Patents

Literature

286results about "Thinning machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

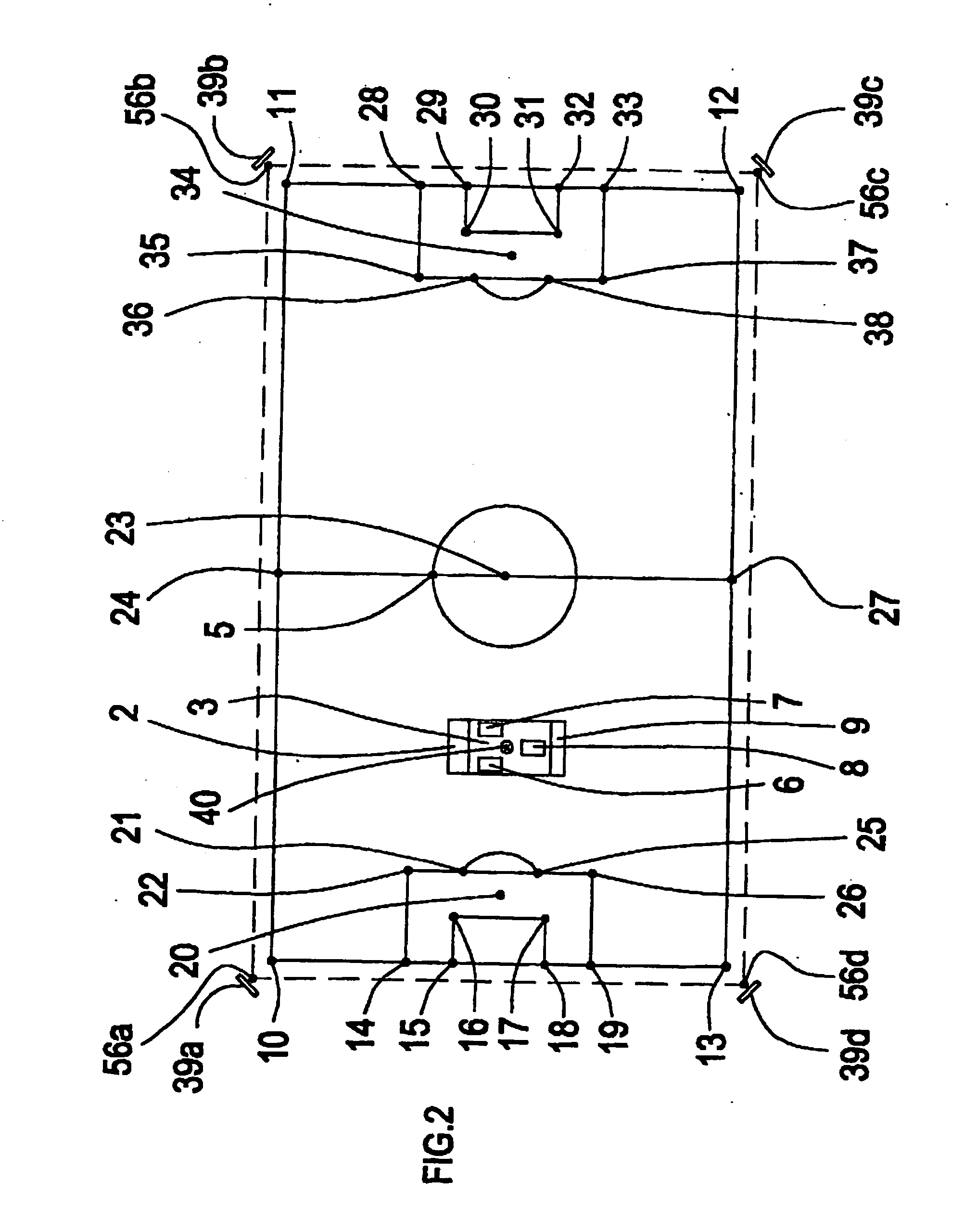

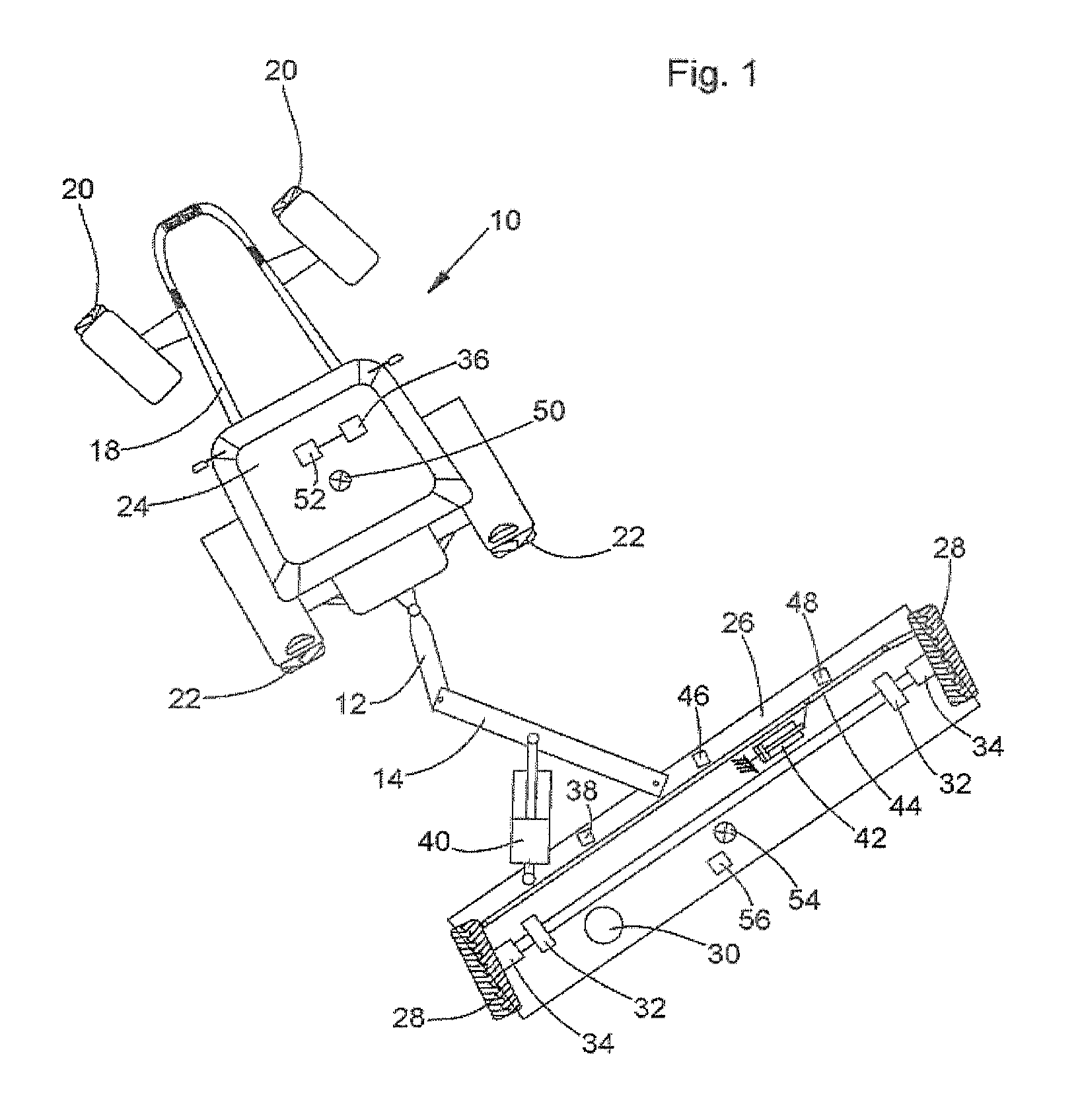

Method and system for efficiently traversing an area with a work vehicle

InactiveUS6907336B2Instruments for road network navigationAnalogue computers for trafficEngineeringTurning radius

A border of a designated area is defined within a work area. A designated axis is determined for the designated area. A series of generally parallel rows are aligned consistent with a travel axis having a known alignment with respect to the designated axis. One of the generally parallel rows is aligned as a starting row. The vehicle is pointed in a starting direction along or generally parallel to the travel axis. The vehicle engages in a turn path segment after an end of the starting row to move the vehicle at least somewhat perpendicular to the travel axis between the starting row and a next row. A turn path segment has a turn radius greater than or equal to a minimum turning radius of the vehicle, where the starting row and the next row are spatially separated by a multiple of effective vehicular implement widths less an overlap allowance. The turn path segment is defined so as to skip one or more intervening parallel rows between the starting row and the next row.

Owner:DEERE & CO

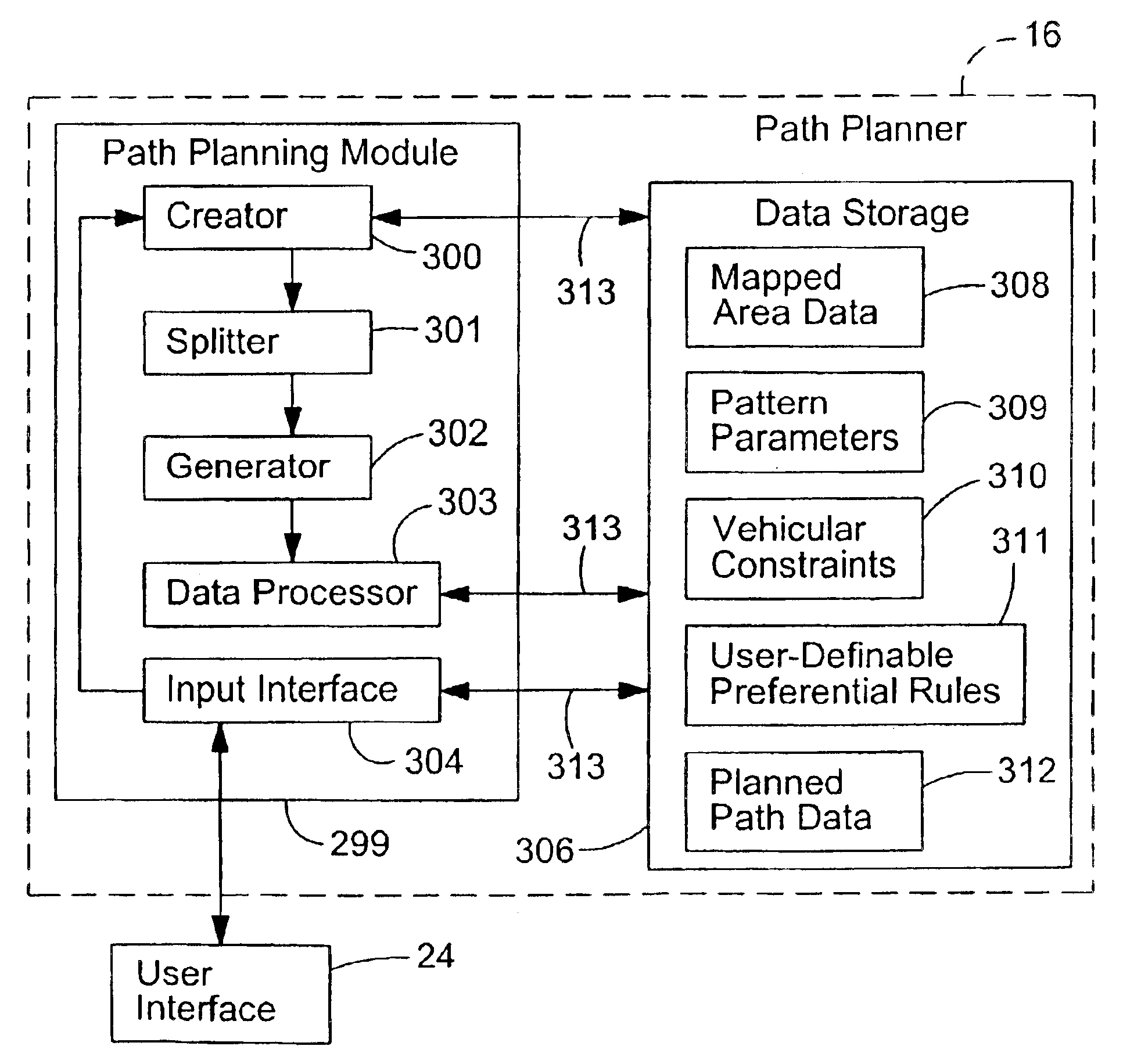

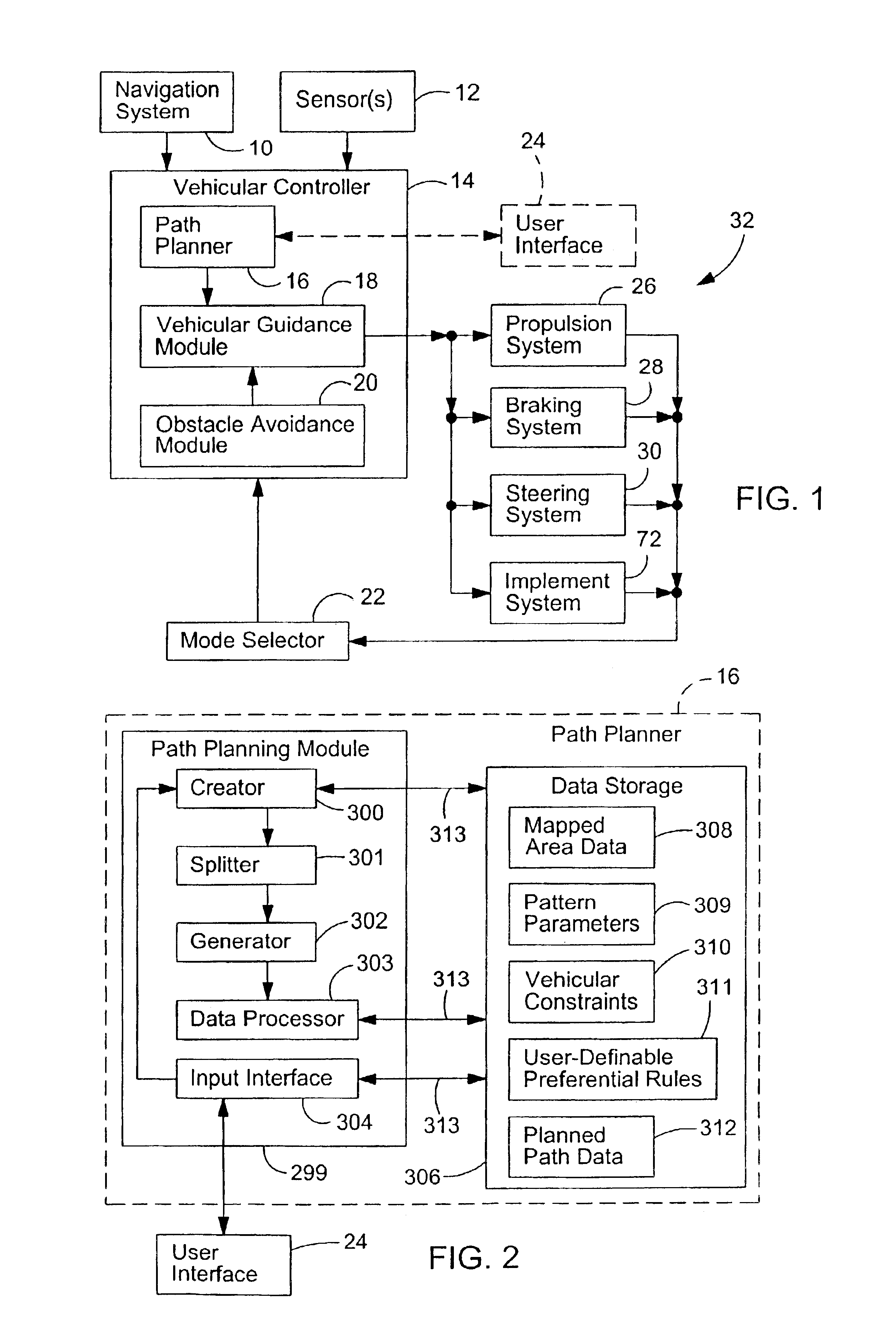

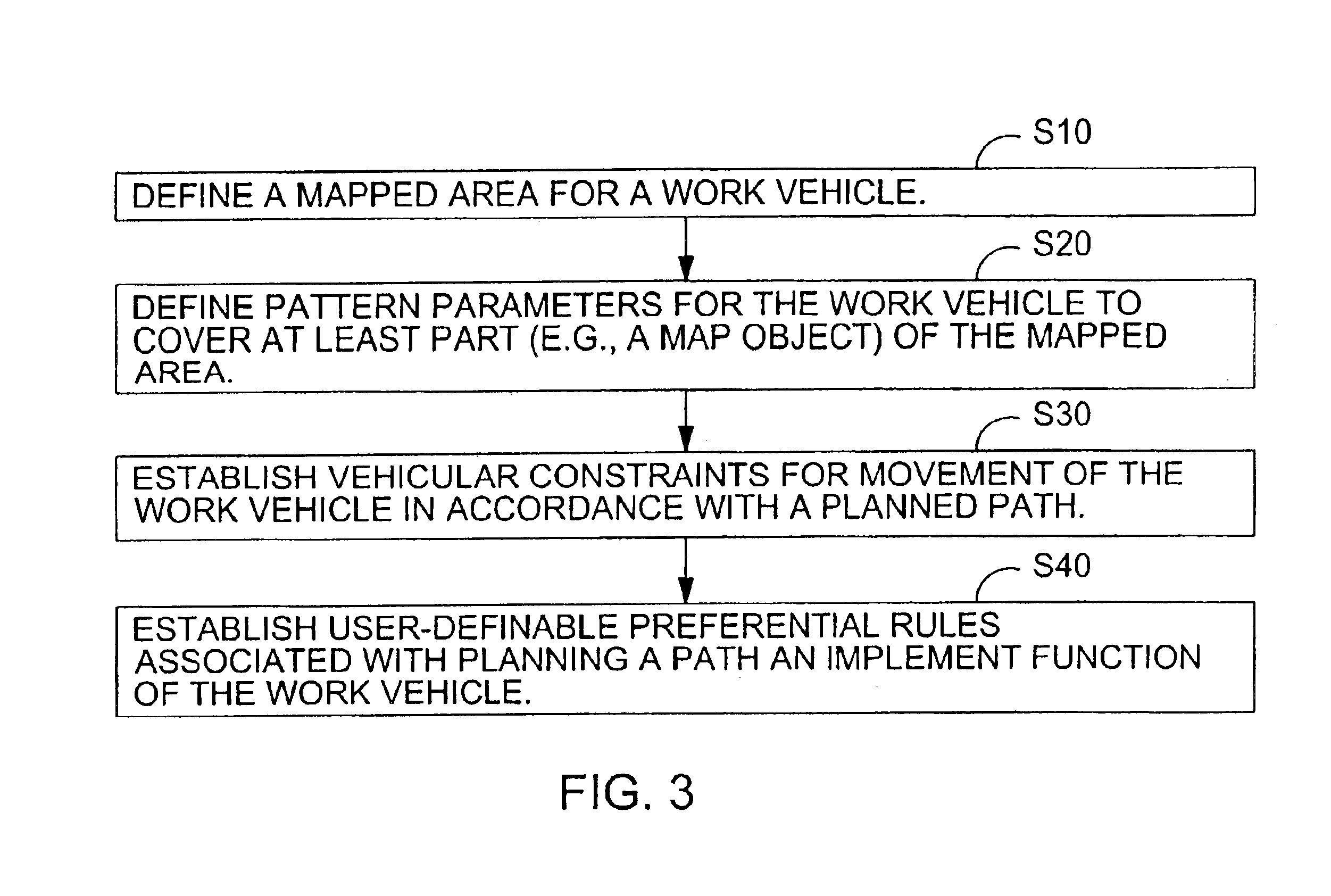

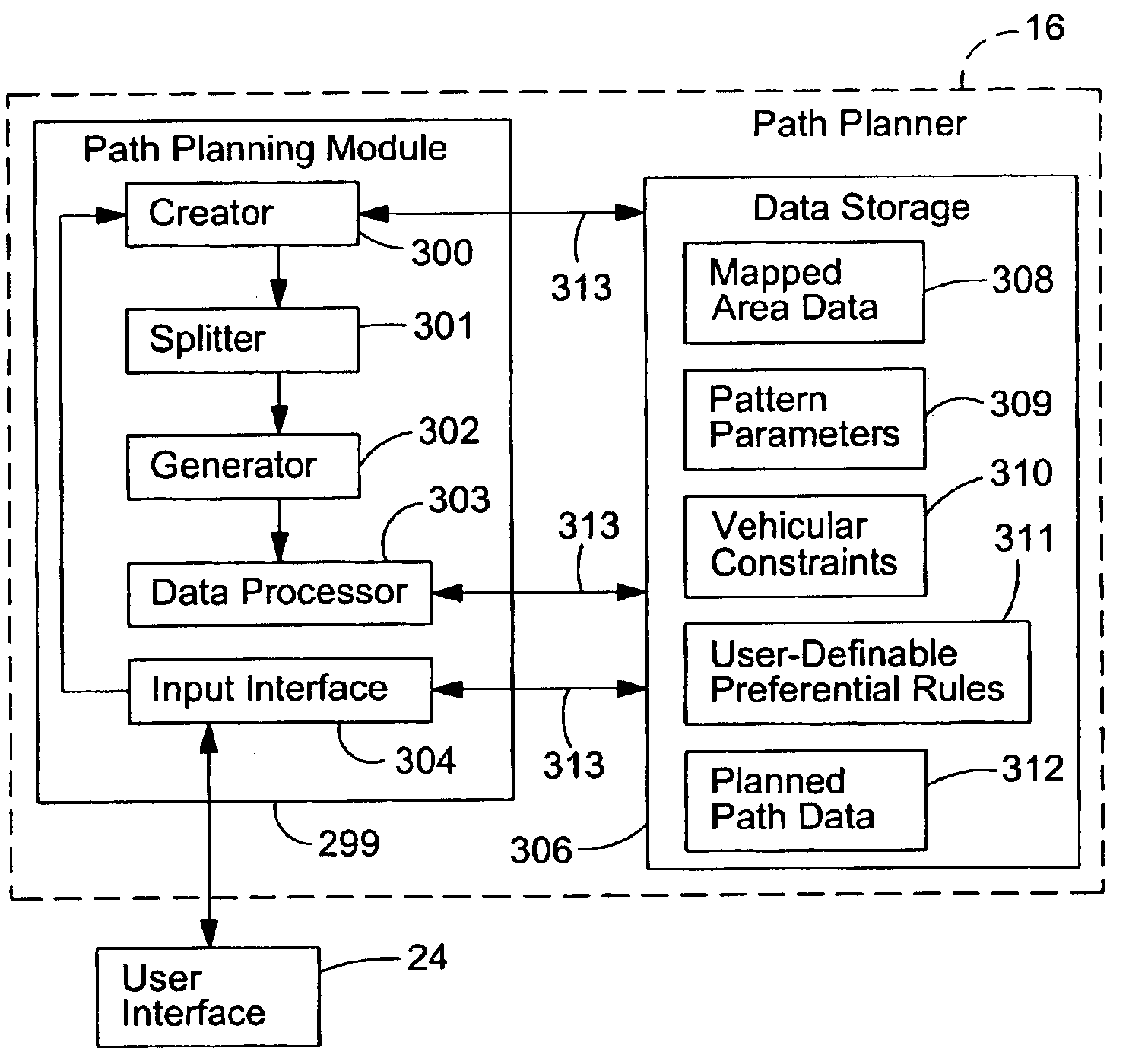

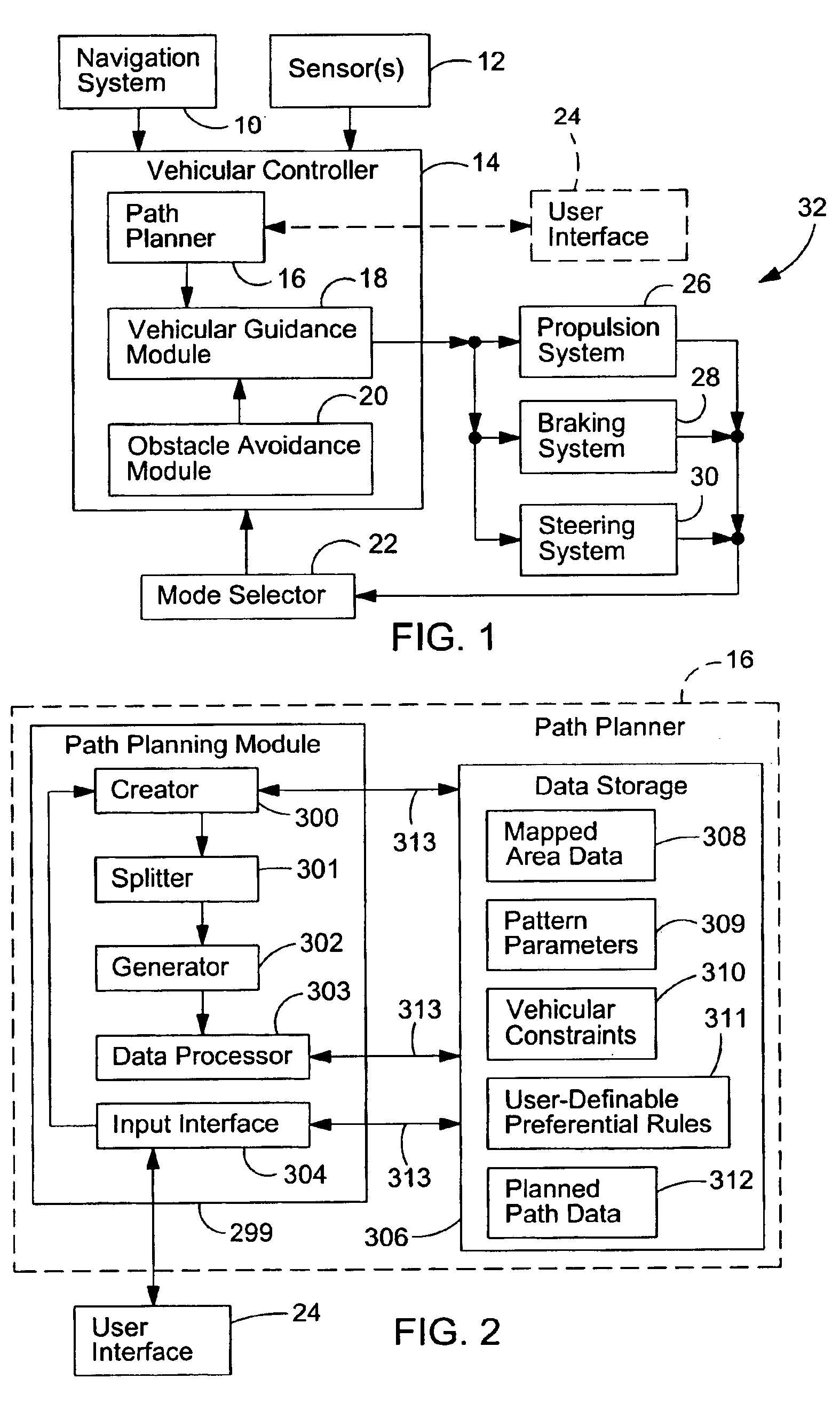

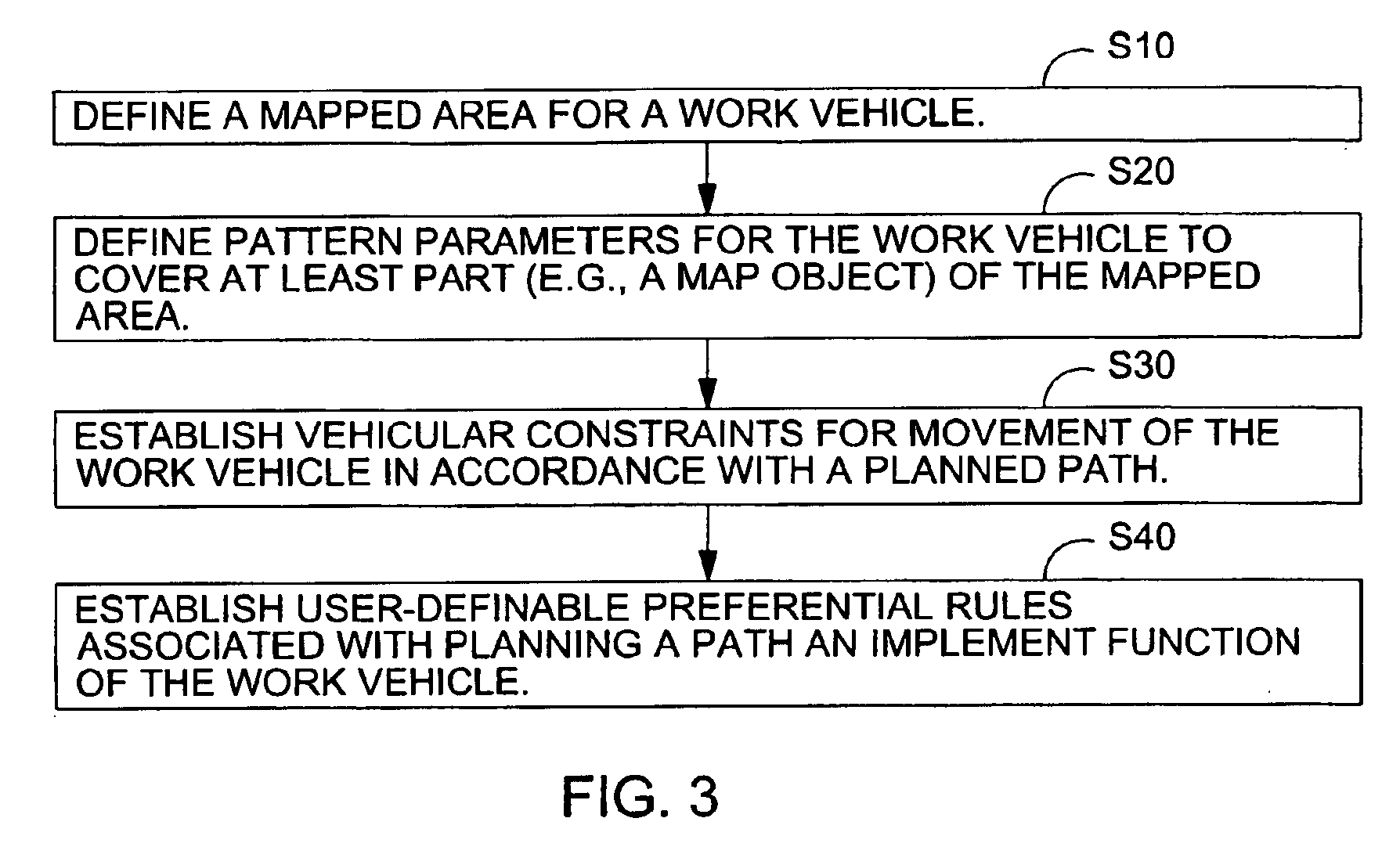

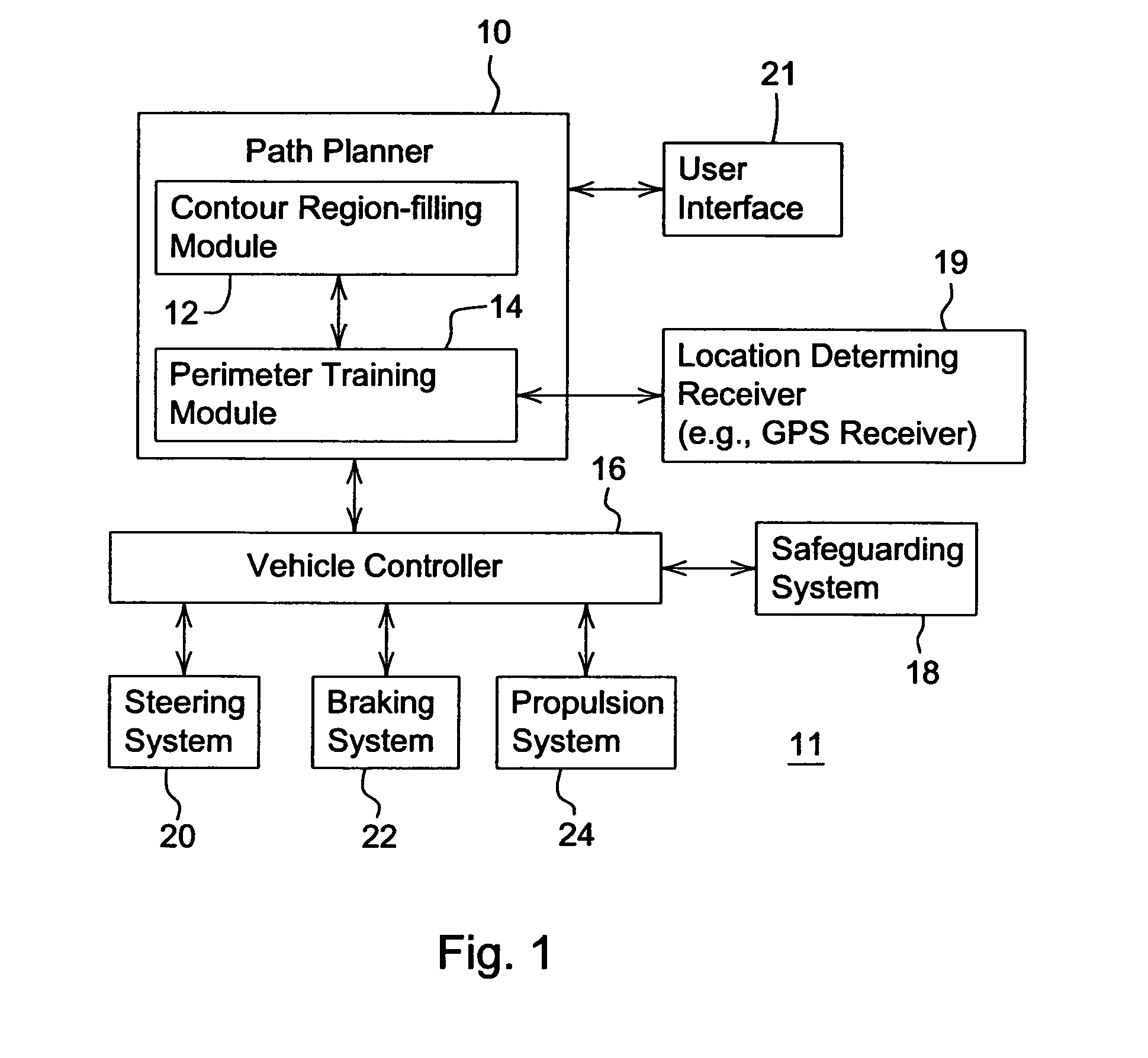

Path planner and a method for planning a path of a work vehicle

InactiveUS7010425B2Instruments for road network navigationAnalogue computers for trafficUser inputReal-time computing

A method for planning a path for a vehicle comprises creating a travel row transparency over a mapped area. The travel row transparency comprises one or more travel rows are split into travel row sections defined by intersecting the travel row with a map object (e.g., a boundary of mapped area). Partition nodes are generated from the travel row sections. The partition nodes or partition edges are linked together to form a potential drivable path consistent with user input and vehicular constrains. An efficient ordering of the partition nodes are determined consistent with the user input. A path is generated by looping through the ordered partition nodes in the determined efficient order.

