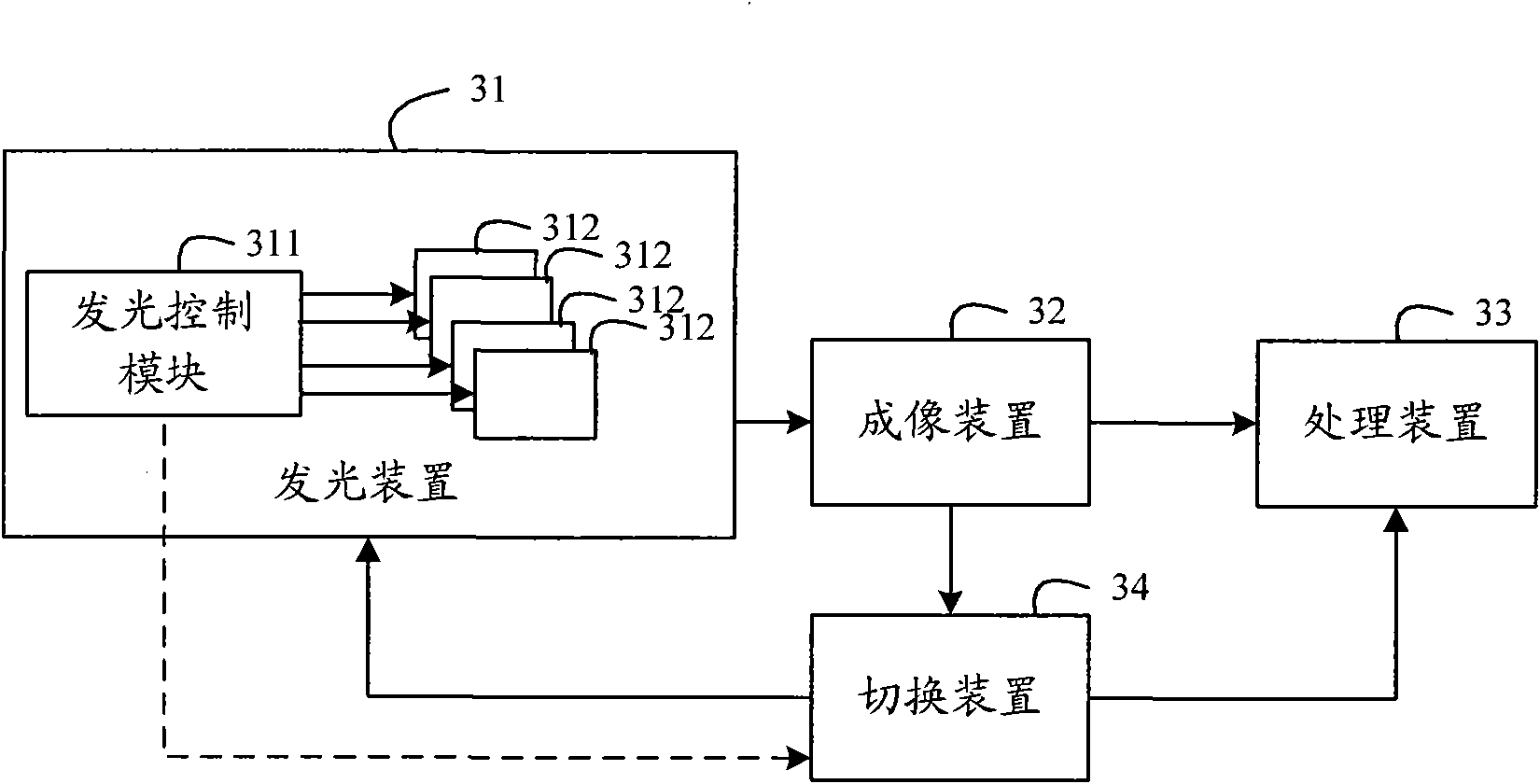

Imaging system and method for expanding mobile range of imaging device

InactiveCN101559283AAvoid the drawback of limited movable rangeEasy to implementVideo gamesEngineeringAngle of view

