Evaporation and concentration device for ultra-clean high-purity electronic chemicals and application of evaporation and concentration device

An electronic chemical, evaporation and concentration technology, applied in evaporation, evaporator accessories, chemical instruments and methods, etc., can solve problems such as affecting the accuracy of sample detection, metal impurity contamination, affecting test results, etc., to avoid external air pollution, Low maintenance costs and the effect of avoiding sample contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

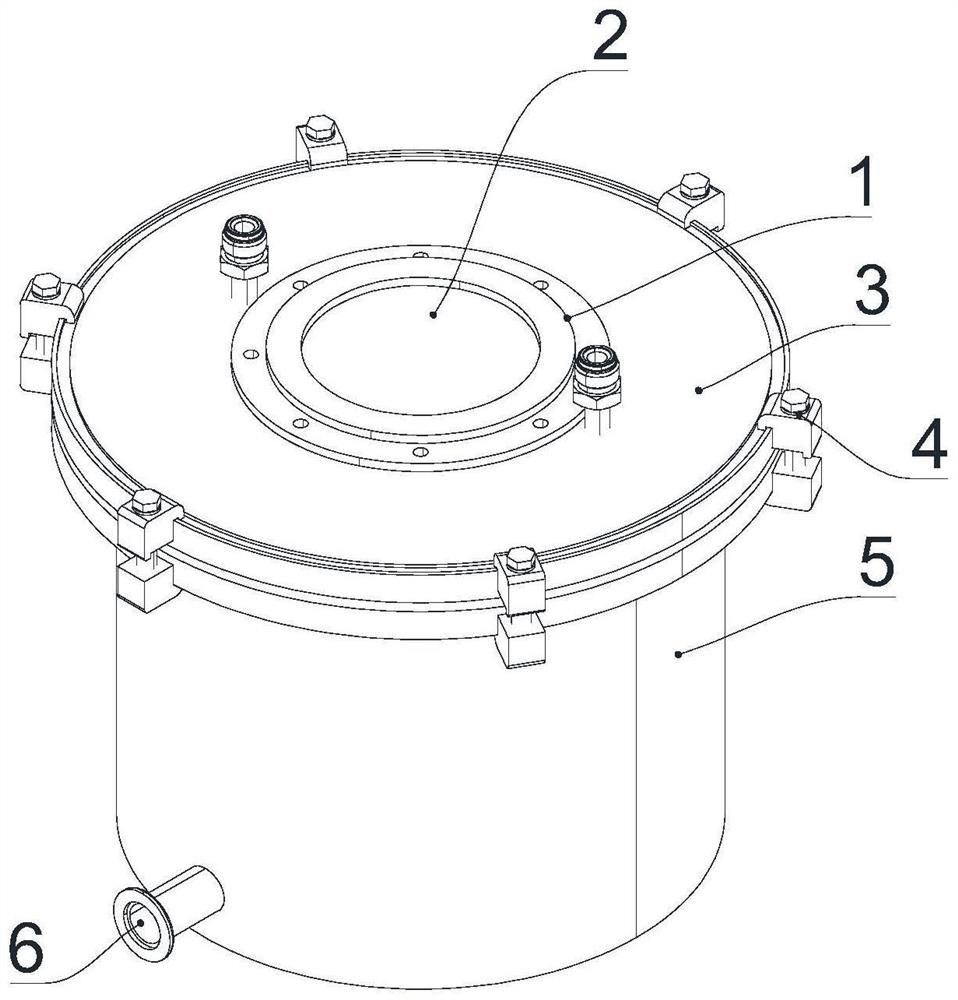

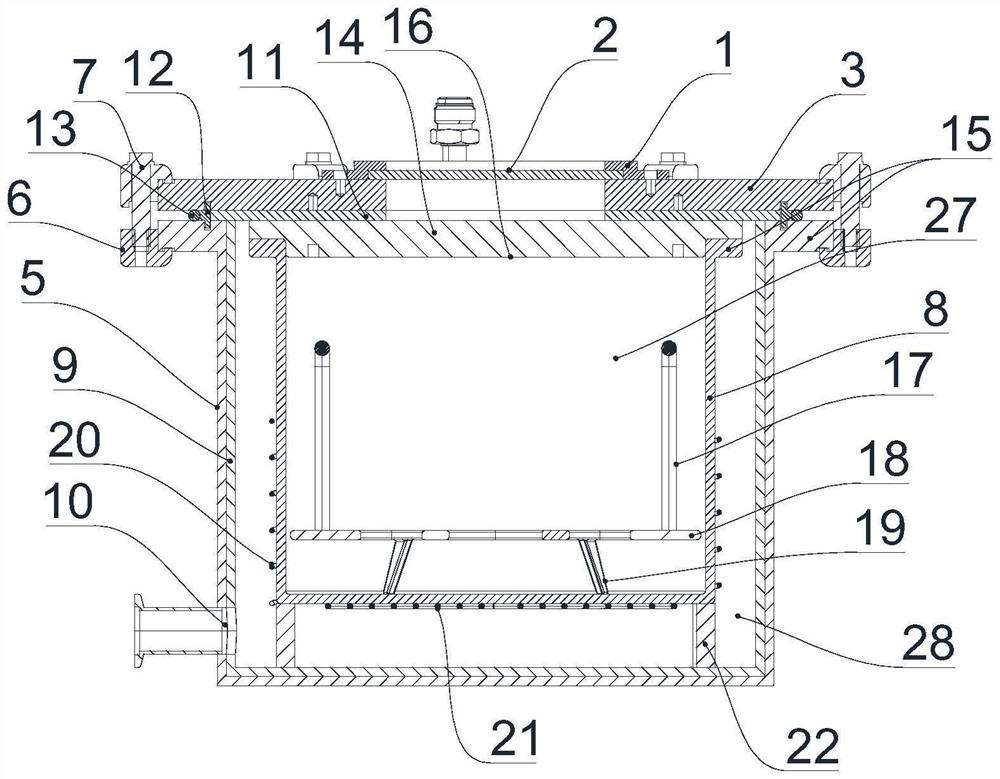

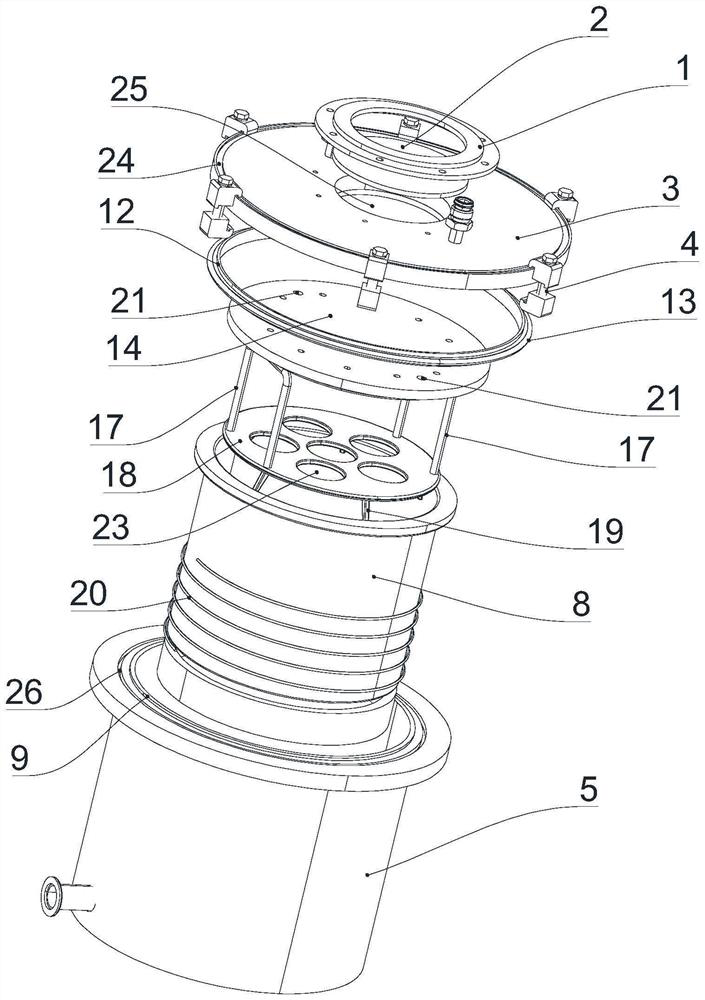

[0029] see Figure 1-Figure 6 , this embodiment discloses an evaporation and concentration device for ultra-clean and high-purity electronic chemicals, including an outer shell 5, an inner shell 8, a vacuum pumping device, and a heating assembly; the inner cavity of the outer shell 5 is a primary vacuum chamber body 28, the inner cavity of the inner housing 8 is a secondary vacuum cavity 27, and the primary vacuum cavity 28 and the secondary vacuum cavity 27 are respectively connected with the vacuum pumping equipment; the inner housing 8 is arranged in the primary vacuum chamber 28, and the top of the outer casing 5 and the inner casing 8 is provided with a top cover seal for sealing the top openings of the primary vacuum chamber 28 and the secondary vacuum chamber 27. Assembly, the top cover sealing assembly is detachably arranged on the top of the outer casing 5 and the inner casing 8, and the heating end of the heating assembly acts on the inner casing 8; in the secondary ...

Embodiment 2

[0043] In this example, the evaporation concentration device for ultra-clean and high-purity electronic chemicals described in Example 1 is applied in ICP-MS detection, and it is used as a sample pretreatment device for ICP-MS detection, so that the sample meets the detection requirements , and is conducive to improving the detection accuracy. The inner casing 8 in this embodiment is made of high-purity quartz, and the secondary vacuum cavity 27 is a quartz cavity, which effectively improves the local clean space, and has the advantages of corrosion resistance, no precipitation of metal ions, dust or insoluble particles; Simultaneously, the inner cover 14 in this embodiment is also made of high-purity quartz, and the peripheral surface of its side wall is a quartz frosted structure; the parts that may be in contact with steam can only be made of high-purity quartz or Teflon. At this time, in order to adapt to the possible precipitation of corrosive gases in the sample pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com