Owner:DEERE & CO

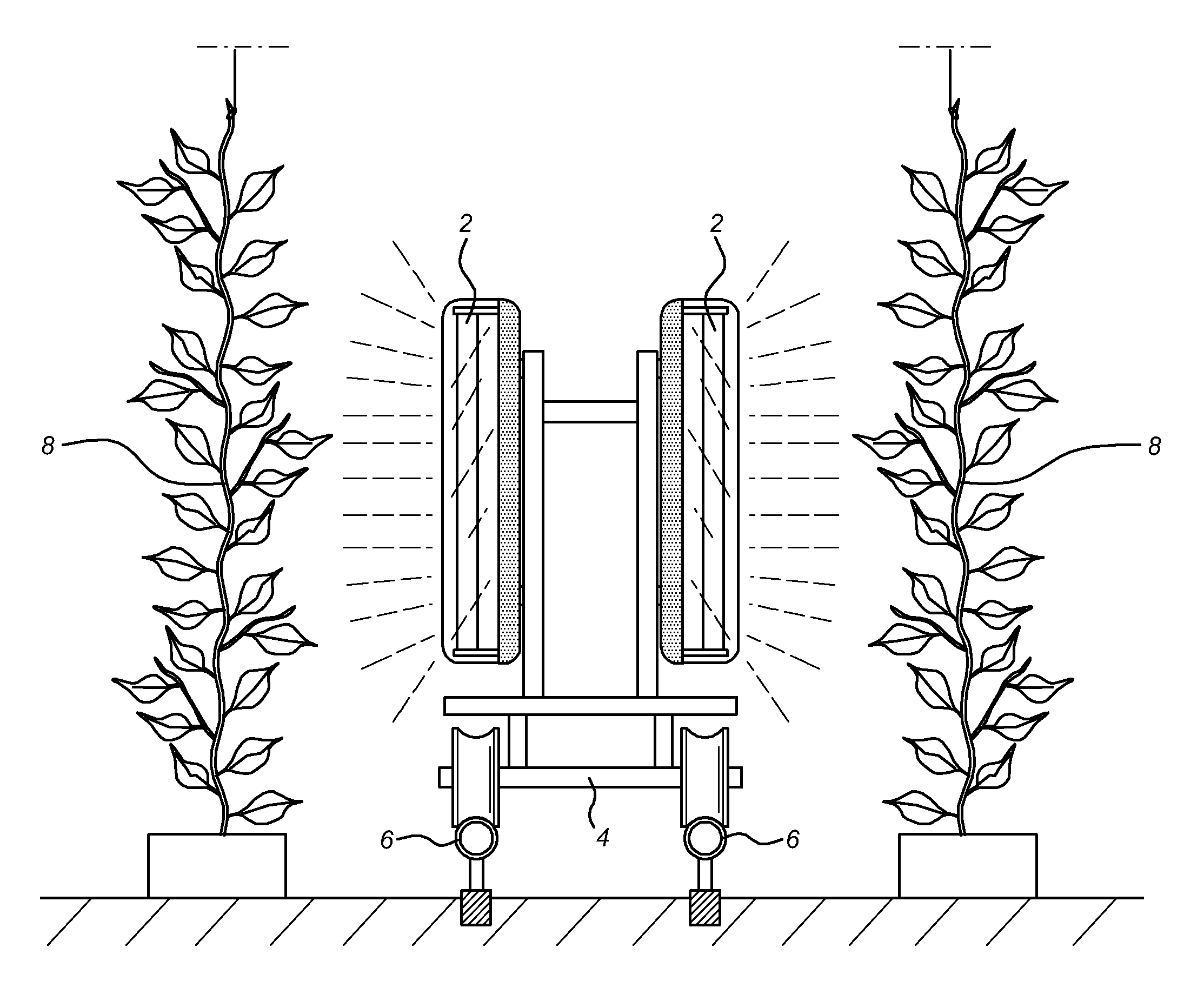

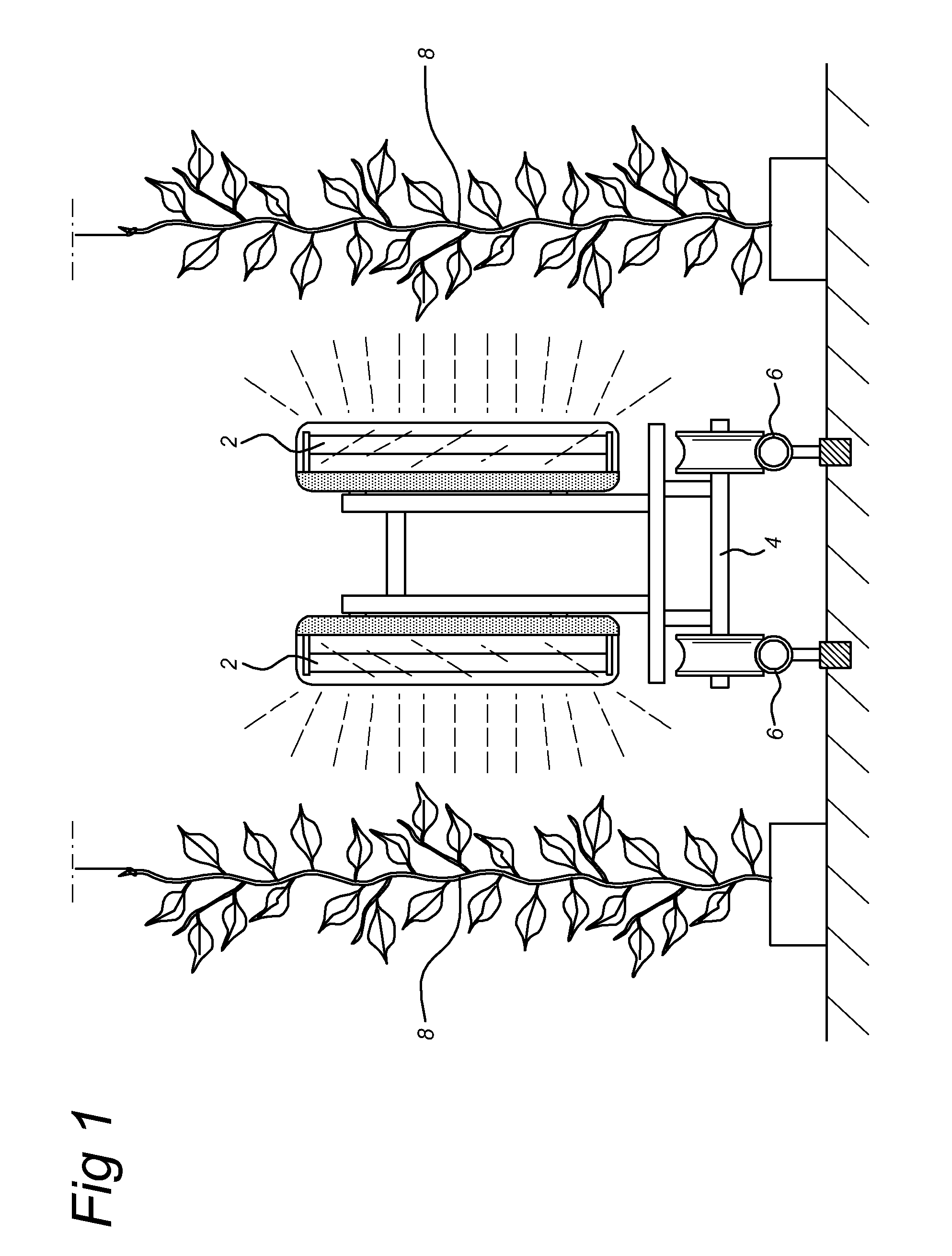

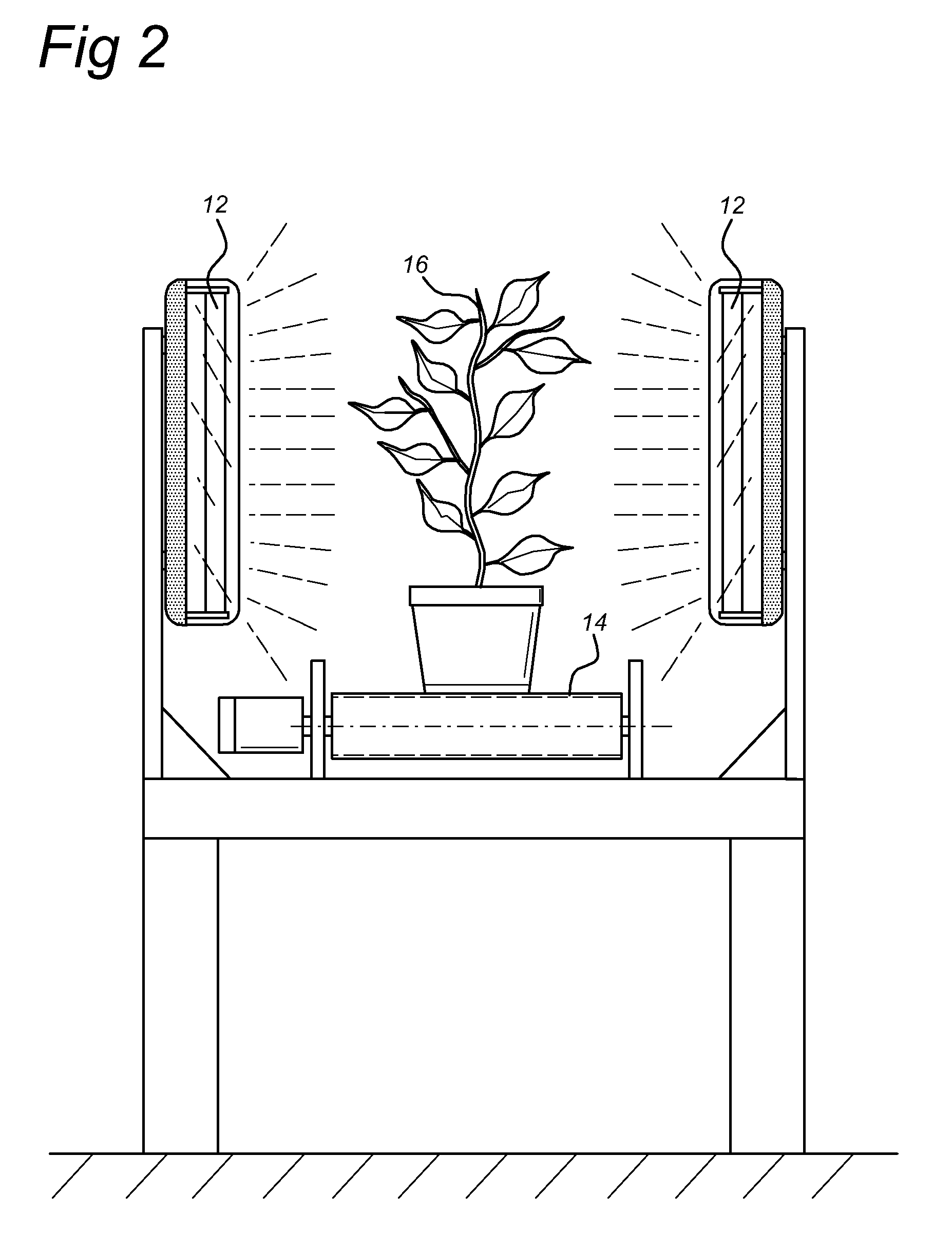

Methods for Treating Live Plants or Live Plant Parts or Mushrooms with UV-C Light

InactiveUS20090272029A1Increase humidityIncrease crop yieldDead plant preservationAgricultural machinesPlant TubersMushroom

The present invention relates to a method for controlling pathogen growth on live plants and mushrooms using UV-C light and an apparatus for use in the method. Also provided are methods for removing surplus leaves and methods for destroying aerial plant parts prior to harvest of underground roots, tubers or bulbs.

Owner:CLEAN LIGHT

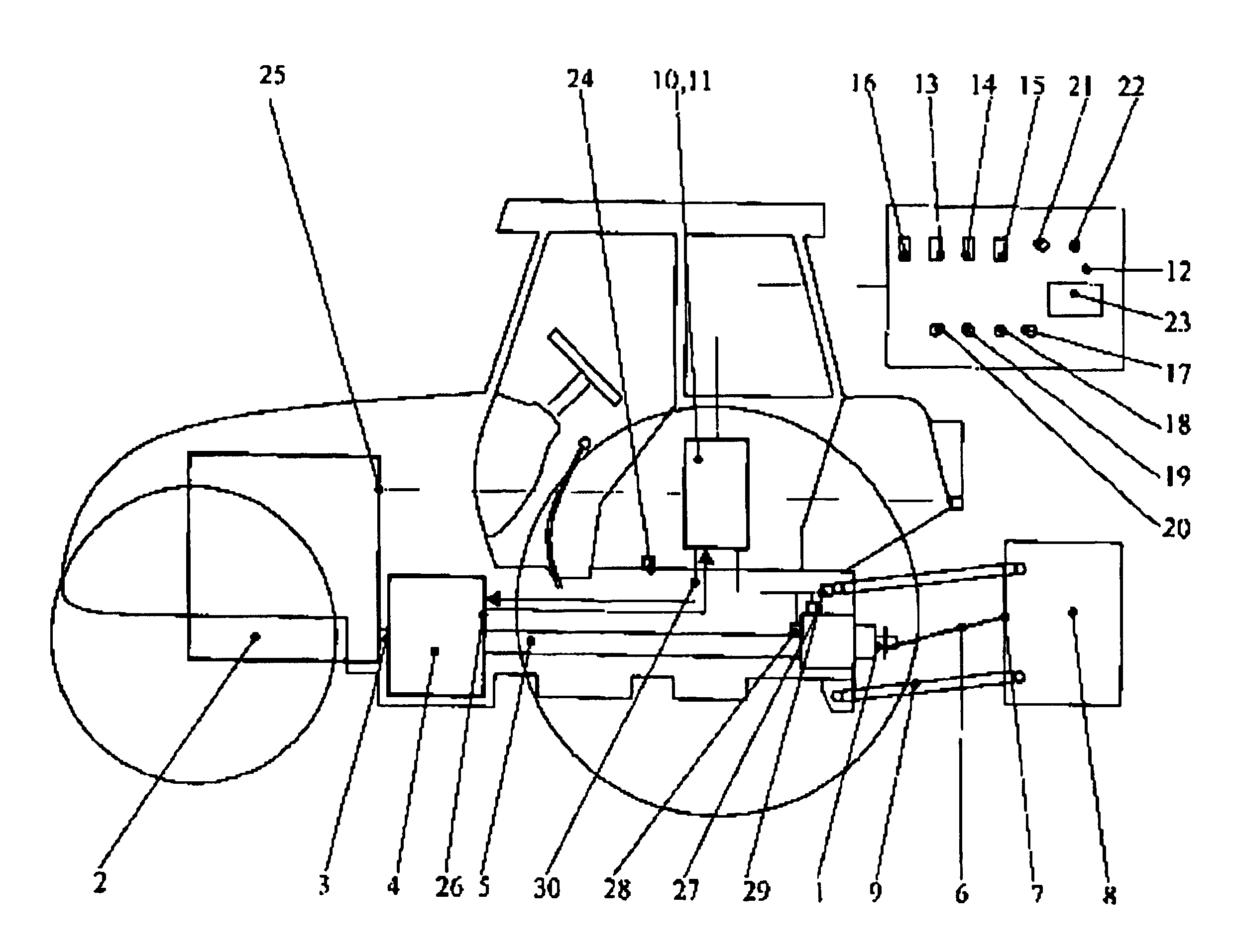

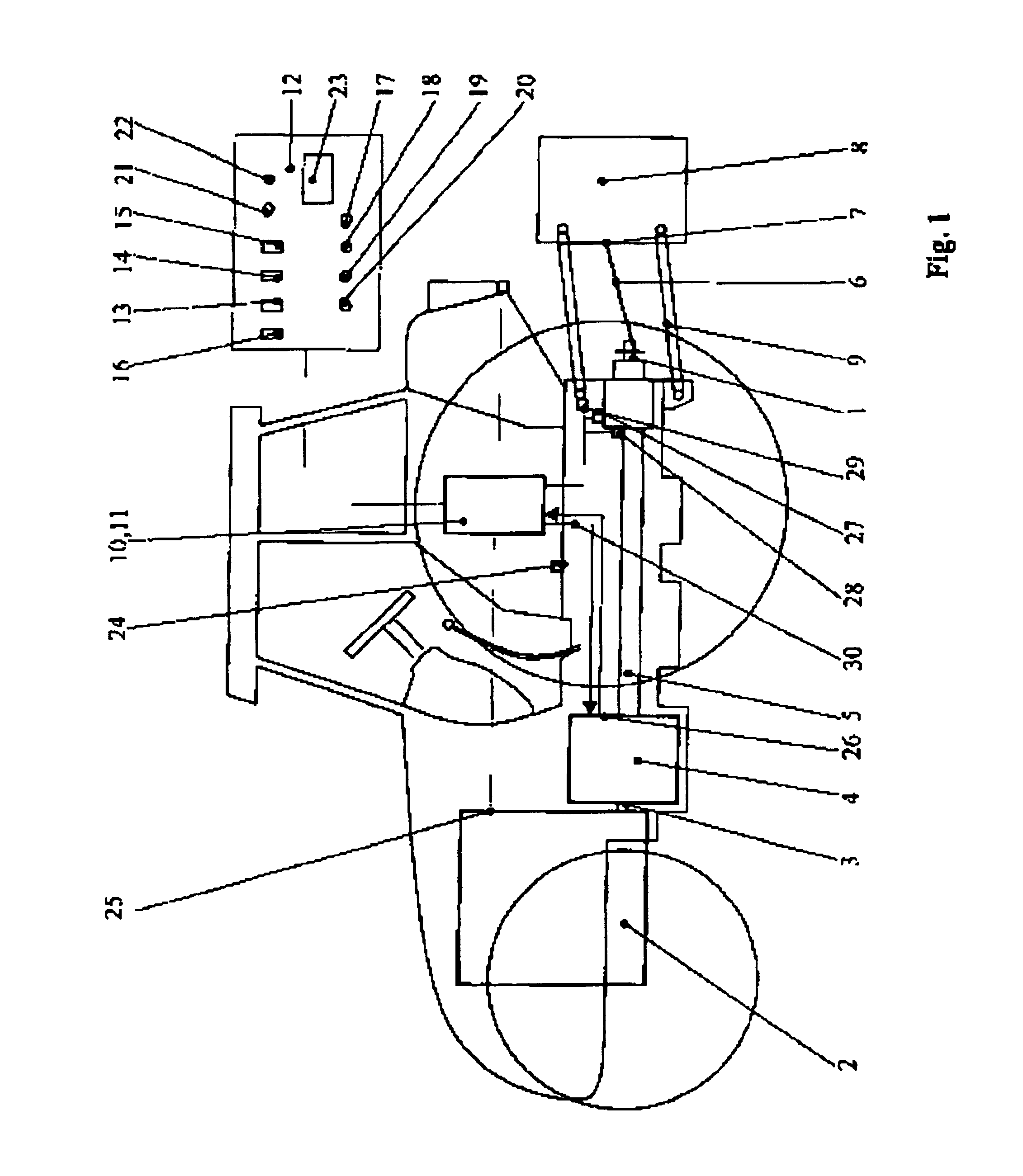

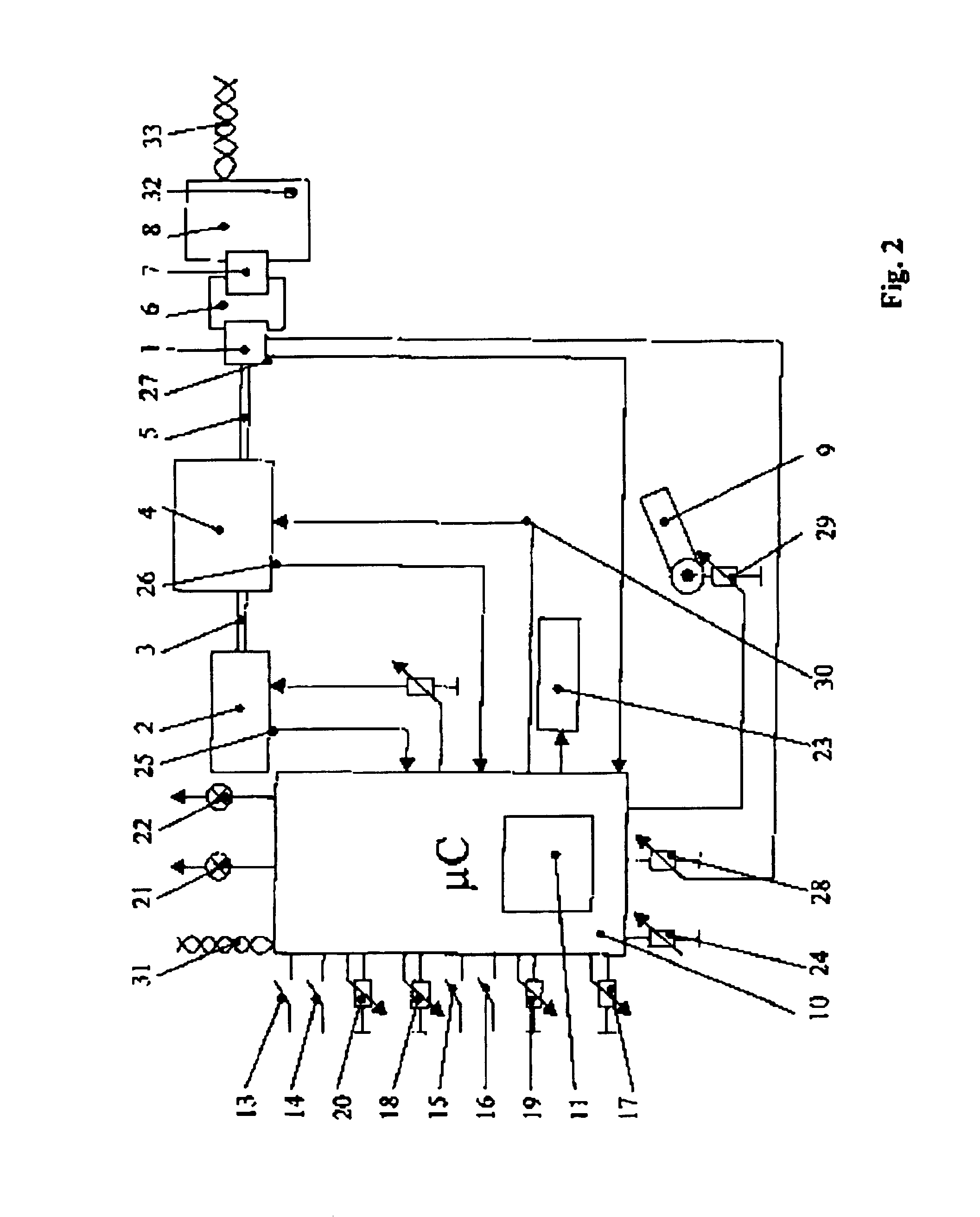

Control system for the drive of a pto for an agricultural vehicle

InactiveUS6942595B2High power uptakeIncrease powerAuxillary drivesAgricultural machinesControl systemActuator

A control system for the drive of a power take-off mechanism on an agricultural tractor that records machine-specific values of the implement attached to the tractor. The drive train between the tractor engine and the power take-off includes a CVT transmission. The control device is connected with a processor via a signal lead for receiving its output signals. The control device is connected for the formation of output signals via input leads with switches, controls, sensors, and actuators for the tractor to read the machine specific parameters of the attached implement.

