Multistage rotary compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

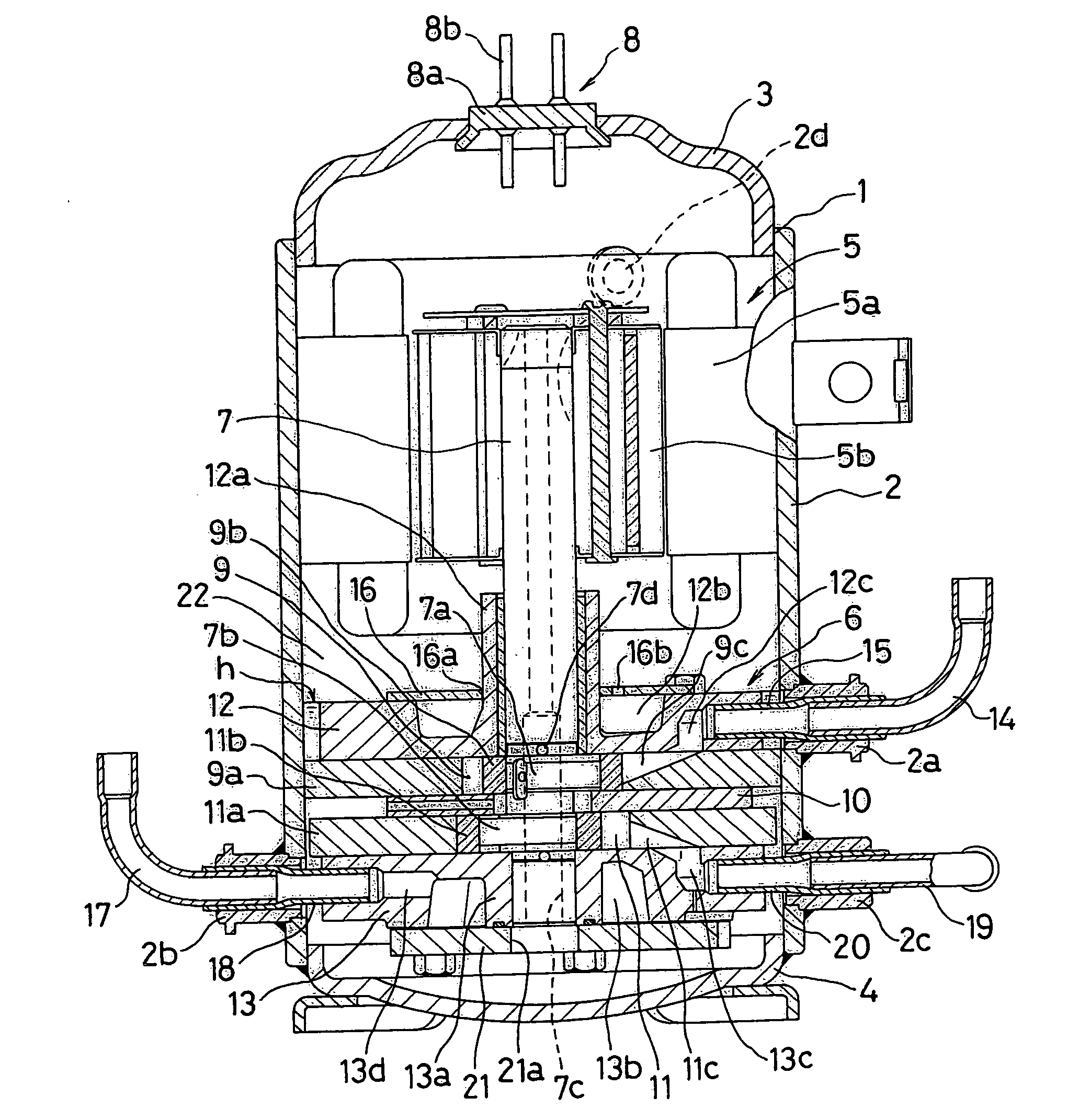

[0025] First, a first embodiment of the present invention shown in FIG. 1 will be described. The reference numeral 1 is a closed vessel. The closed vessel 1 is comprised of a cylindrical vessel 2 and end caps 3, 4 attached to opening end portions of the vessel 2, and is provided in such a manner that a motor-operating element 5 and a rotary compressing element 6 are positioned at upper and lower portions in this closed vessel 1 respectively.

[0026] The motor-operating element 5 is comprised of an annular stator 5a fixed to an inner surface of the vessel 2 and a rotor 5b, which rotates inside the stator 5a. The rotor 5b is journalled to an upper end portion of a rotating shaft 7. This motor-operating element 5 rotates the rotor 5b by feed to the stator 5a through a terminal 8 attached to the end cap 3.

