Deep-sea non-contact electric power transmission packaging structure

A non-contact, power transmission technology, applied in circuit devices, circuits, inductors, etc., can solve the problems of short service life, high price, difficult implementation, etc., and achieve the effect of long service life, reliable connection and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

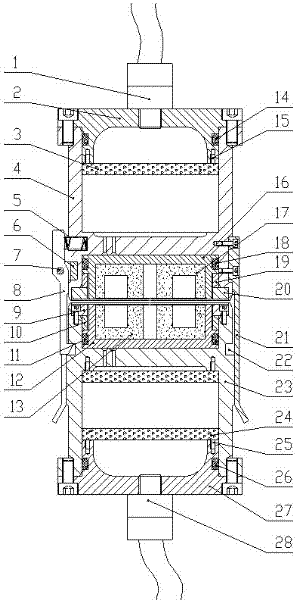

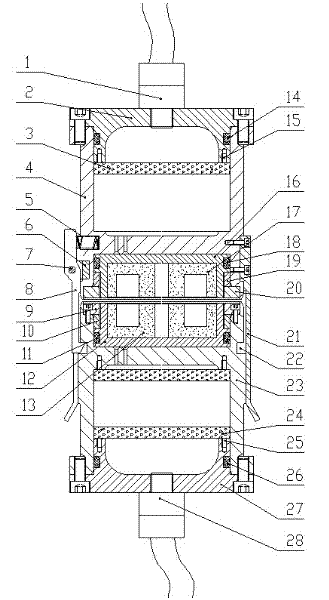

[0017] Further illustrate the present invention below in conjunction with accompanying drawing:

[0018] like figure 1 As shown, the packaging structure of the non-contact power transmission in the deep sea environment involved in the present invention includes a primary coupling joint and a secondary coupling joint;

[0019] The primary coupling joint includes a primary end face pressure ring 9, a primary sleeve 10, a primary magnetic core sealing ring 11, a primary magnetic core support frame 12, a primary magnetic core 13, a hook groove 22, a primary housing 23, a primary control circuit board 24, and a primary Circuit board installation hole 25, primary end cover sealing ring 26, primary end cover 27, primary watertight connector 28.

[0020] The primary watertight connector 28 is threadedly connected with the primary end cover 27, and the primary end cover 27 has a sealing groove, and the primary end cover sealing ring 26 is placed in the sealing groove, and the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com