Owner:BLUE LEAF I P INC +1

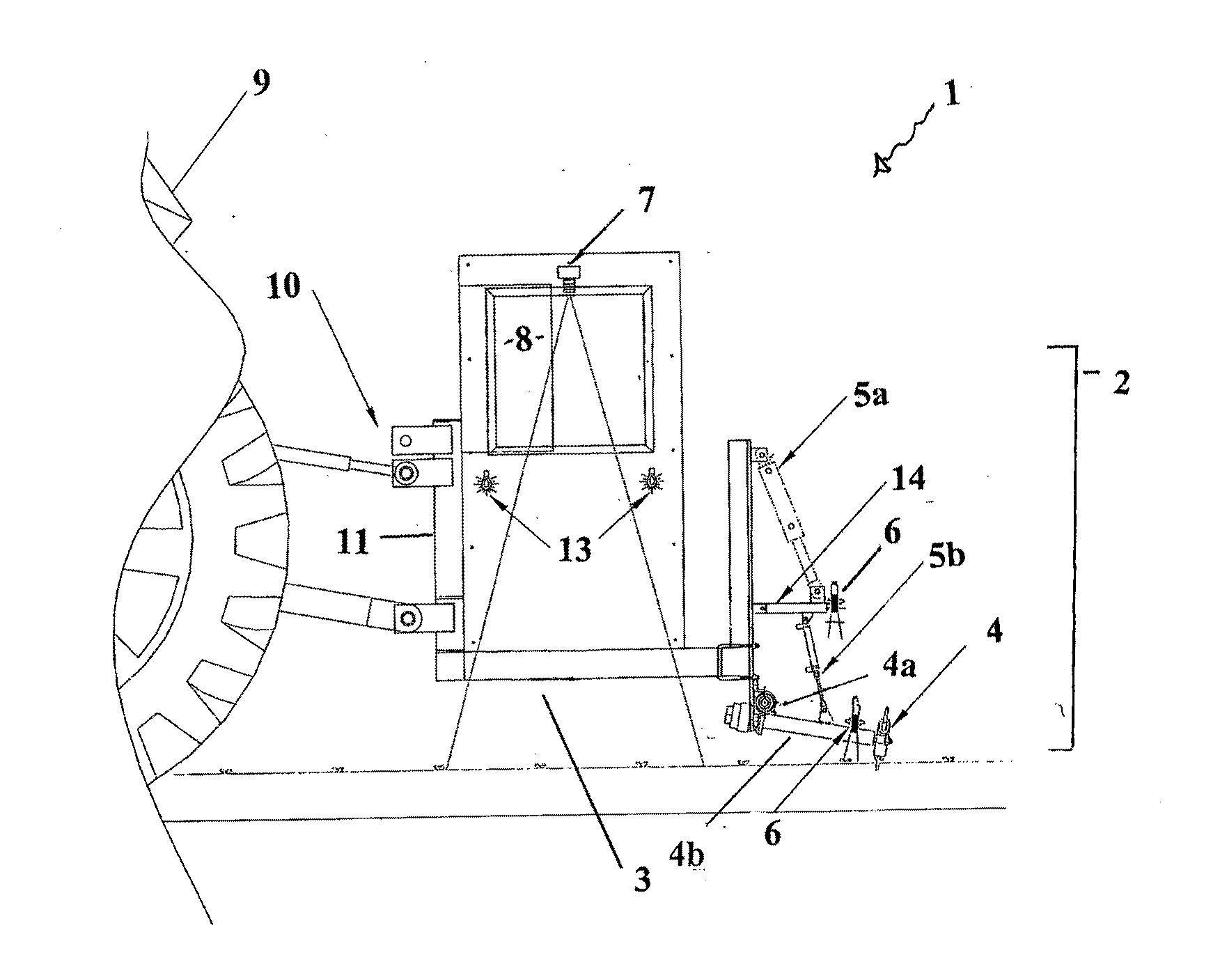

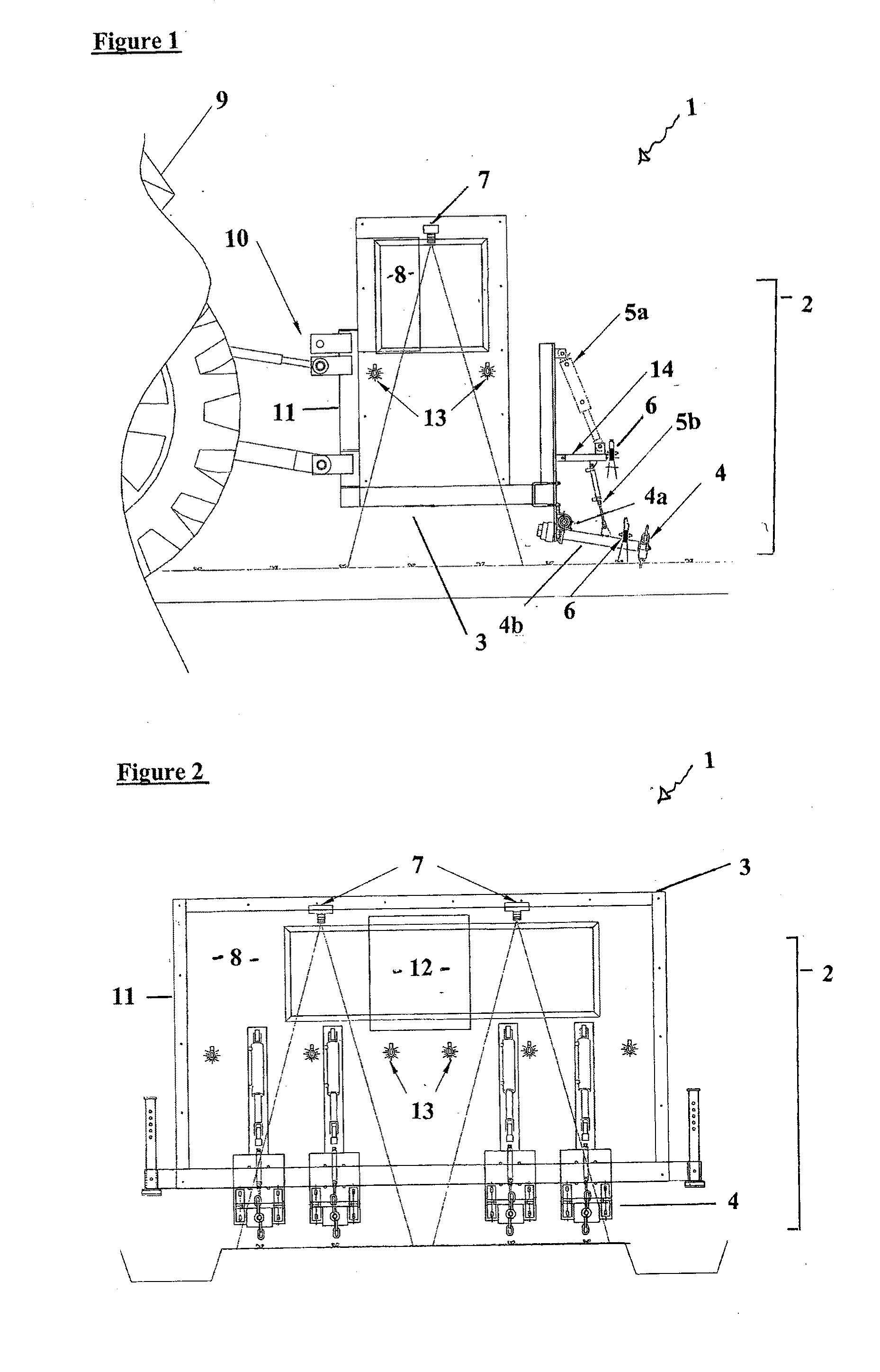

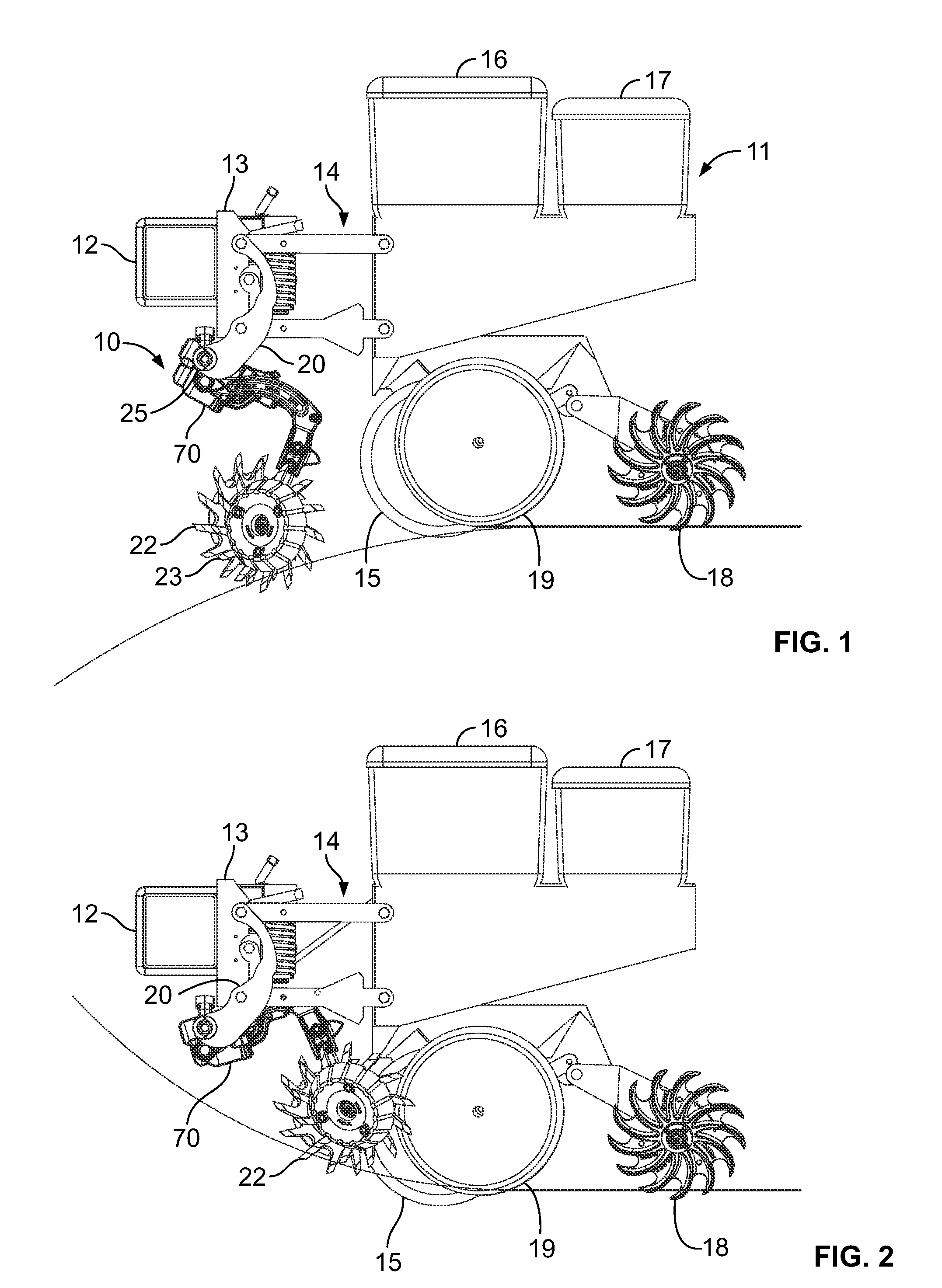

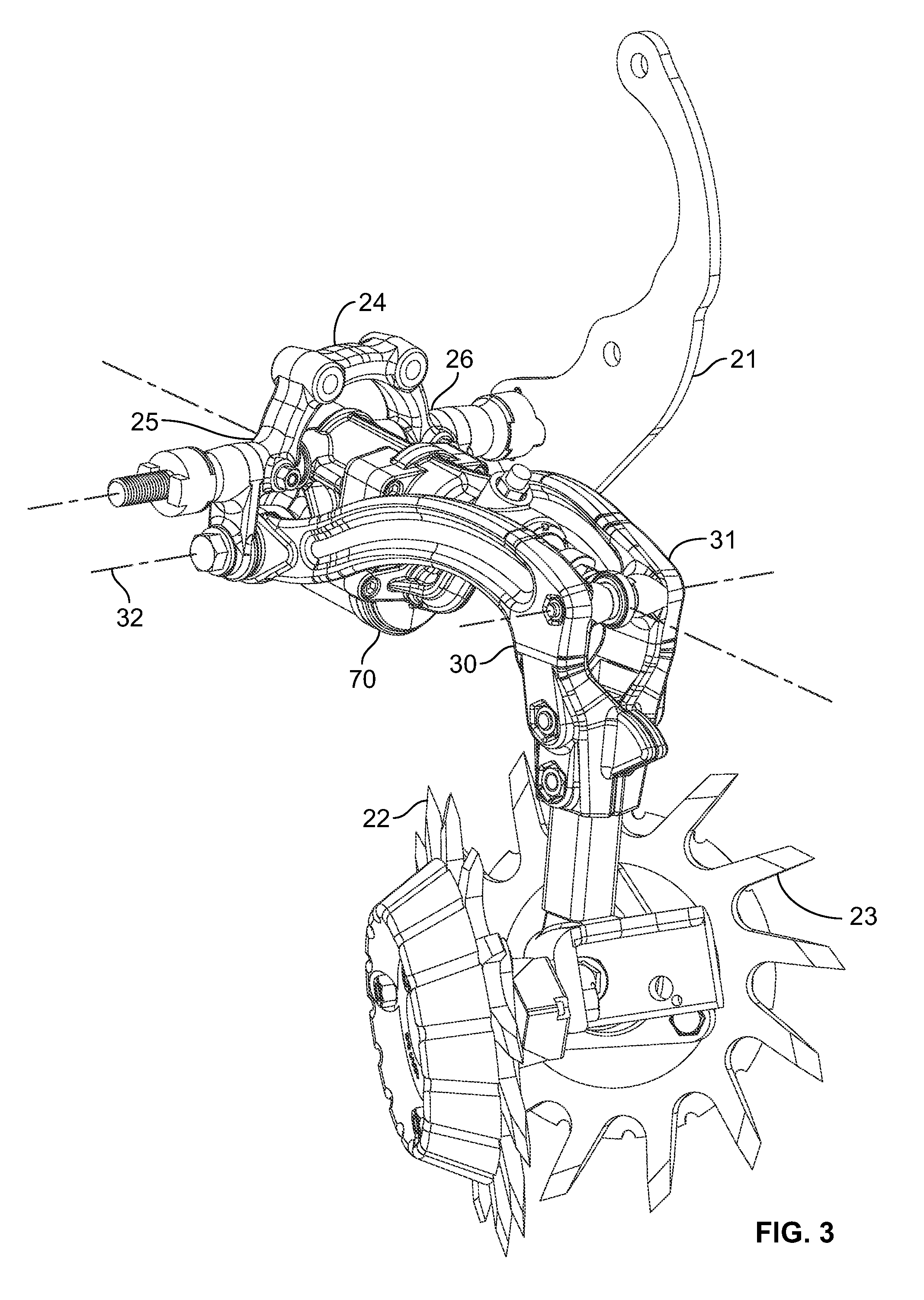

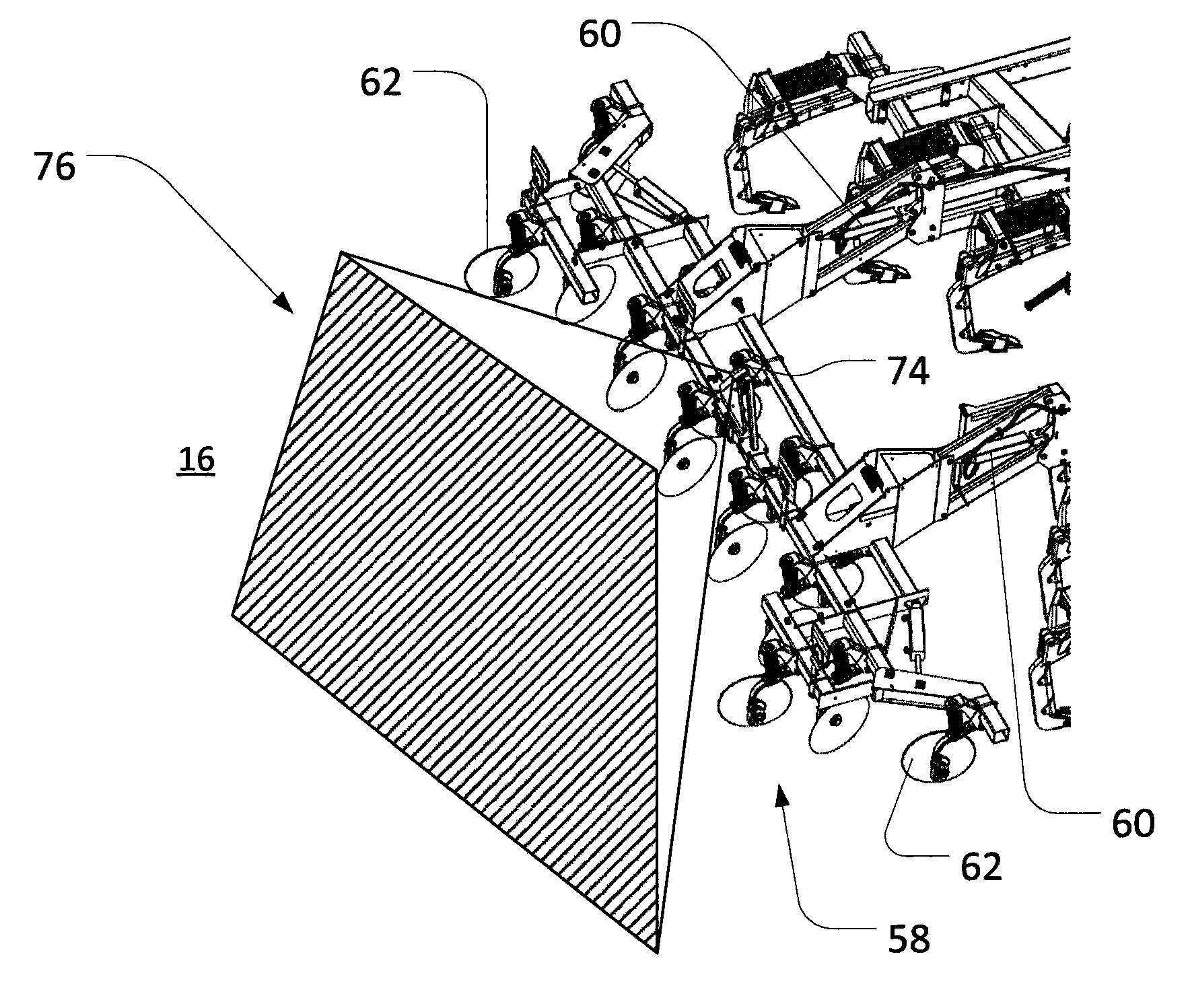

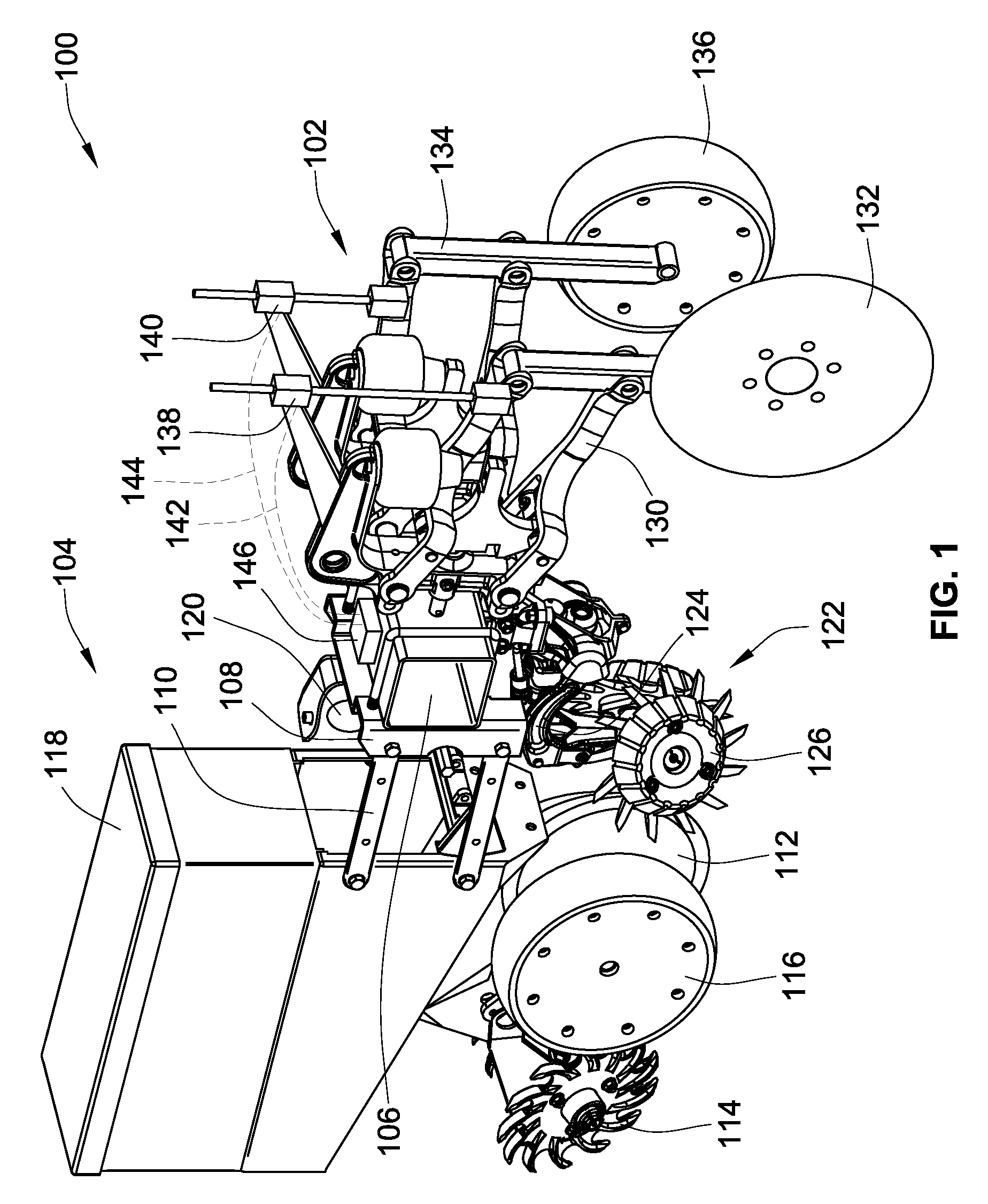

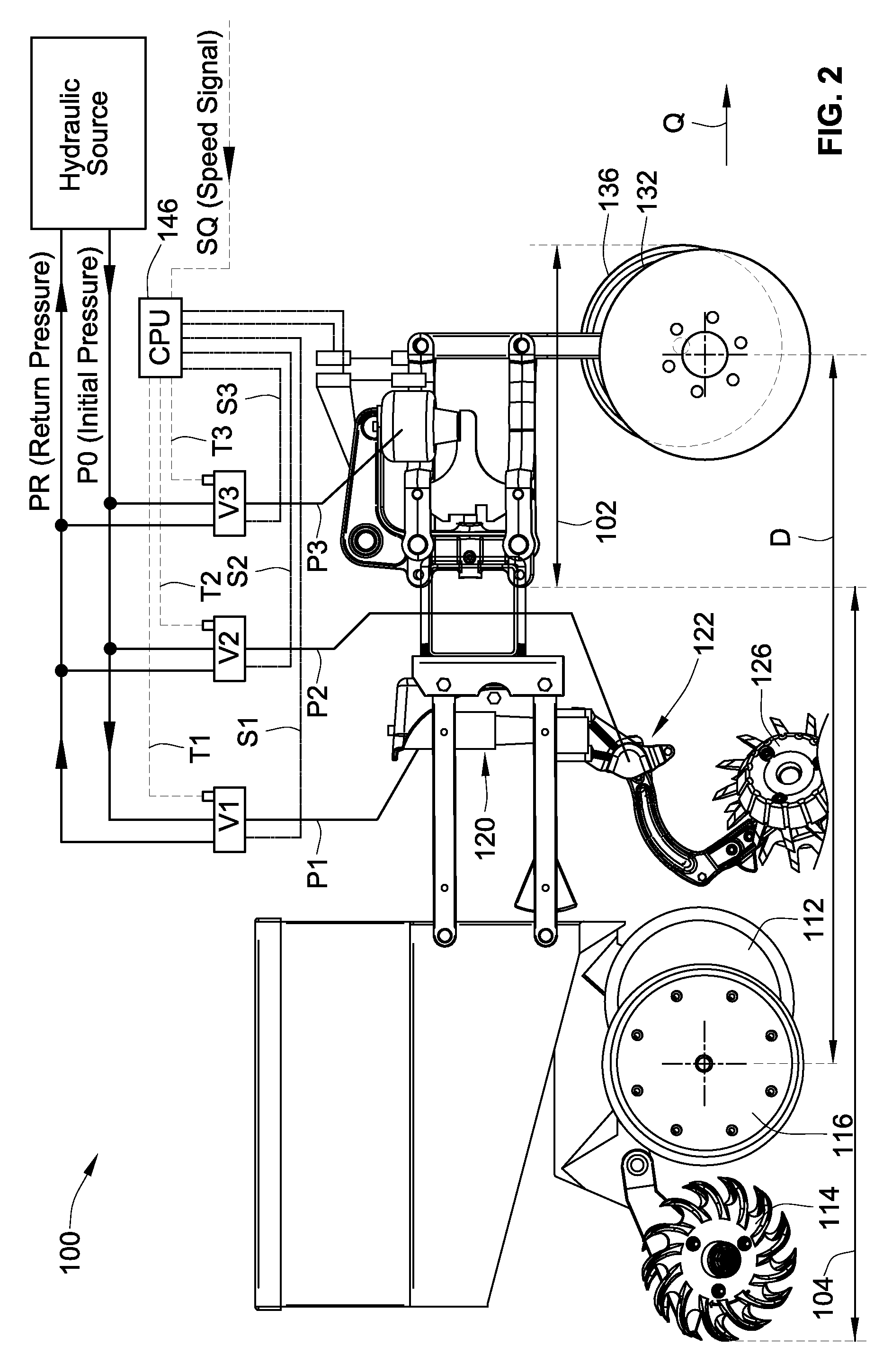

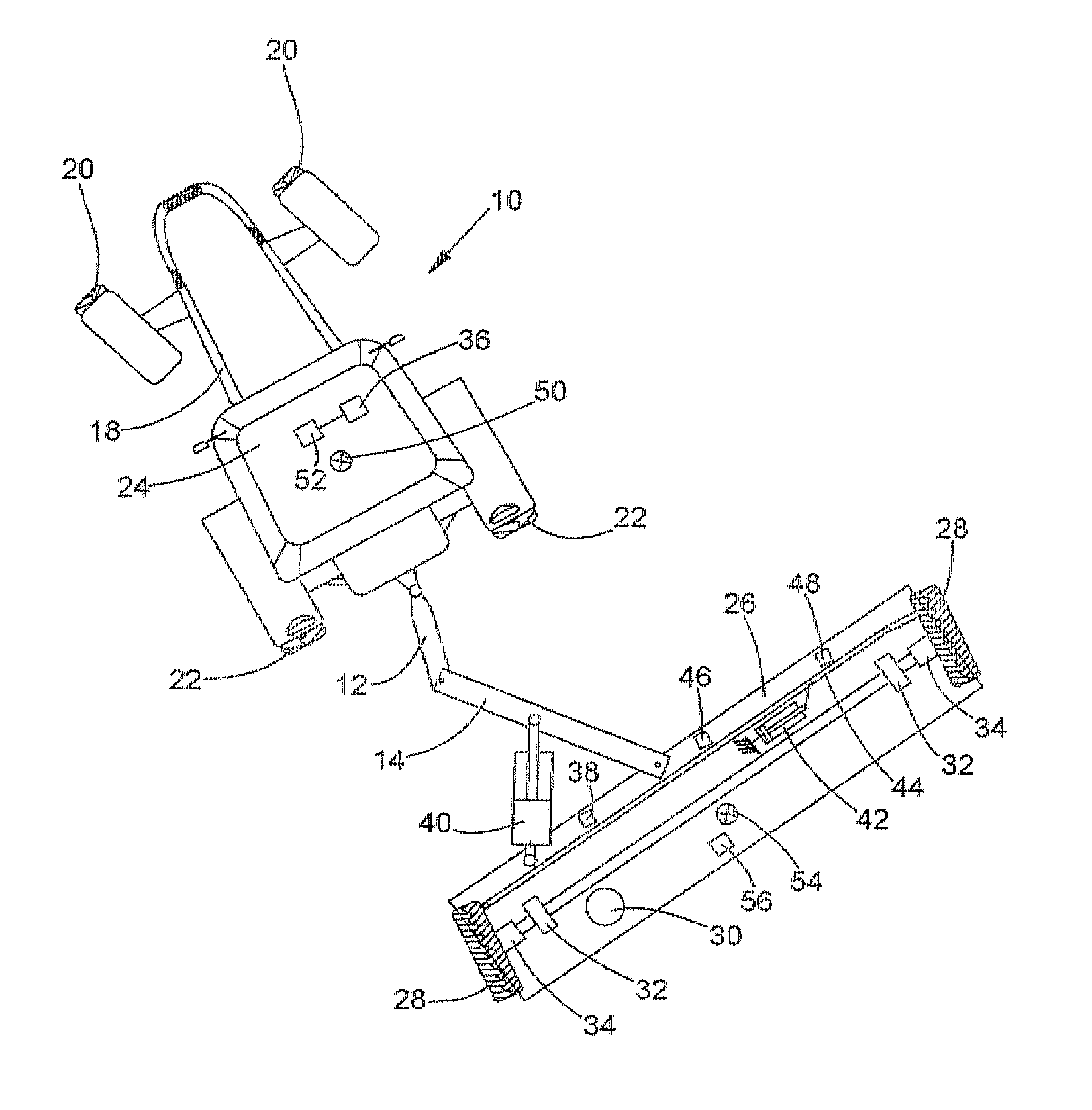

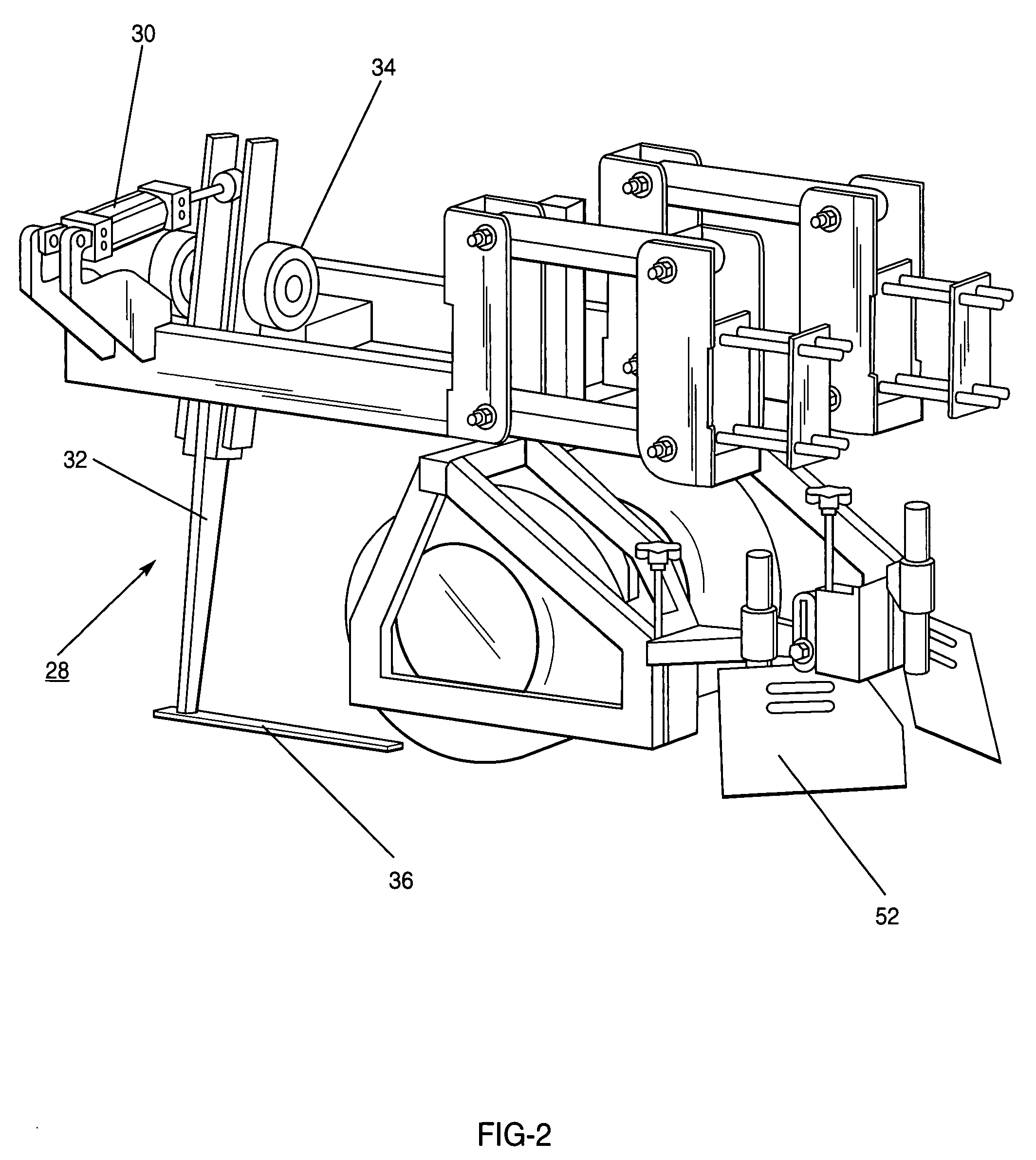

Crop thinning systems

InactiveUS20110211733A1Achieve the thinning or weeding of crops more economicallyImage enhancementImage analysisImaging processingThinning

A thinning or weeding apparatus includes an image processing apparatus. The image processing apparatus includes an automated visual detection system which includes a visual sensor system and an image processing system capable of receiving an image from the visual sensor system. The image processing apparatus then processes the image in the image processing system to determine where plants are located and to determine which plants will be thinned or weeded and which will not.

Owner:FOOTHILL PACKING

Agricultural implement with automatic down pressure control

Owner:DAWN EQUIPMENT COMPANY

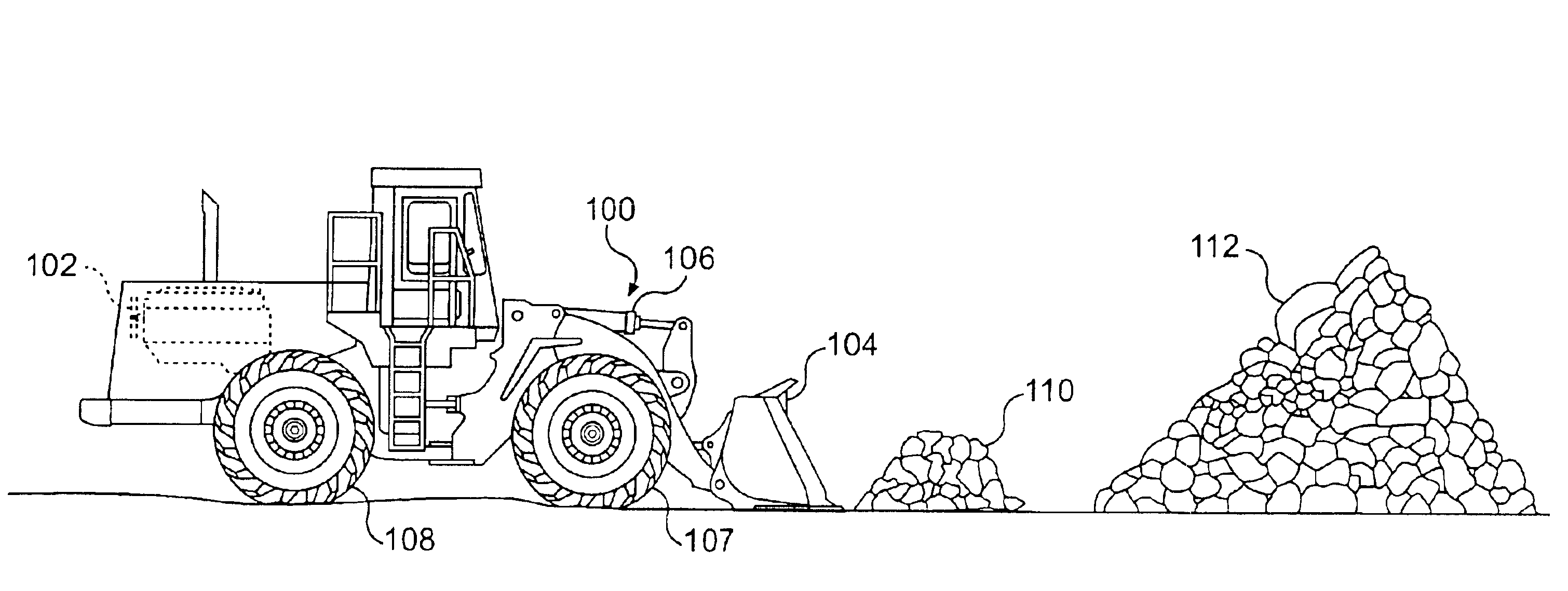

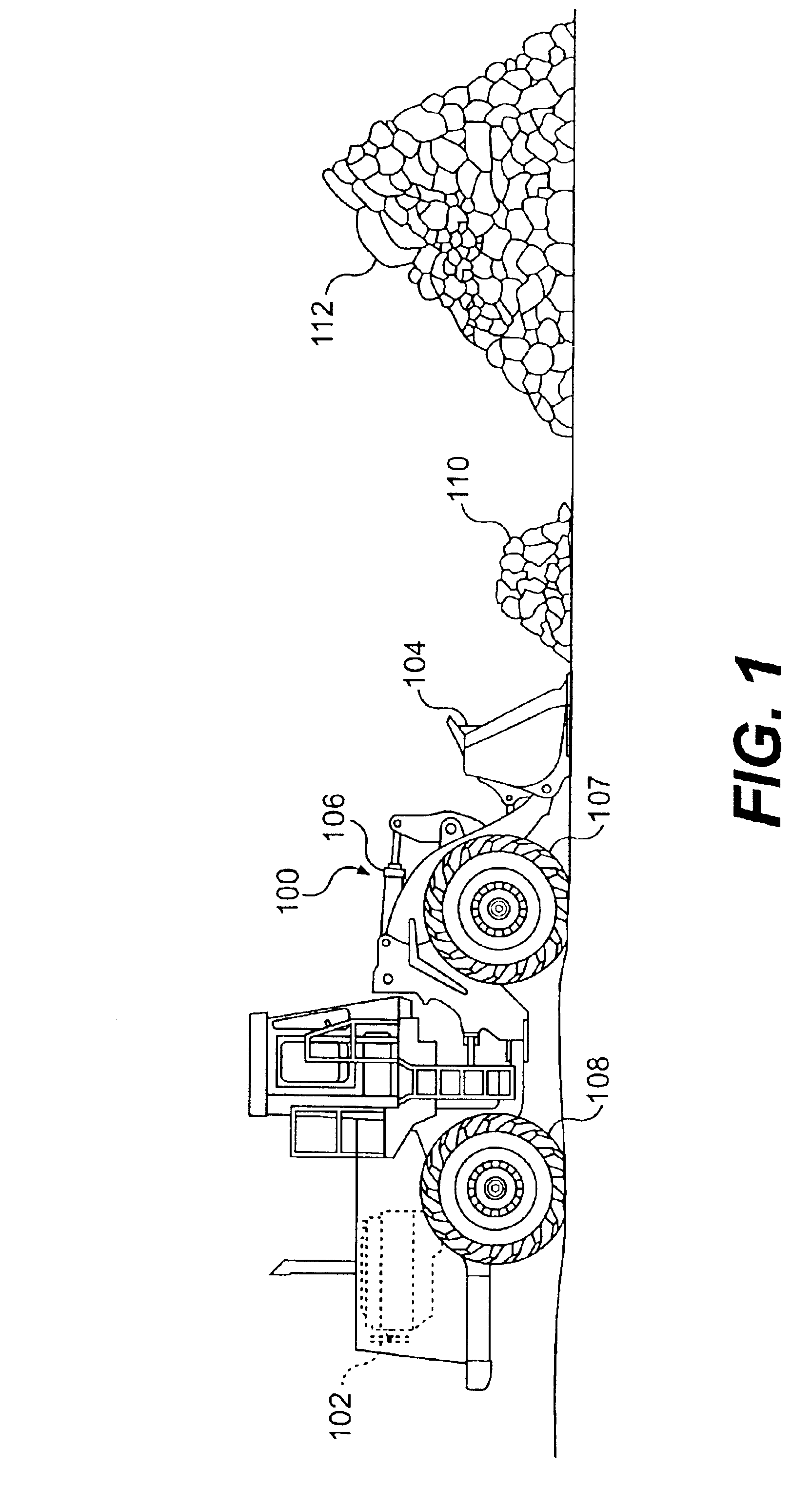

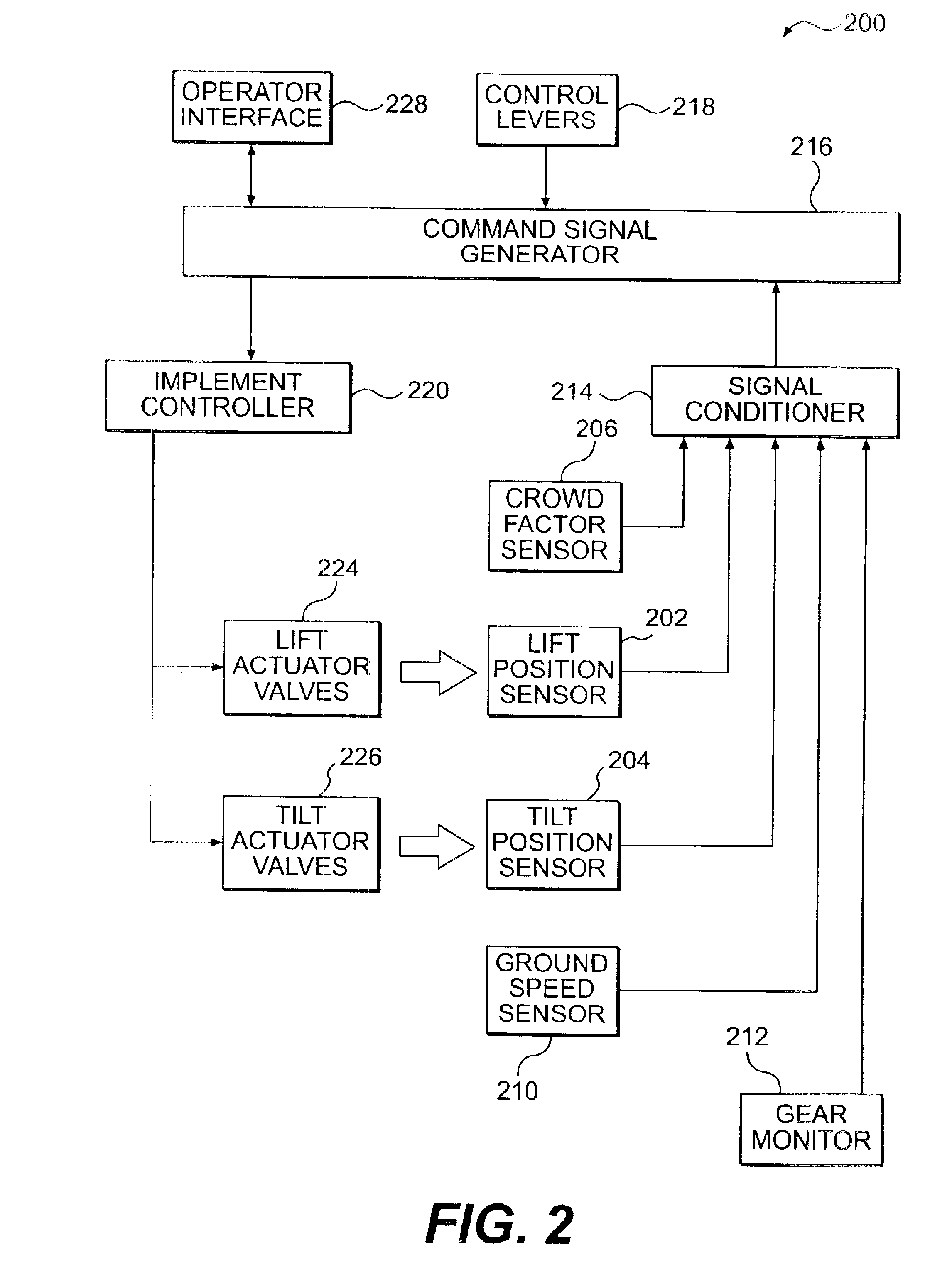

Method and system for automatic bucket loading

A method for controlling an automatic bucket control system during loading of a work implement of a work machine is disclosed. The method includes the steps of determining when the work implement engages a pile of material, initiating the automatic bucket control system in response to the work implement engaging the pile of material, determining a ground speed of the work machine, and generating a lift command based upon the ground speed. After fully engaging the material, the system may further adjust tilt commands and / or lift commands based upon a monitored crowd factor to control operation of the work implement.

Owner:CATERPILLAR INC

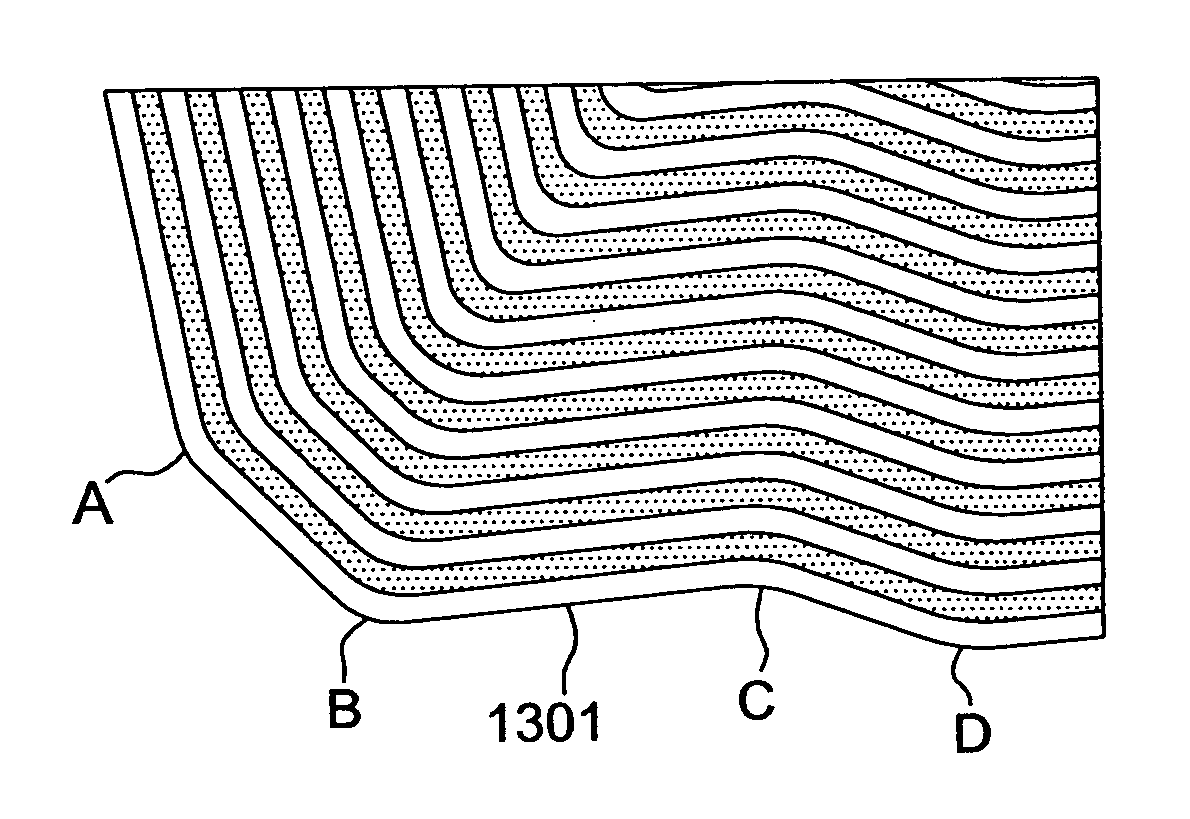

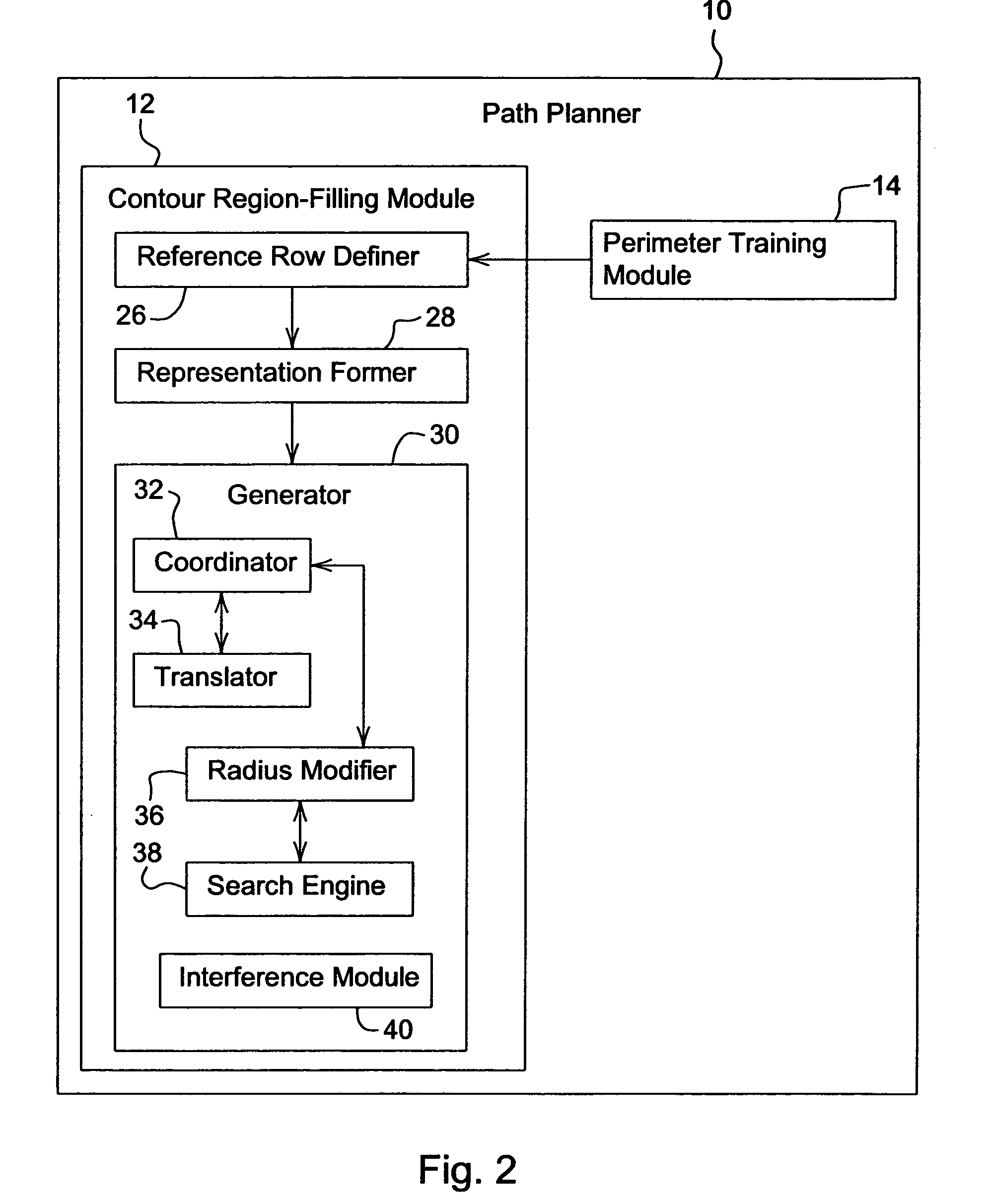

Path planner and method for planning a contour path of a vehicle

InactiveUS7216033B2Instruments for road network navigationRoad vehicles traffic controlLinear componentComputer graphics (images)

In accordance with one embodiment of the invention, a path planner and method for planning a path of a vehicle defines a reference row having a reference contour in a work area. A representation of the defined reference row is established. The defined reference row comprises a curved component, a generally linear component, or both. A generator generates one or more contour rows with a tracking contour that tracks or mirrors the reference contour based on a vehicular width and a radius difference parameter associated with the curved component. The contour rows are generated by a translation technique for the generally linear component and a radius modification technique for the curved component.

