Seal structure of motive shaft of high temperature furnace

A sealing structure and high-temperature furnace technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve problems such as poor sealing performance, easy entry of air into the furnace body, and affecting the quality of pyrolysis reactions, etc., to meet the needs of use, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

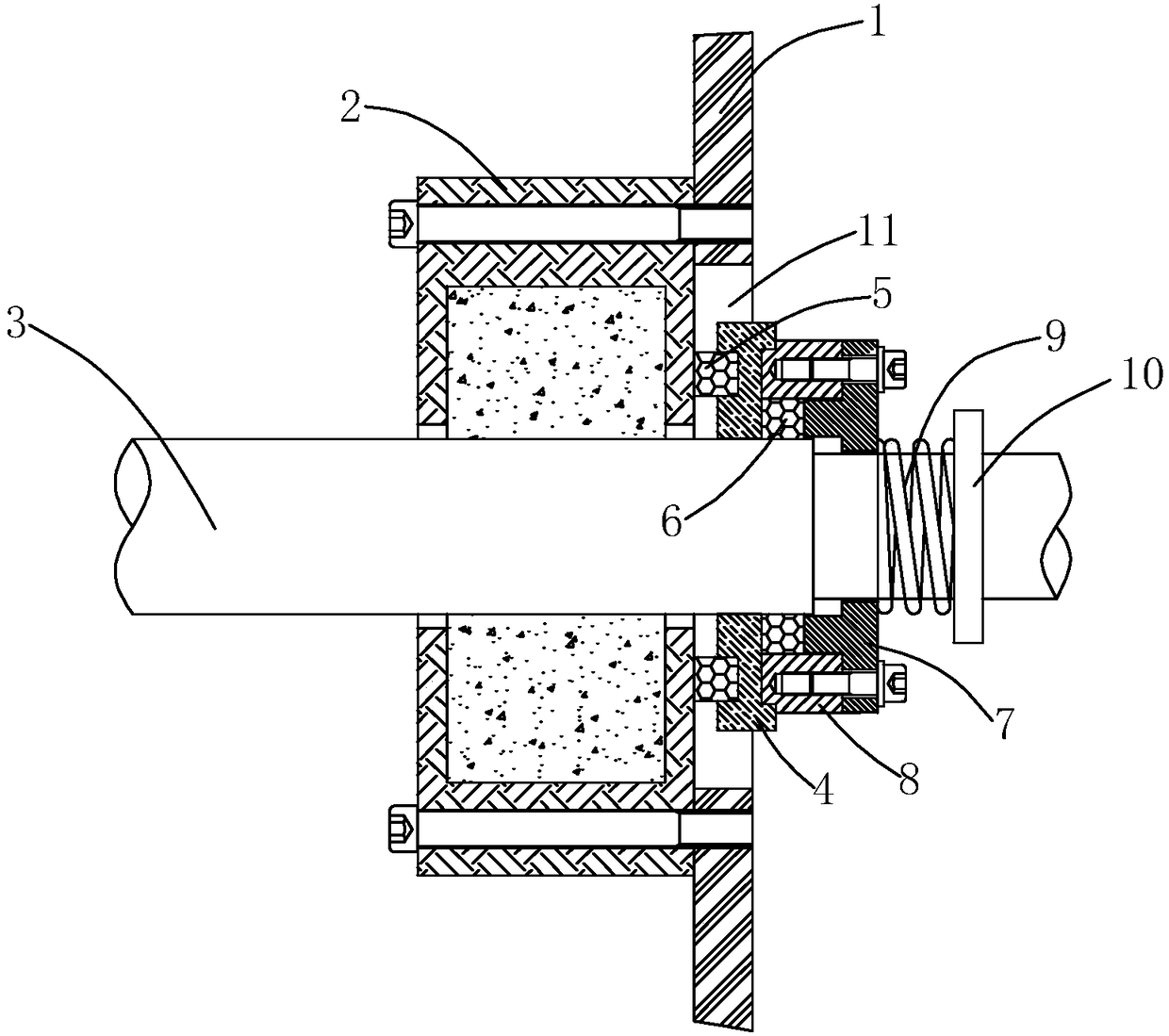

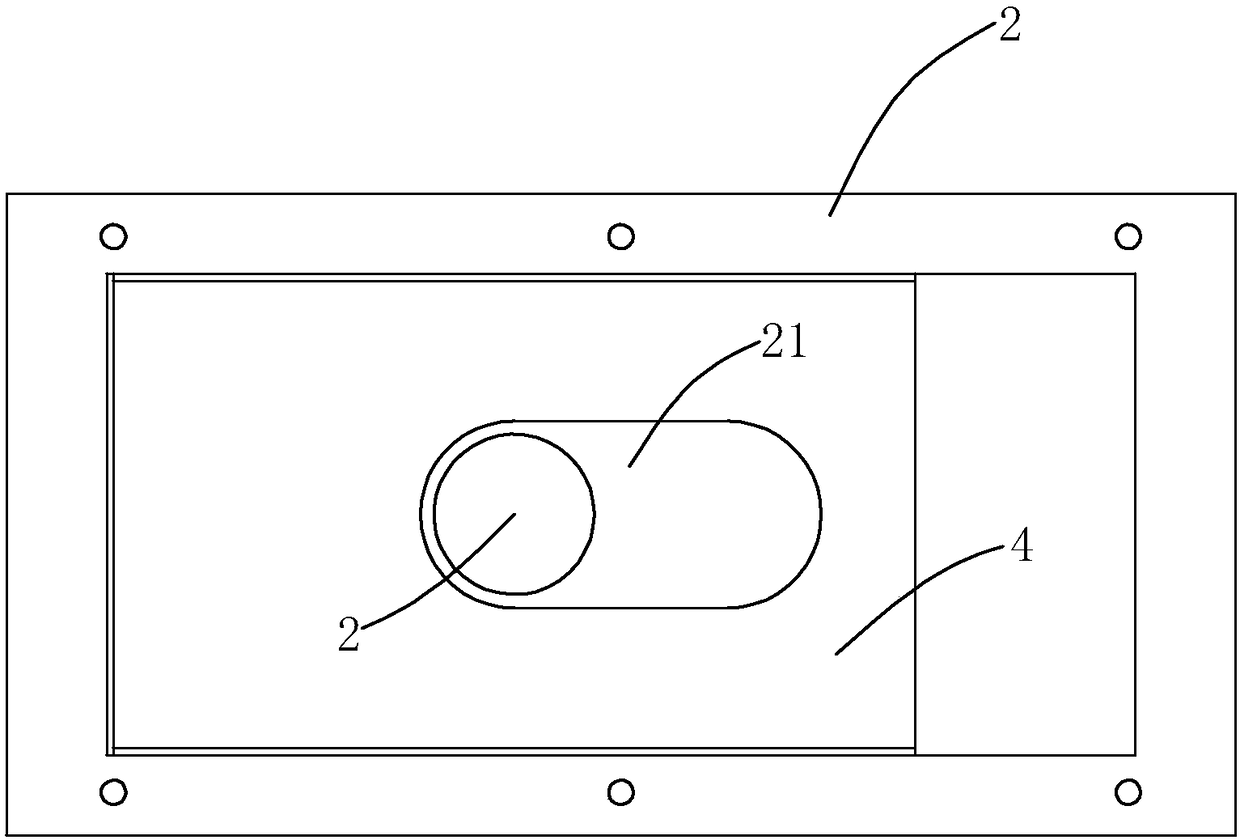

[0017] refer to Figure 1 to Figure 2 , a moving shaft sealing structure of a high-temperature furnace according to the present invention, comprising a furnace body 1, on which a gap 11 for accommodating the moving shaft 3 is arranged, and the furnace body 1 is provided with a gap 11 in line with the gap 11 Adapted mounting block 2, the mounting block 2 is sealingly connected with the edge of the notch 11, the mounting block 2 is provided with a through-hole groove 21 for sliding the moving shaft 3, and the moving shaft 3 is inserted through Set in the through-hole groove 21, one end of the moving shaft 3 placed in the furnace body 1 is connected with a sealing plate 4, and the sealing plate 4 and the mounting block 2 are sealed by a first sealing member 5 The moving shaft 3 and the sealing plate 4 are connected in a sealed manner through a second sealing member 6 . When in use, the moving shaft 3 and the sealing plate 4 slide together, and the first sealing member 5 can keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com