Full-automatic quality detection device of micro drill point for drilling PCB

A PCB board and detection device technology, which is applied in the field of full-automatic quality detection devices for micro-drills for PCB board drilling, can solve the problems of low detection efficiency, labor, and stability to be improved, so as to ensure stability and reliability, Ensure measurement accuracy, optimize loading and unloading and measurement path effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

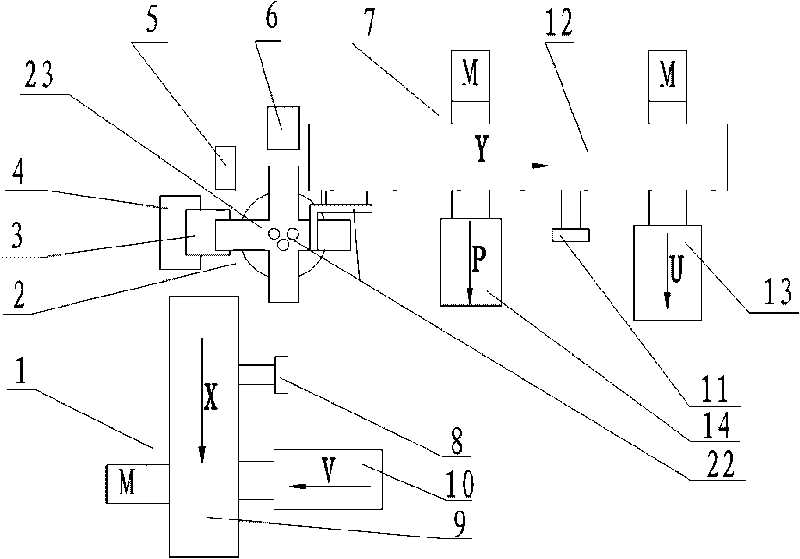

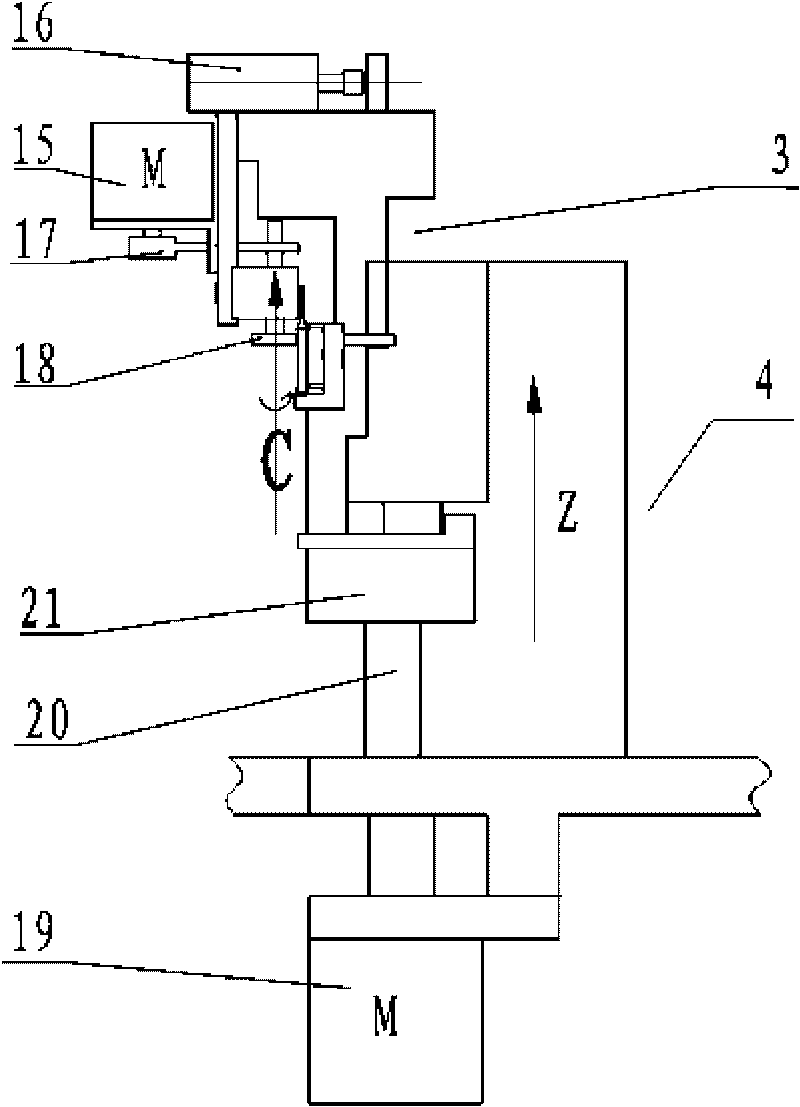

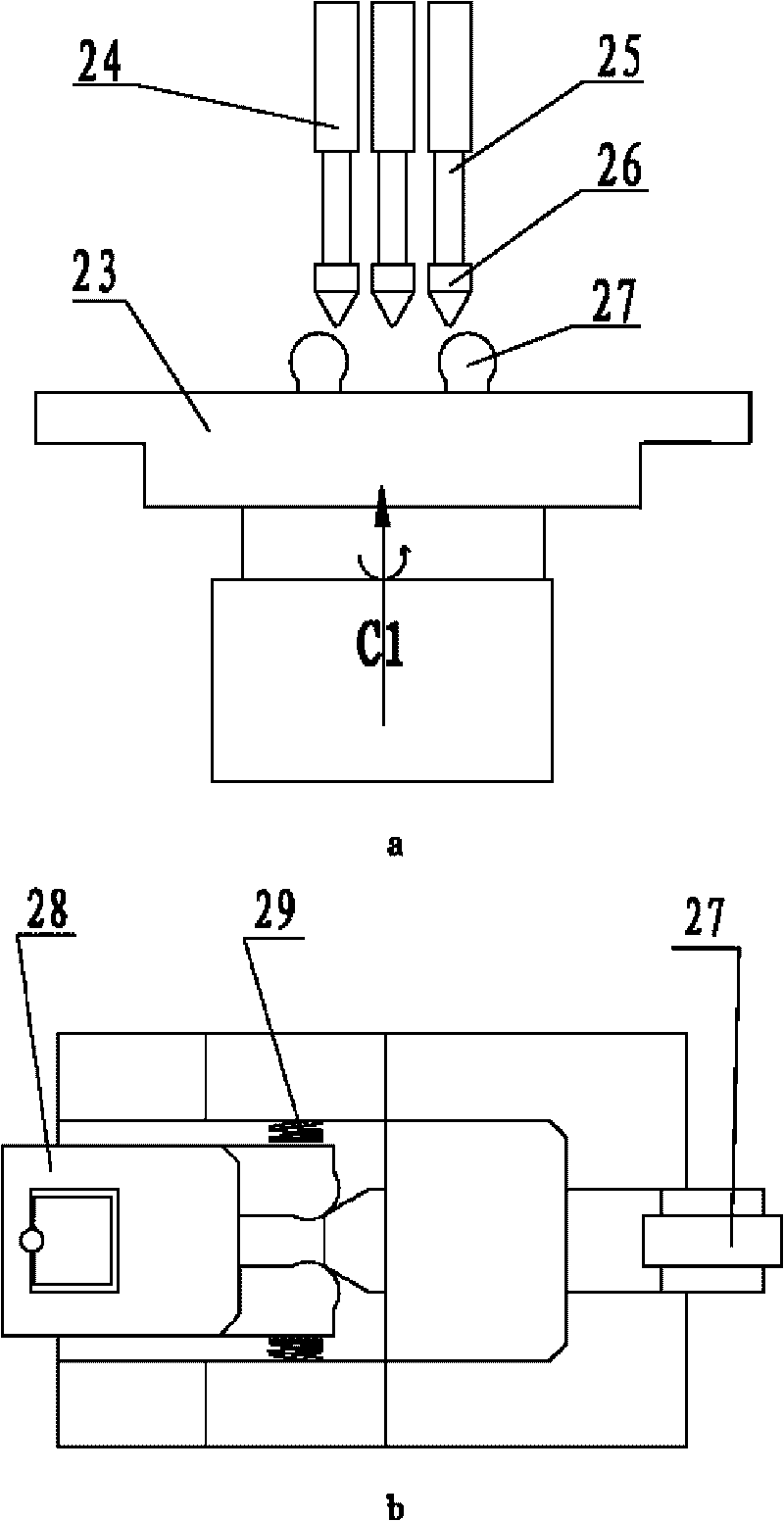

[0022] like figure 1 As shown, this embodiment includes: a feeding mechanism 1, a rotary table 2, a micro-drilling rotary mechanism 3, a height adjustment mechanism 4, a side measurement mechanism 5, a blade surface measurement mechanism 6 and a blanking mechanism 7, wherein: the rotary table 2. Set on the working platform, the loading mechanism 1 and the unloading mechanism 6 are respectively set on the loading position and the unloading position of the working platform. The side detection position of the table 2, the visual detection device composed of the side measurement mechanism 5 and the blade surface measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com