Owner:DEERE & CO

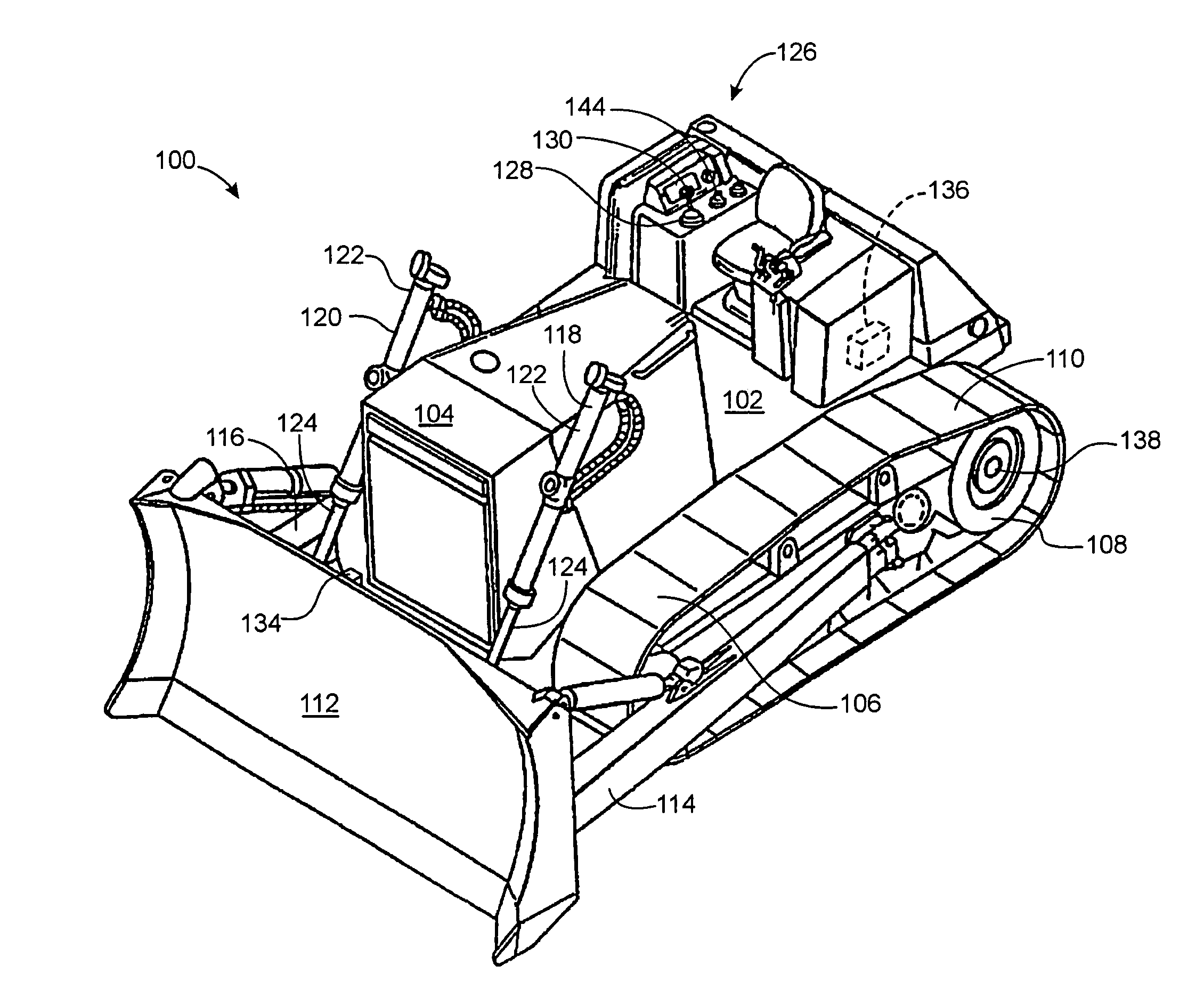

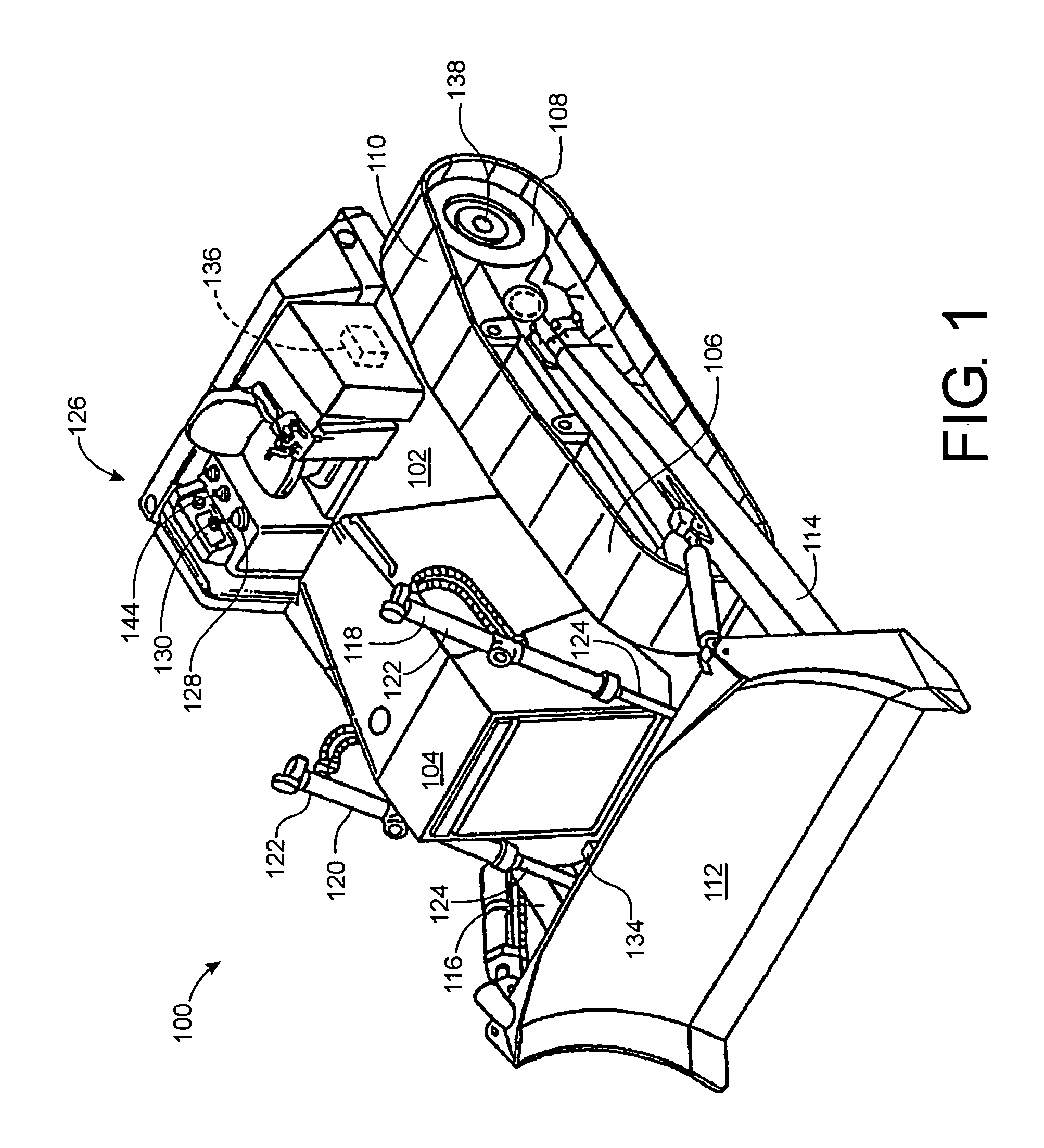

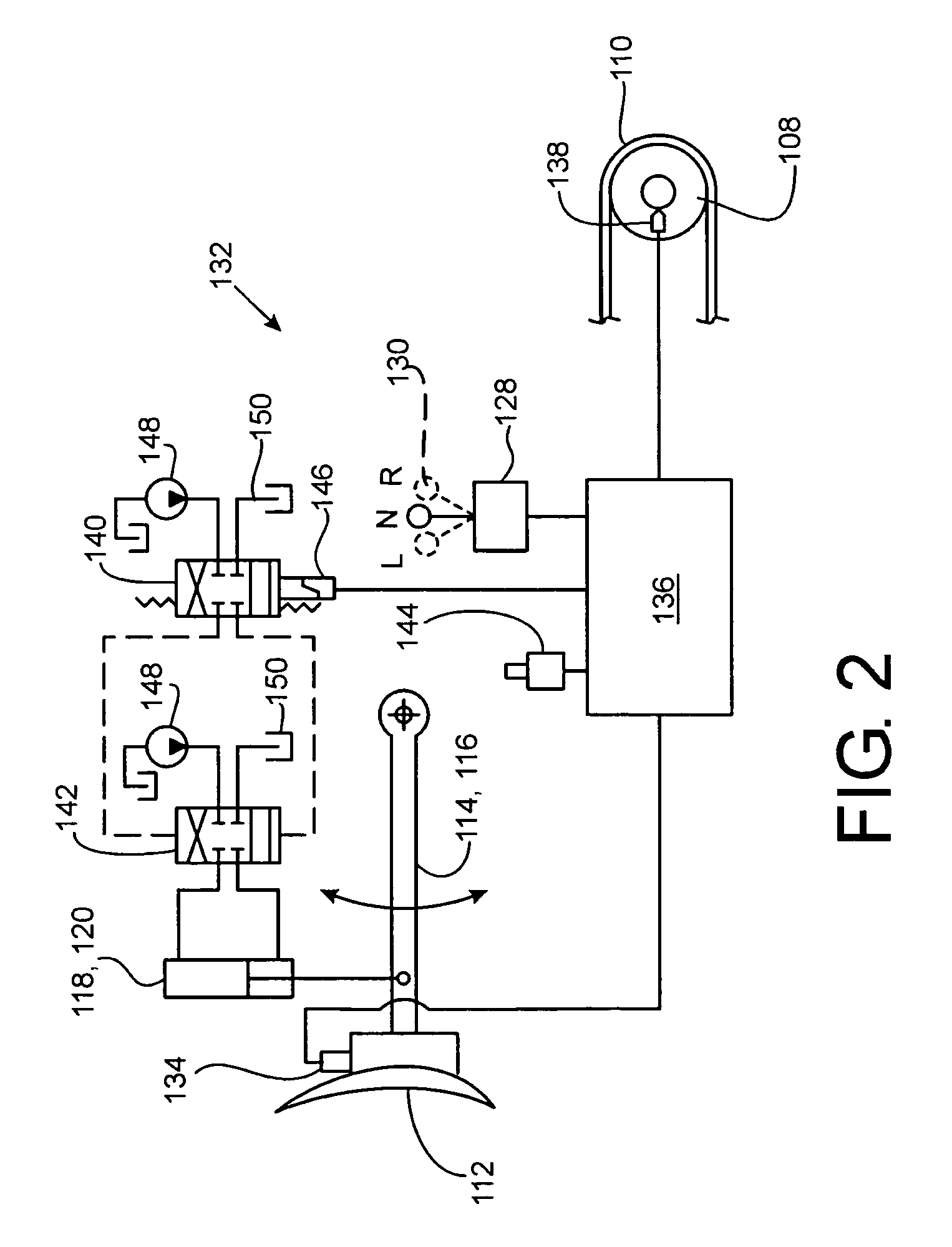

Bulldozer autograding system

A dozer blade control system controls the position of a bulldozer blade, maintaining the blade at a constant position as the dozer travels through a worksite. The control system monitors the angle of the dozer blade with respect to the earth and when it senses that the dozer blade is tilting, it corrects the dozer blade's position by extending or retracting hydraulic cylinders that couple the dozer blade to the chassis of the crawler-tractor. When the dozer chassis pitches forwards, the blade begins to tilt forward and to drop closer to the ground. The control system senses this forward rotation of the blade and retracts the hydraulic cylinders that couple the blade to the chassis, causing the blade to return to and maintain its original position. Conversely, when the dozer chassis pitches backwards and the blade begins to tilt backward and rise higher above the ground, the control system extends the hydraulic cylinders coupling the blade to the chassis and lowers the blade, causing the blade to return to and maintain its original position with respect to the earth.

Owner:BLUE LEAF I P INC

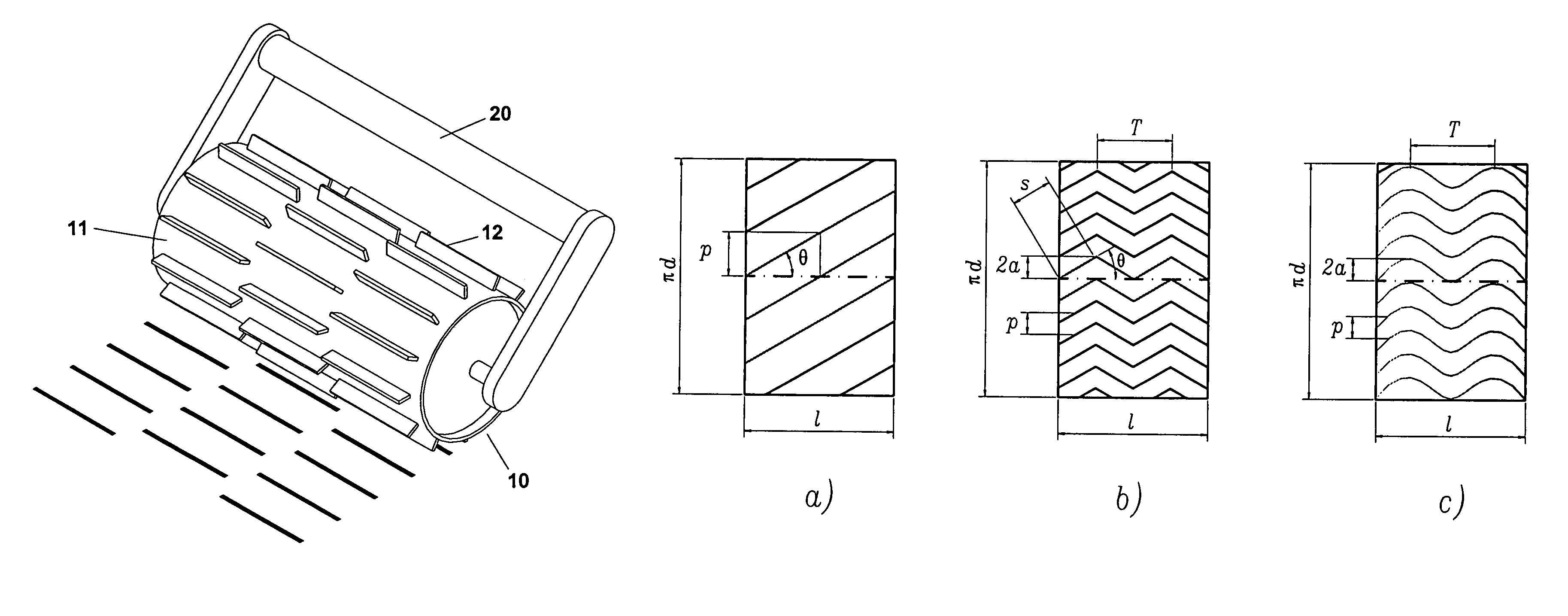

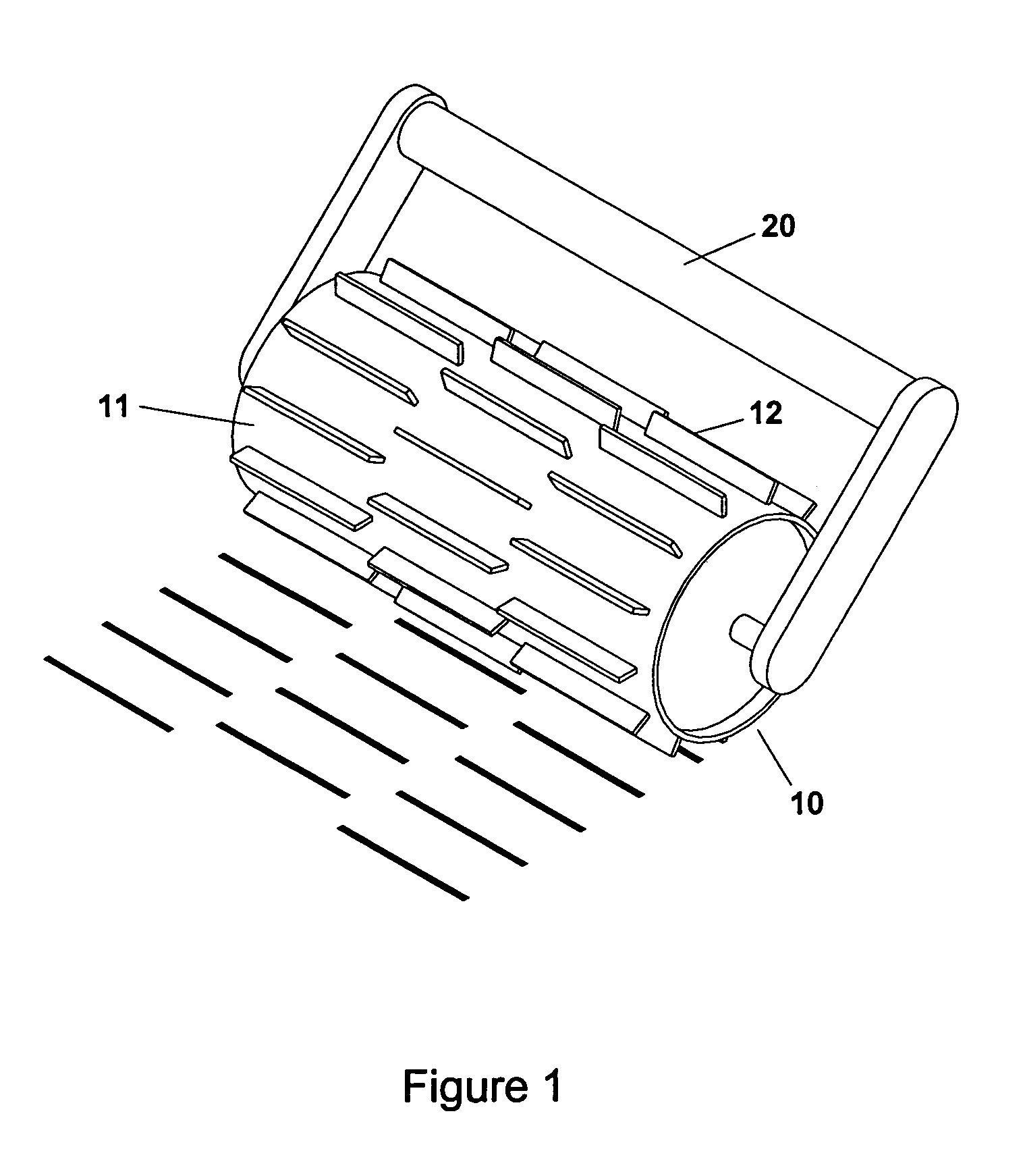

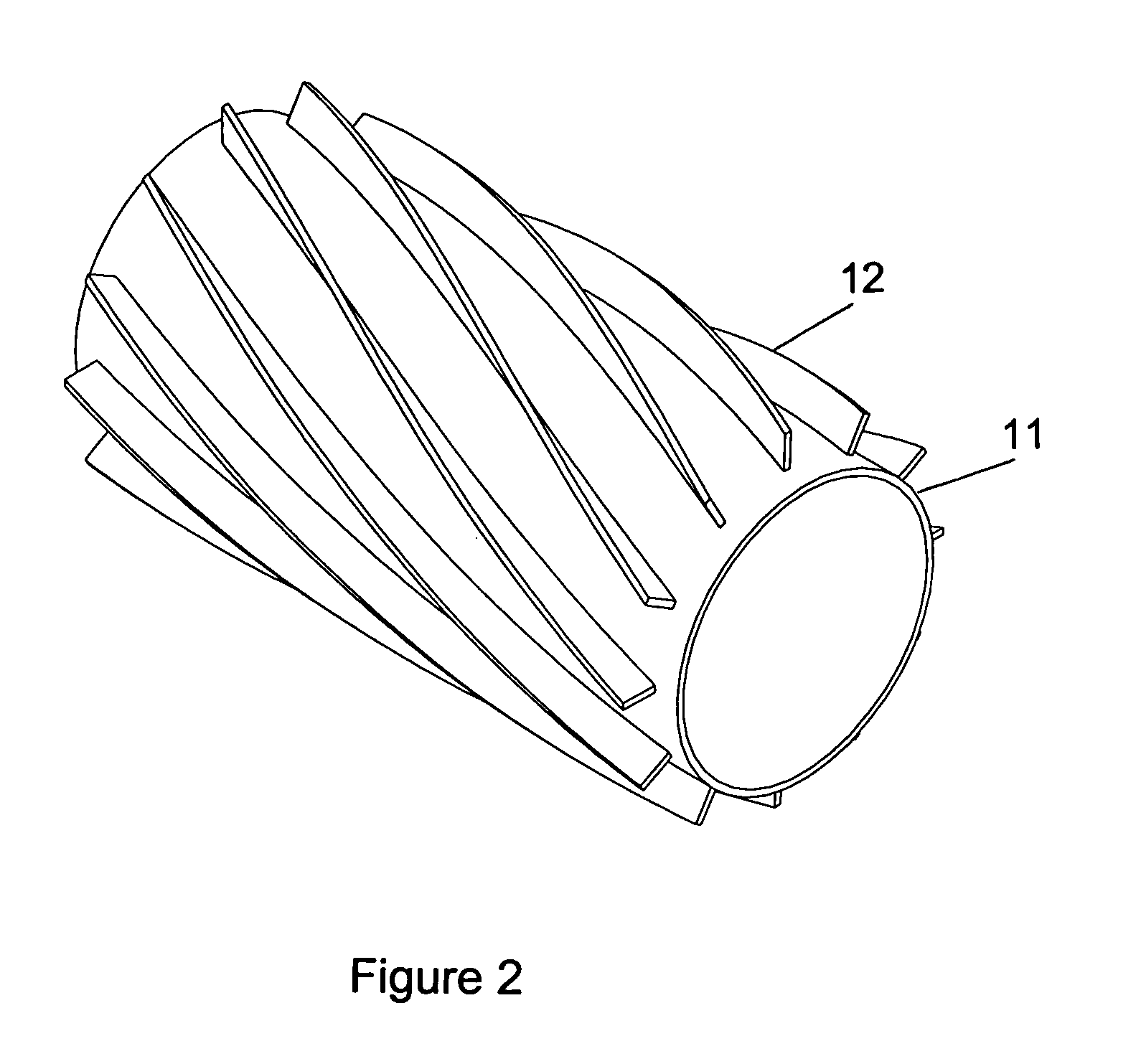

Smooth rolling cover crop roller

Cover crops may be rolled and crimped using an apparatus which may be rolled across a field at a relatively high speed without excessive vibration. The apparatus includes a substantially cylindrical drum which has a plurality of rows of outwardly extending blades projecting therefrom. The blades may be wave-shaped, curved, substantially straight and discontinuous, blades paired with a plurality of spaced apart outwardly extending rings, or combinations thereof. In use as the apparatus is rolled across a field having a crop thereon, the blades contact and crimp the stalks of the crop, effectively killing the plant.

