Catalytic regeneration flue gas denitrification, dust removal and desulfurization system and pressure reduction method

A technology for regenerating flue gas, denitrification and dust removal, applied in chemical instruments and methods, separation methods, general control systems, etc., can solve the problems of low piping difficulty, reduce boiler pressure, boiler pressure reduction, etc., and achieve low piping difficulty and low modification volume Small, the effect of increasing the operation of the same cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

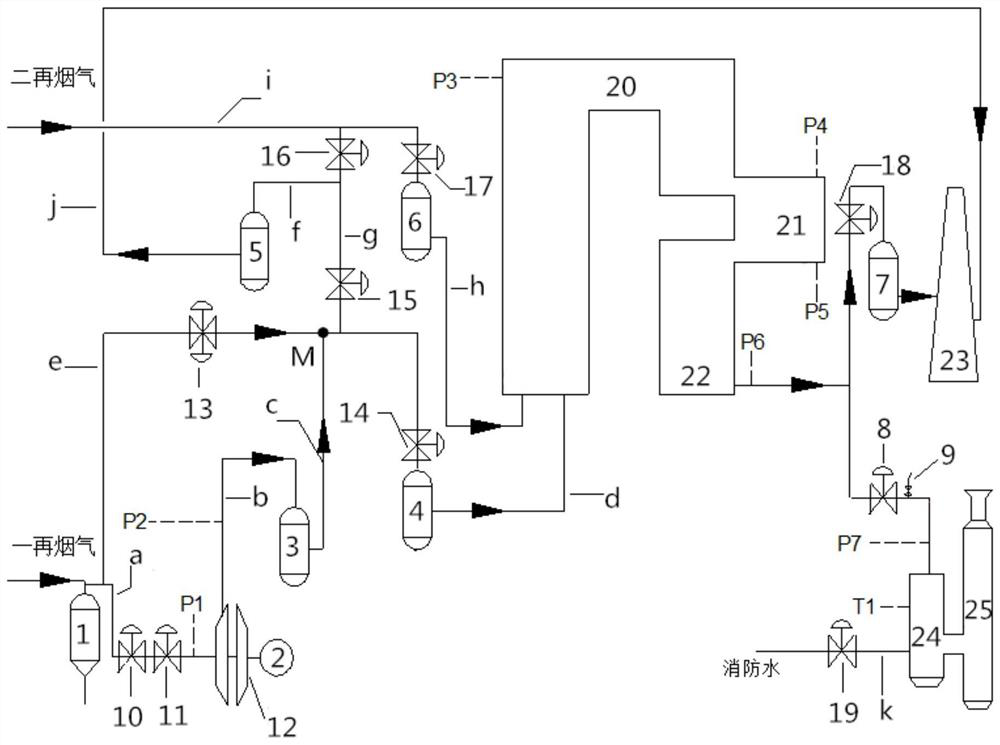

[0053] In the present invention, the system can be operated under various working conditions. In the first embodiment of the present invention, when the system is working normally, the high temperature gate valve 10, the high temperature butterfly valve 11, the first stop valve 14, the second The four cut-off valves 17 and the triple eccentric double butterfly plate butterfly valve 8 are opened to control the closing of the third cut-off valve 16, the second cut-off valve 15 and the fifth cut-off valve 18, the vent valve 9 and the quenching water valve 19, and the secondary flue gas is passed through the hood unit, boiler denitrification unit, through the triple eccentric double butterfly plate butterfly valve 8 and then into the chilling tower 24 and dust removal and desulfurization comprehensive tower 25 for denitrification, dust removal and desulfurization.

[0054] In the present invention, the secondary flue gas enters the boiler 20 of the boiler denitrification unit throu...

