A steel pile tube internal expansion type pile hanger

A technology of pile tube and expansion type, which is applied in the field of steel pile tube internal expansion type pile hanger, can solve the problems of difficult installation and maintenance, many processing procedures, high quality requirements, etc. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

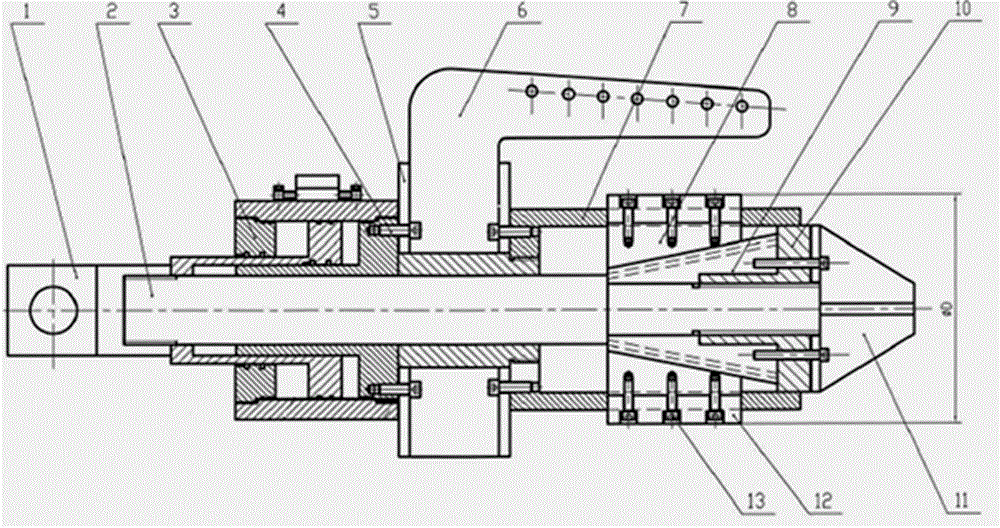

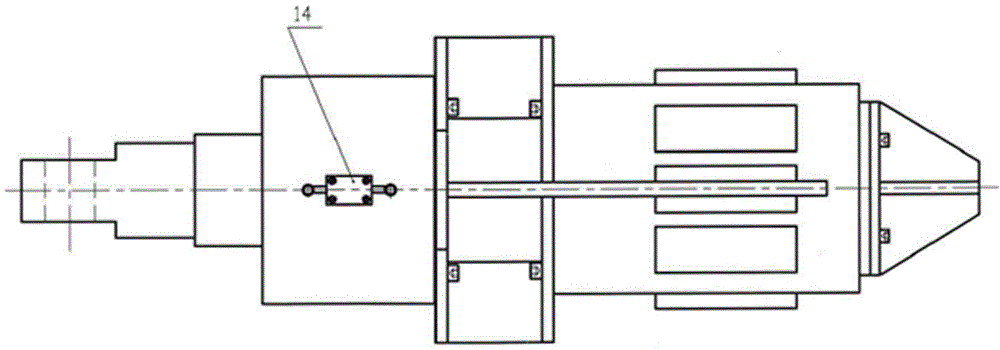

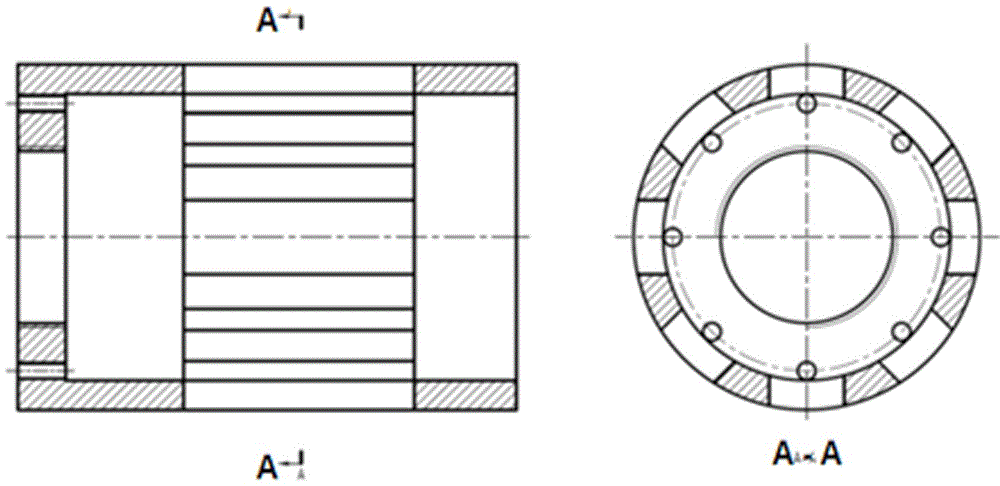

[0020] Such as figure 1 , 2 as shown, A steel pile pipe internal expansion type pile hanger, including lifting lug 1, central shaft 2, hollow oil cylinder 3, connecting seat 5, balance boom 6, guiding cylinder 7, radial moving wedge 8, axial moving cone Body wedge 9, load-bearing retaining ring 10, tough pile plate 11, diameter-expanding friction plate 12 and diameter-expanding bolt 13, lifting lug 1, central shaft 2, hollow oil cylinder 3, connecting seat 5, guiding cylinder 7, axial movement The cone wedge 9 and the load-bearing retaining ring 10 are installed on the same axis in sequence to form a driving cone; the lifting lug 1 and the hollow oil cylinder 3 are located on the upper part of the central shaft 2, and the cone wedge 9 and the load-bearing retaining ring 10 are axially moved Located at the lower part of the central axis 2; the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com