Owner:AGRI UNITED STATES OF AMERICA REPRESENTED BY THE SEC OF THE +1

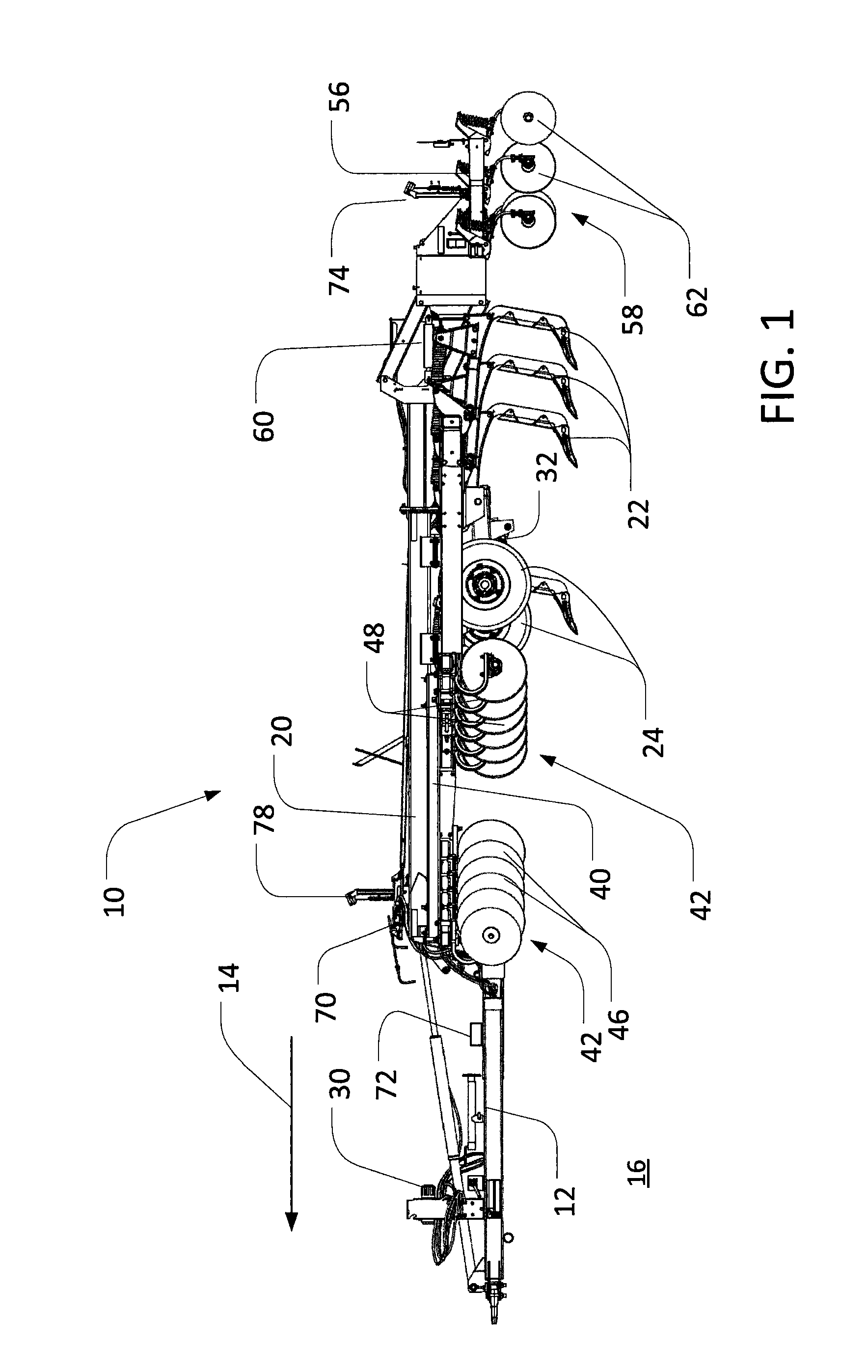

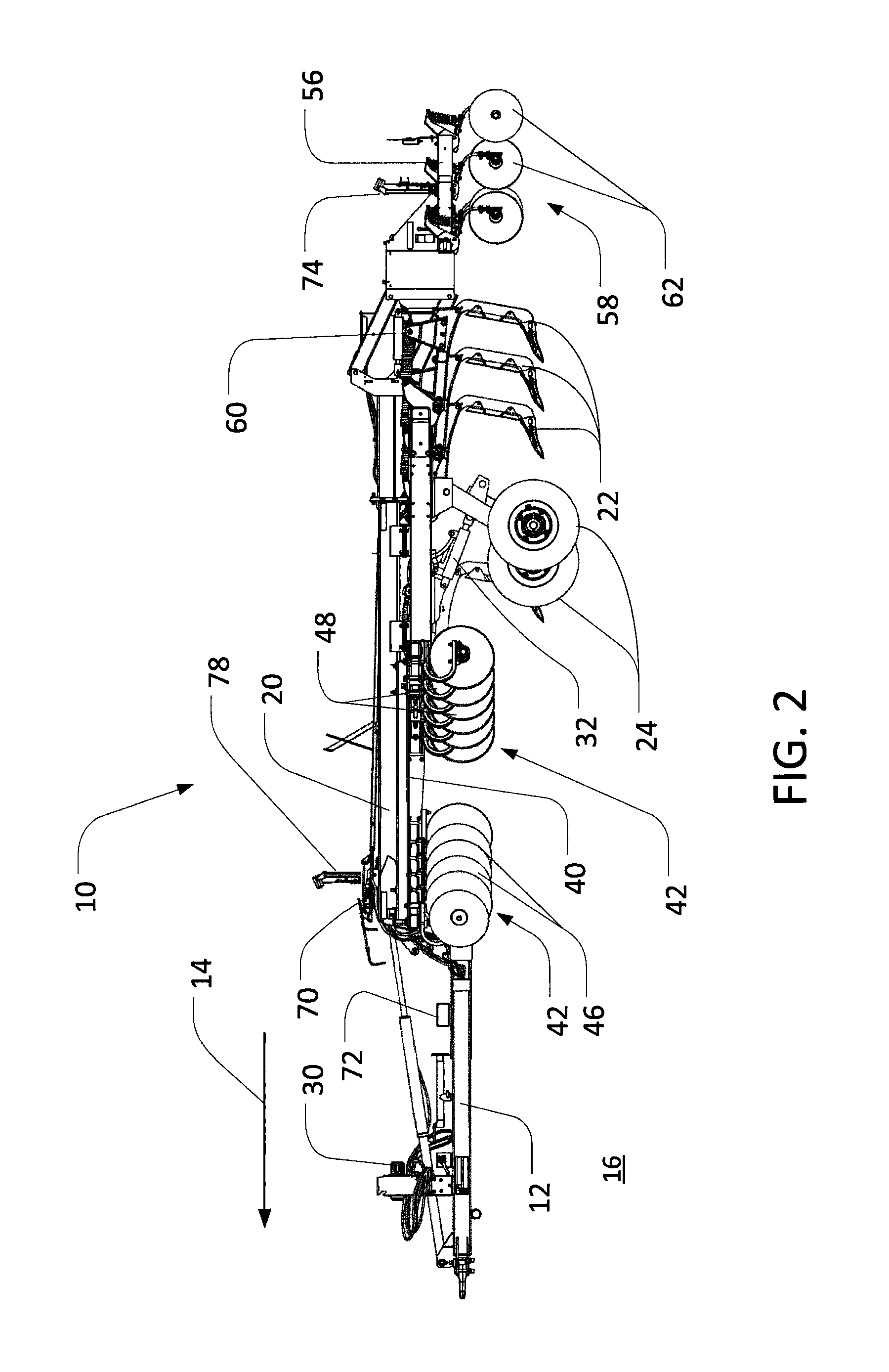

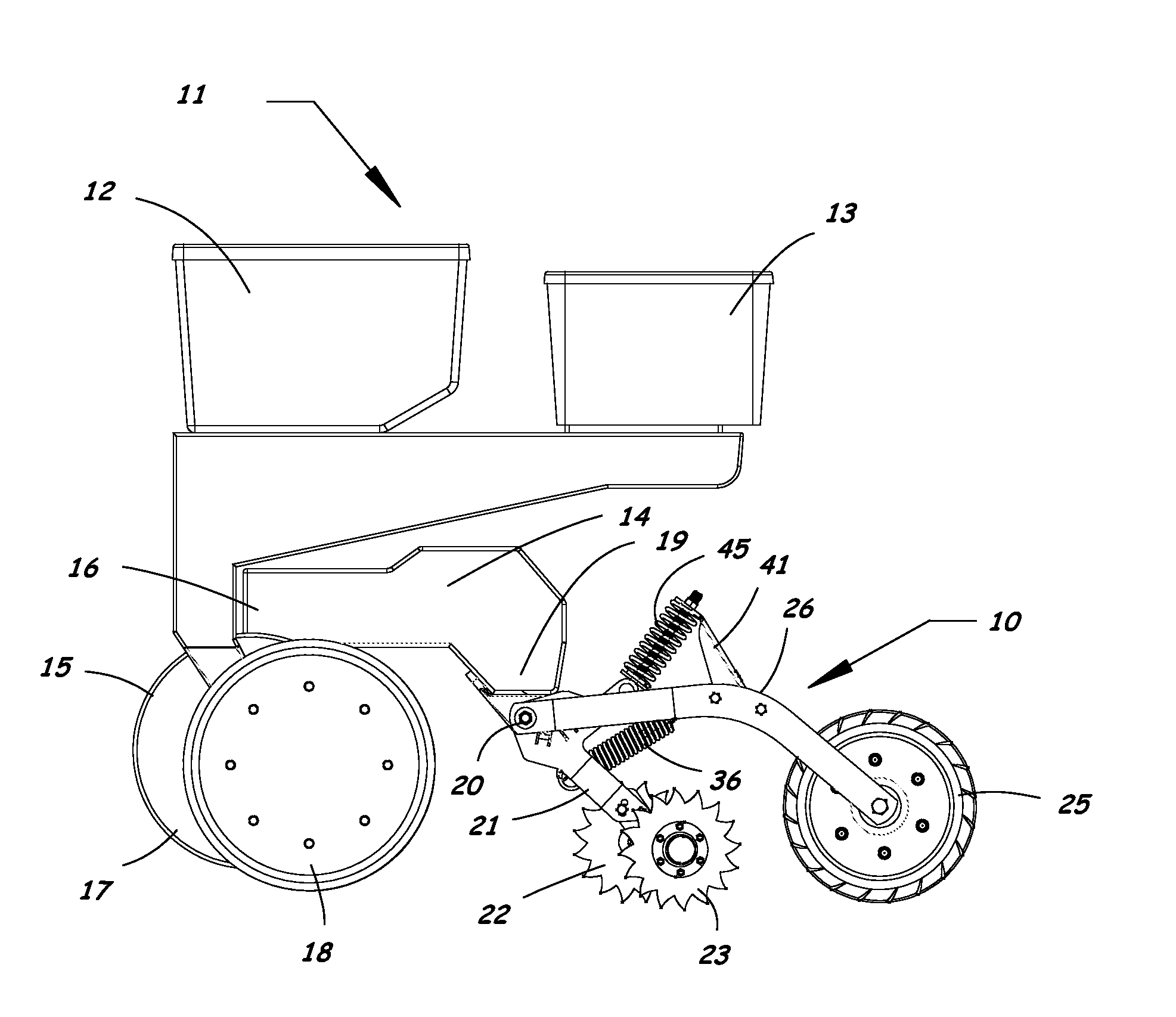

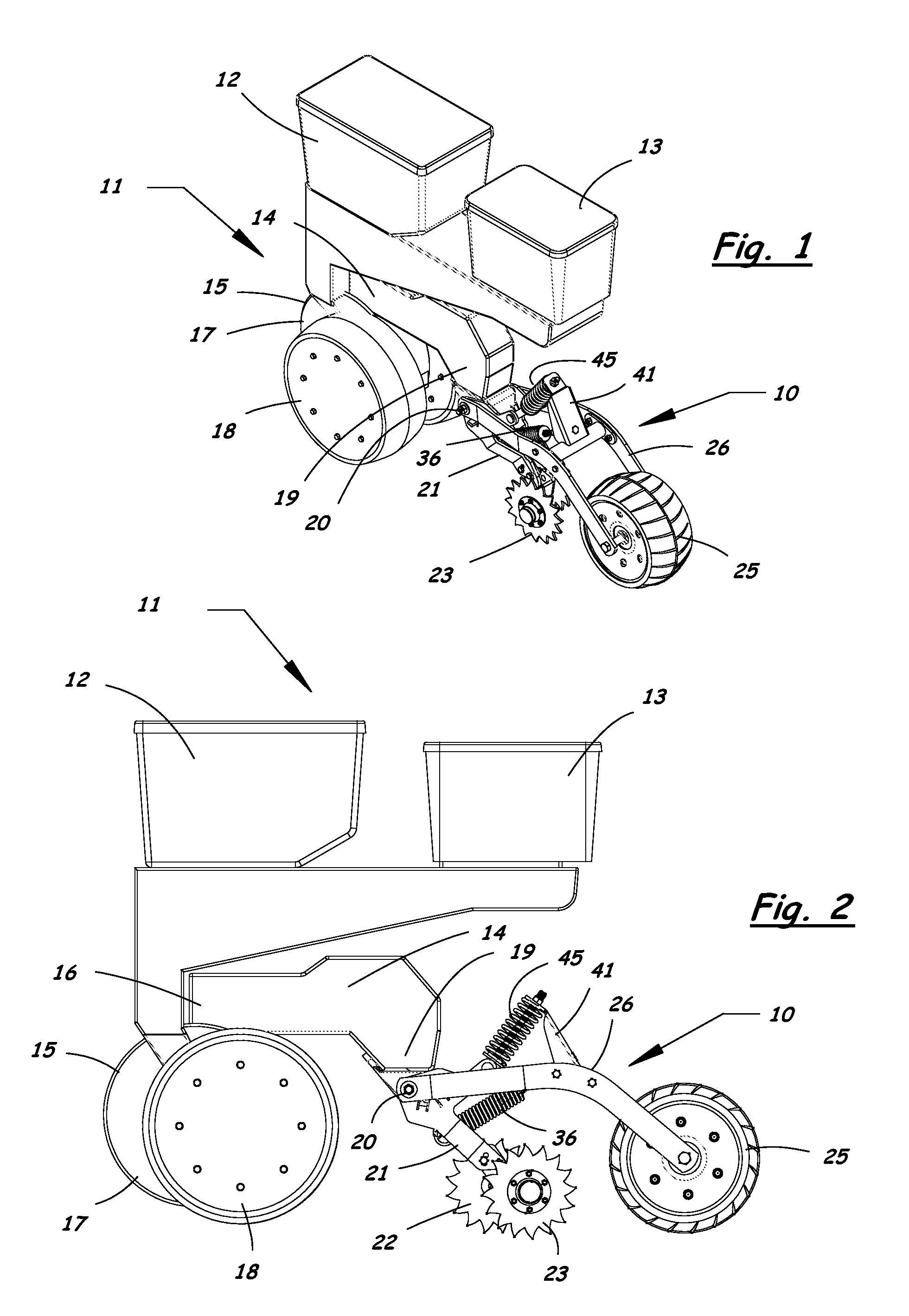

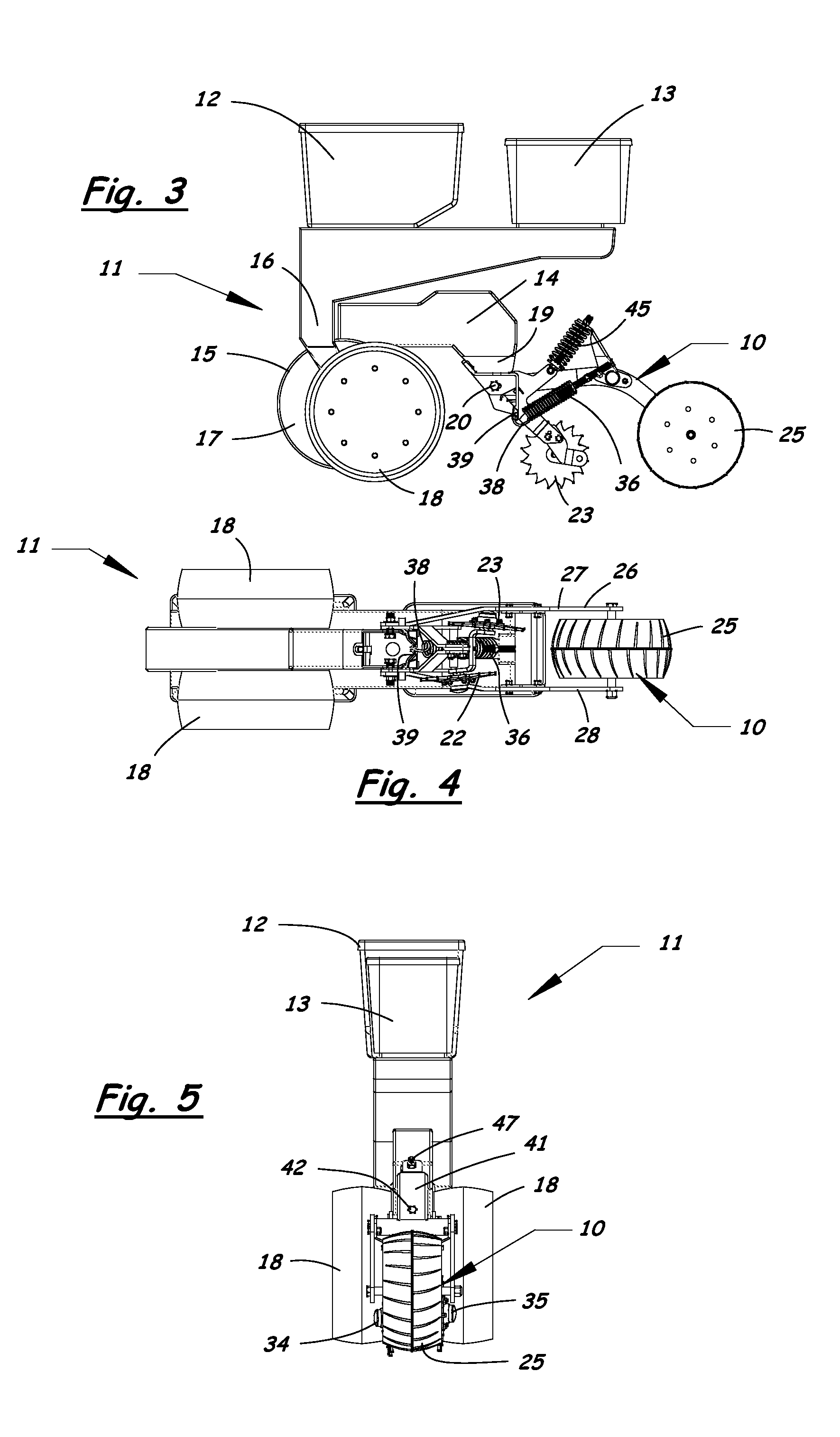

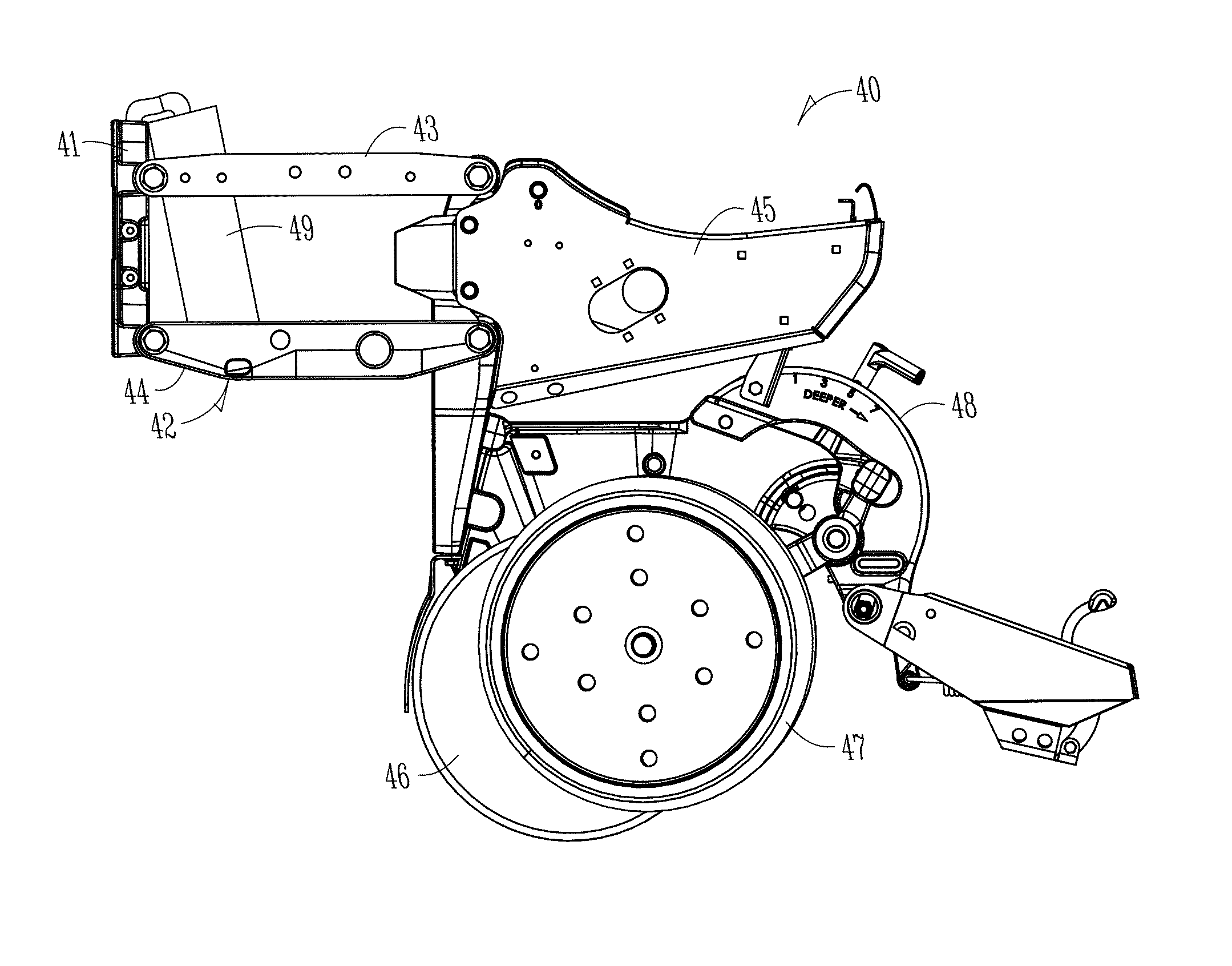

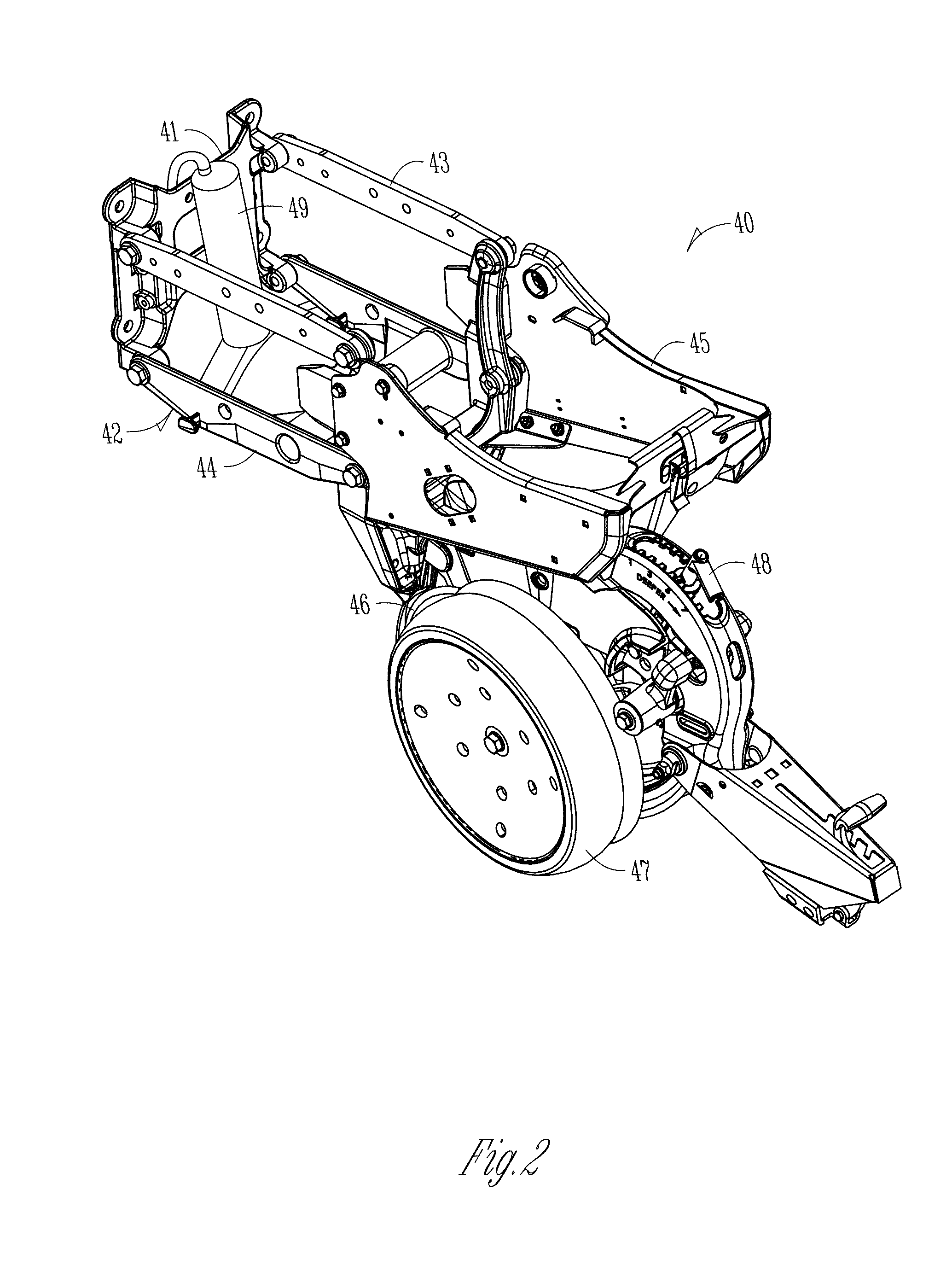

Row unit for agricultural implement

An agricultural row unit for use with a towing frame hitched to a tractor includes an attachment frame adapted to be rigidly connected to the towing frame, and a furrow-opening module comprising a first linkage pivotably coupled to the attachment frame, a first movable frame pivotably coupled to the linkage to permit vertical pivoting movement of the first movable frame relative to the linkage, a furrow-opening device mounted on the first movable frame, and a first biasing element pivotably attached to the linkage and coupled to the first movable frame for urging the furrow-opening device downwardly against the soil. The row unit also includes a furrow-closing module and a second biasing element for urging the at least one furrow-closing device downwardly against the soil.

Owner:DAWN EQUIPMENT COMPANY

Implement/vehicle steering control system and method

InactiveUS20090032273A1Avoid skewPrevent movementAgricultural machinesGuiding agricultural machinesControl systemEngineering

A control system controls steering of an implement which is coupled to an agricultural utility vehicle. The control system includes a control unit, a sensor, a hydraulic system on the utility vehicle, an electronically actuatable hydraulic valve, a hydraulic actuator on the implement and a steerable wheel on the implement. A status variable of the utility vehicle or of the implement can be detected with the sensor and transmitted to the control unit. A current operating state of the utility vehicle and / or of the implement is determined by the control unit. The hydraulic valve is connected to the hydraulic system and to the actuator. The hydraulic valve can be actuated as a function of the current operating state of the utility vehicle and / or of the implement in order to block the steering of the wheel with the actuator.

Owner:DEERE & CO

Residue monitoring and residue-based control

Owner:DEERE & CO

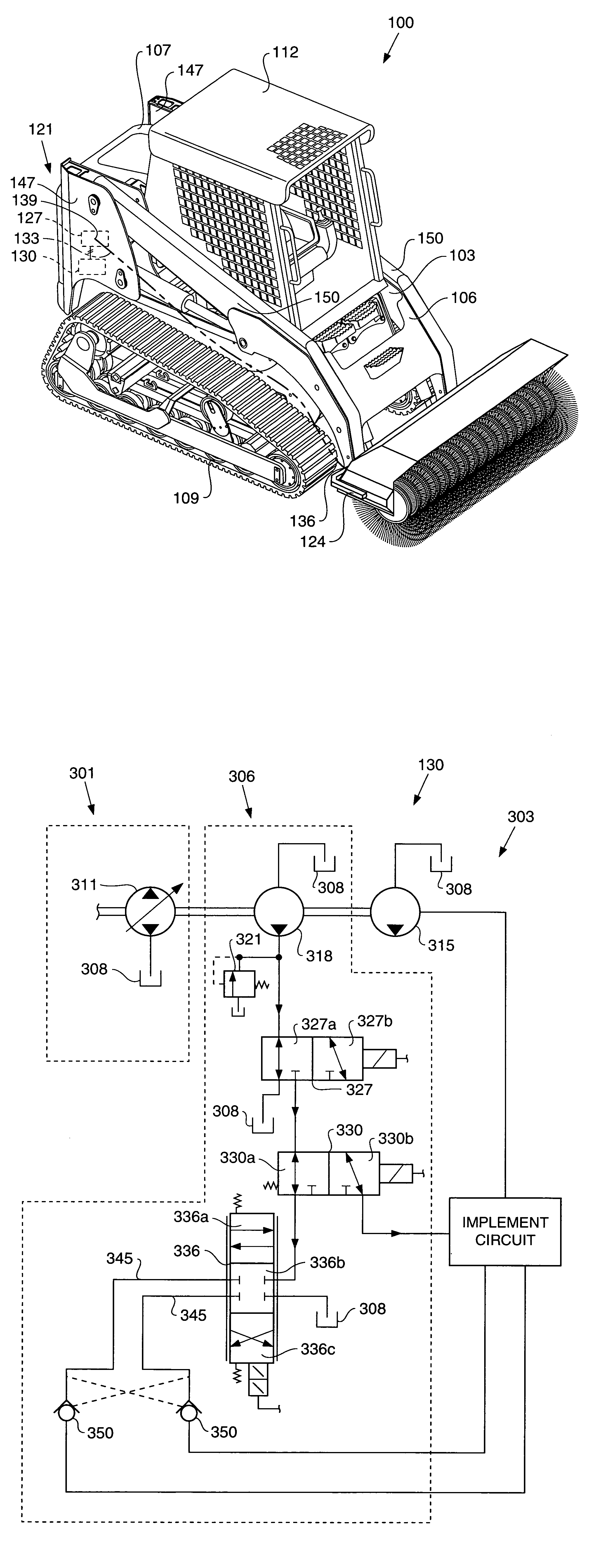

Method of changing operating characteristics of an implement

InactiveUS7017674B2Machines/dredgers working methodsMechanical machines/dredgersProduction rateComputer module

Changing operating characteristics of an implement can expand the capabilities of and enhances the productivity of the implement. The disclosed method and apparatus for changing operating characteristics of an implement comprises, providing the operating characteristics of the implement with a predetermined operational range consisting of a plurality of values, connecting the implement with a work machine, sending a first input signal identifying the operational range to an electronic control module, operating the implement at a first value within the operational range, sending a second input signal relating to a second value within the operational range to the electronic control module, and sending an output signal from the electronic control module to one of the work machine and the implement to change from the first value to the second value.

Owner:CATEPILLAR SARL

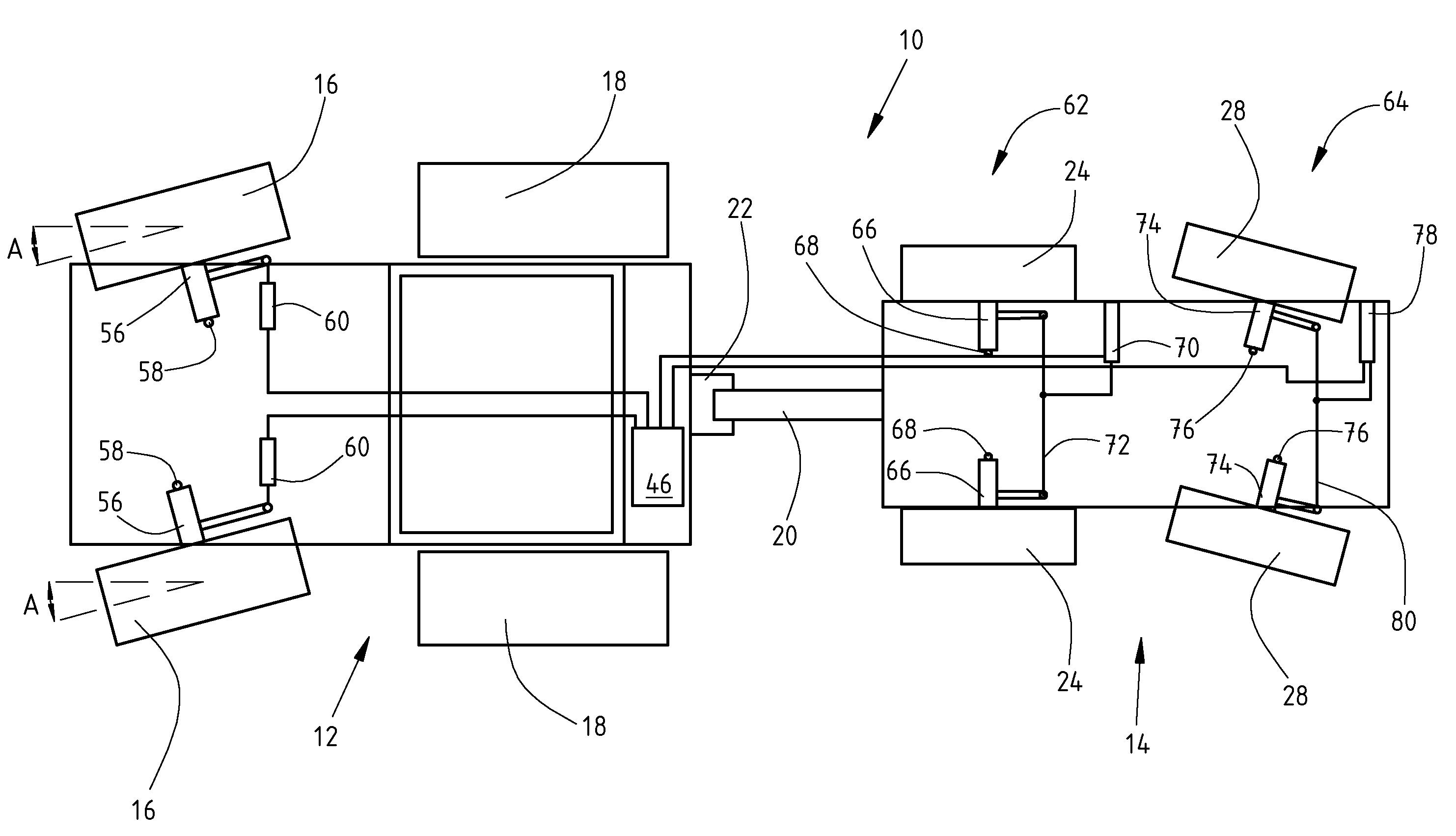

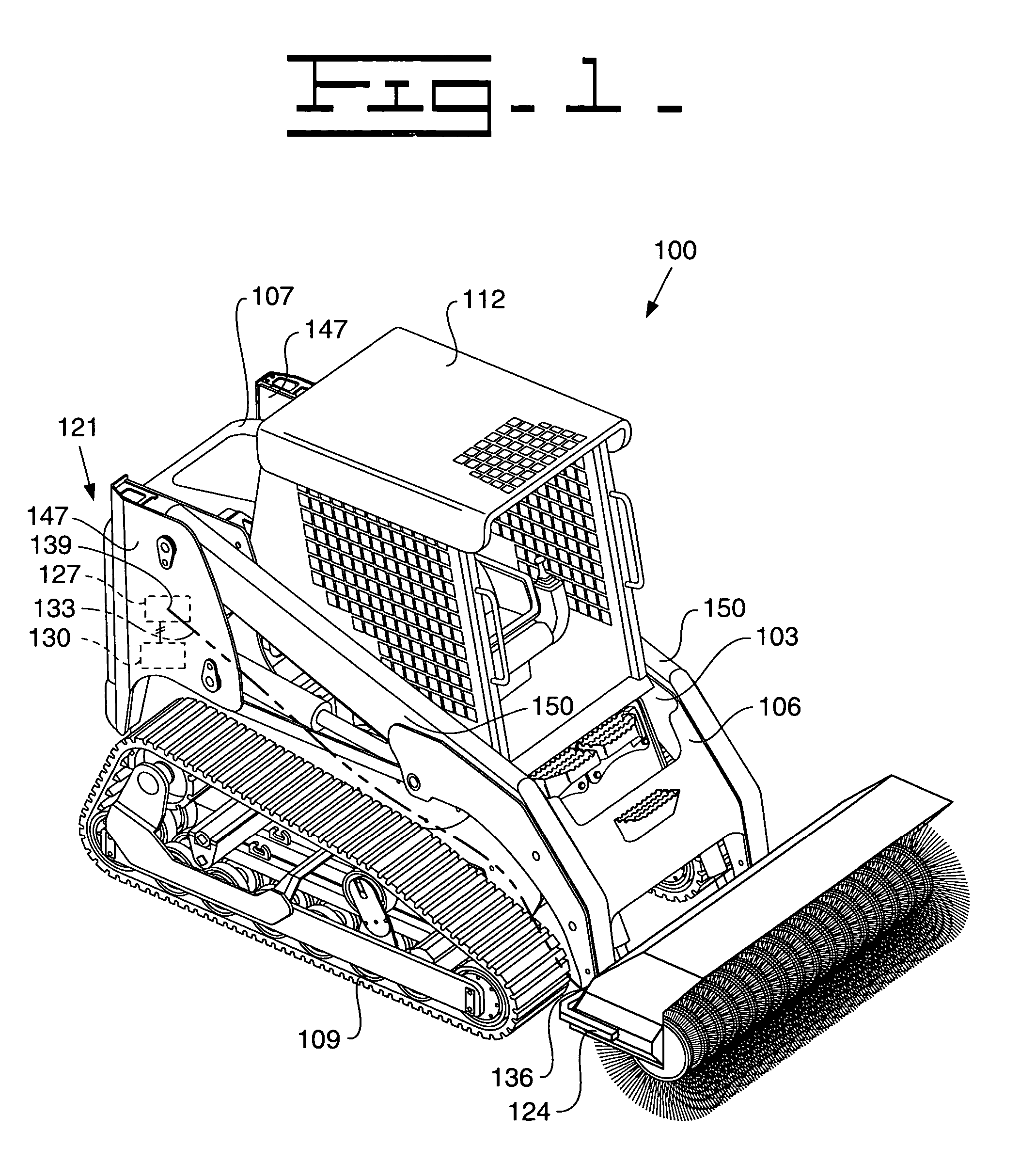

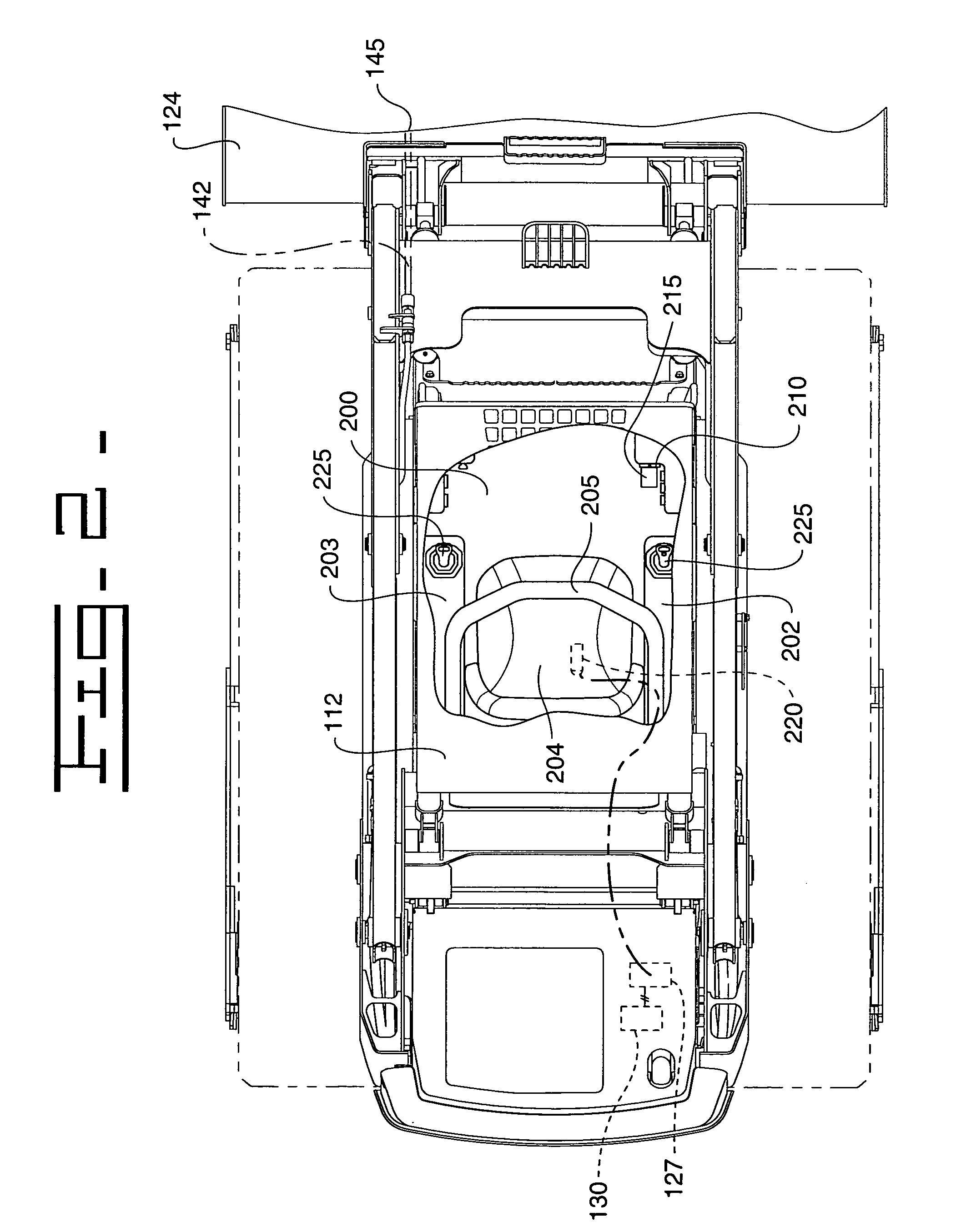

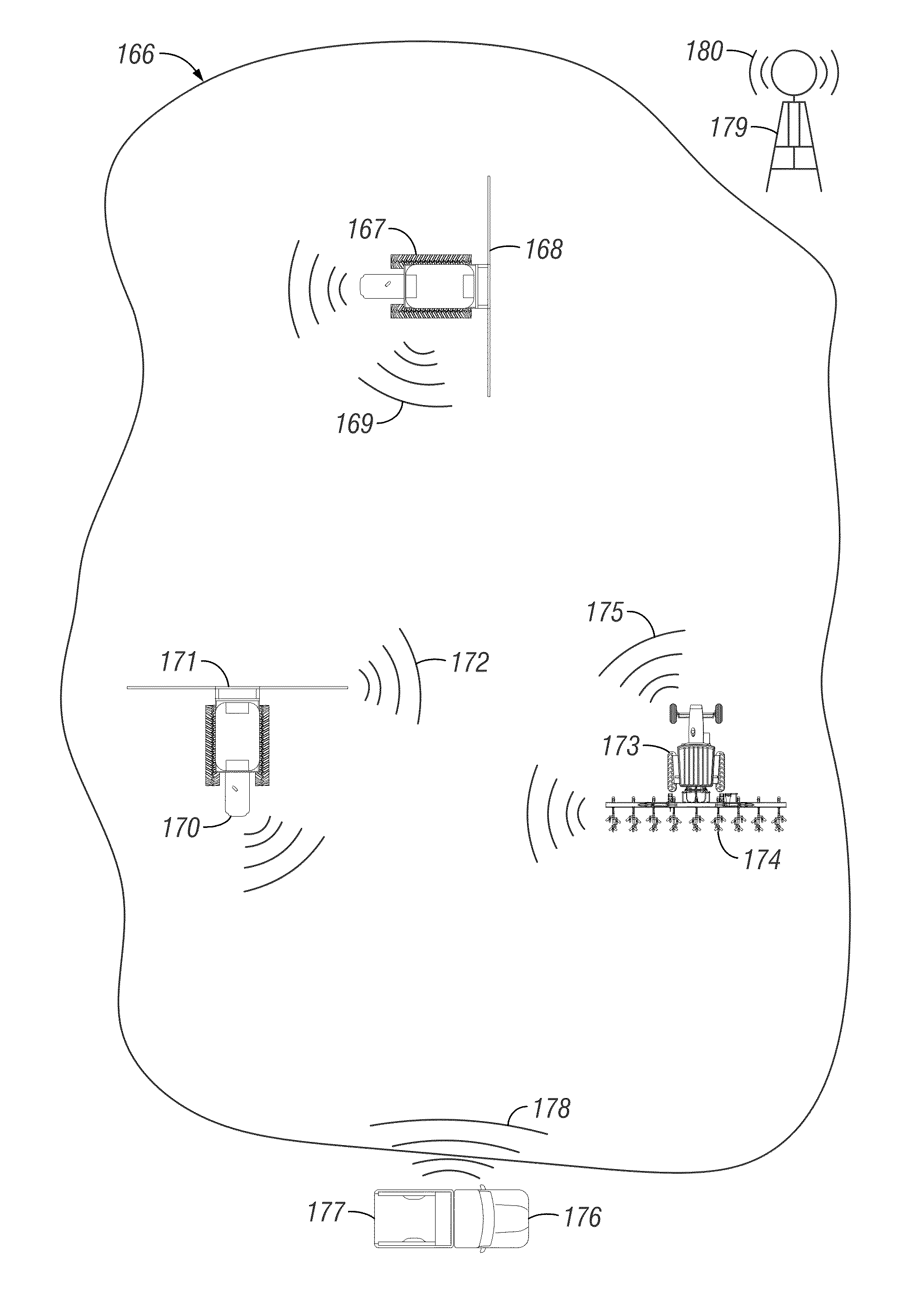

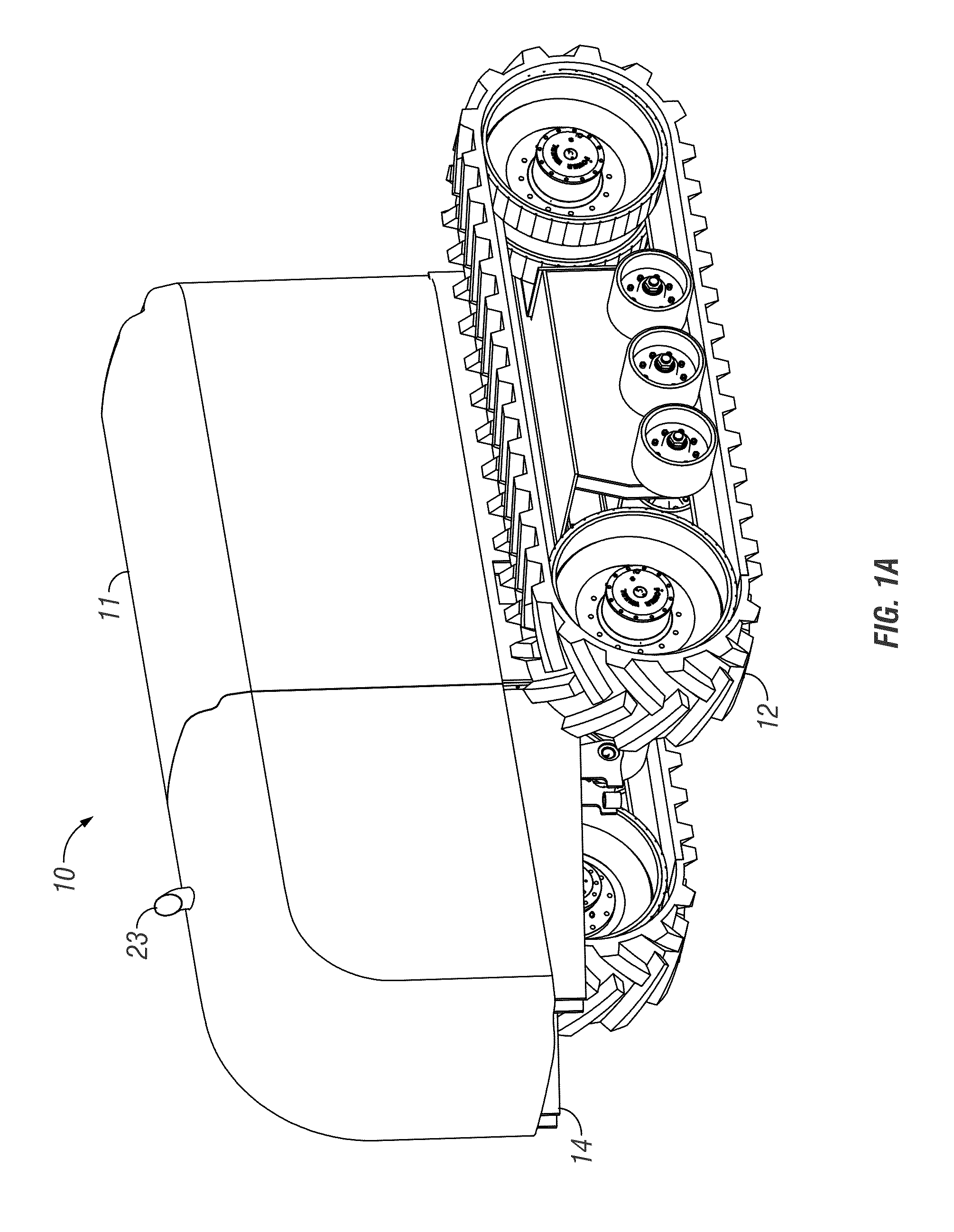

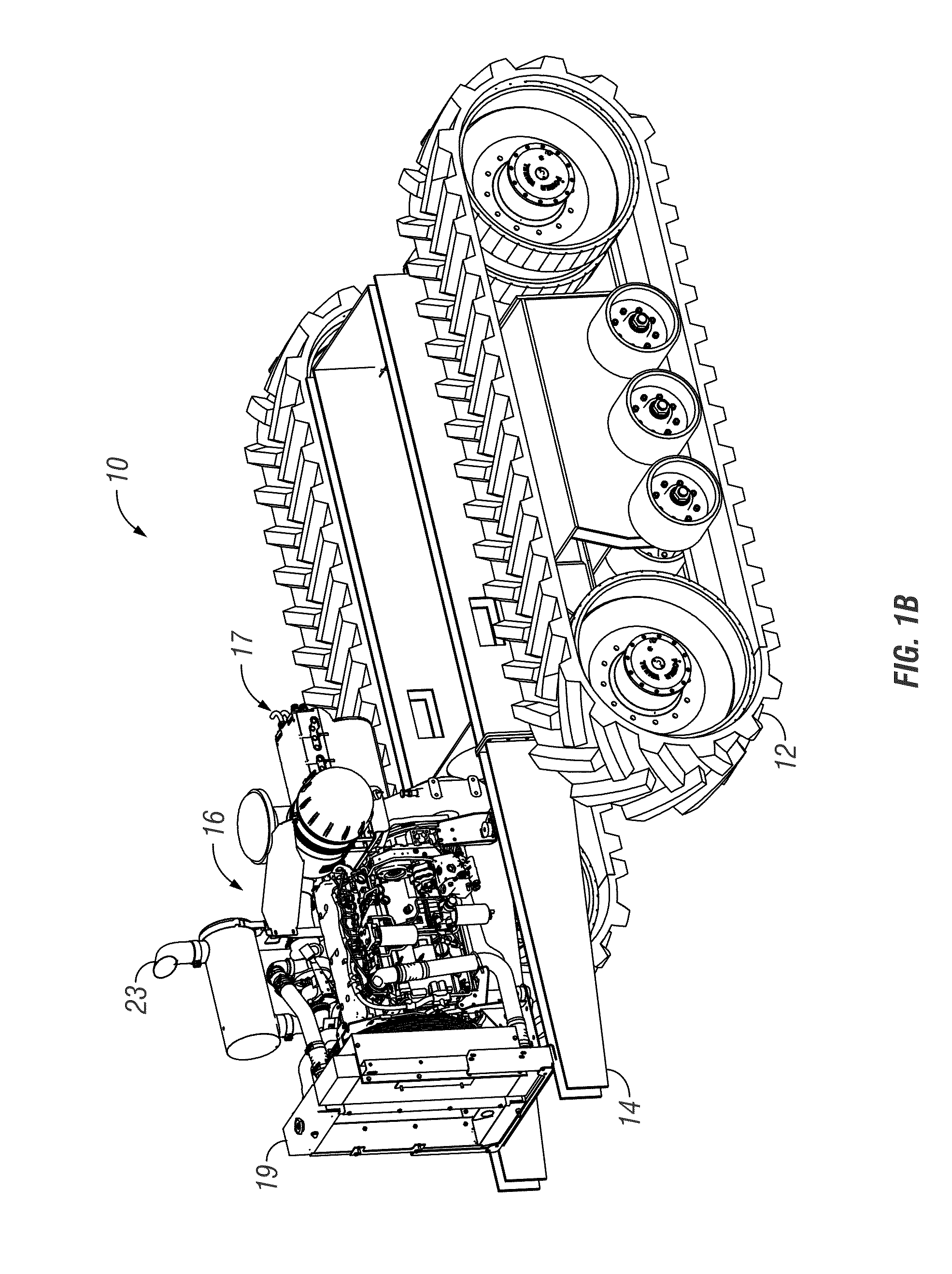

Autonomous systems, methods, and apparatus for ag based operations

ActiveUS20150101519A1Shorten the timeOvercome deficienciesSpadesAgricultural machinesIntelligent controlAutomotive engineering

The use of self-powered, autonomous vehicles in agricultural and other domestic applications is provided. The vehicles include a self-propelled drive system, tracks or wheels operatively connected to the drive system, a power supply operatively connected to the drive system, an attachment mechanism for attaching equipment to the vehicle, and an intelligent control operatively connected to the drive system, power supply, and attachment mechanism. The vehicle is configured to connect to the equipment to perform agricultural operations based upon the equipment. Multiple vehicles can be used in a field at the same time. Furthermore, the invention includes the ability to move one or more of the autonomous vehicles from field to field, home to field, or from generally any first location to a second location.

Owner:KINZE MFG INC

Furrow closing assembly and method

Agricultural planter row units feature soil finishing assemblies for closing a seed groove after seed is placed in the soil. An adjustable furrow closing assembly enhances upper seed groove coverage and closure with soil resulting in sustained relative humidity levels and optimum seed-to-soil contact for faster seed germination. The furrow closing assembly includes a closing wheel assembly having at least one closing wheel and a press wheel assembly having a press wheel following behind the closing wheels. The closing wheels and press wheel are attached to the planter row unit in a manner allowing the press wheel to move vertically relative to the closing wheels. Adjustable down-force systems are provided to vary the down force applied to the closing wheels and the press wheel to maintain optimum soil contact in irregular terrain and in varying soil densities and conditions to provide optimum soil coverage and compaction of the seed bed.

Owner:AG FOCUS LLC

Agricultural apparatus for sensing and providing feedback of soil property changes in real time

Owner:DAWN EQUIPMENT COMPANY

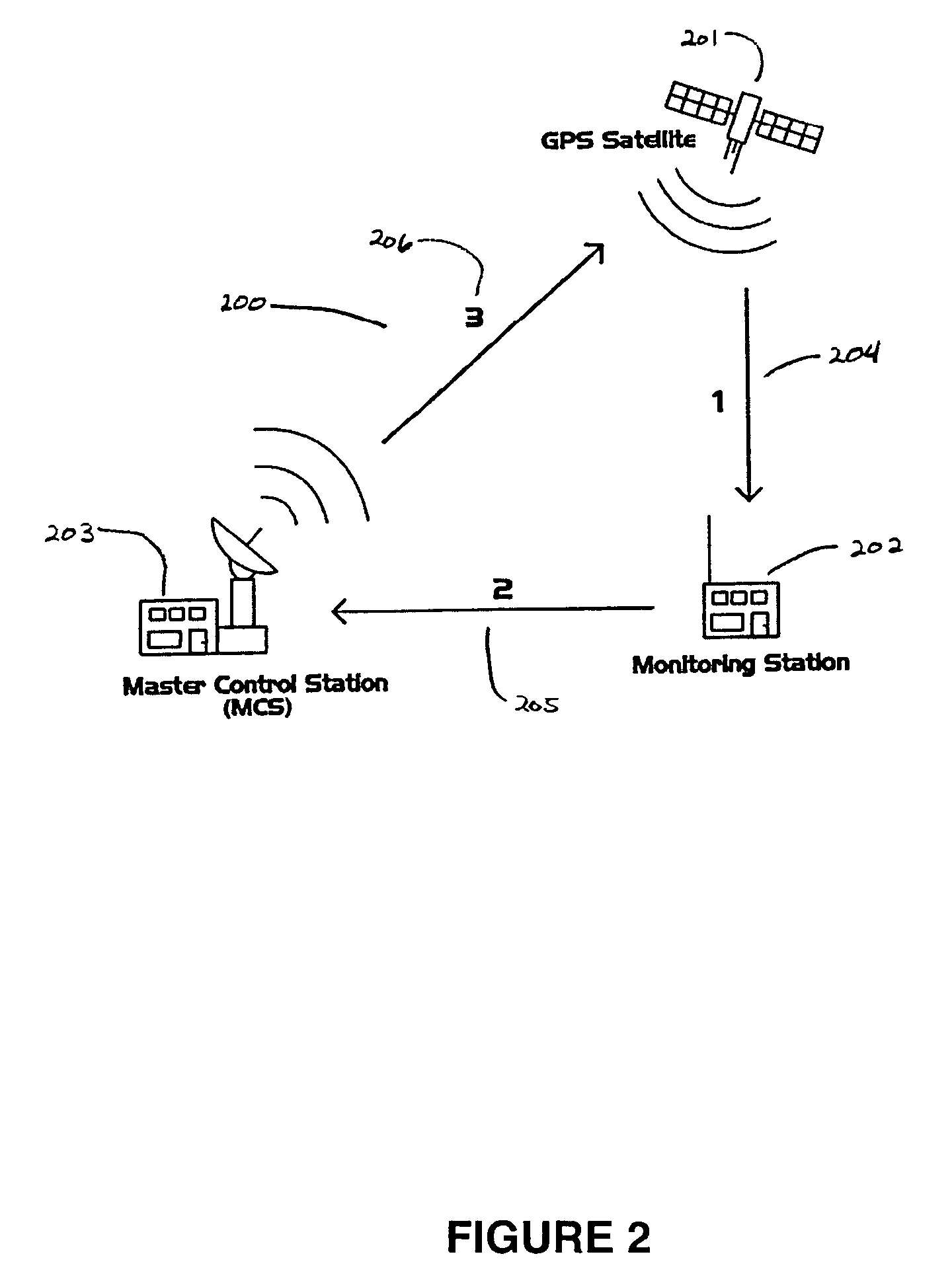

Method and system for tracking the positioning and limiting the movement of mobile machinery and its appendages

ActiveUS7734397B2Avoid damageAnalogue computers for trafficSoil-shifting machines/dredgersEngineeringData bank

Owner:WILDCAT TECH

Constant work tool angle control

A method of controlling a work tool with respect to a design surface gradient identifies surface gradient and determines a desired angle for the work tool. Movement of the machine is monitored and the distance between the design surface gradient and the work tool is determined. The angle of the work tool is varied based on one or more of these parameters.

