Refrigeration compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

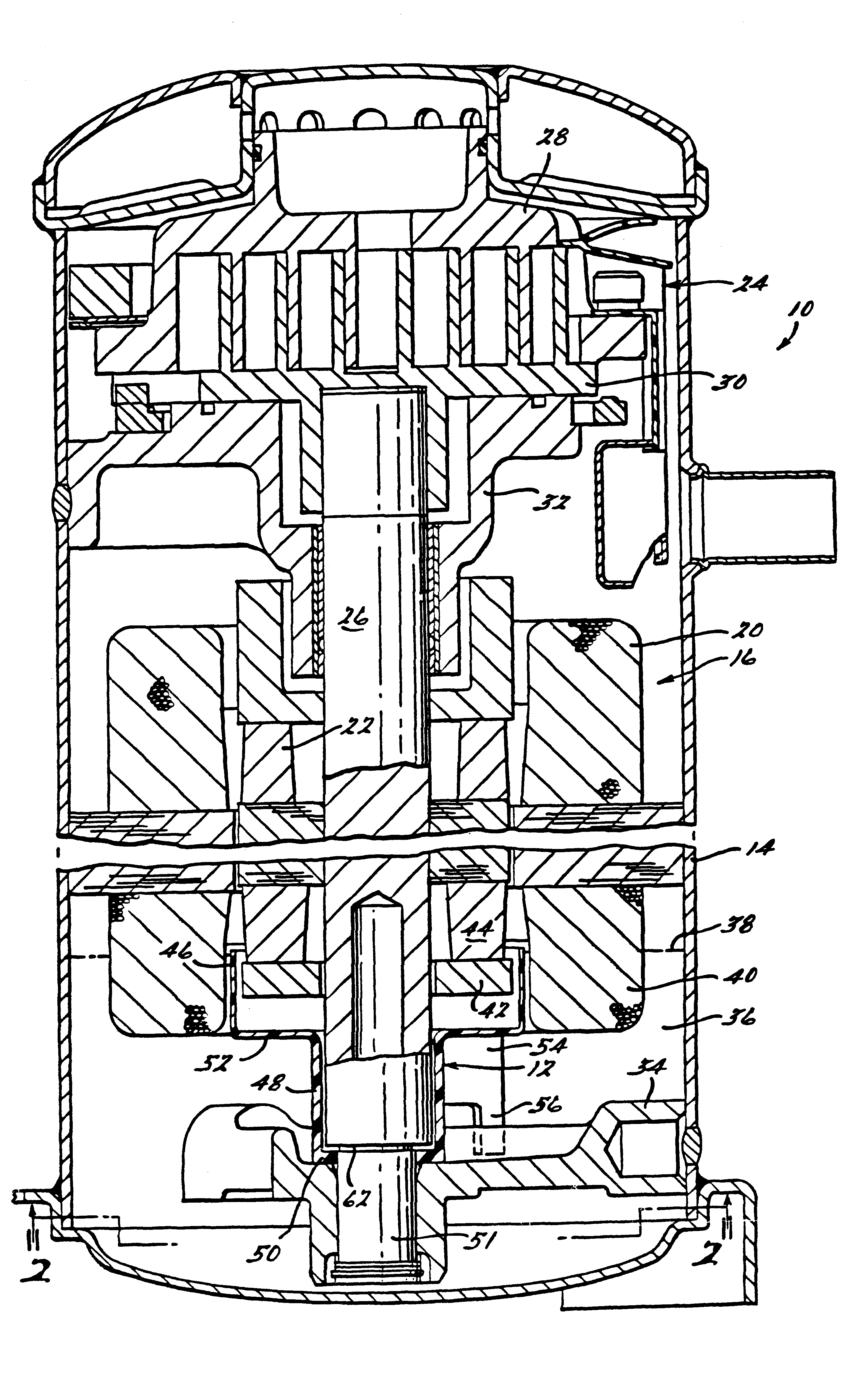

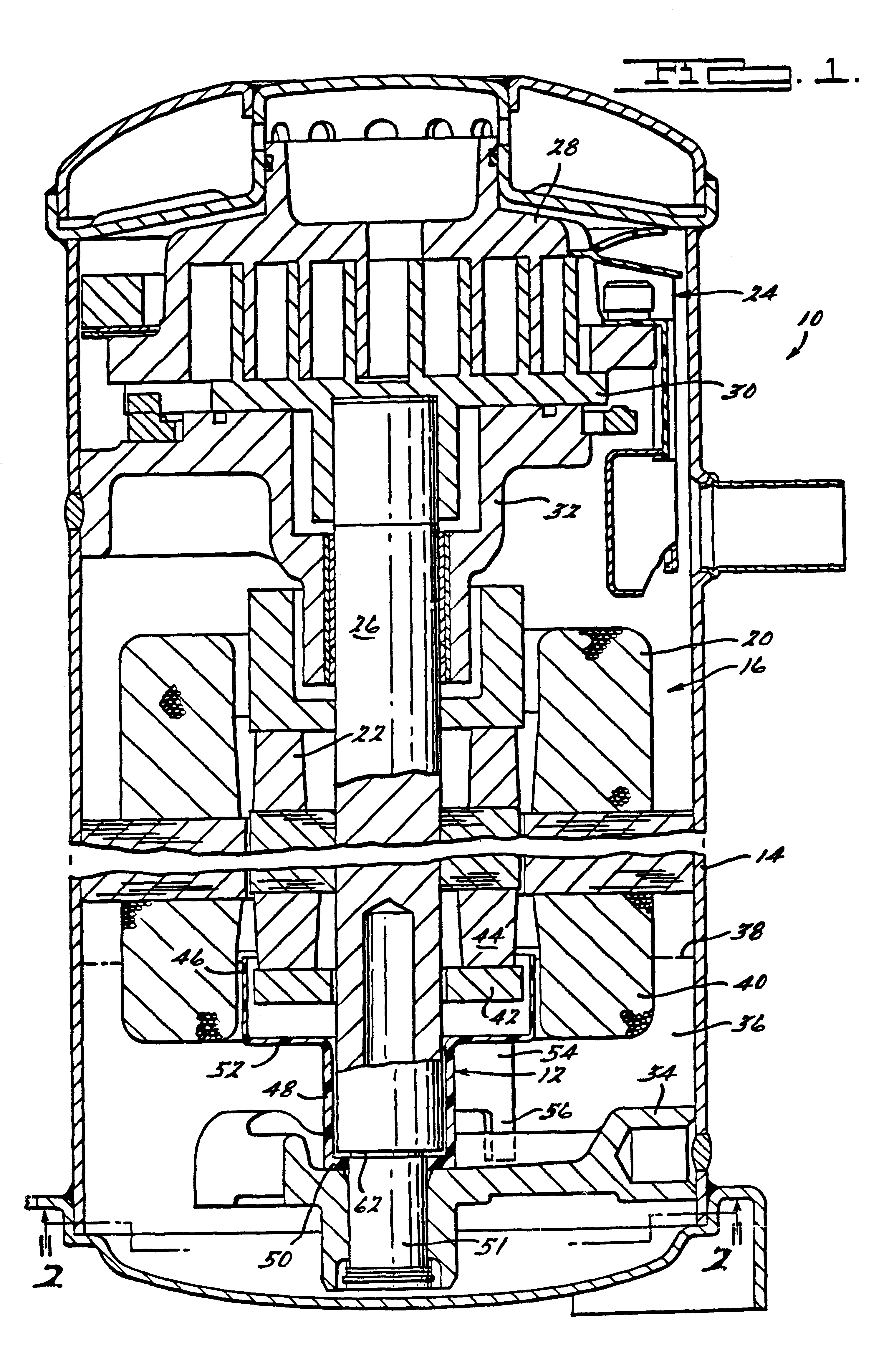

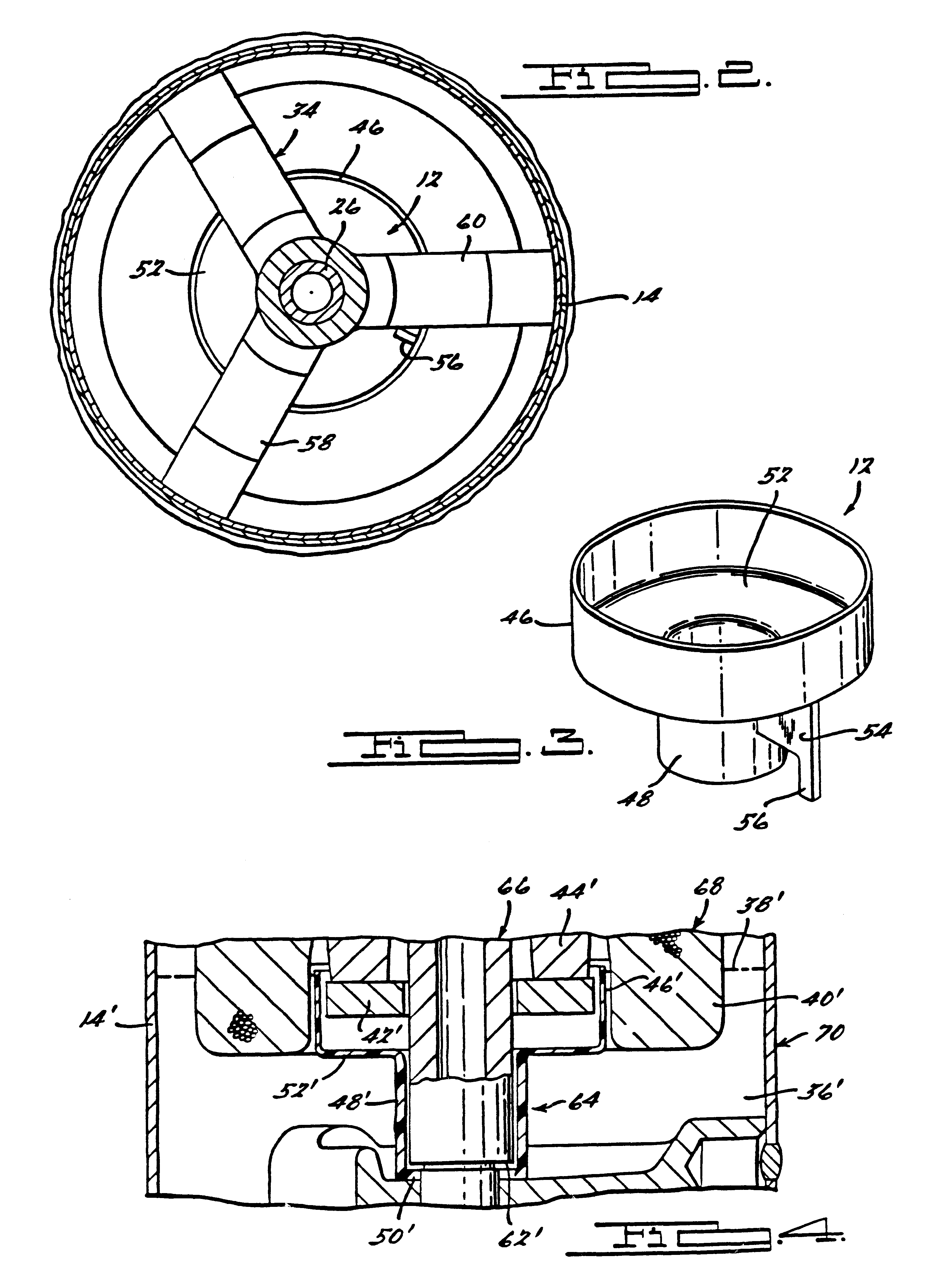

Referring now to the drawings and more specifically to FIG. 1, there is shown a hermetic refrigeration compressor 10 incorporating a shield 12 all in accordance with the present invention.

Compressor 10 comprises an outer shell or housing 14 within the lower portion of which is disposed an electric motor 16 including a stator 20 and a rotor 22. Motor 16 is operative to drive a compressor assembly 24 disposed in the upper portion of shell 14 via a drive shaft 26 extending therebetween and to which rotor 22 is secured adjacent the lower end. As shown, compressor assembly 24 is of the scroll type and incorporates an upper fixed scroll member 28 and a lower scroll member 30 which is driven by drive shaft 26 in orbiting motion relative to the fixed scroll member 28. Drive shaft 26 is rotatably supported within shell 14 by means of upper and lower bearing assemblies 32 and 34 respectively each of which are fixedly secured to shell 14. Compressor 10 is described in greater detail in present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com