Embodiment 1

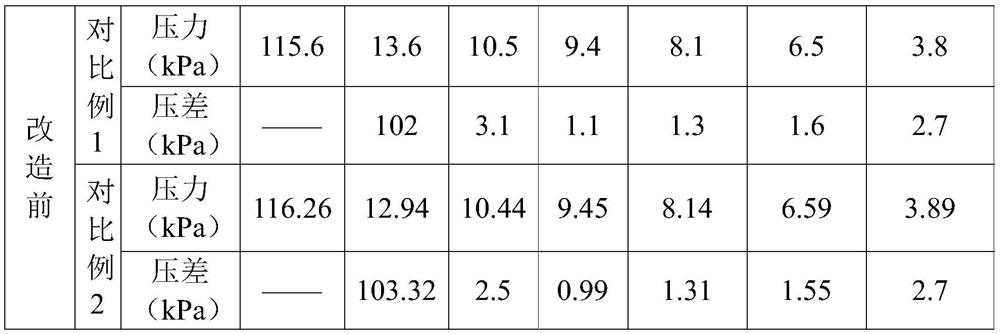

[0069] The original catalytic regeneration flue gas denitrification, dust removal and desulfurization system was transformed, and the position of the stop valve and water seal tank in front of the quenching tower was transformed into a triple eccentric double butterfly plate butterfly valve 8 and a vent valve 9.

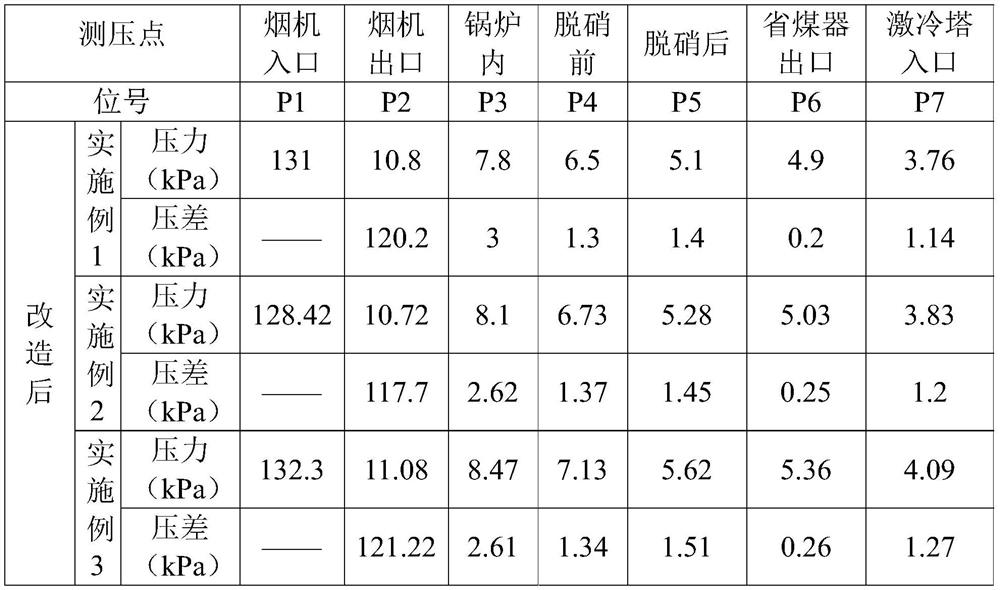

[0070] The specific control process is: sequentially control the opening of the high temperature gate valve 10, the high temperature butterfly valve 11, the first stop valve 14, the fourth stop valve 17 and the triple eccentric double butterfly valve 8, control the third stop valve 16, the second stop valve 15, the The five stop valve 18, the vent valve 9 and the quenching water valve 19 are closed, and the angle of the triple eccentric double butterfly plate butterfly valve 8 is electrically adjusted to 90°, and the flue gas passes through the three-stage cyclone separator 1, and the solid is precipitated and then passed into the hood In the unit, open the high-tempe...

Embodiment 2

[0072] The original catalytic regeneration flue gas denitrification, dust removal and desulfurization system was transformed, and the position of the stop valve and water seal tank in front of the quenching tower was transformed into a triple eccentric double butterfly plate butterfly valve 8 and a vent valve 9.

[0073] The specific control process is: sequentially control the opening of the high temperature gate valve 10, the high temperature butterfly valve 11, the first stop valve 14, the fourth stop valve 17 and the triple eccentric double butterfly valve 8, control the third stop valve 16, the second stop valve 15, the The five stop valve 18, the vent valve 9 and the quenching water valve 19 are closed, and the angle of the triple eccentric double butterfly plate butterfly valve 8 is electrically adjusted to 90°, and the flue gas passes through the three-stage cyclone separator 1, and the solid is precipitated and then passed into the hood In the unit, open the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com