Owner:CATERPILLAR INC

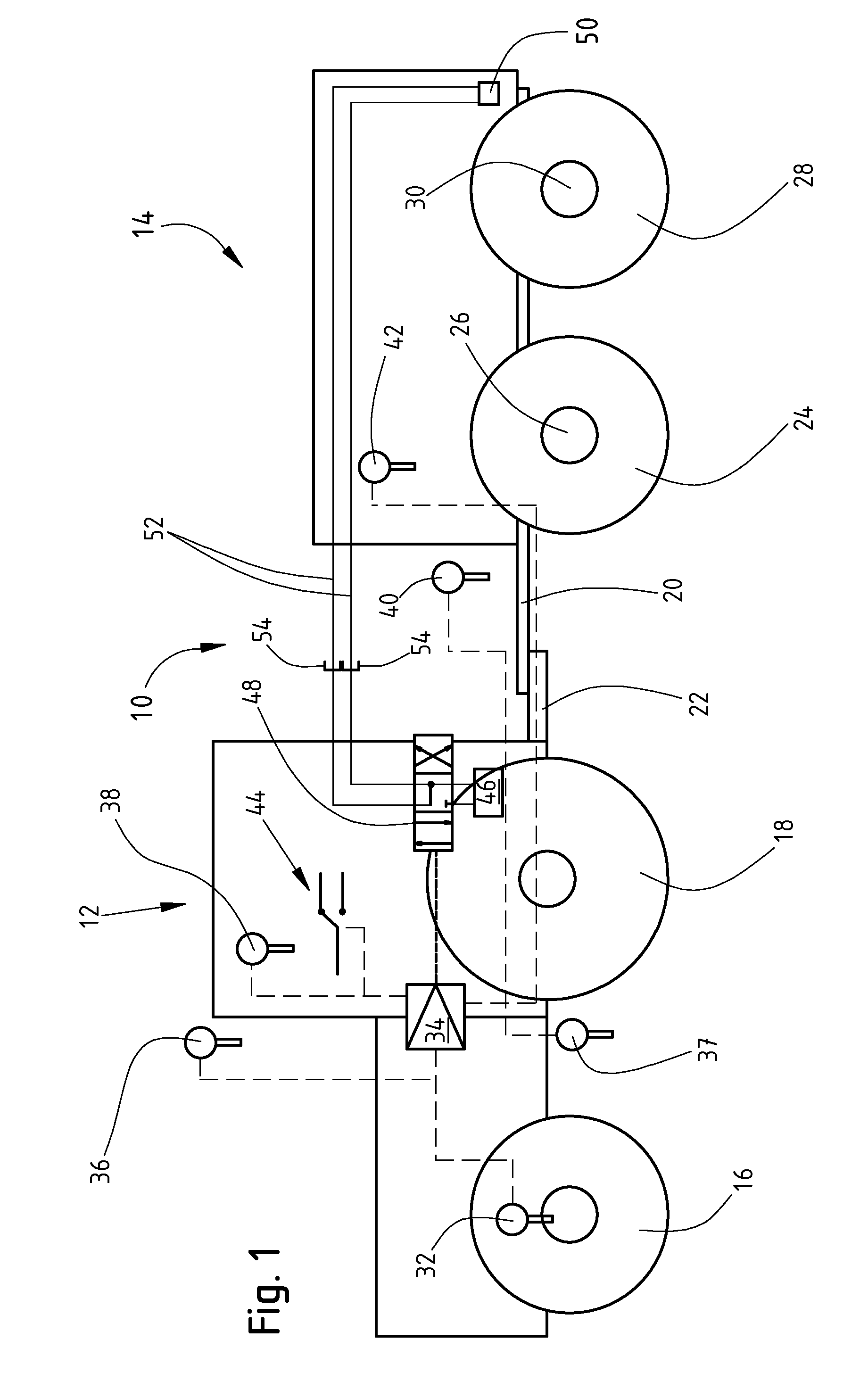

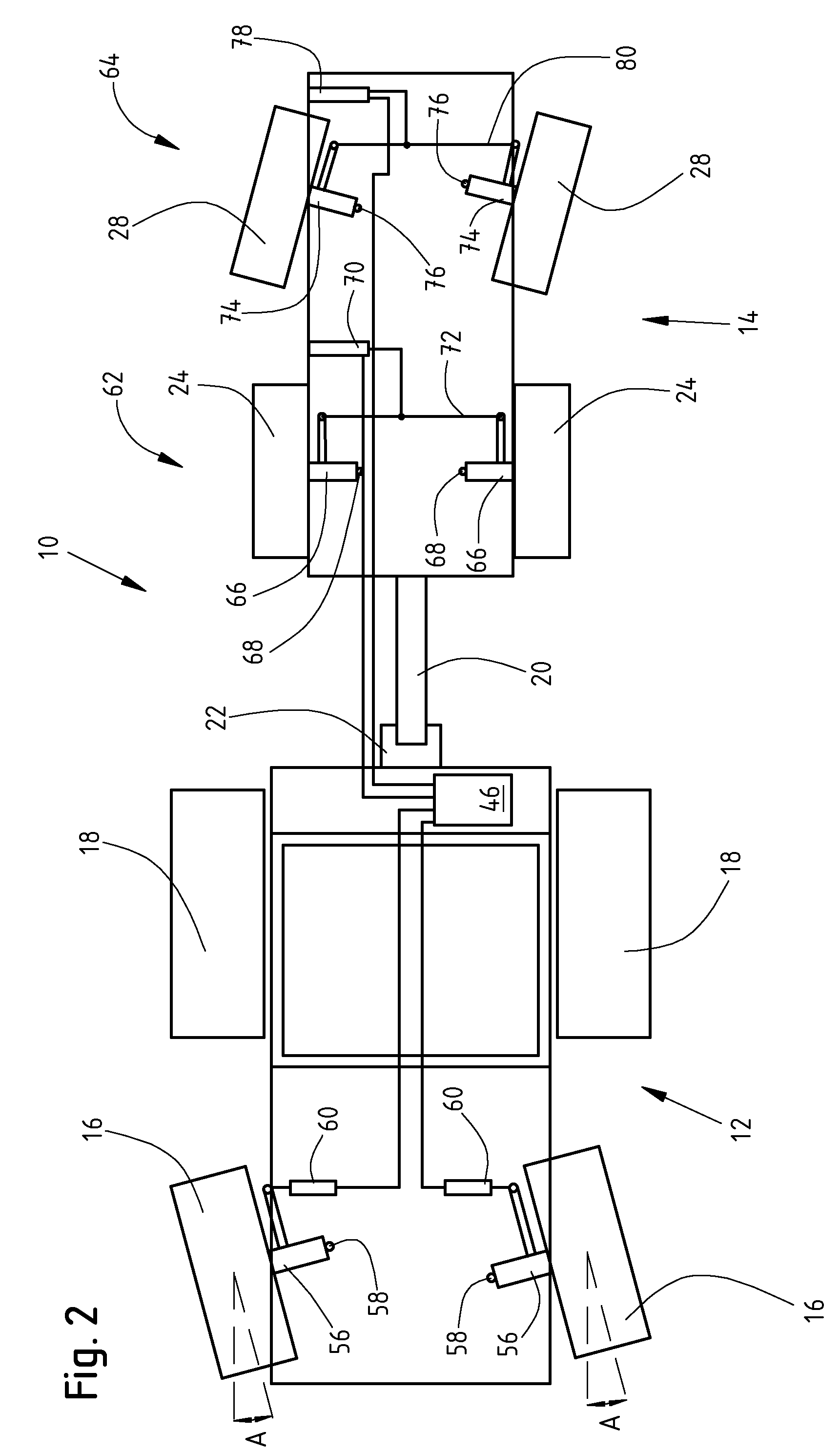

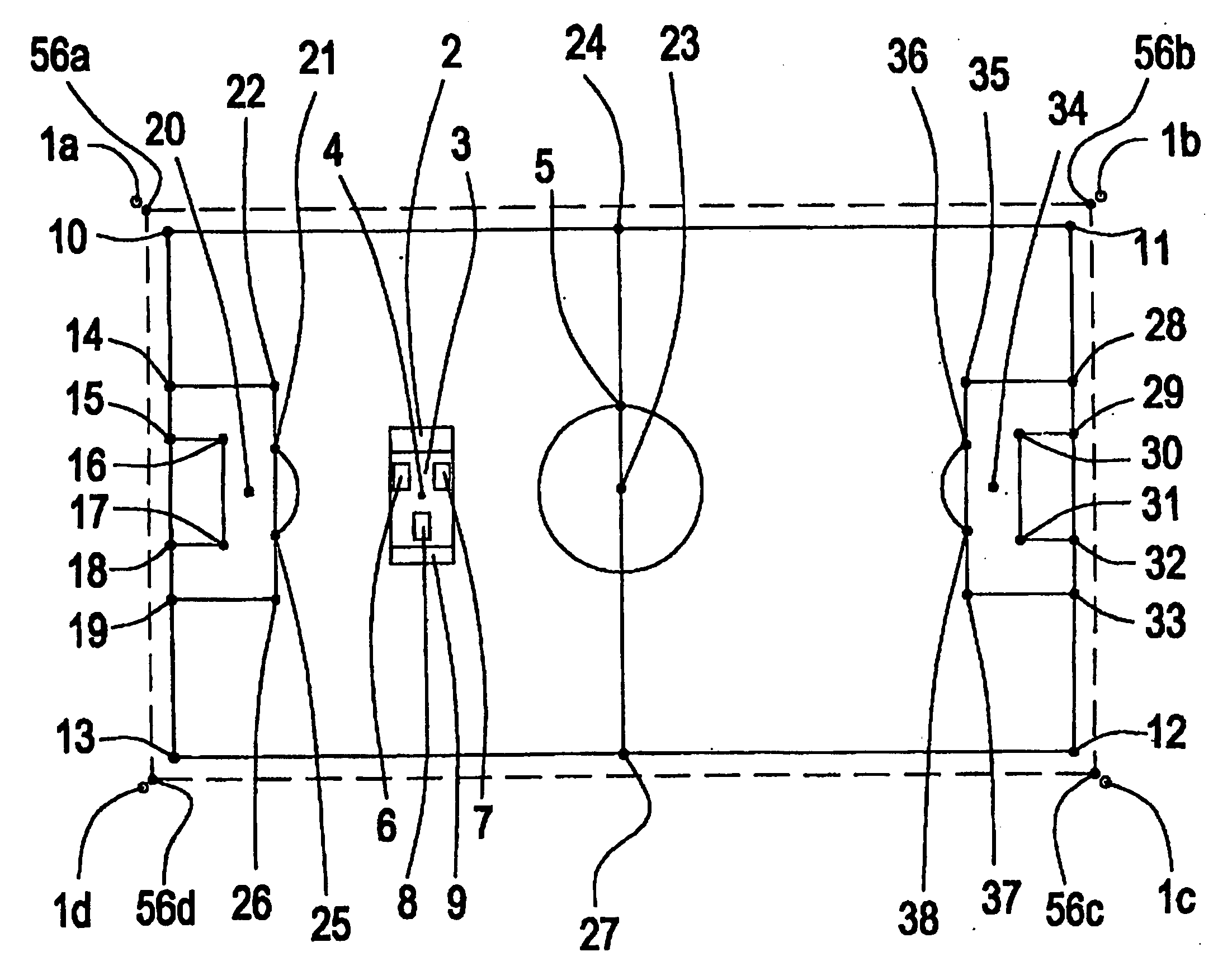

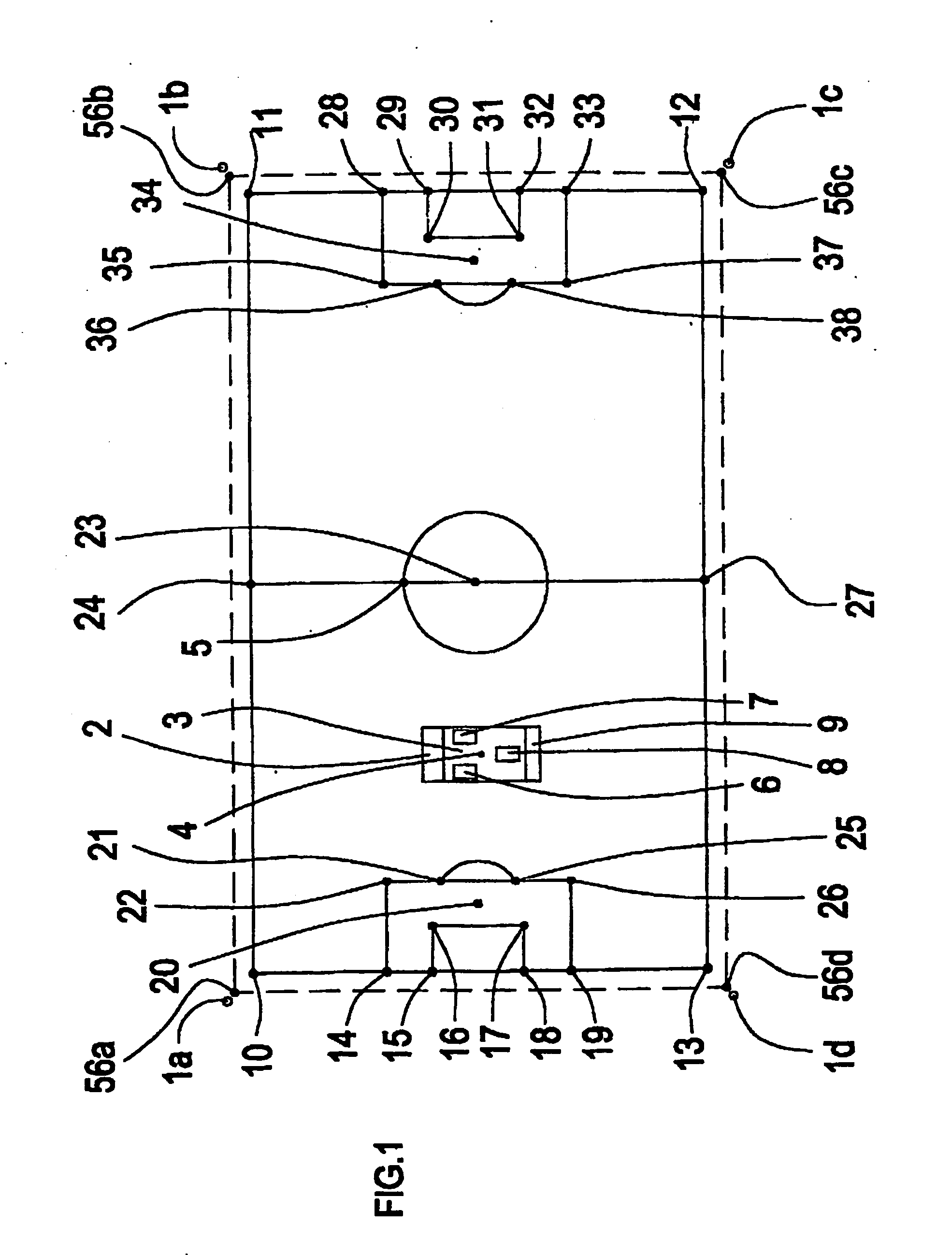

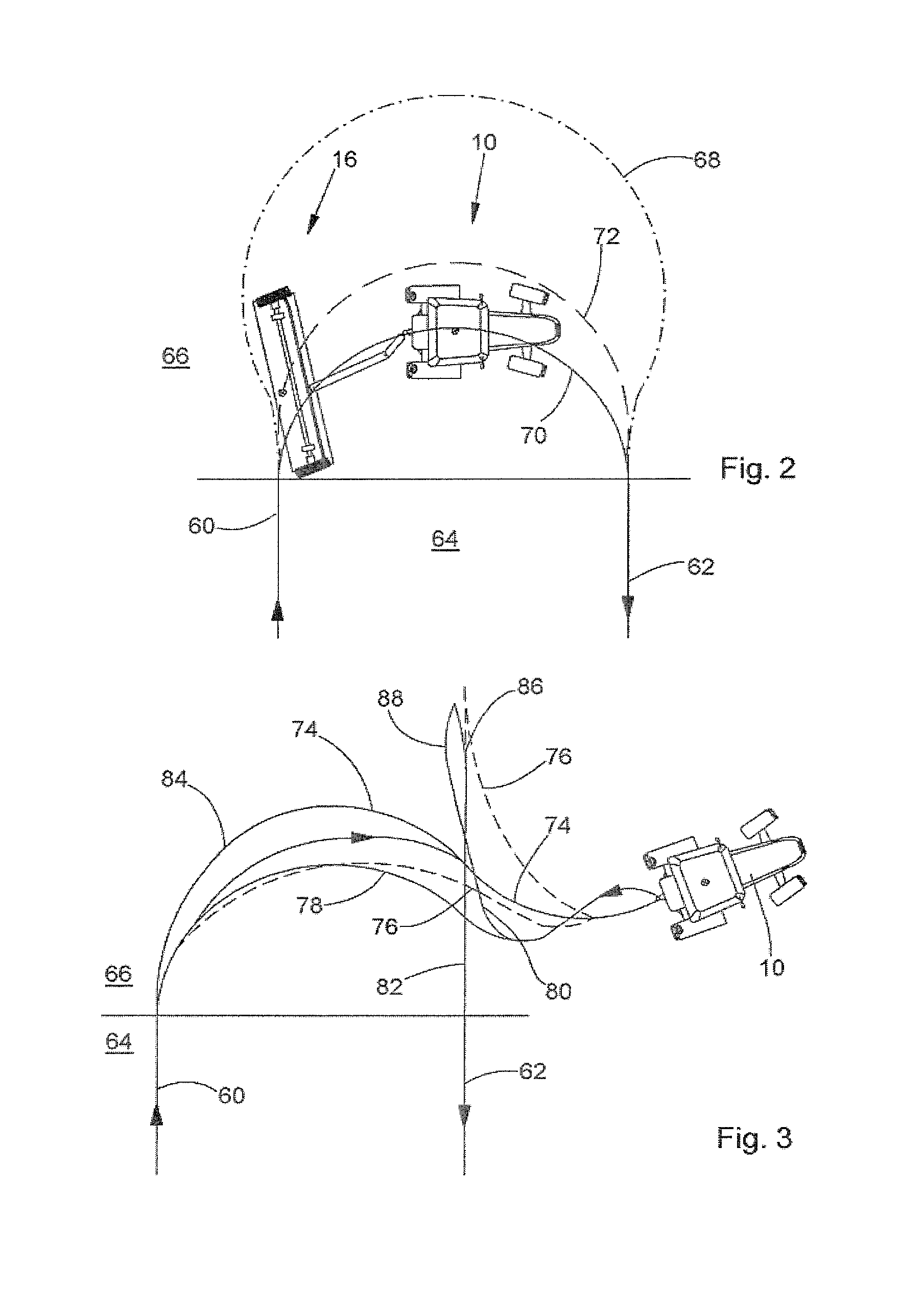

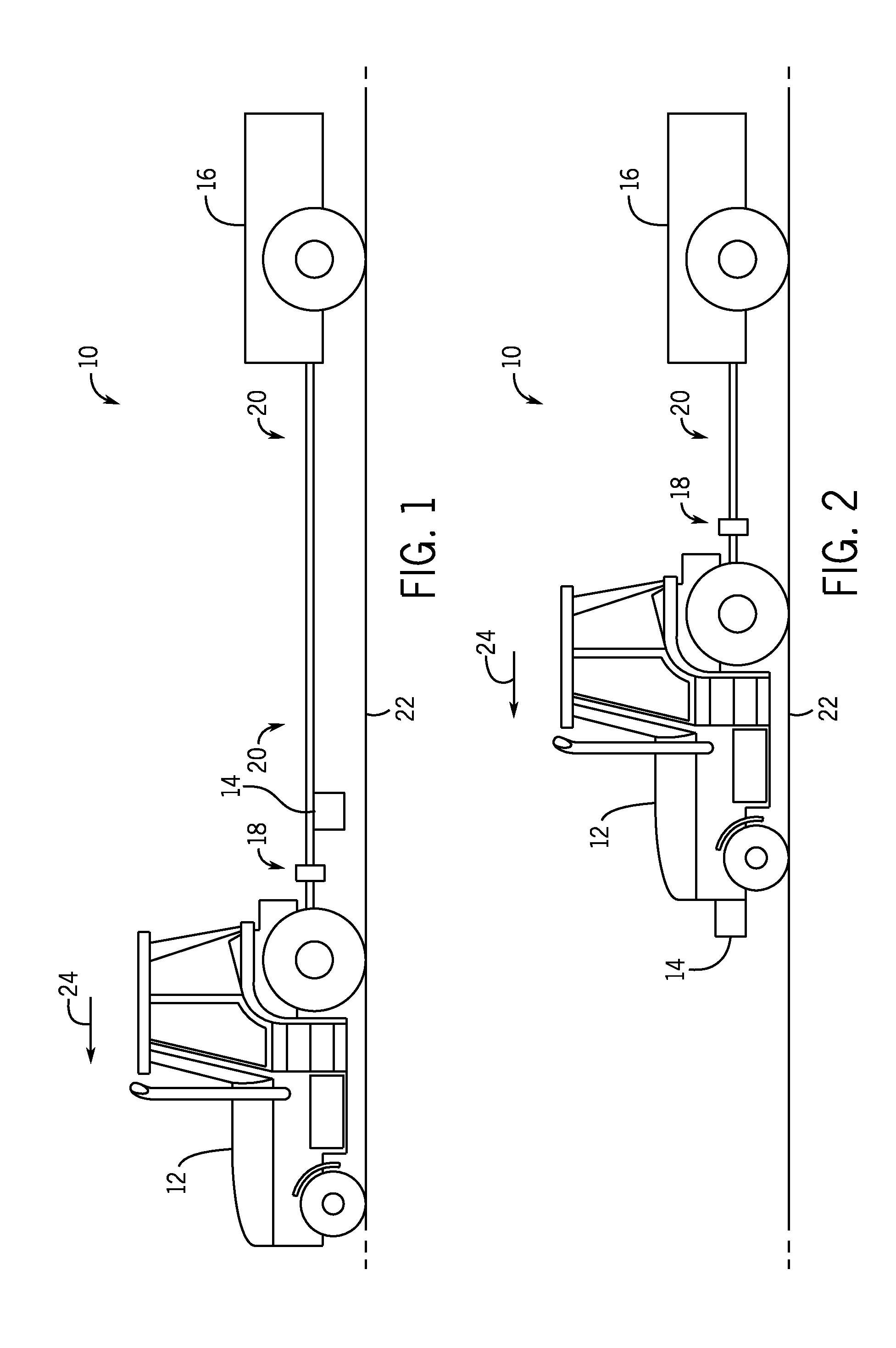

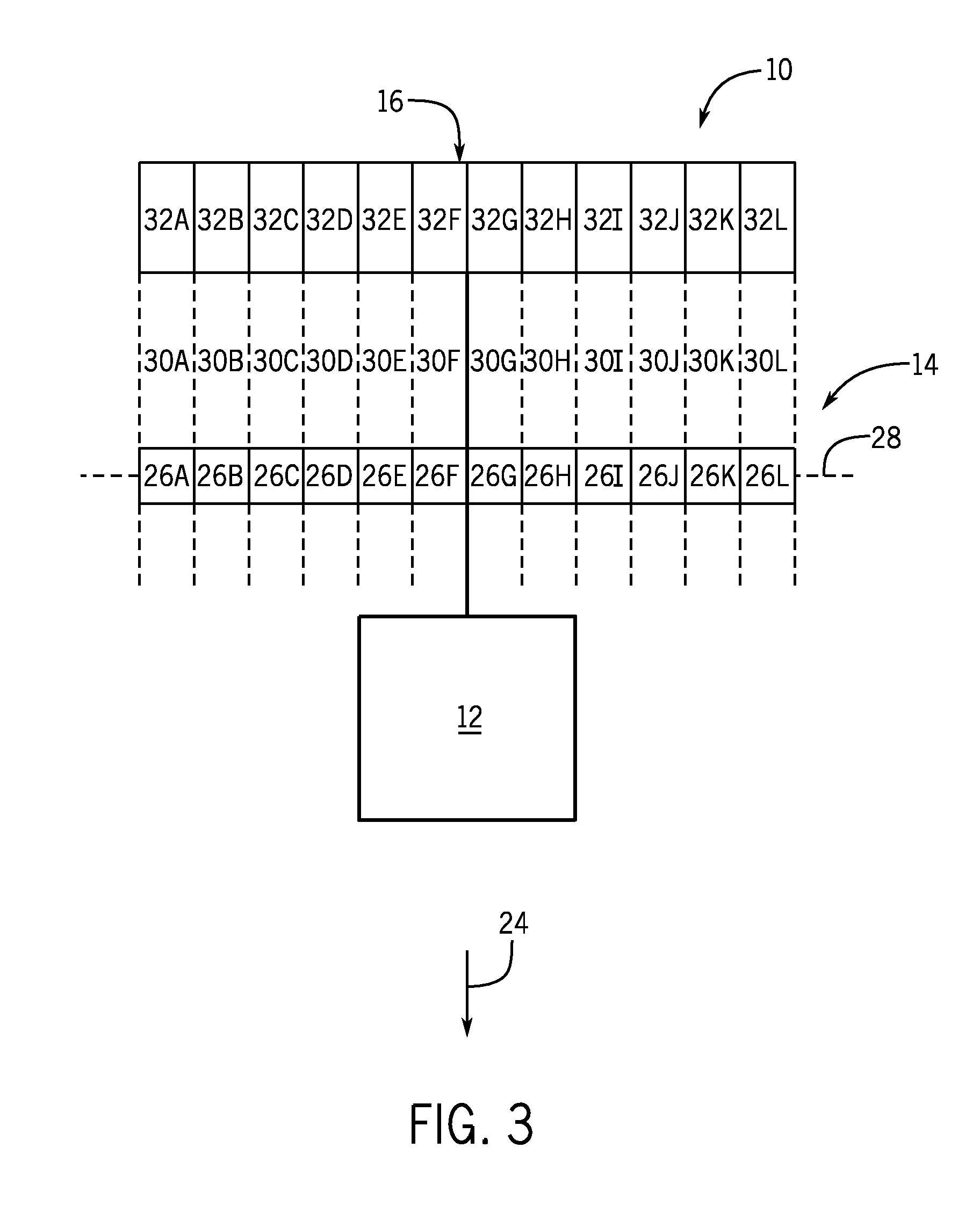

Combination of a tractor and an implement

A combination is described of a tractor (10) and an implement (12) which is pulled by the tractor (10), by means of a draw bar (14) coupled to the tractor (10) so as to be pivotable about the vertical axis, is supported on the ground by wheels (28) and comprises a cultivating element (30) for cultivating a field (64). A control device (36) is used to activate a first actuator (40) with which the position of the draw bar (14) in relation to the implement (16) can be changed. The control device (36) activates the first actuator (40) in such a manner that the latter adjusts the draw bar (14) with the effect of moving the implement (16) towards an outside of a curve.

Owner:DEERE & CO

Process and steering system for the automatic steering of an agricultural vehicle

InactiveUS7400957B2Low costDigital data processing detailsMechanical machines/dredgersAutomatic steeringComputer graphics (images)

An automatic steering of an agricultural tractor on a surface of a field to be processed is accomplished by equipping the tractor with a camera for taking a picture of a region of the field, which is in front of the tractor, including the surface that is to be processed, generating a pixel data file from a picture signal of the camera, generating texture information with respect to the texture of the surroundings of the pixels contained in the data file, classifying the pixels of the pixel data file while considering the texture information, in order to generate a binary information as to whether or not a particular pixel is to be associated with the surface that is to be processed, generating a steering signal based on the results of the classification, and repositioning the steering device of the harvesting machine according to the steering signal so that the machine is steered automatically along the surface that is to be processed.