[0027] The terminal 8 is comprised of a base 8a fixed to an mounting hole of the end cap 3 and a plurality of connecting terminals 8b provided on the base 8a while penetrating through ...

example 2

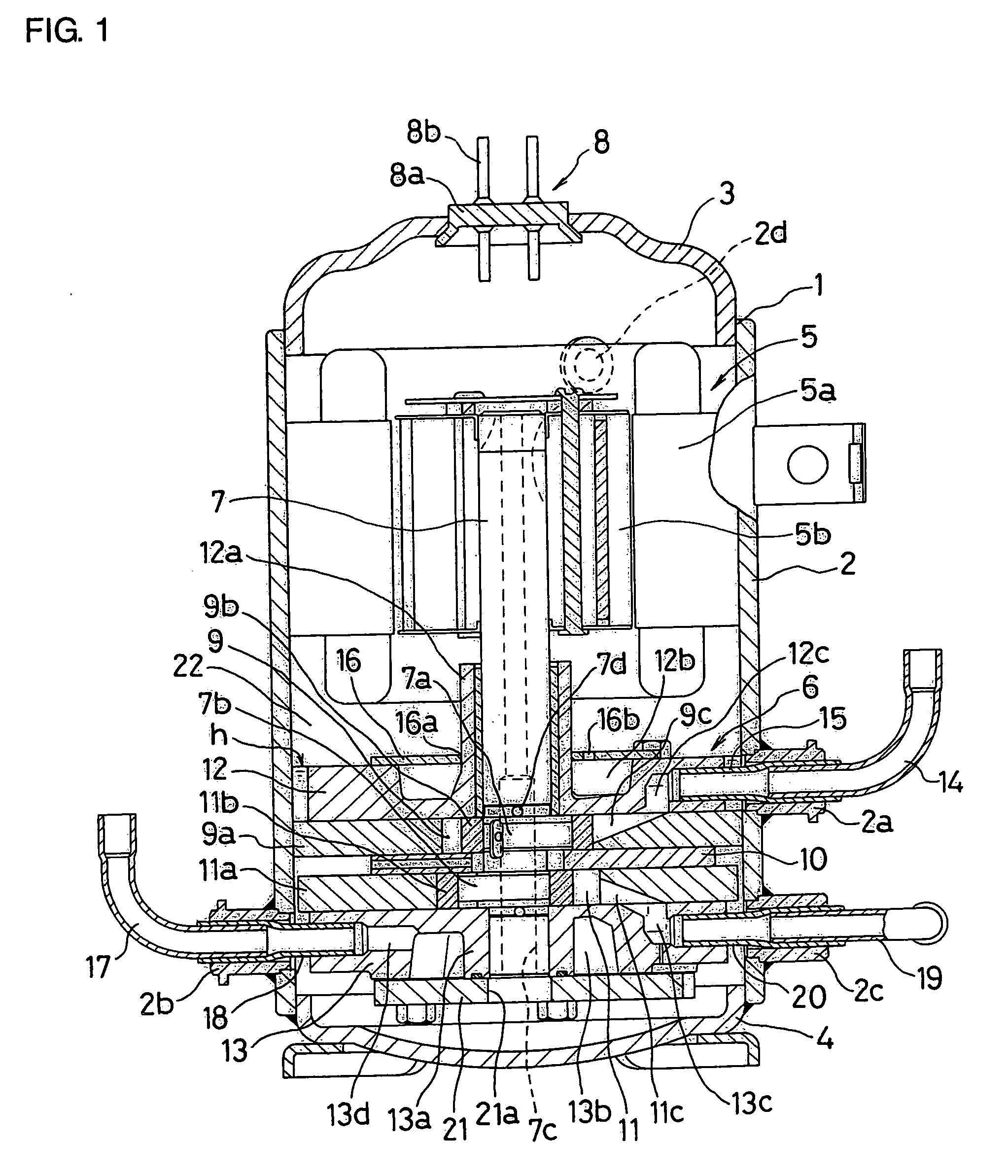

[0042] Next, a second embodiment shown in FIG. 2 will be described. In the second embodiment the components corresponding to the above-mentioned first embodiment are denoted by the same reference numerals as described above.

[0043] In FIG. 2, the reference numeral 1 is a closed vessel. The closed vessel 1 is comprised of a vessel 2 formed into a substantially cylindrical shape and end caps 3, 4 attached to opening end portions of the vessel 2, and is provided in such a manner that a motor-operating element 5 and a rotary compressing element 6 are positioned at upper and lower portions in this closed vessel 1 respectively.

