Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

A hole sealing device and layer-penetrating drilling technology, which is applied in safety devices, sealing/package, mining equipment, etc., can solve the problems of difficult to effectively seal borehole fissure channels, borehole air leakage failure, poor pressure resistance, etc. problem, achieve the effect of reducing the cost of sealing equipment, reducing the cost of sealing, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

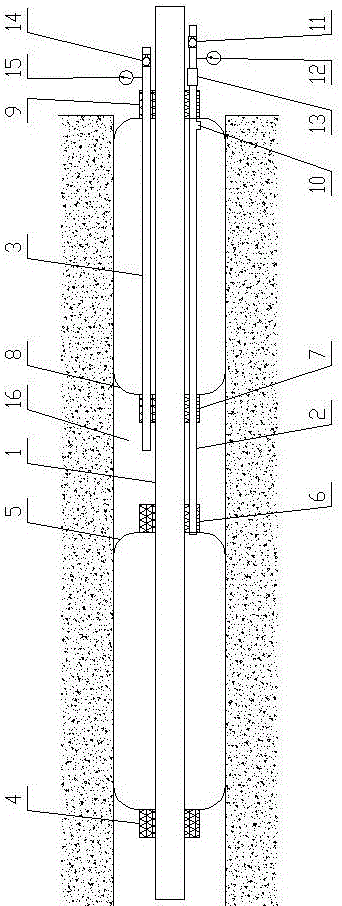

[0028] Such as figure 1 As shown, the coal mine of the present invention uses gas plugging at both ends and a middle water seal drilling and sealing device for piercing layers, including gas drainage pipe 1, gas injection pipe 2 and water injection pipe 3 arranged in parallel with each other; one end of gas drainage pipe 1 is the inner end, and the other end is the outer end; the gas drainage pipe 1 is sequentially provided with a first stopper 4, a first expansion air bag 5, a second stopper 6, a third stopper 7, and a second stopper. Two inflation airbags 8 and the fourth stopper 9, the gas injection tube 2 passes through the fourth stopper 9, the second inflation bag 8, the third stopper 7 and the second stopper 6 from the outside to the inside, and the gas injection tube The inner port of 2 communicates with the interior of the first inflation bag 5, and the gas injection pipe 2 is provided with an air injection hole 10 communicating with the interior of the second inflati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com