Owner:DEERE & CO

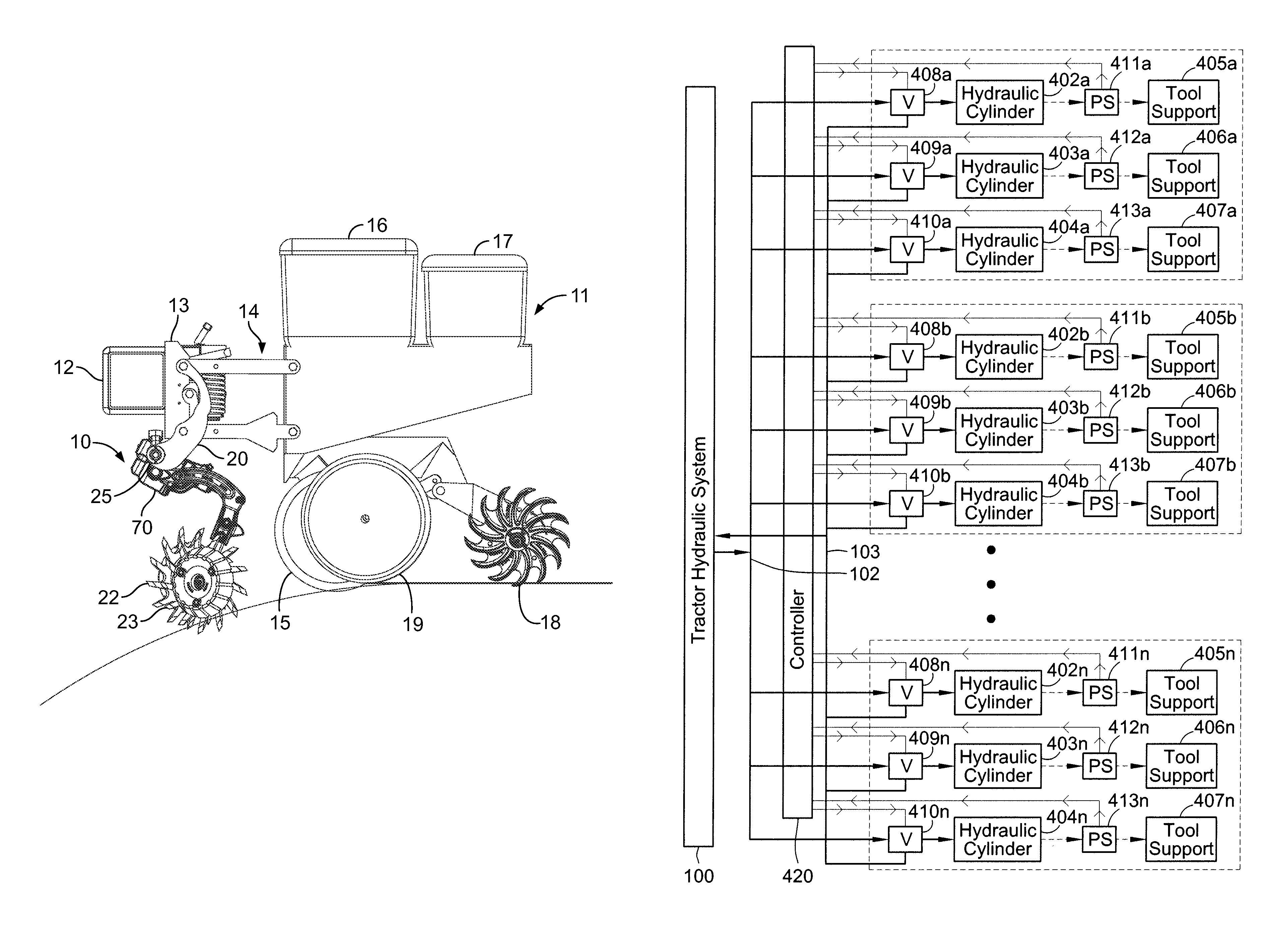

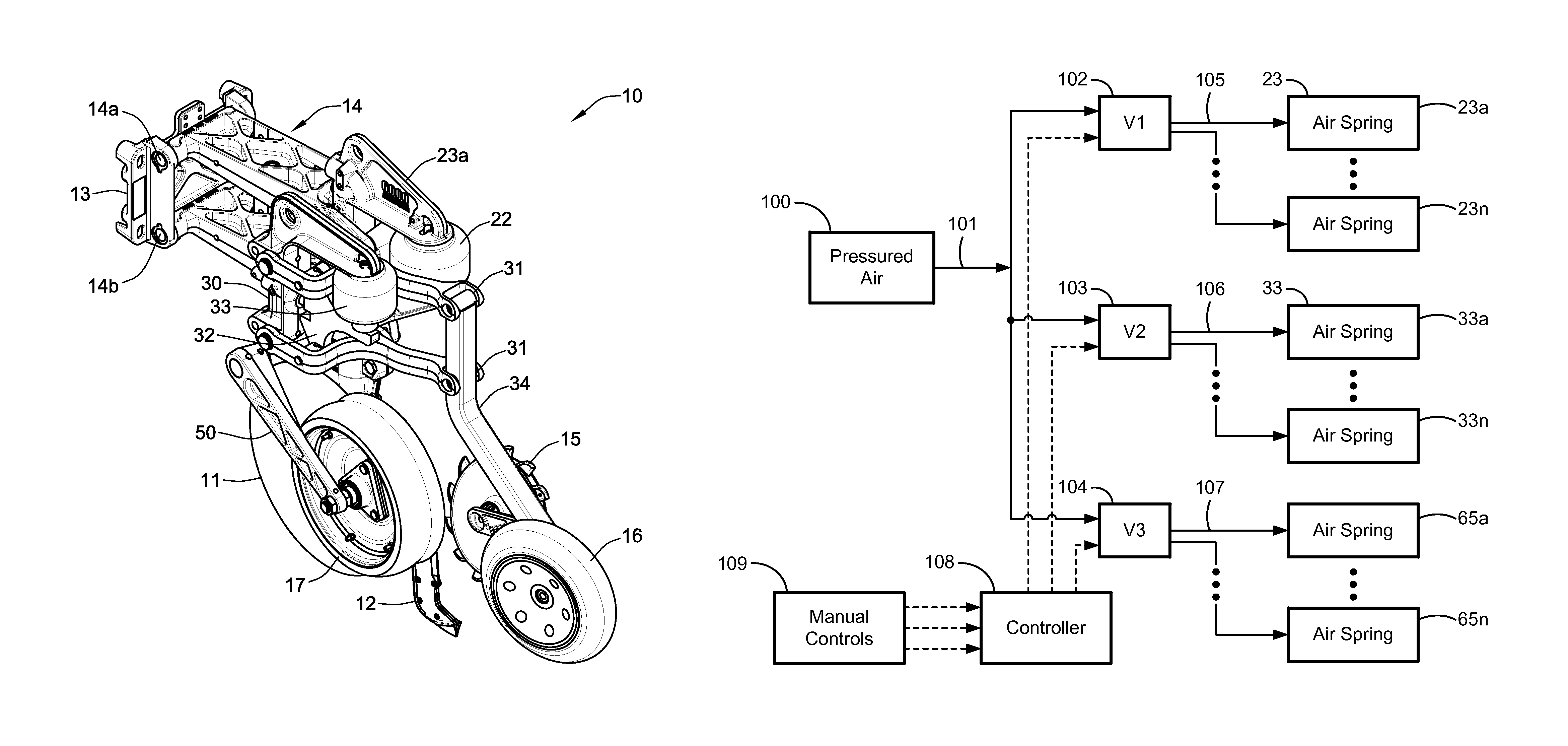

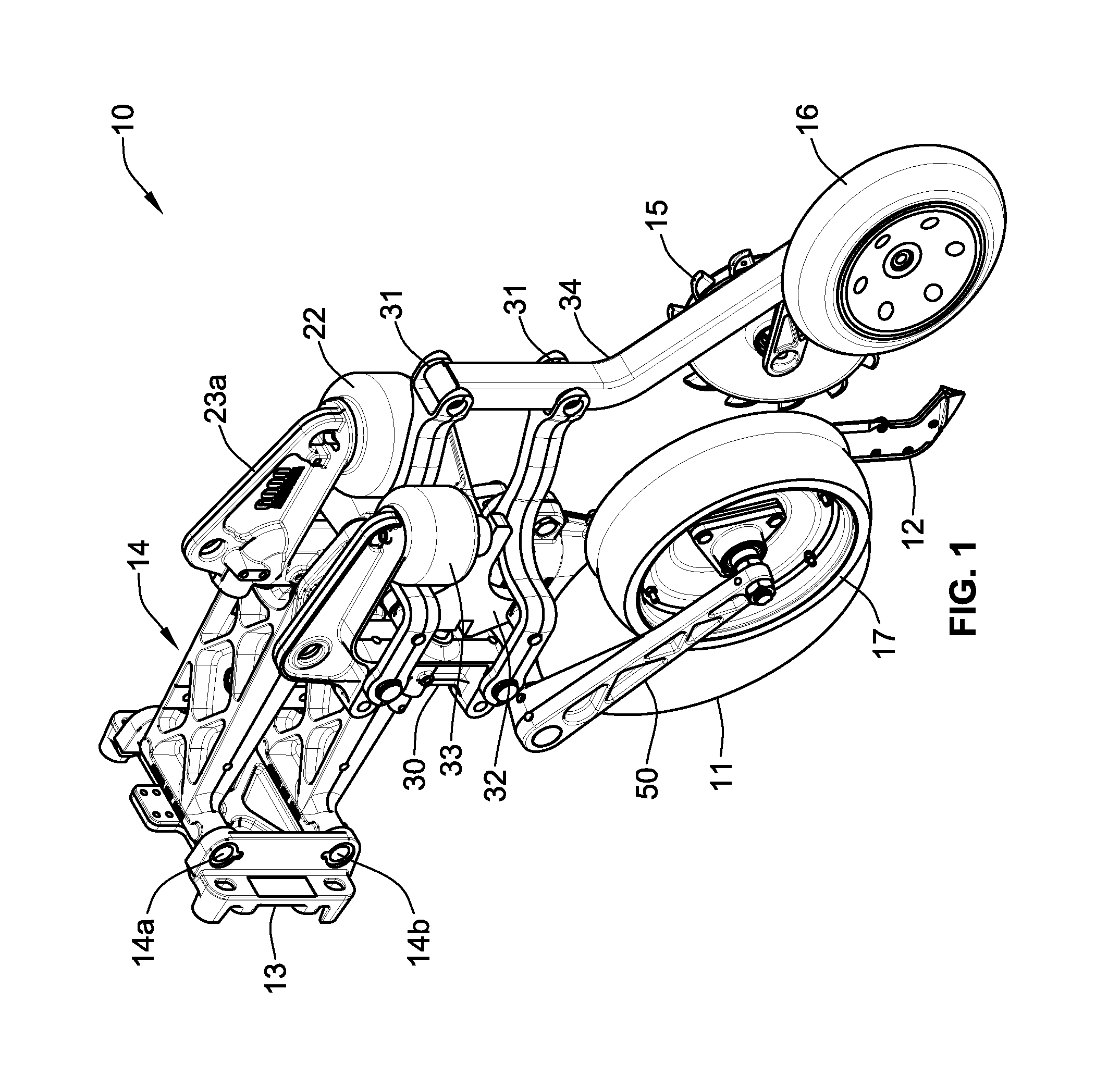

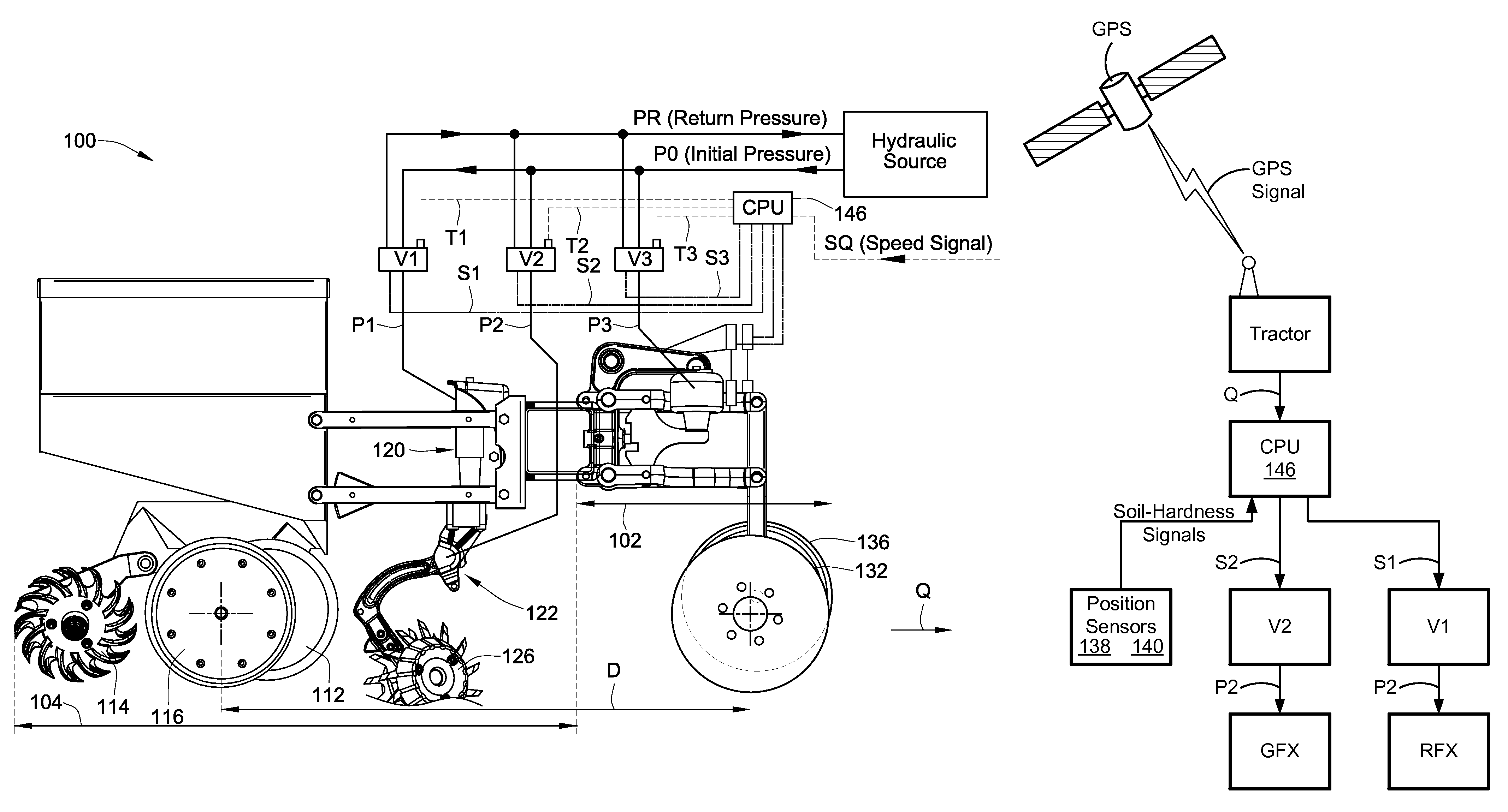

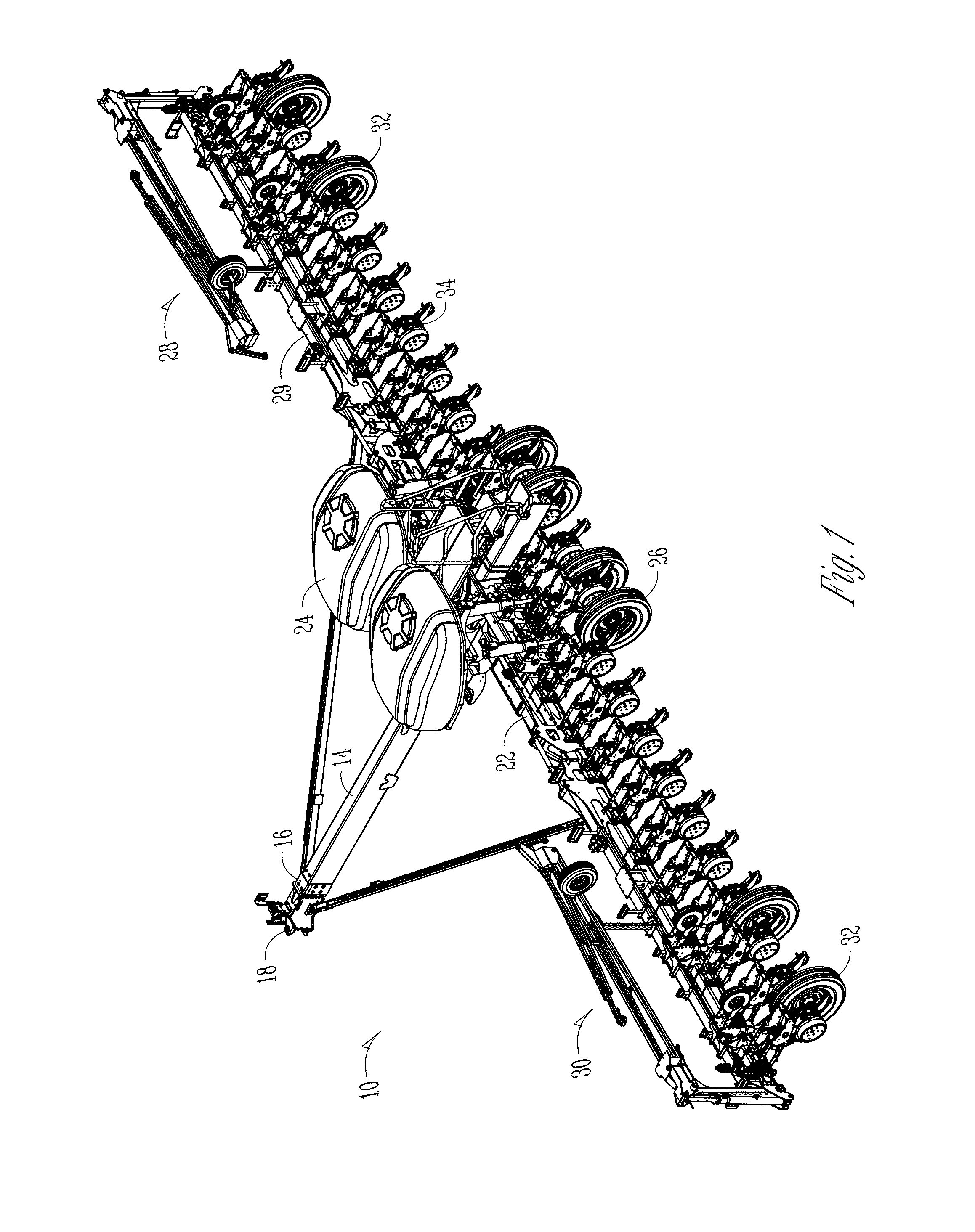

Apparatuses, methods, and systems for providing down force for an agricultural implement

ActiveUS20150264857A1Reduce the amount requiredOvercome deficienciesSpadesAgricultural machinesEngineeringLinear actuator

An agricultural planter includes systems, methods, and apparatus for providing down force pressure at row units of the planter. The row units may include an electric linear actuator connected to linkages of the row units to provide and maintain a down force pressure for the row unit. The linkage may also be removed and replaced with a strut or like mechanism to apply a direct down force pressure to components of the row unit. One or more sensors can be included to obtain information related to the ground to automatically adjust the amount of down force provided based upon a ground characteristic in order to maintain a substantially uniform furrow depth.

Owner:KINZE MFG INC

Tractor with automatic steering arrangement

ActiveUS7721830B2Digital data processing detailsSteering initiationsHydraulic motorHydraulic cylinder

A tractor has hydraulically driven wheels at a cab end and castor wheels at an engine end. It can be driven cab forward in a working mode with a header on the forward end. It is rotated to engine forward in the transport position for more stable higher speed travel. The driven wheels are driven by hydraulic motors each having their own drive pump the output of which is controlled by a cam plate. There is provided an automatic steering system having a guidance controller arranged to receive GPS position information and feed back signals and to generate output for controlling a hydraulic control valve for controlling flow in hydraulic fluid for a double acting hydraulic control cylinder arranged to actuate pivotal movement of the steering link member independently of the steering shaft.

Owner:MACDON INDS

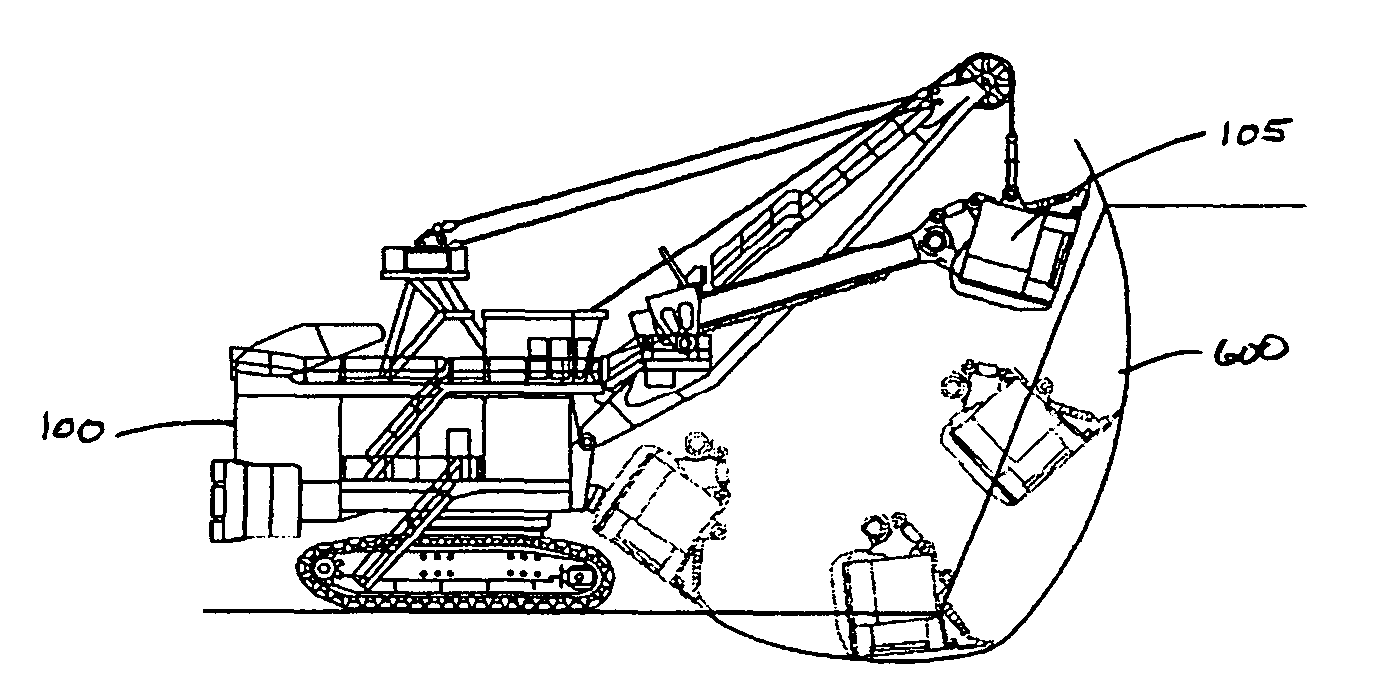

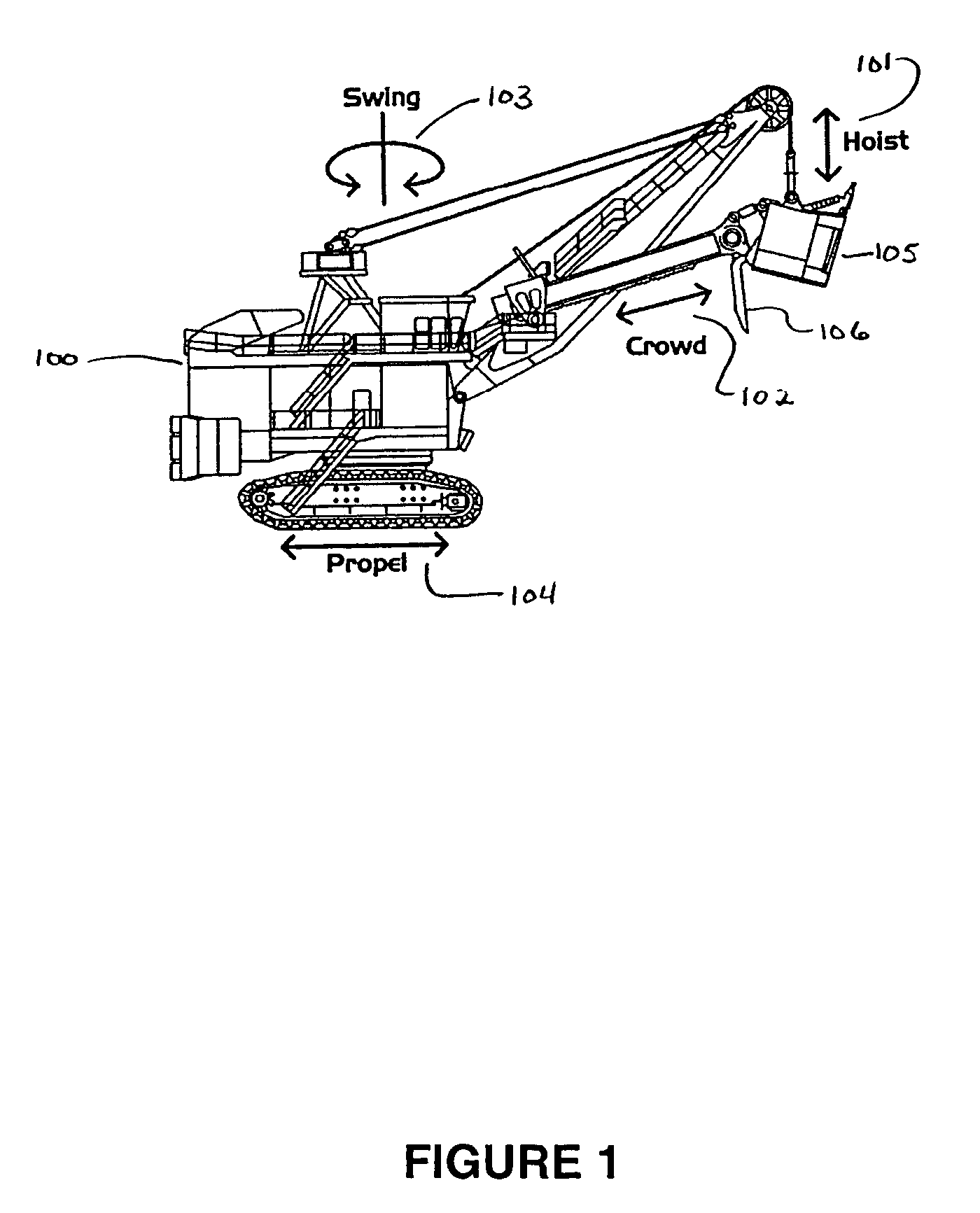

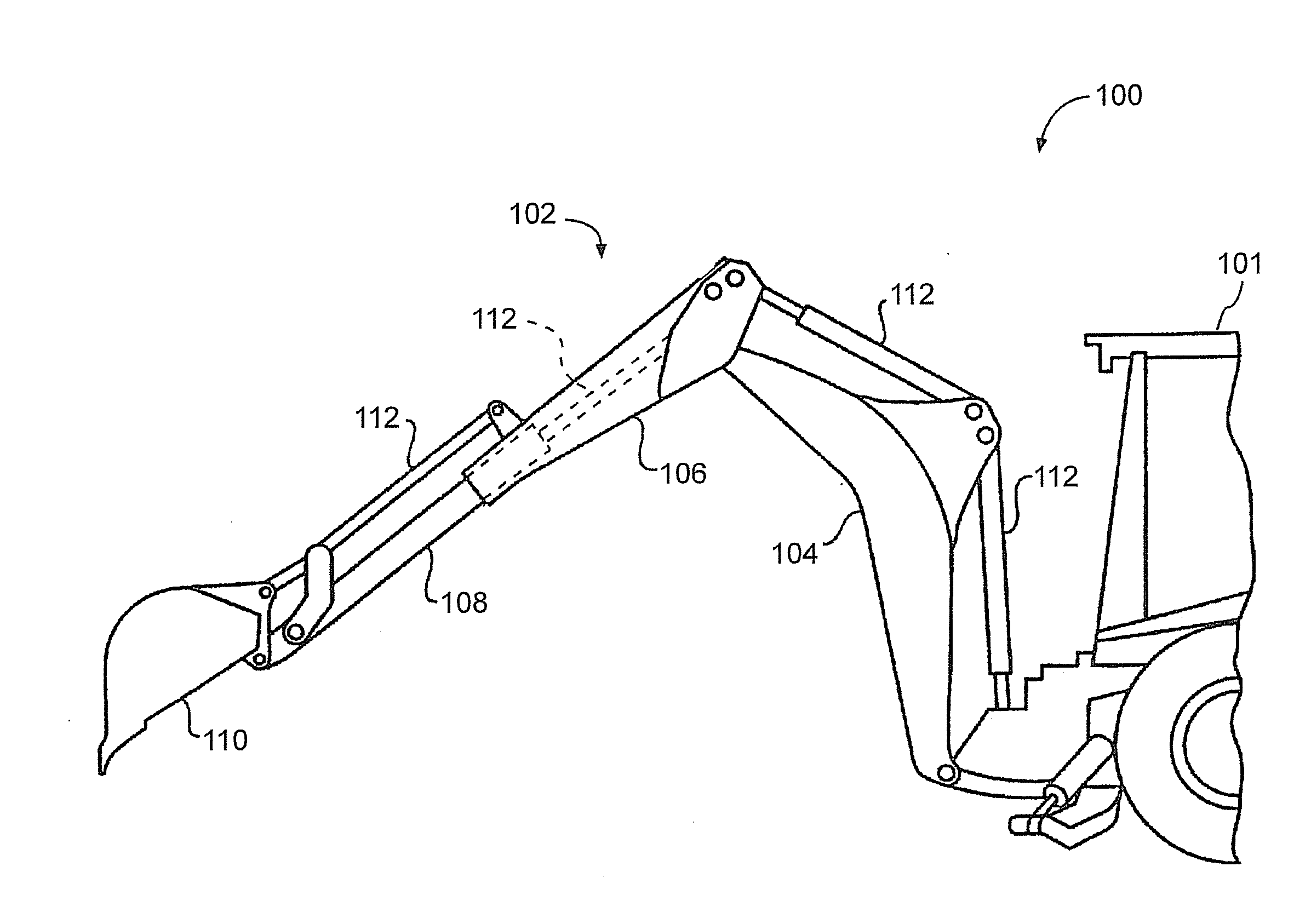

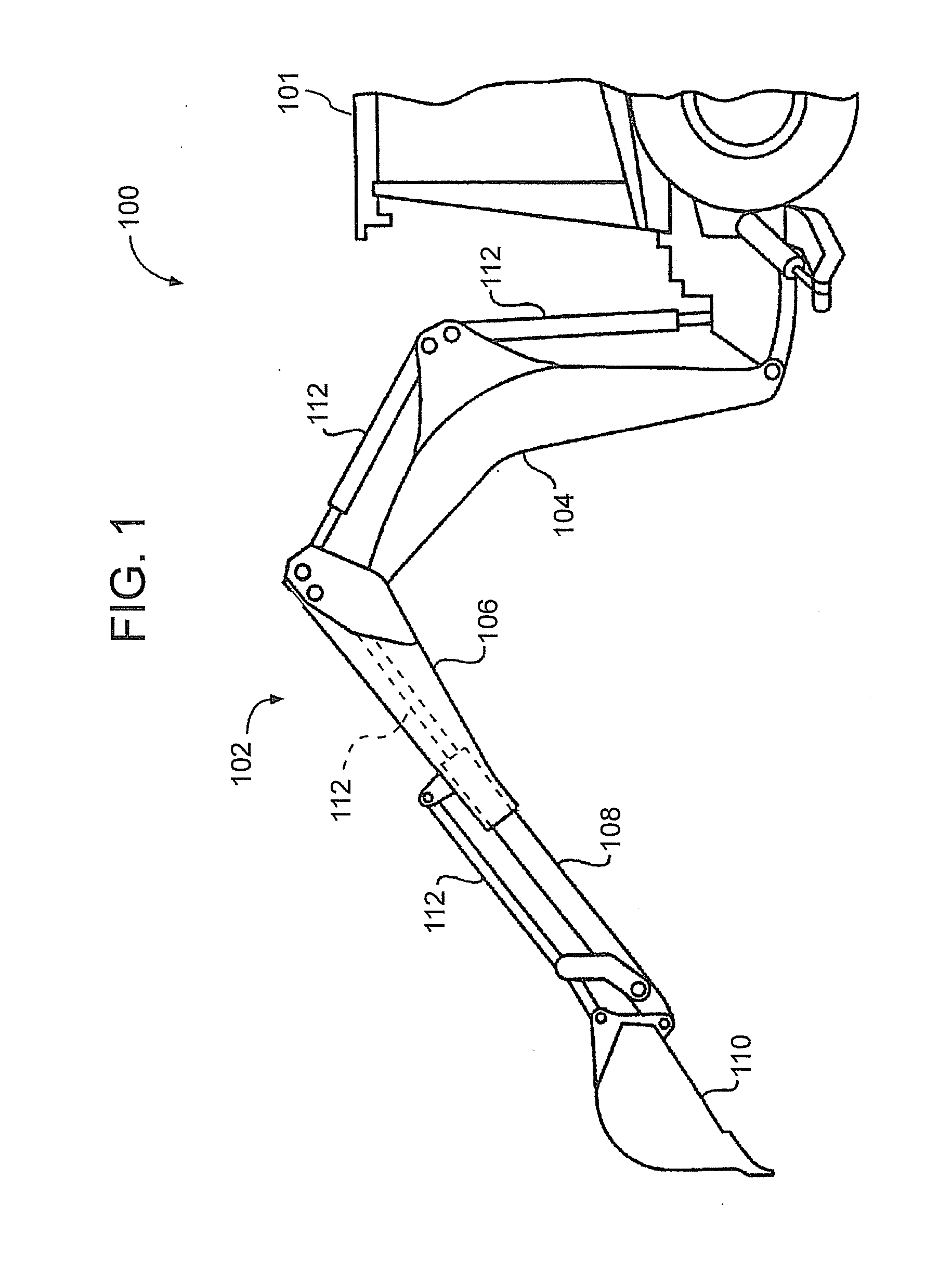

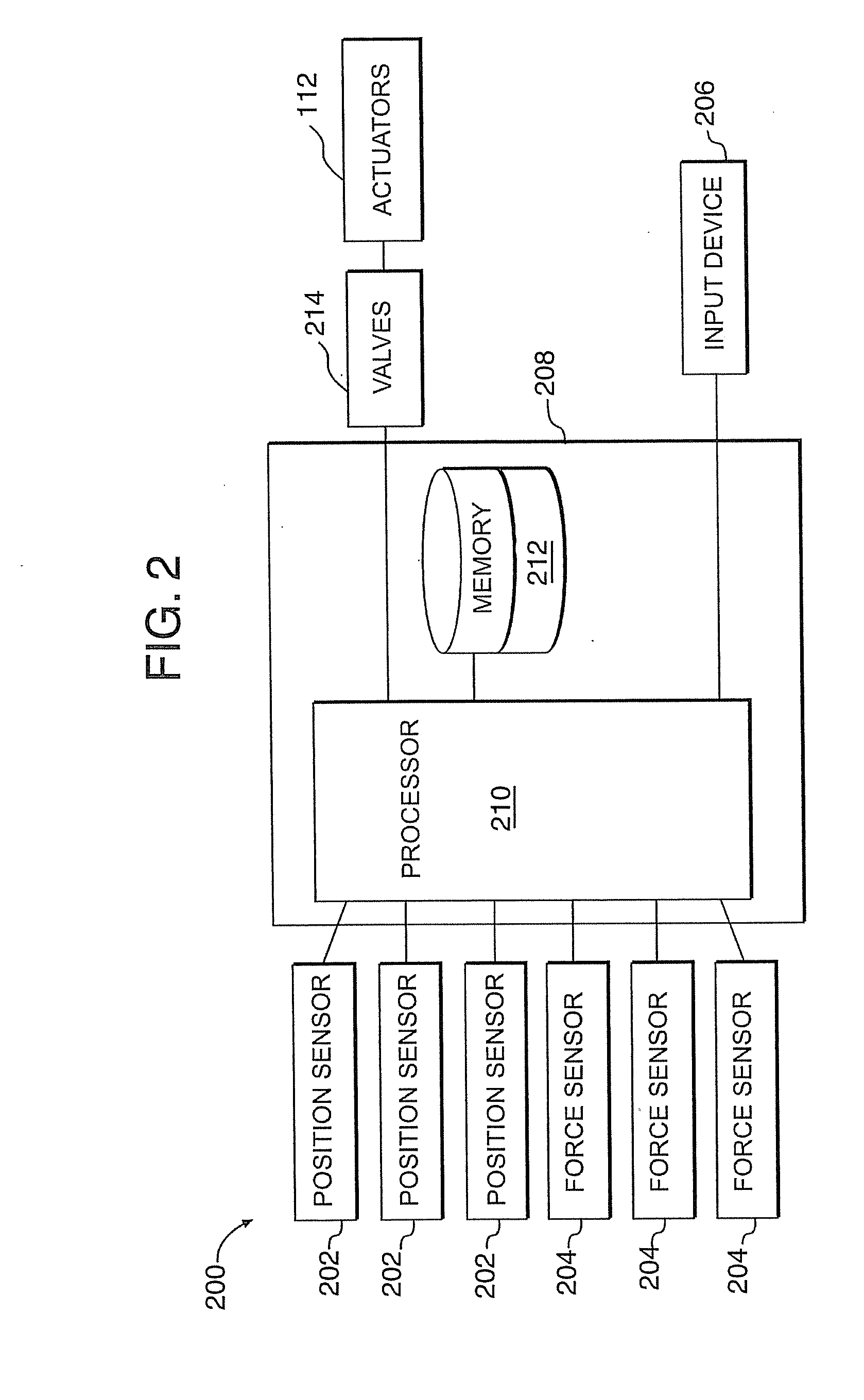

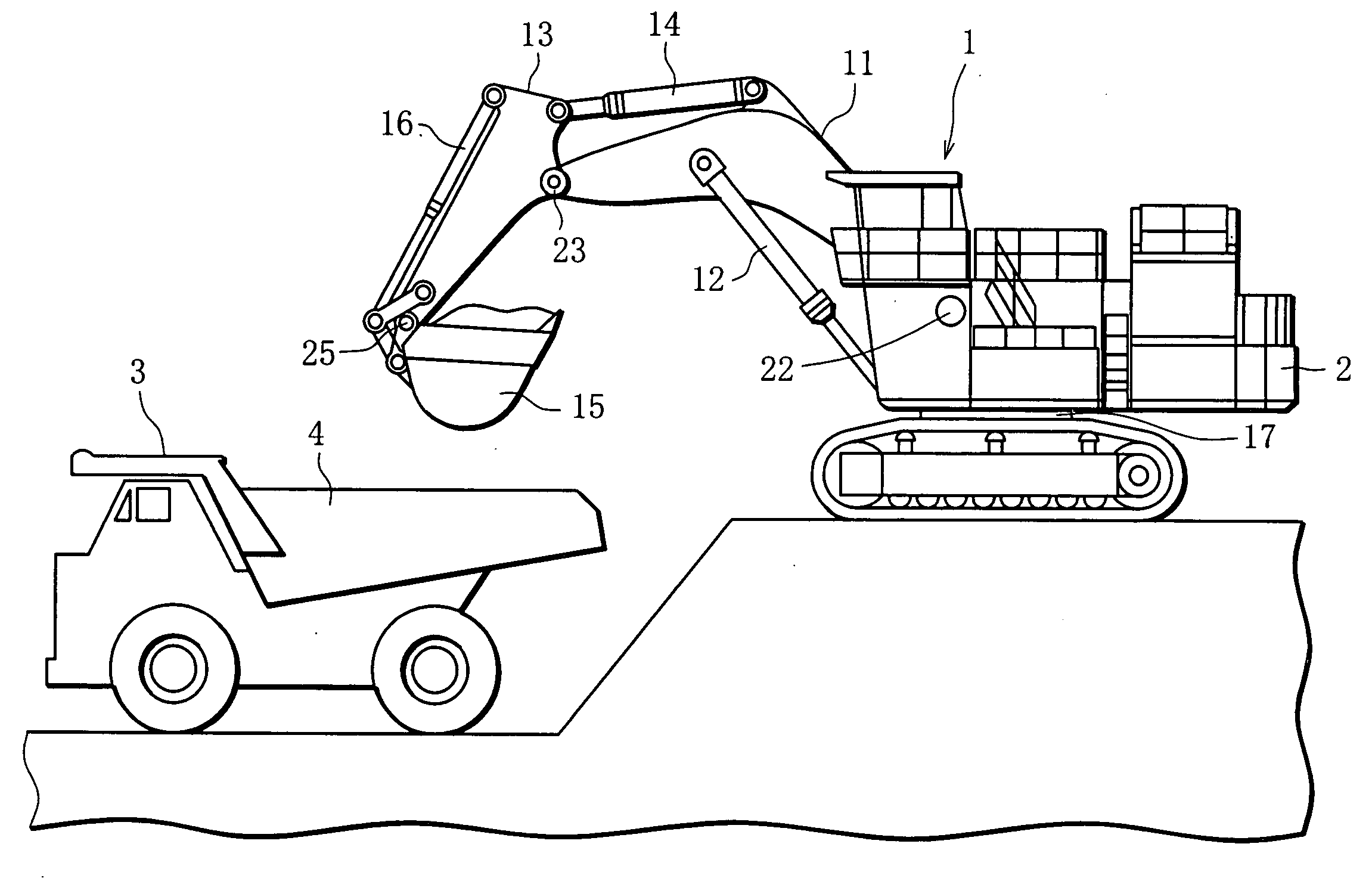

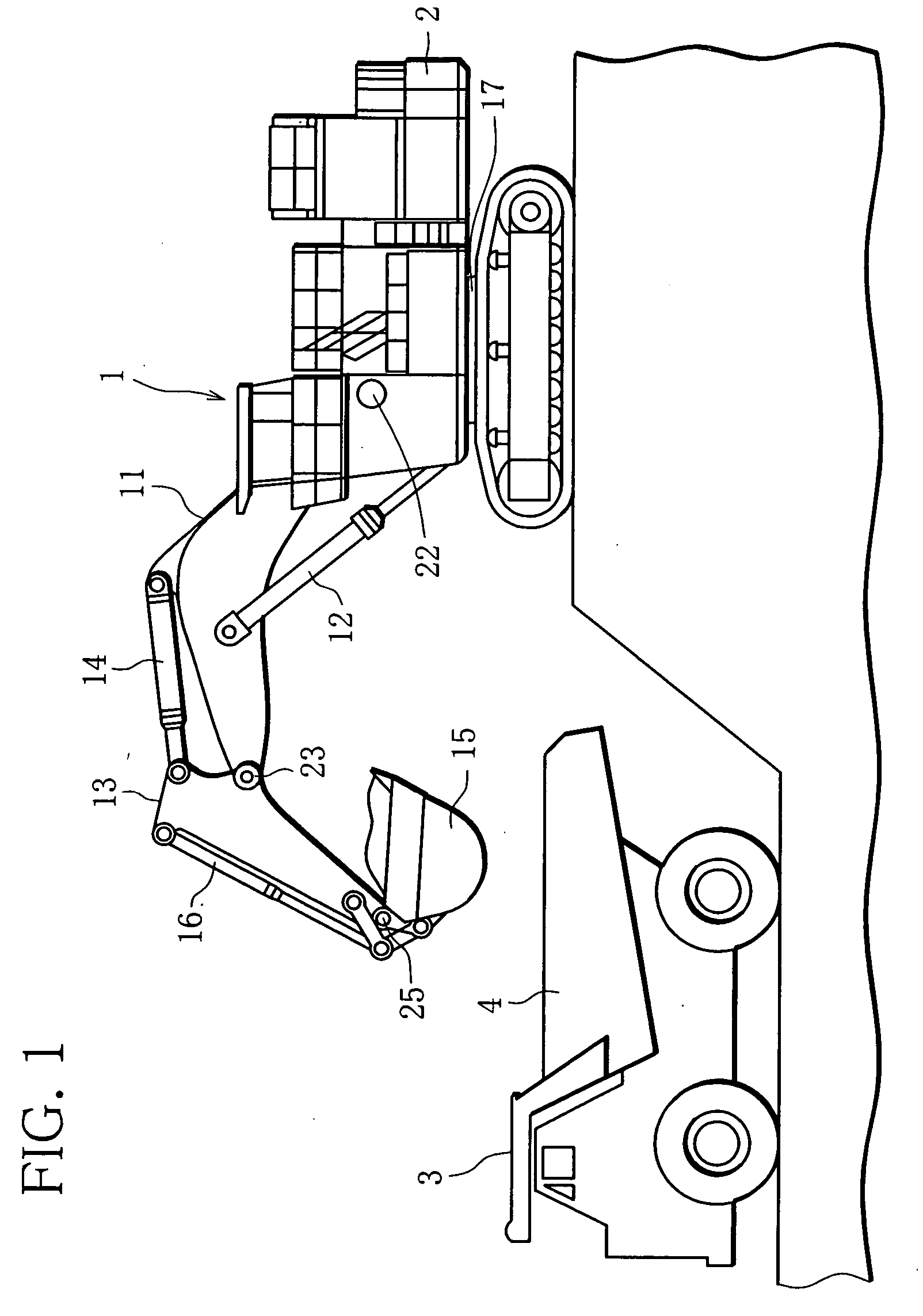

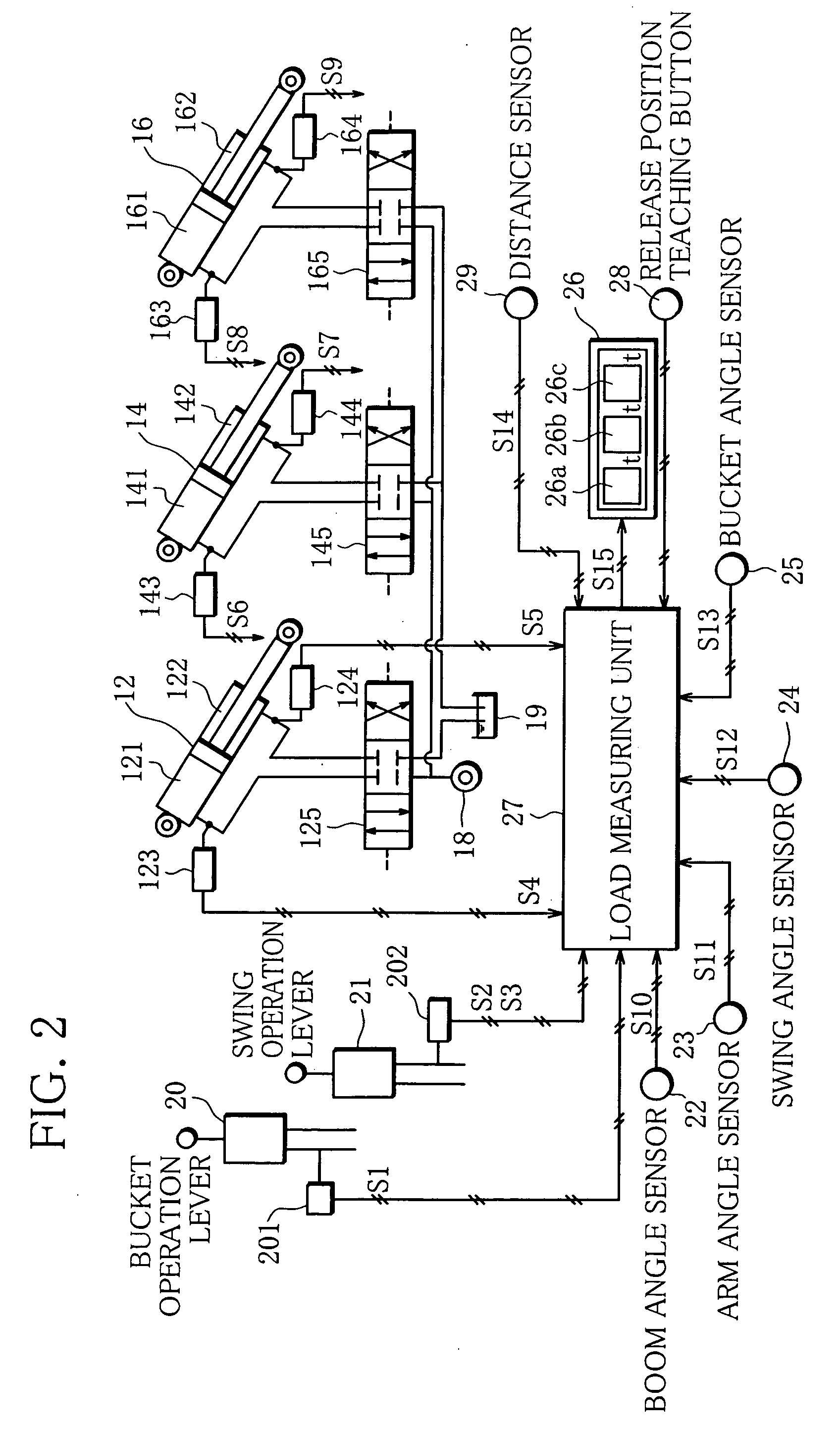

Hydraulic shovel work amount detection apparatus, work amount detection method, work amount detection result display apparatus

InactiveUS20050000703A1Precise managementIncrease weightAnalogue computers for trafficSoil-shifting machines/dredgersExcavatorMaterial transfer

During transfer of a material by a hydraulic excavator, load computing means periodically computes the weight of the material in a bucket of the excavator. Average value computing means computes an average value of weights of the material including a currently computed weight and a predetermined number of weights computed prior to the currently computed weight (M6), and standard deviation computing means computes, based on the average value, a standard deviation of the weights of the material (M7). True load value determining means selects a minimum standard deviation from among the standard deviations computed by the standard deviation computing means from the start of the transfer of the material to a different location until the end of the transfer of same, and judges the average value based on which the minimum standard deviation was computed, to be a true value of the weight of the material (M10, M11).

