Painted glass defect detection device based on area-array camera parallel-acquisition system

A collection system and defect detection technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as unfavorable production, complicated technology, and difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the concrete implementation of the present invention is described in detail:

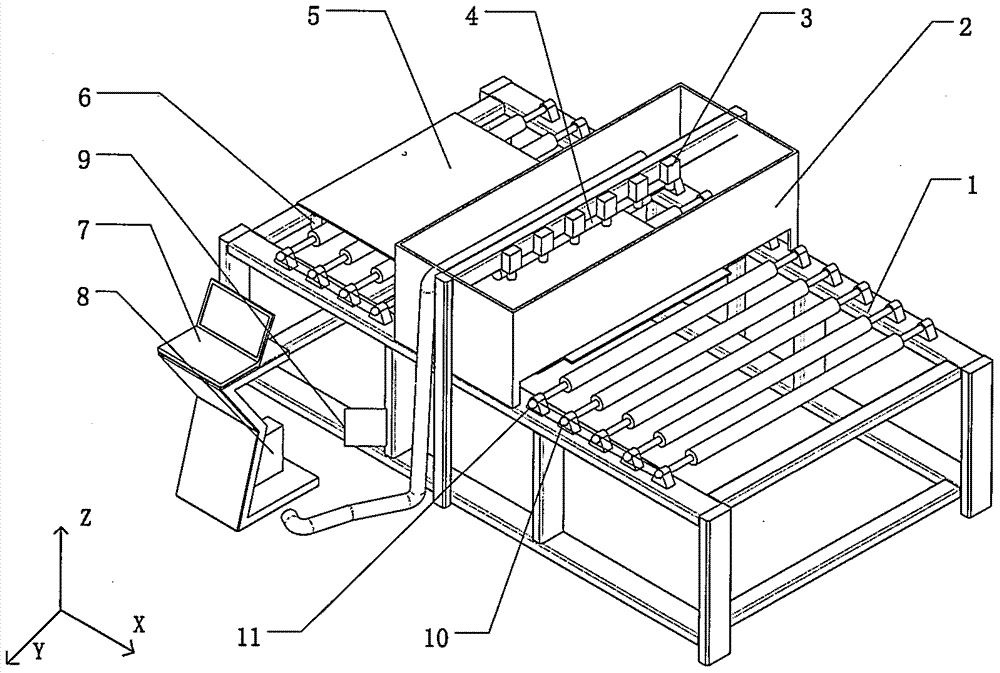

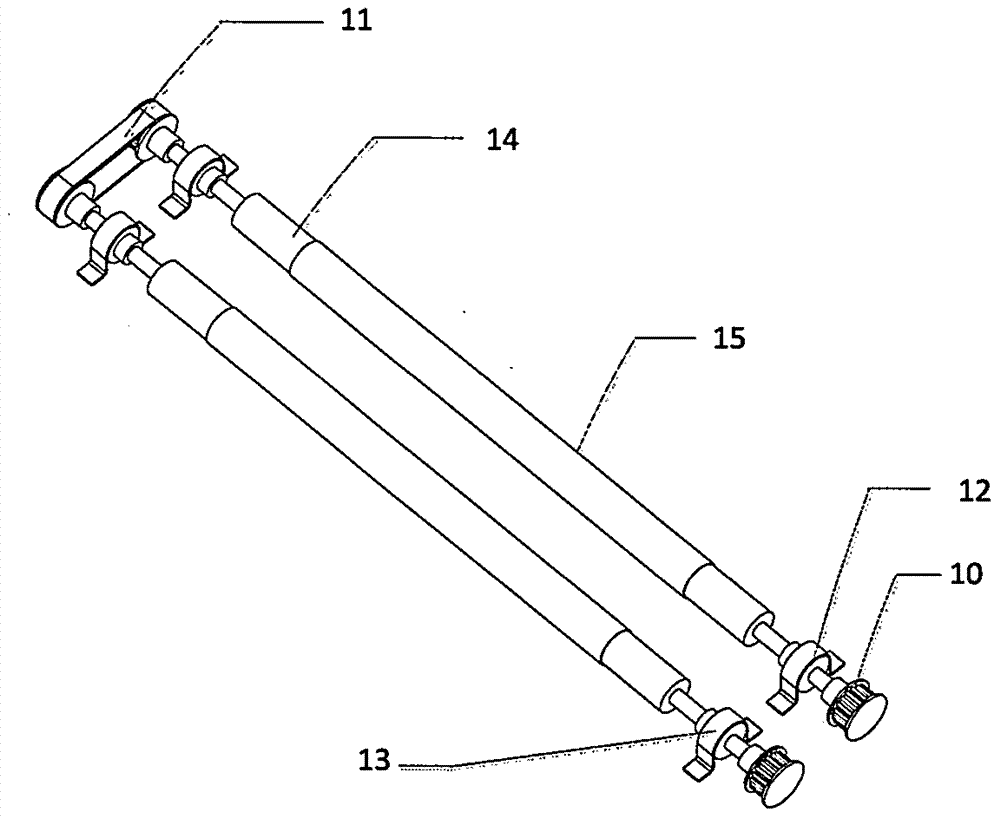

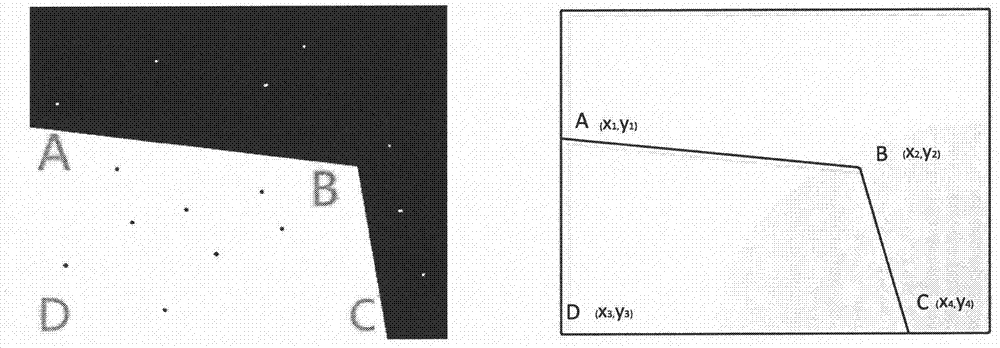

[0026] attached figure 1 It is the overall structure diagram of the glass detection device, mainly including 1 support stand 2 hood 3 camera 4 light source 5 glass to be tested 6 proximity switch 7 host computer 8 switch 9 motor 10 pulley 11 transmission belt, set 5 glass to be tested to stick and roll when running The side of the platform is operated from bottom to top. After starting the system, the 9 motor starts and drives a driving idler to rotate, and drives the entire rolling platform to move through the 11 transmission belt. When the 5th glass to be tested passes through the 6th proximity switch, the 3rd camera and the 4th light source are automatically turned on, and the 3rd camera takes pictures according to a certain frame rate, and transmits the photo to the 7th host computer for processing; since the image taken by the 3rd camera is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com