[0044] The motor-operating element 5 is comprised of an annular stator 5a fixed to an inner surface of the vessel 2 and a rotor 5b, which rotates inside the stator 5a. The rotor 5b is journalled to an upper end portion of a rotating shaft 7. This motor-operating element 5 rotates the rotor 5b by feed to the stator 5a through a terminal 8 attached to the end cap 3. ...

example 3

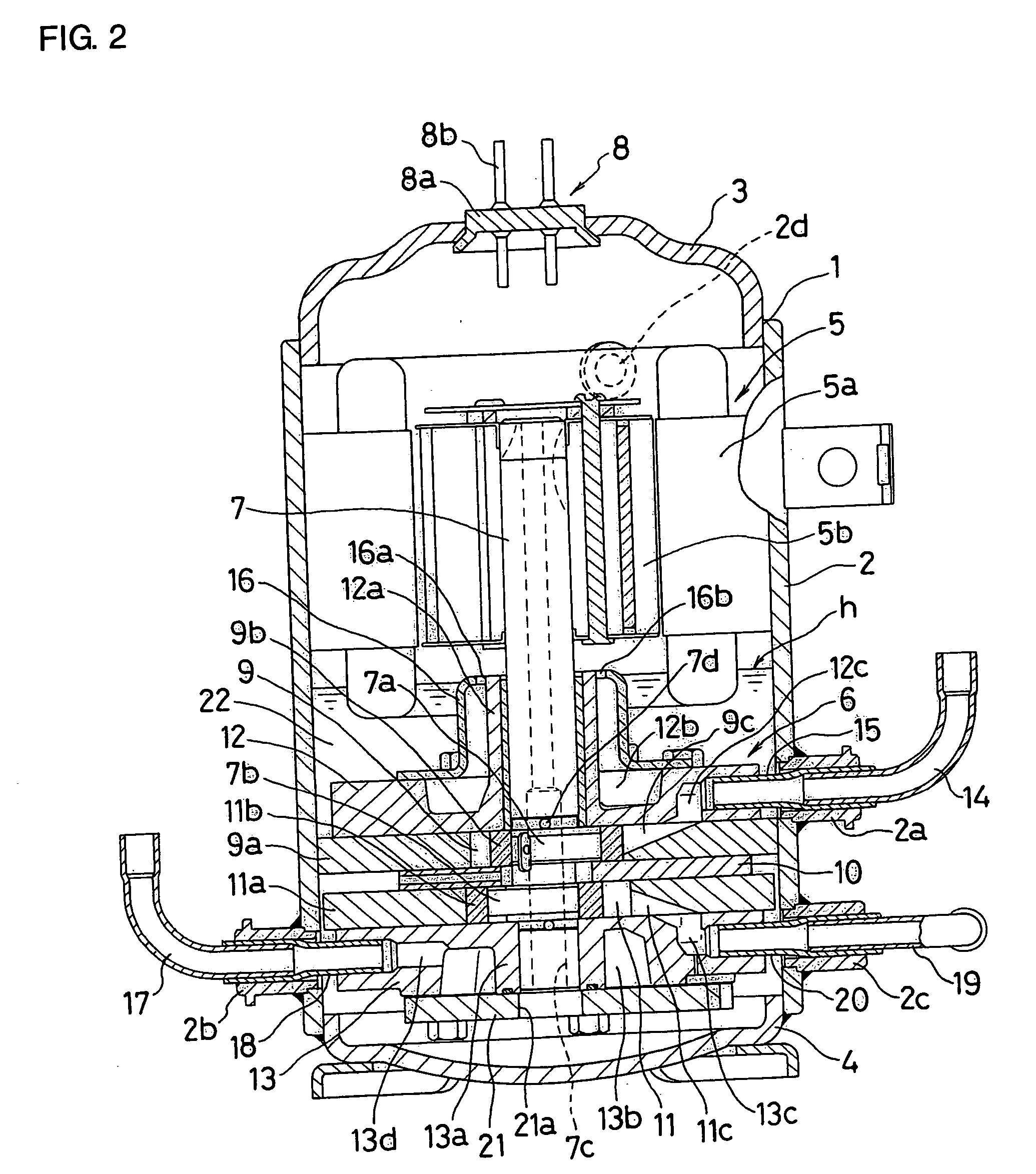

[0061] Next, a third embodiment shown in FIG. 3 will be described. In the third embodiment the components (which contain substantially the same components even if their positions are different) corresponding to the above-mentioned first embodiment or second embodiment are denoted by the same reference numerals as described above.

[0062] In FIG. 3, the reference numeral 1 is a closed vessel. The closed vessel 1 is comprised of a vessel 2 into a substantially cylindrical shape and end caps 3, 4 attached to opening end portions of the vessel 2, and is provided in such a manner that a motor-operating element 5 and a rotary compressing element 6 are positioned at upper and lower portions in this closed vessel 1 respectively.

[0063] The motor-operating element 5 is comprised of an annular stator 5a fixed to an inner surface of the vessel 2 and a rotor 5b, which rotates inside the stator 5a. The rotor 5b is journalled to an upper end portion of a rotating shaft 7. This motor-operating elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com