The invention discloses an imaging system and a method for expanding the mobile range of an imaging device; the system is provided with at least two light-emitting groups; each light-emitting point group comprises two light-emitting points; all the light-emitting points are arranged on a fixing plane; only one light-emitting group is lighted up at the same moment; and the actual space between two light-emitting points in different light-emitting groups is different. When in use, according to the current mobile range of the imaging device, the current light-emitting group is determined and lightened. And then the actual space between two light-emitting points in the current light-emitting group is required to be adopted to replace corresponding parameters in the posture calculation formula of the imaging device, and the formula after replacement is adopted to calculate the posture information of the imaging device. By using the invention, the mobile range of the imaging device can be expanded without the increase of the perspective of the imaging device.

Owner:SUNPLUS TECH CO LTD +1

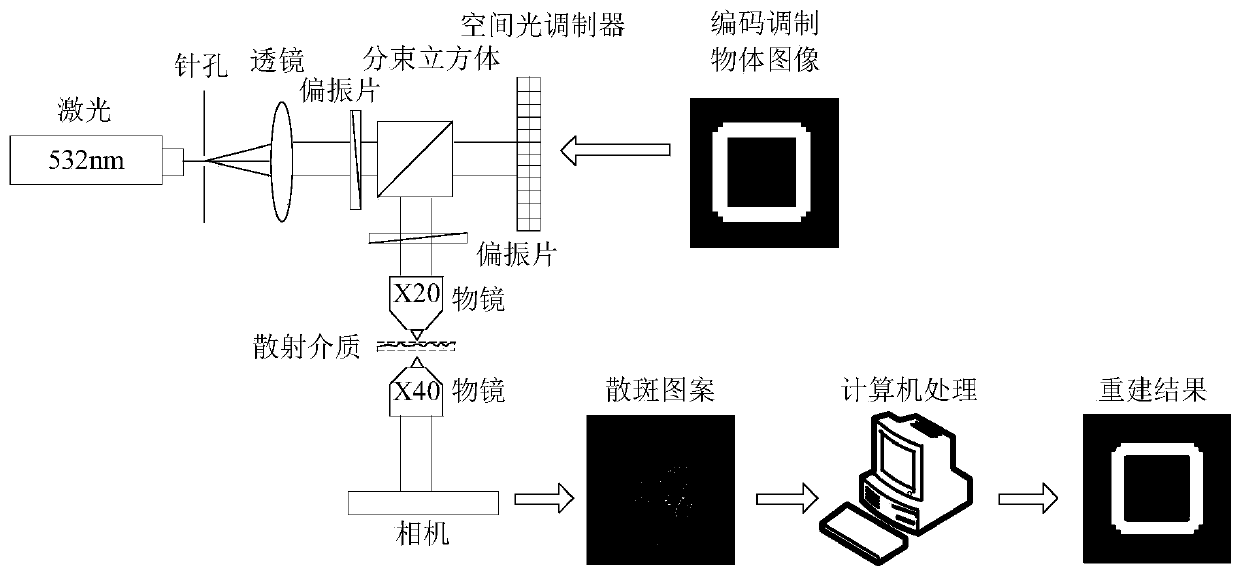

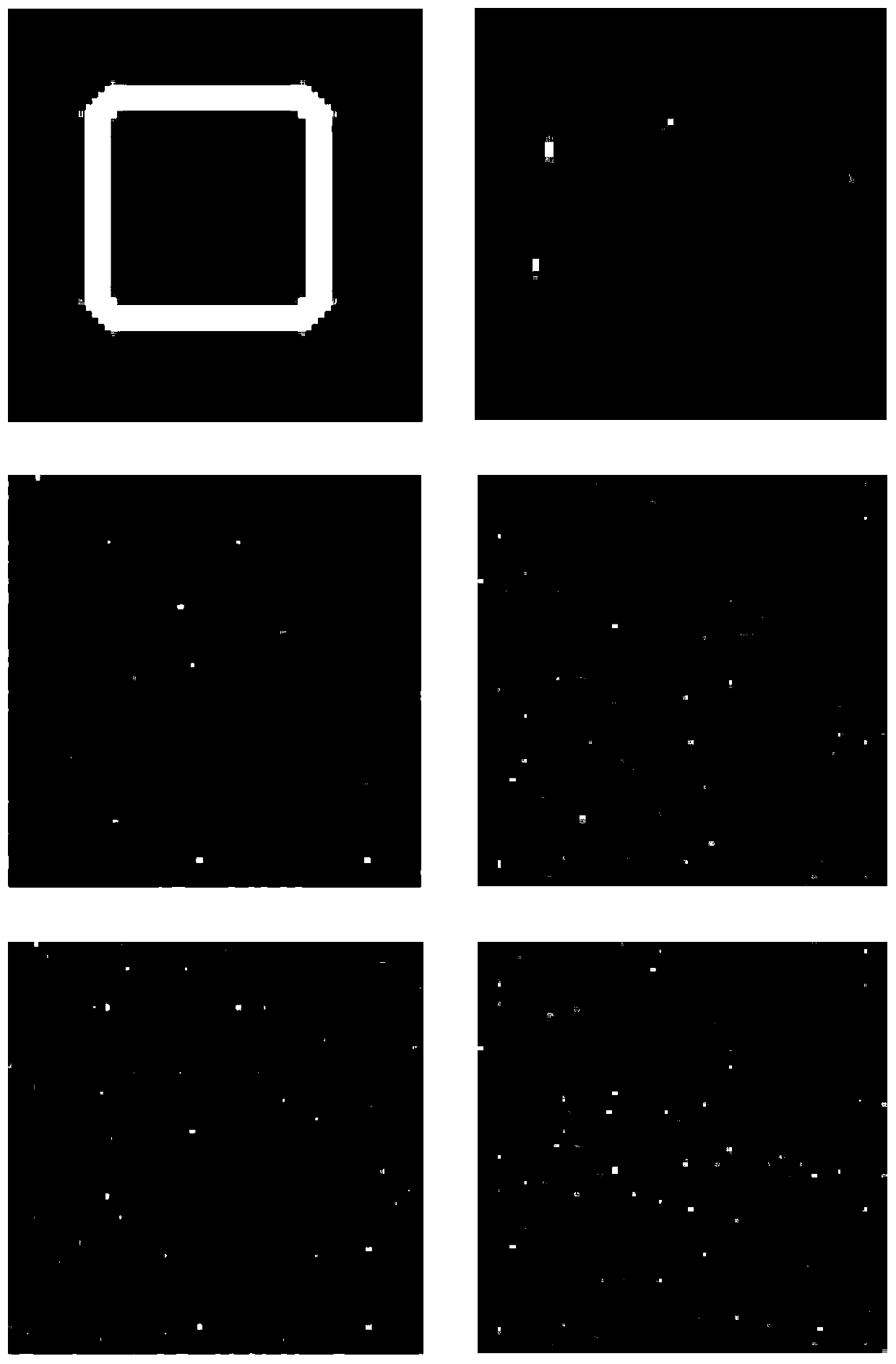

Scattering medium imaging method and system based on semi-definite optimization and medium

InactiveCN110987818AImproving Imaging AccuracyImprove efficiency2D-image generationCharacter and pattern recognitionFeature vectorMaximum eigenvalue

The invention provides a scattering medium imaging method and system based on semi-definite optimization, and a medium, and the method comprises the steps: a scattering characteristic extraction stepof a scattering medium: estimating a scattering characteristic corresponding to the scattering medium through collecting a group of output speckle patterns corresponding to a known object image in thepresence of the scattering medium; and an image reconstruction step: after the scattering characteristic matrix corresponding to the scattering medium is estimated, according to a semi-definite optimization theory, solving a semi-definite programming problem to obtain a product of the image of the object to be reconstructed and Hermitian transposition thereof, and then extracting a characteristicvector corresponding to a maximum characteristic value of the product, thereby realizing scattering medium imaging. The method is used for improving the imaging precision and efficiency in the presence of a scattering medium, and the imaging precision is ensured while the efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

