Proportional direction valve

A proportional directional valve, proportional electromagnet technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of fracture, proportional electromagnet deformation, easy oil leakage, etc., to improve the sealing environment, work The effect of low thrust and low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

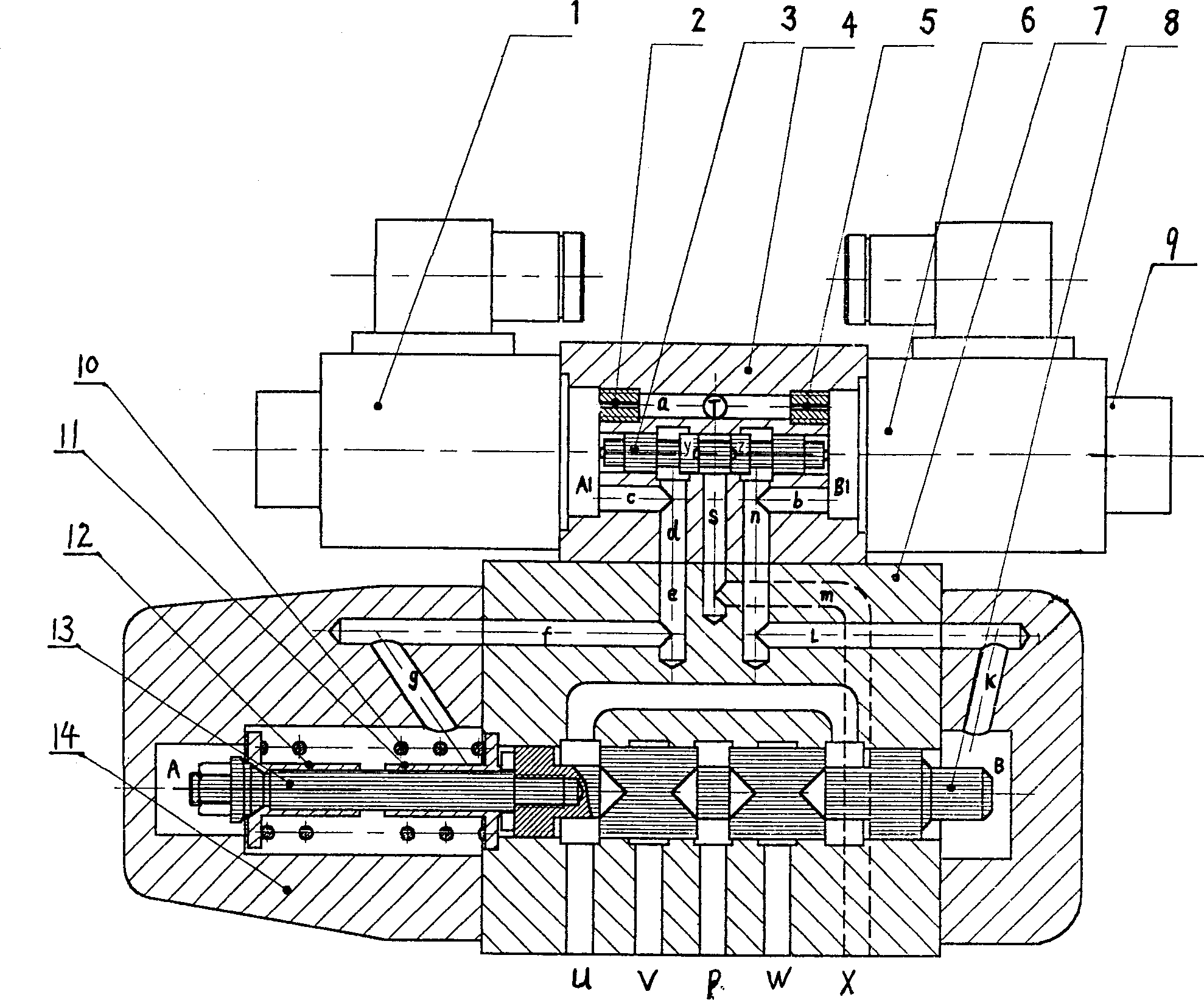

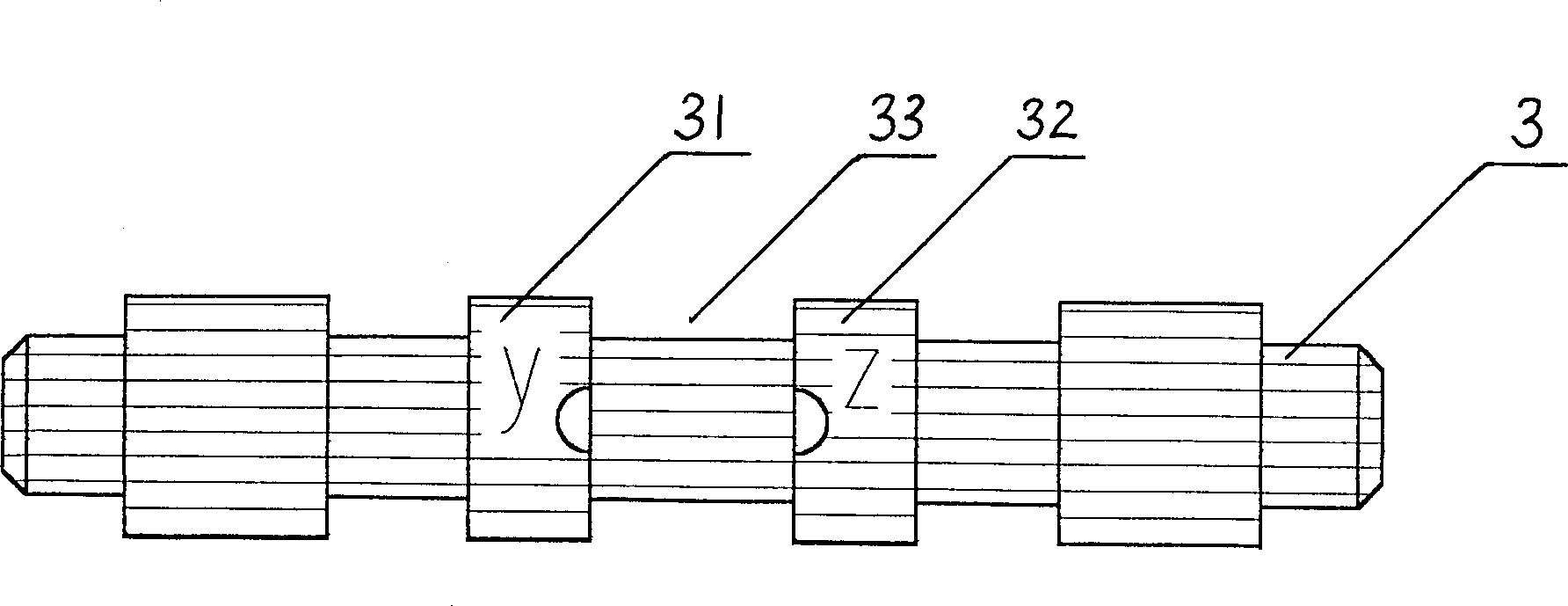

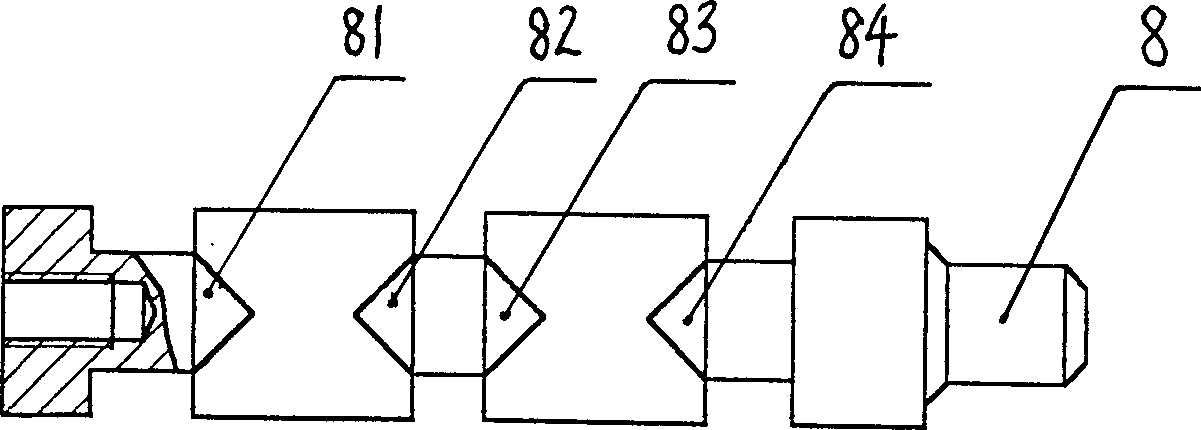

[0012] Such as figure 1 As shown, the proportional directional valve product of the present invention includes two parts, the pilot valve 9 and the main valve 14 . The pilot valve 9 includes proportional electromagnets 1 and 6 at the left and right ends, a pilot valve body 4 , and a pilot valve core 3 arranged in the pilot valve body 4 . A transverse oil passage a is arranged inside the pilot valve body 4, and a T hole communicating with the return oil of the control oil is arranged on the oil passage a. Damping screws 2 and 5 are respectively set at the ports where the transverse oil passage a enters the left and right proportional electromagnet ejector rod oil chambers A1 and B1. At the lateral position below the pilot valve spool 3, two oil passages c and b are drawn from the left and right proportional solenoid ejector rod oil chambers A1 and B1 respectively, and vertical oil passages d and n are respectively arranged at the transverse hole ends of the oil passages c and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com