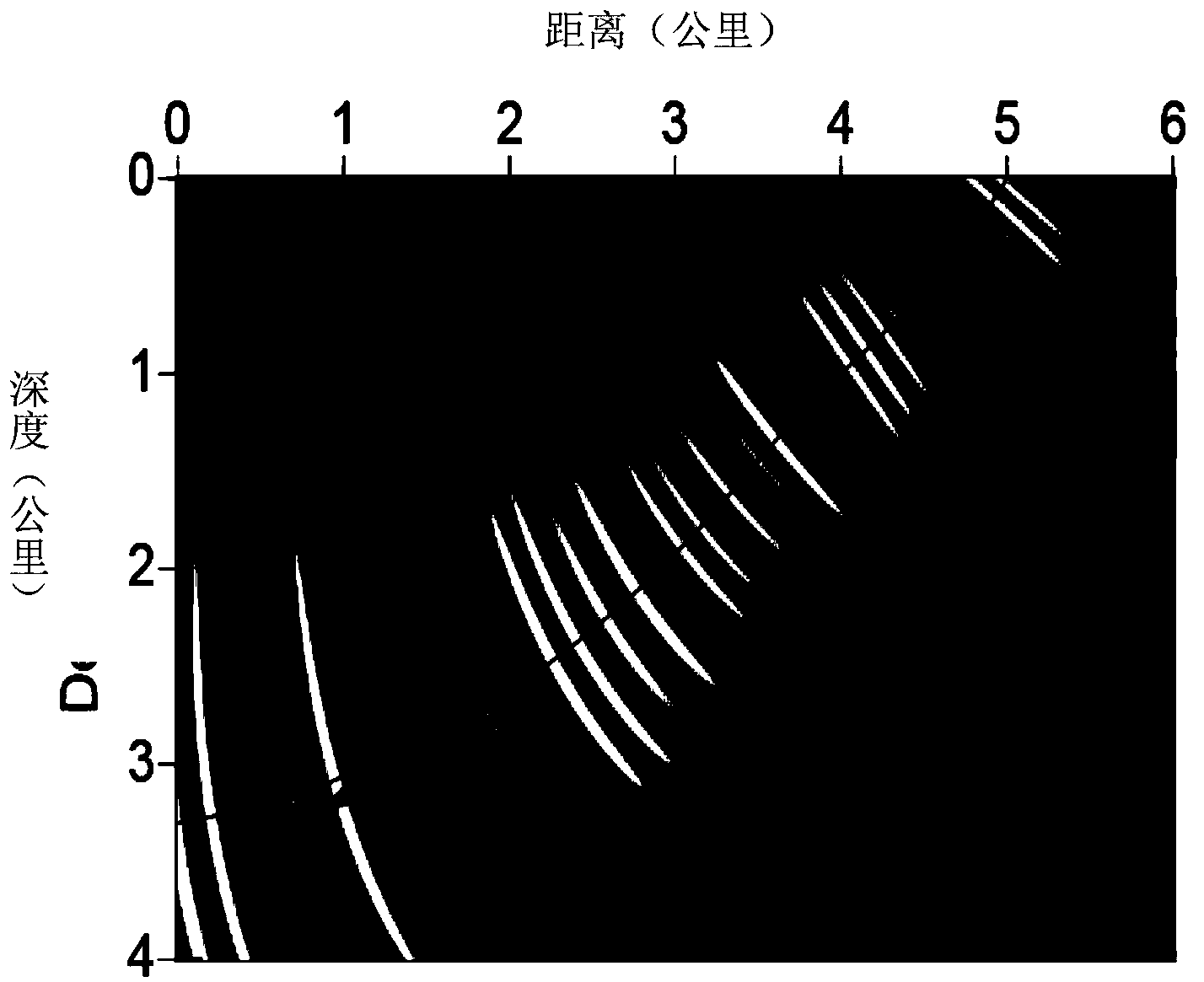

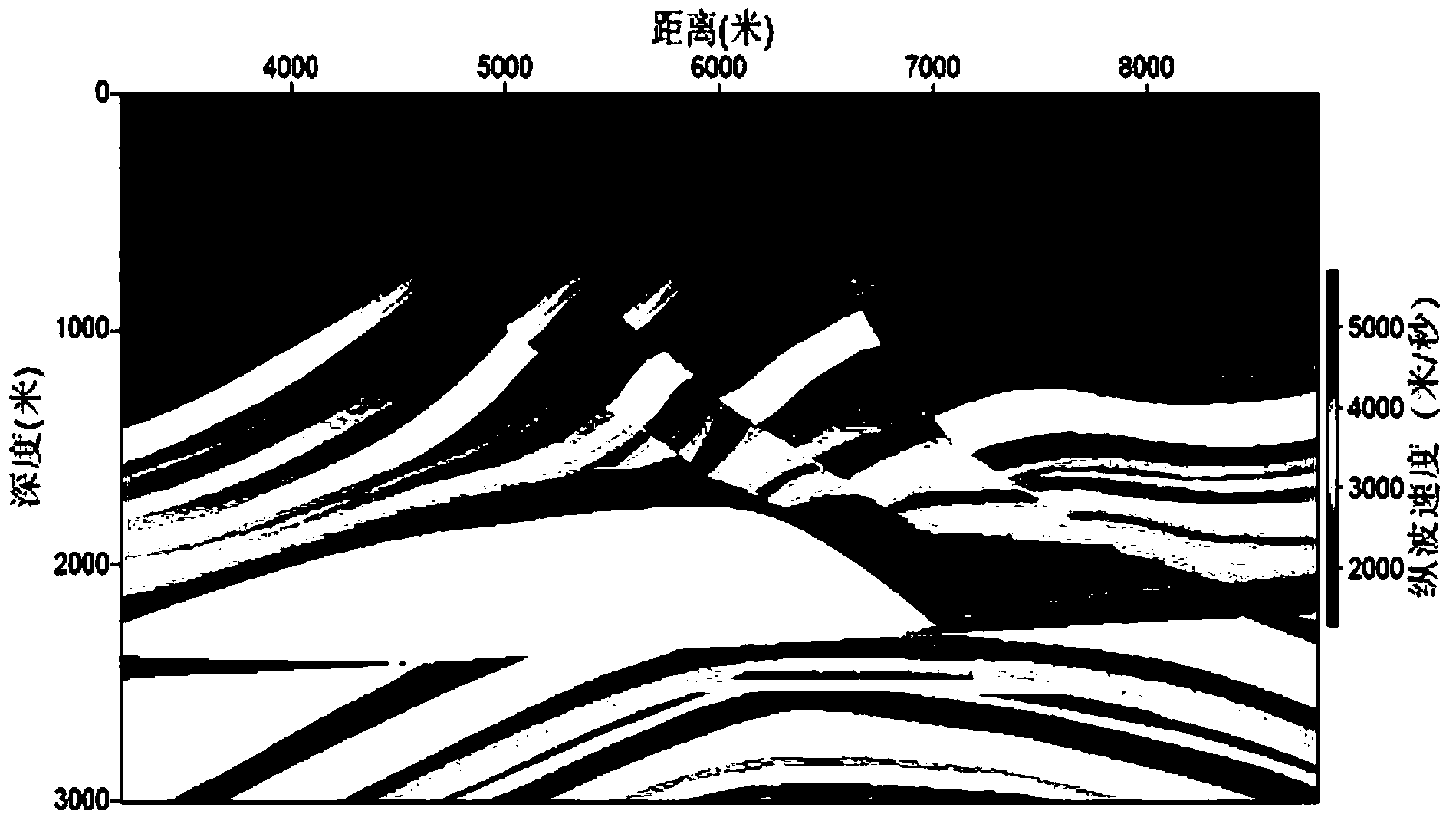

Earthquake prestack migration imaging method

ActiveCN102944894BOffset easyOffset is easy to implementSeismic signal processingWave fieldAmplitude weighting

The invention relates to an earthquake prestack migration imaging method which includes the following steps: (1) obtaining observing system information and data features by scanning earthquake records, and calculating to obtain migration initial parameters; (2) launching gauss beam central ray from a cannon point, and calculating travel time and amplitude weighting factors in a nearby area of the ray; (3) launching ray from all gauss beam central positions of a demodulator probe wave field, and calculating travel time and amplitude weighting factors in a nearby area of the ray; (4) by using the travel time and the amplitude weighting factors of the gauss beam at the cannon point and the gauss beam at the demodulator probe position to a certain underground point, the earthquake record is returned to the position according to travel time information and amplitude weighting factor information; (5) repeating the step (1) to the step (4) for each cannon earthquake record, migration results of all canons are obtained and stacked according to corresponding positions to obtain a migration stacking result of a cannon set, and a final migration result is obtained by filtering false appearances on a wave field path. The earthquake prestack migration imaging method can obtain migration imaging in a key target area fast and can be widely applied to various oil gas exploration processes.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Full-automatic quality detection device of micro drill point for drilling PCB

InactiveCN101706256BReal-time precise axial positioning heightGuaranteed stabilityUsing optical meansImaging qualityEngineering

The invention relates to a full-automatic quality detection device of a micro drill point for drilling a PCB in the technical field of tool detection, which comprises a feeding mechanism, a rotary worktable, a micro drill rotary mechanism, a height adjusting mechanism, a vision detection device and a discharging mechanism, wherein the feeding mechanism, the rotary worktable and the discharging mechanism are respectively and correspondingly arranged at a feeding station, a rotary station and a discharging station of a working platform, the micro drill rotary mechanism and the height adjusting mechanism are sequentially arranged at the side face of the rotary table, the vision detection device is arranged at a vision detection station of the working platform, the feeding station and the rotary station are arranged at the same side, the discharging station and the feeding station are positioned at two ends of the working platform, and the vision detection station and the discharging station are positioned at the same side. The micro drill rotary mechanism and the height adjusting mechanism can enable a micro drill to simultaneously realize the circumferential rotation and the axial real-time precise adjustment, can fine adjust the axial positioning height of the micro drill in real time, and ensure the imaging quality of a blade surface and the measurement precision of geometric parameters.

Owner:SHANGHAI JIAO TONG UNIV

Automatic metal surface processing device

InactiveCN109352512AGuaranteed imaging accuracyGuaranteed accuracyLapping machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses an automatic metal surface processing device which comprises a feeding support, a polishing support, a plurality of mechanical arms, a polishing head an a transporting clamp, wherein the polishing head an the transporting clamp are in erection joint with the tail nodes of the mechanical arms; the feeding support and the polishing support are arranged in the circumferentialdirection of the mechanical arms; the feeding support comprises a bracket and a feeding table mounted on the bracket; the polishing head further comprises an inner shell, an outer shell, a core body and a rotary head; the inner shell is in the outer shell; the core body is rotatably arranged in the inner shell; and the central axis of the outer wall cylindrical surface of the inner shell and the central axis of the inner wall cylindrical surface of the inner shell are in parallel and do not coincide. According to the automatic metal surface processing device, the inner and outer shells are combined with the core body, the structure is skillful, the air enters the inner shell through a first cavity to blow a driving blade, the driving blade drives the core body to rotate, the air is then discharged out through a second cavity, and the core body rotates to drive the rotary head to rotate so as to realize automatic polishing. The automatic metal surface processing device is simple in structure and convenient to use.

Owner:苏州丰川电子科技有限公司

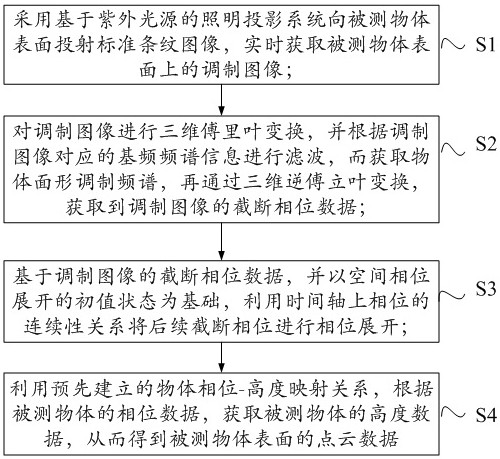

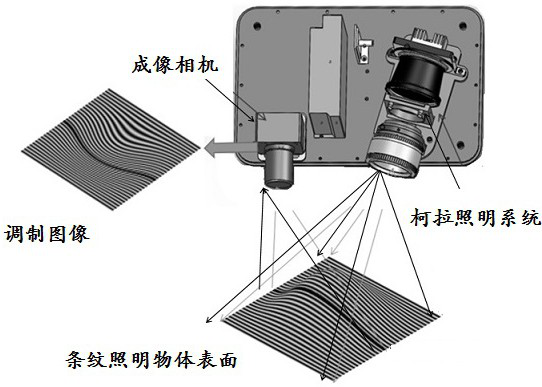

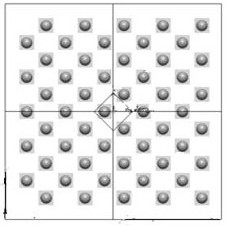

Device and method for dynamic measurement of surface topography of high-temperature molten metal

Owner:SICHUAN UNIV

Focusing device of fixed-focus camera

The invention discloses a focusing device of a fixed-focus camera. The focusing device comprises a lens bracket, a lens shield, a lens and a lens retainer, the lens support is provided with a first light-transmitting hole, the lens shield is suitable for being in threaded connection in the first light-transmitting hole, a limiting screw is arranged on the hole wall of the first light-transmitting hole, and the limiting screw is suitable for locking the lens shield; the lens shield is provided with a second light-transmitting hole, a flange is arranged on the hole wall of the second light-transmitting hole, an elastic piece is arranged on the side, away from the lens support, of the flange, and the bottom of the lens is suitable for abutting against the elastic piece; the lens retainer is provided with three adjusting pieces, and the included angle between every two adjacent adjusting pieces is larger than 60 degrees. The adjusting piece is connected with the flange along the optical axis direction of the lens so as to limit the lens between the lens retainer and the flange; the adjusting member can move along the optical axis direction of the lens. According to the focusing device of the fixed-focus camera, the perfect focusing effect can be achieved under the condition that the requirement for the machining precision of structural accessories is not high.

Owner:GUANGZHOU SOUTH SATELLITE NAVIGATION INSTR

Machining integrated machine for notebook computer shell

InactiveCN109623566AGuaranteed imaging accuracyGuaranteed accuracyGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a machining integrated machine for a notebook computer shell. The machining integrated machine comprises feeding supports, polishing supports, a plurality of mechanical arms, apolishing head and a material-conveying clamp, the polishing head and the material-conveying clamp are mounted at and connected with end joints of the mechanical arms correspondingly, and the feedingsupports and the polishing supports are arranged in the circumferential directions of the mechanical arms correspondingly; the polishing head further comprises an outer shell, an inner shell, a corebody and a rotating head, the core body is rotationally arranged in the inner shell, and the central axis of the core body coincides with the central axis of the cylindrical surface of the outer wallof the inner shell; and the core body comprises an upper shaft part, a driving part and a lower shaft part, an air inlet and an air outlet are formed in the outer shell, the air inlet communicates with a first cavity, and the air outlet communicates with a second cavity. A bearing is loaded into a seat body of a bearing seat through a blocking sheet, the bearing is convenient to demount and mount,when the bearing is worn down and needs to be replaced, the bearing only needs to be removed from the lower part of a grinding head, and the sealing effect inside the shell is ensured.

Owner:苏州丰川电子科技有限公司

A kind of sar imaging method

ActiveCN108061890BFast imagingGuaranteed imaging accuracyRadio wave reradiation/reflectionTime domainPhase filter

The present invention proposes a SAR imaging method, which is focused by correcting SAR data, range compensation, high-order item compensation in azimuth frequency domain, high-order phase filtering in azimuth frequency domain, high-order item compensation in azimuth time domain, and azimuth tilt correction. after the image. Aiming at sub-aperture data processing, the present invention, on the basis of high-order approximate two-dimensional spectrum, simultaneously considers the space-variation of modulation frequency introduced by distance envelope and azimuth target position, and adopts the method of high-order phase filtering in frequency domain to solve the problem, effectively Imaging speed is improved, and on the basis of ensuring imaging accuracy, it can meet the requirements of real-time imaging.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com