Owner:NIHON KENKI CO LTD

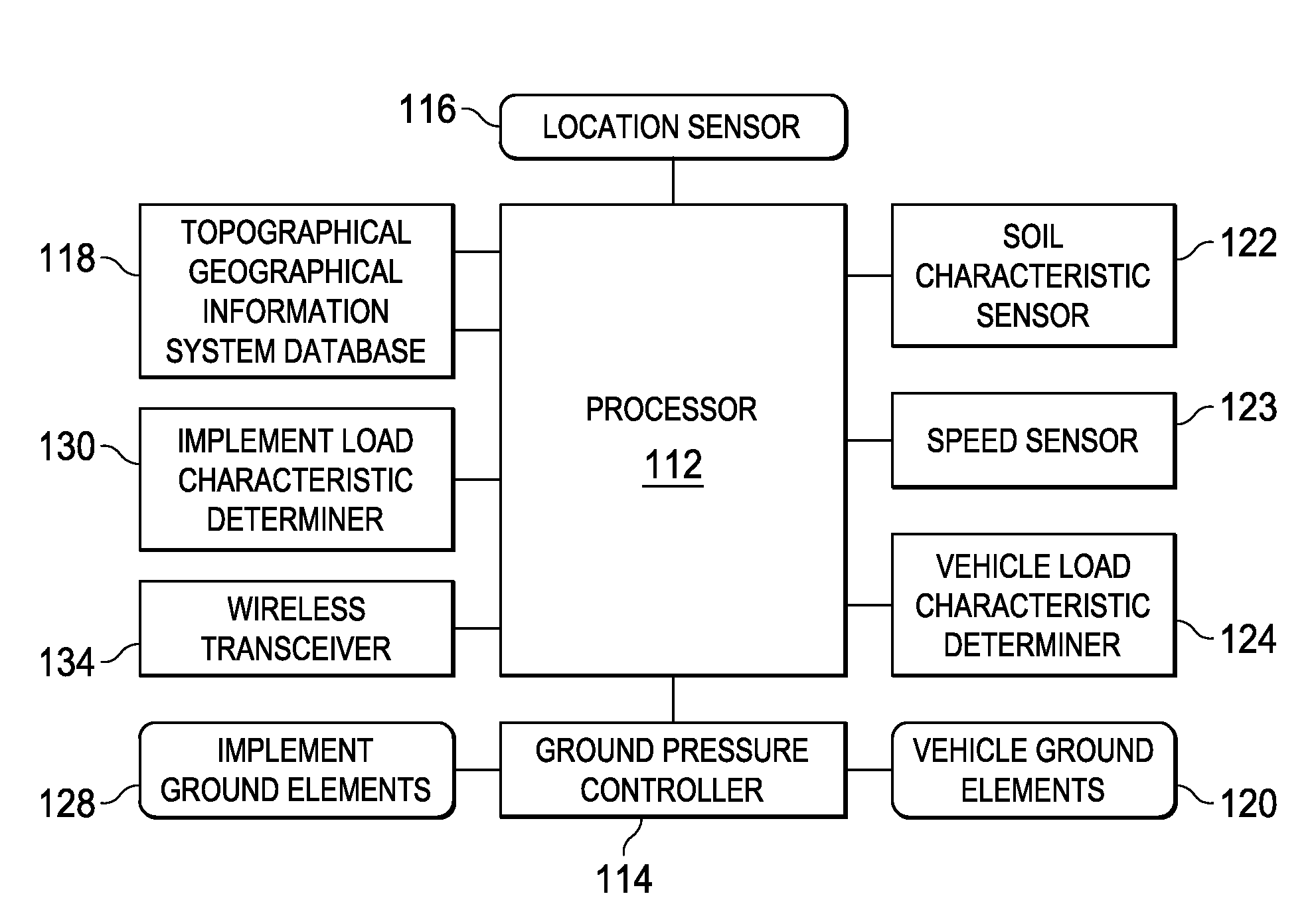

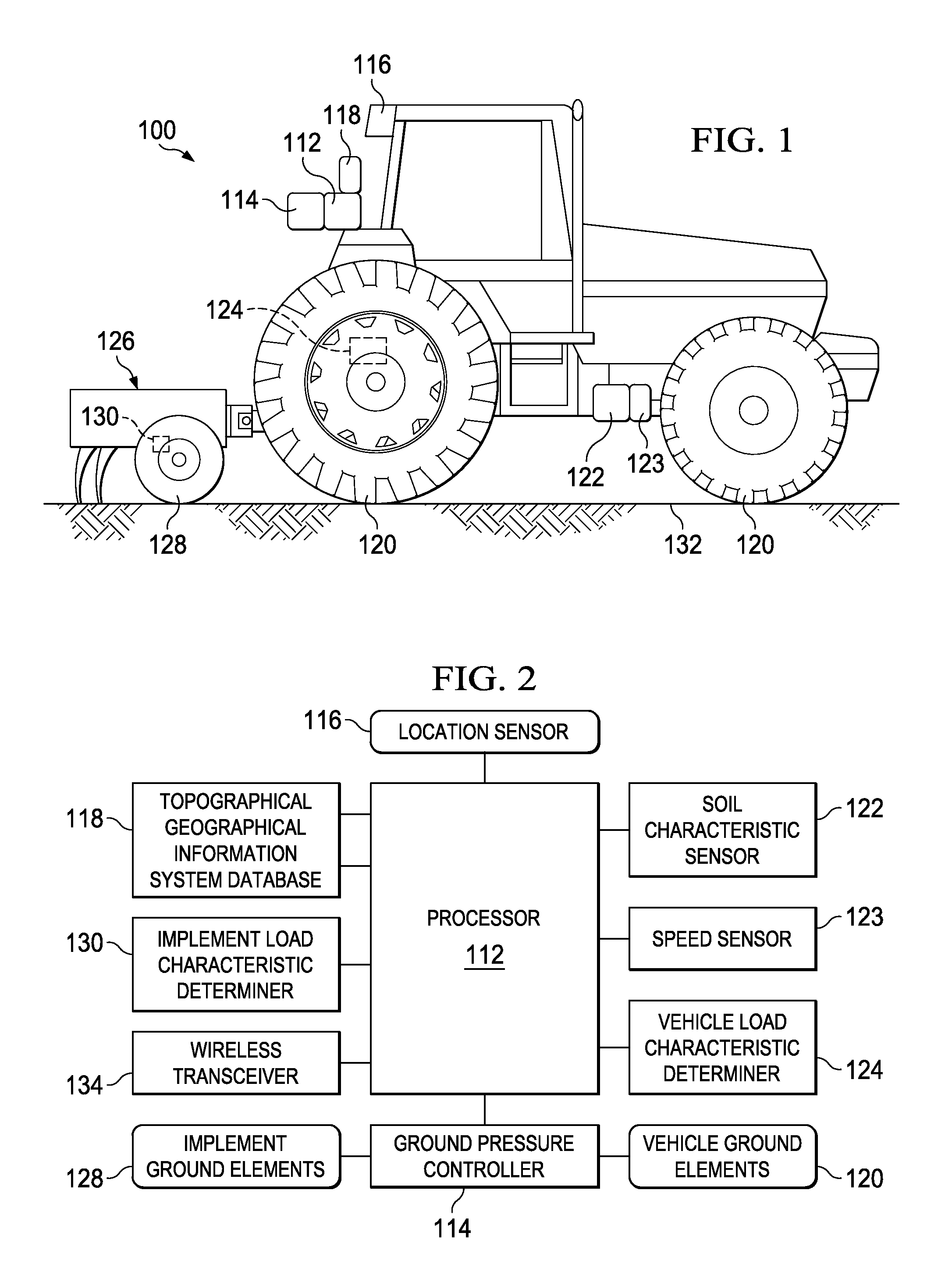

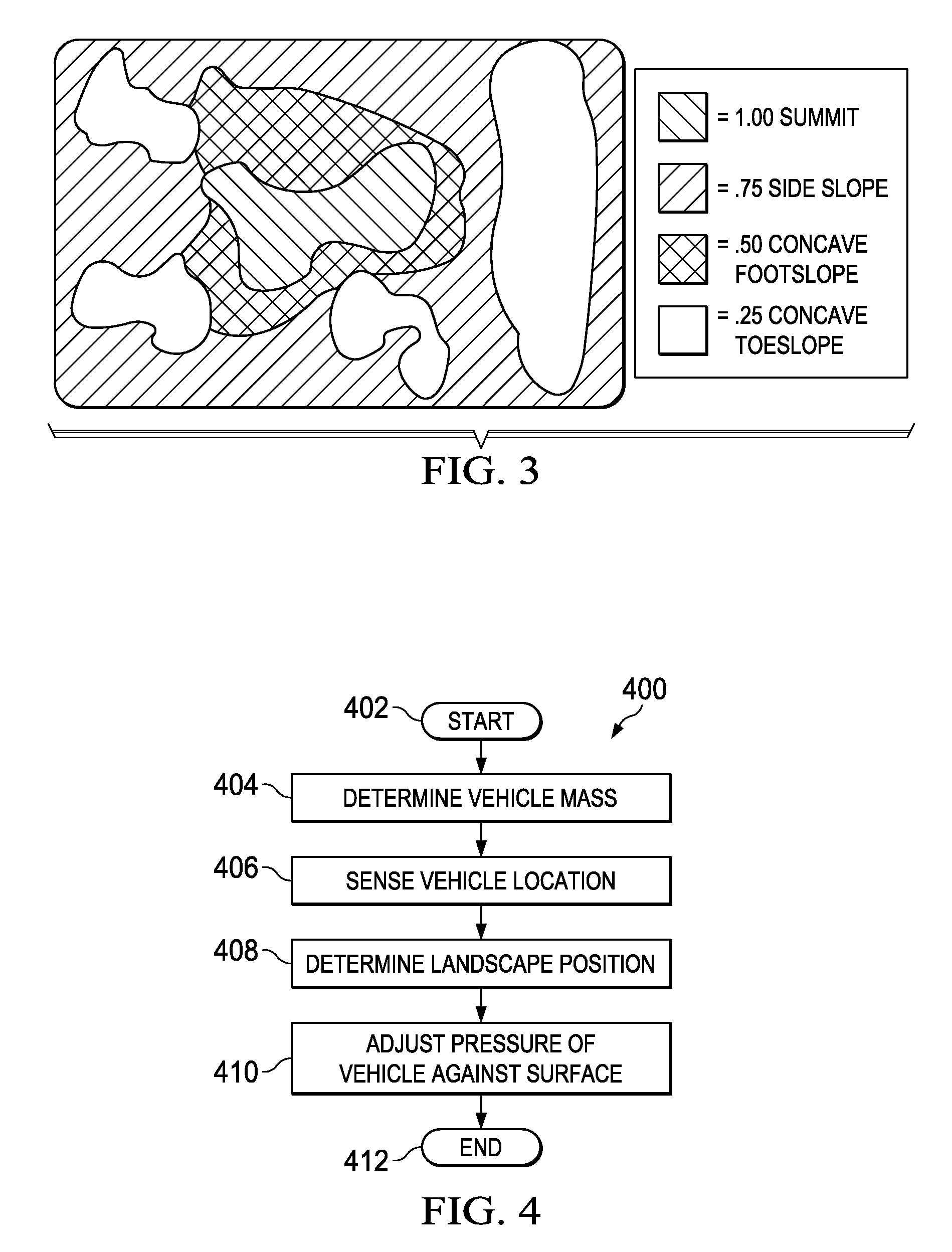

Vehicle soil pressure management based on topography

Systems and techniques are provided for managing an interface between a machine or work vehicle and a surface that the machine / work vehicle travels on in order to provide an optimum work performance level that balances fuel efficiency and surface adversity. Fleet management and reporting capabilities pertaining to such interface management are also provided.

Owner:DEERE & CO

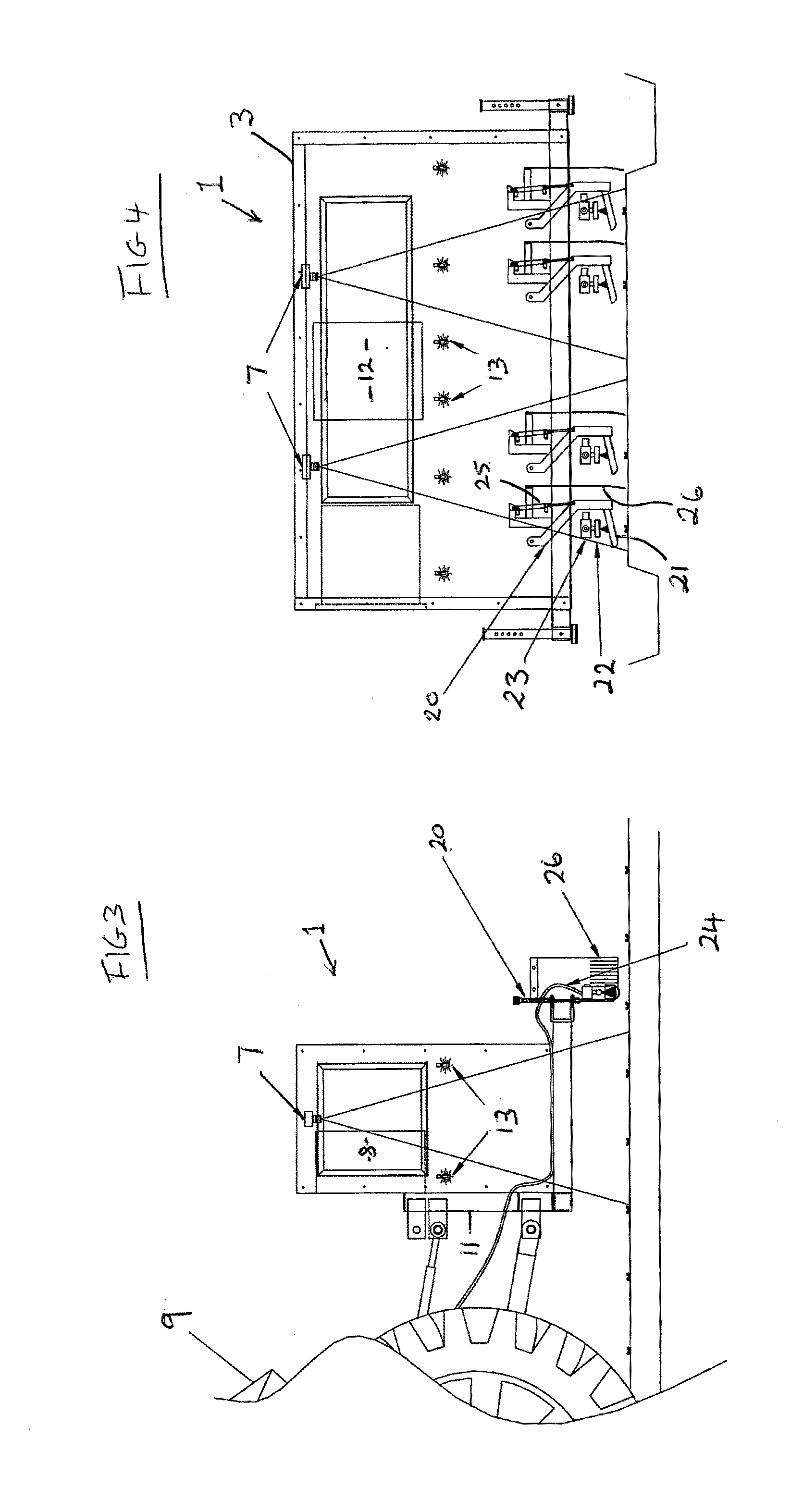

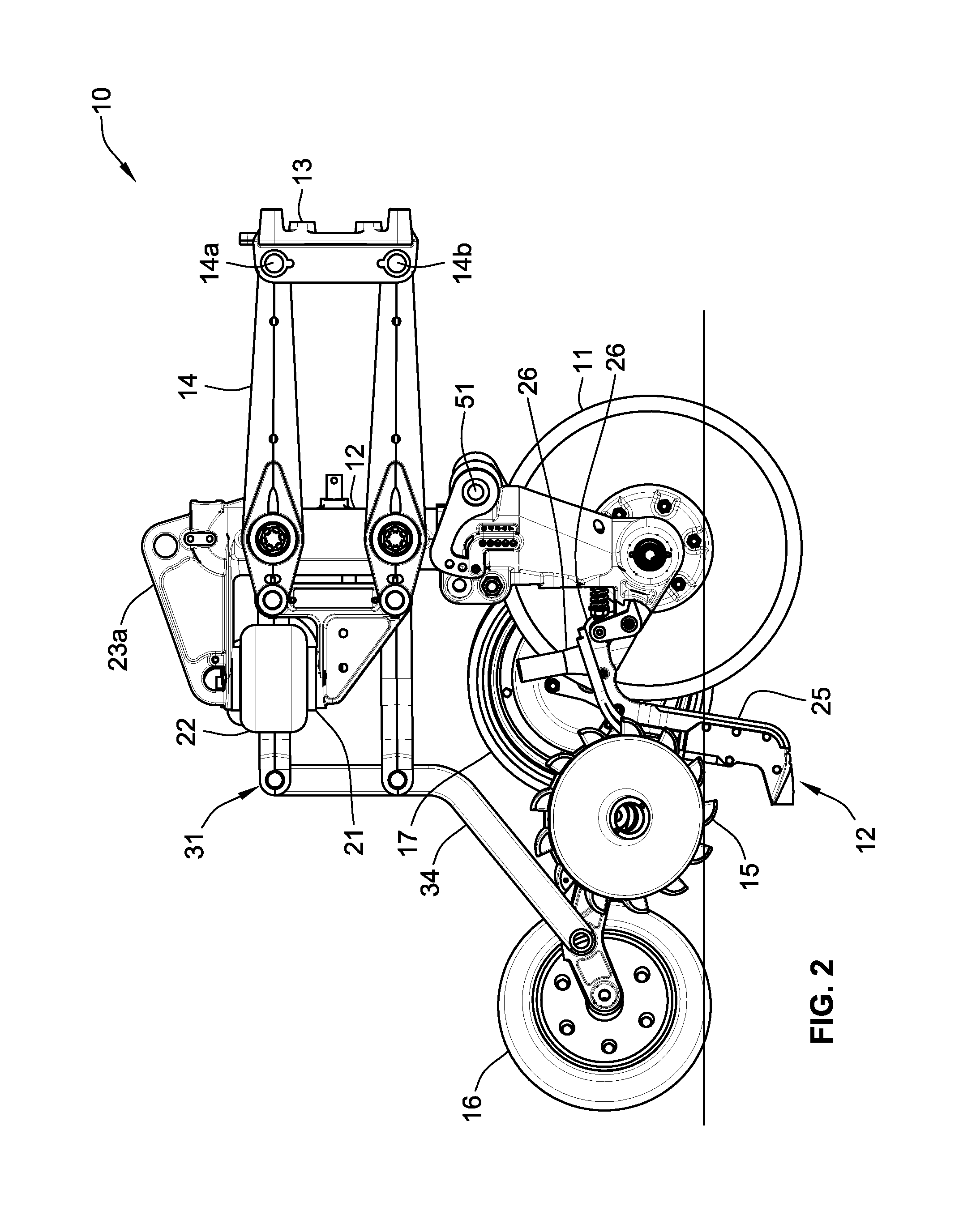

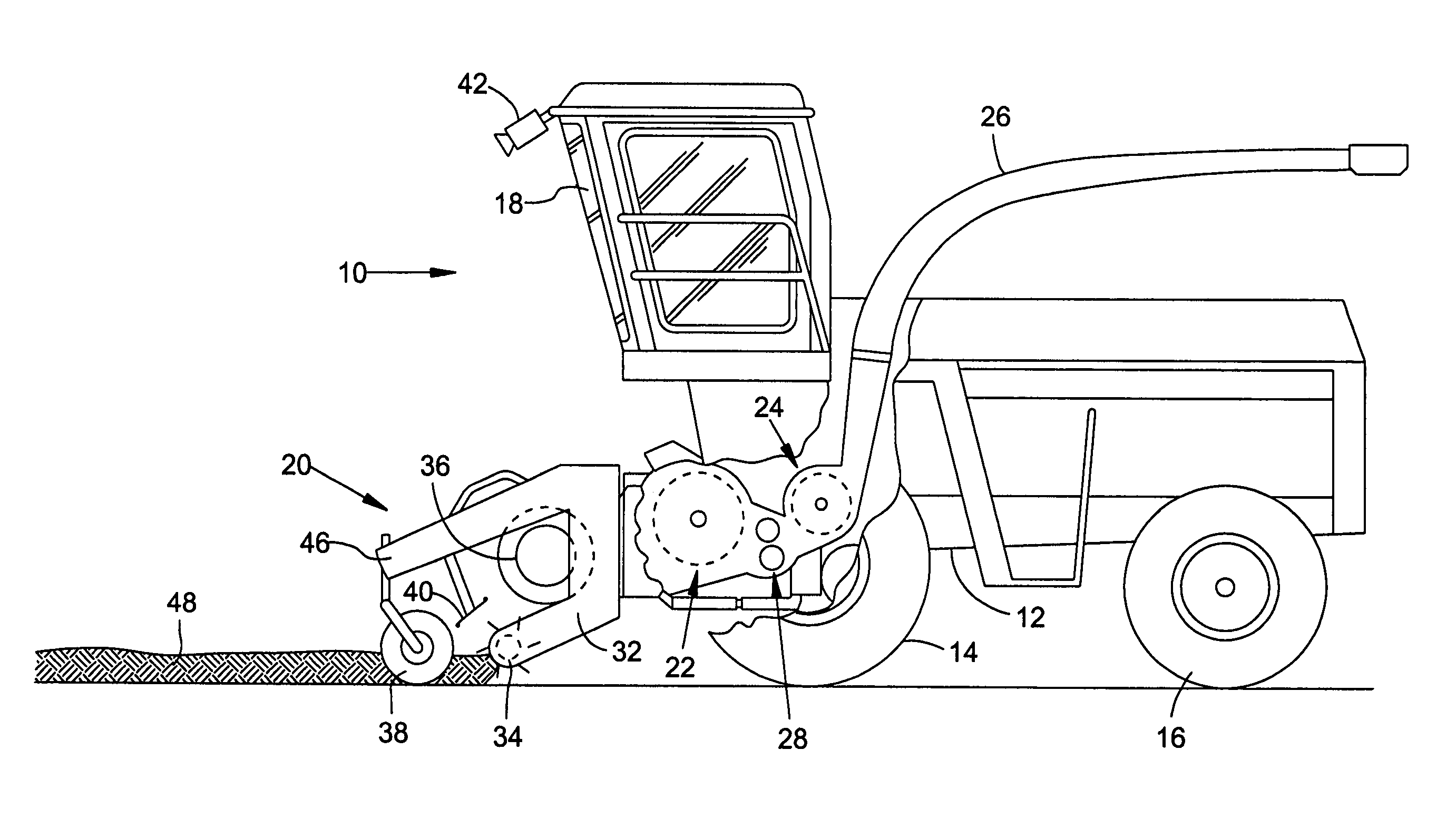

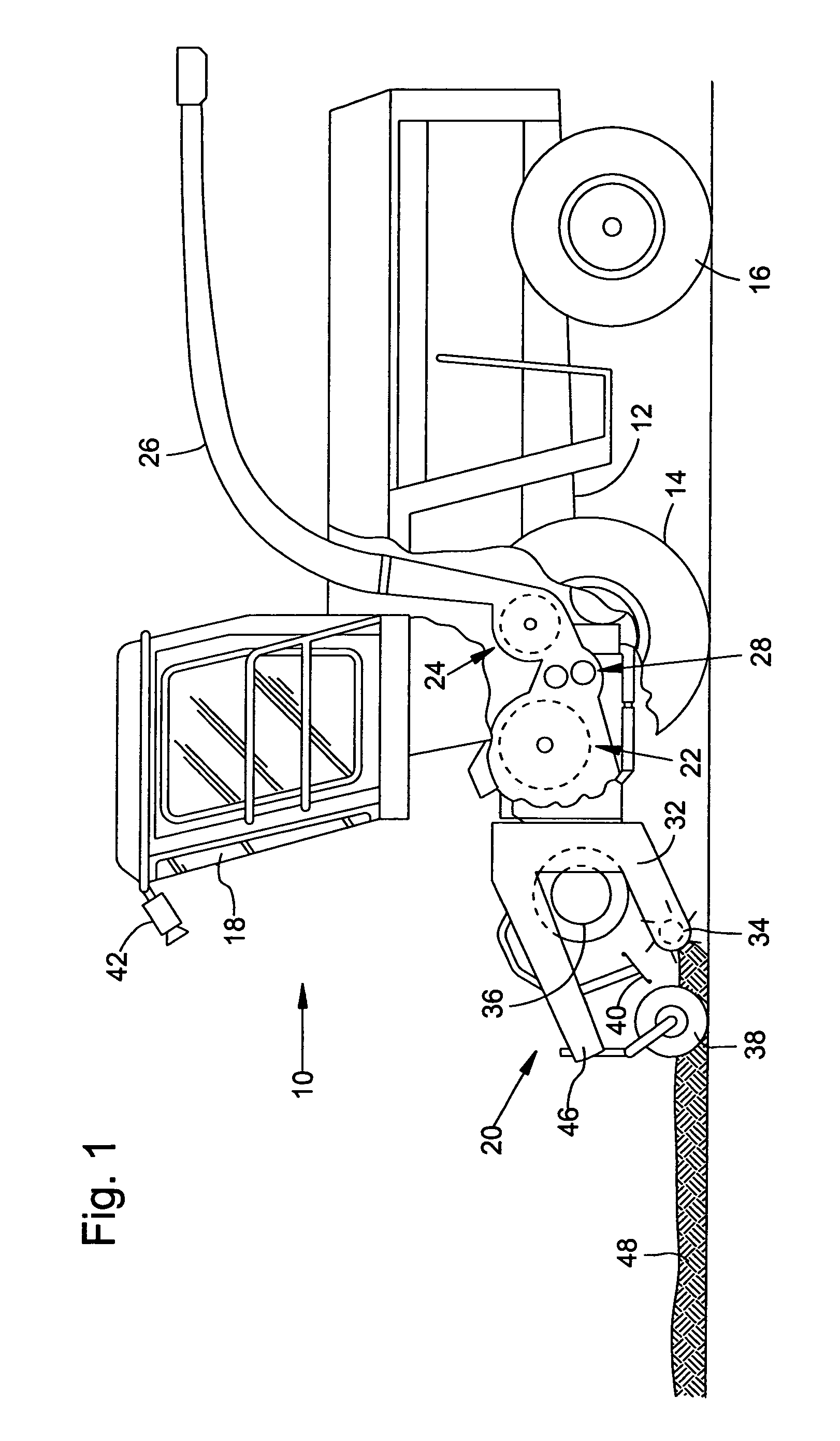

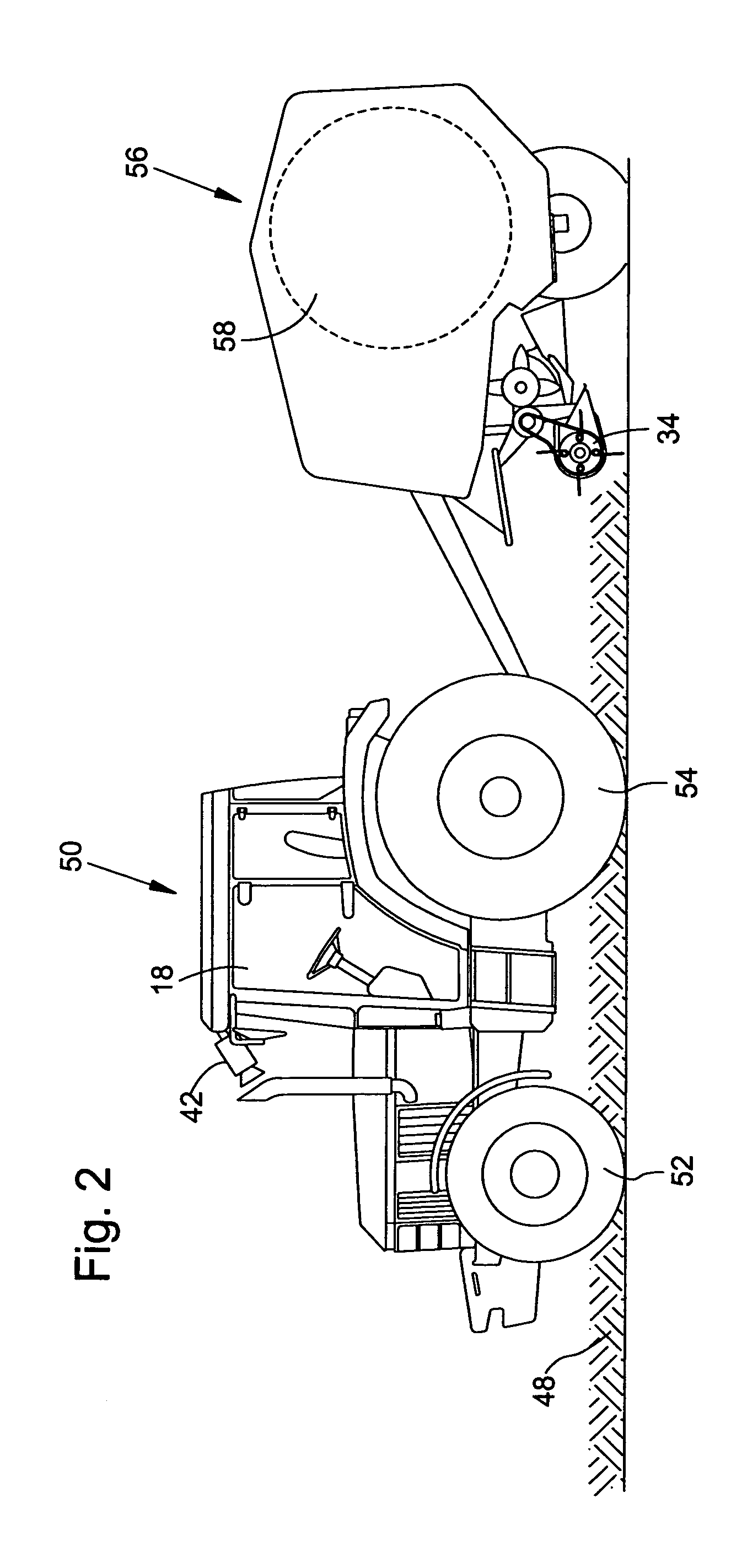

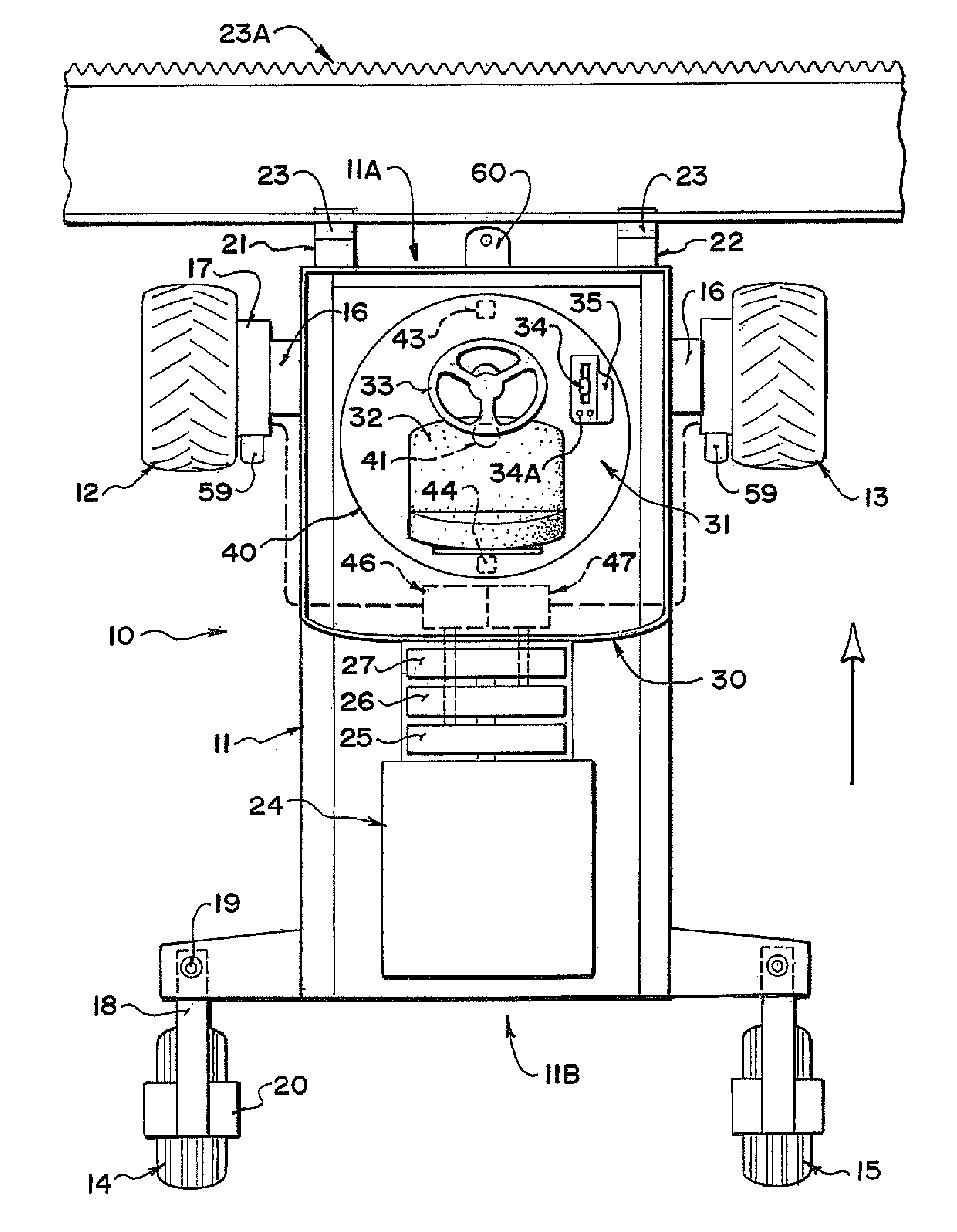

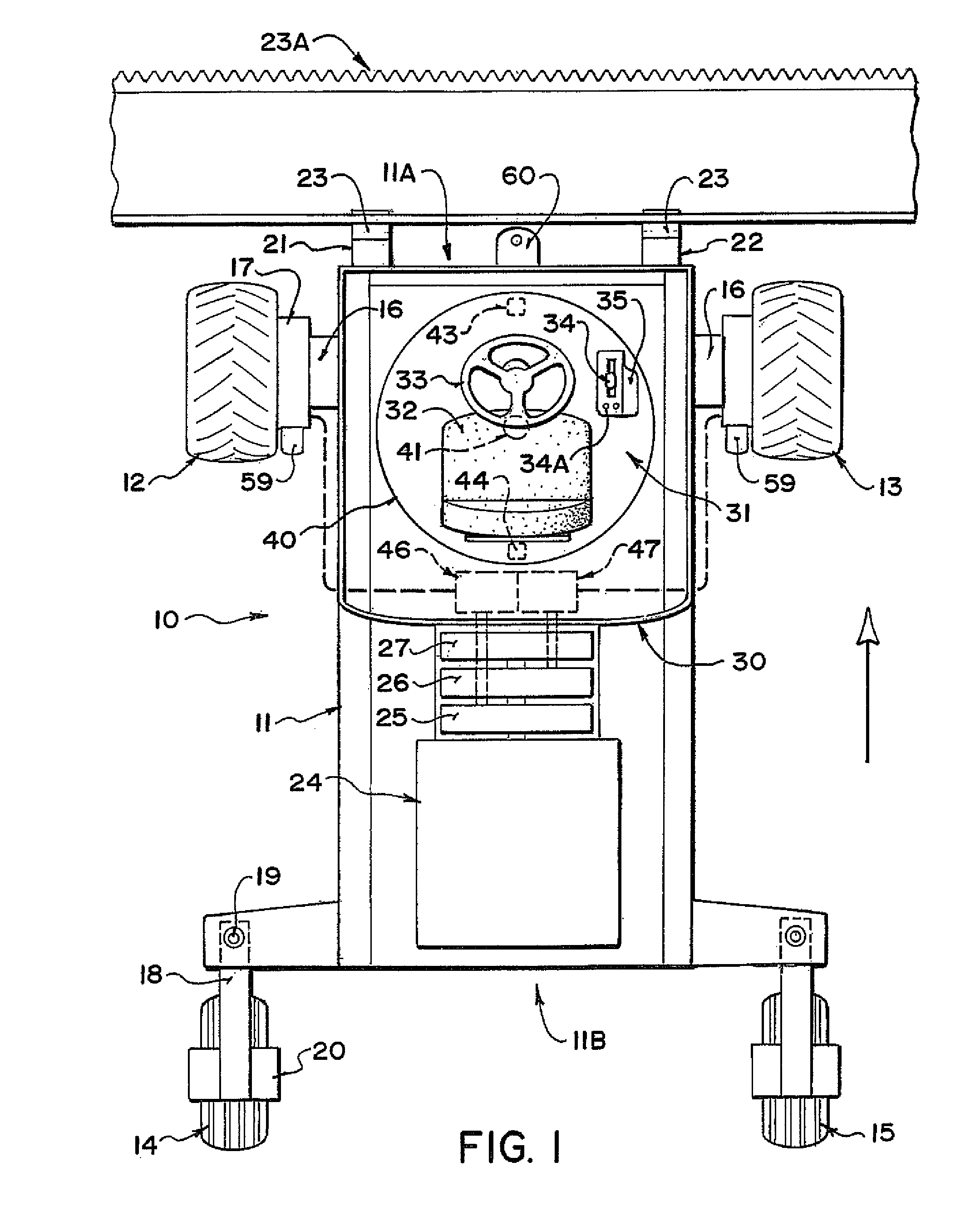

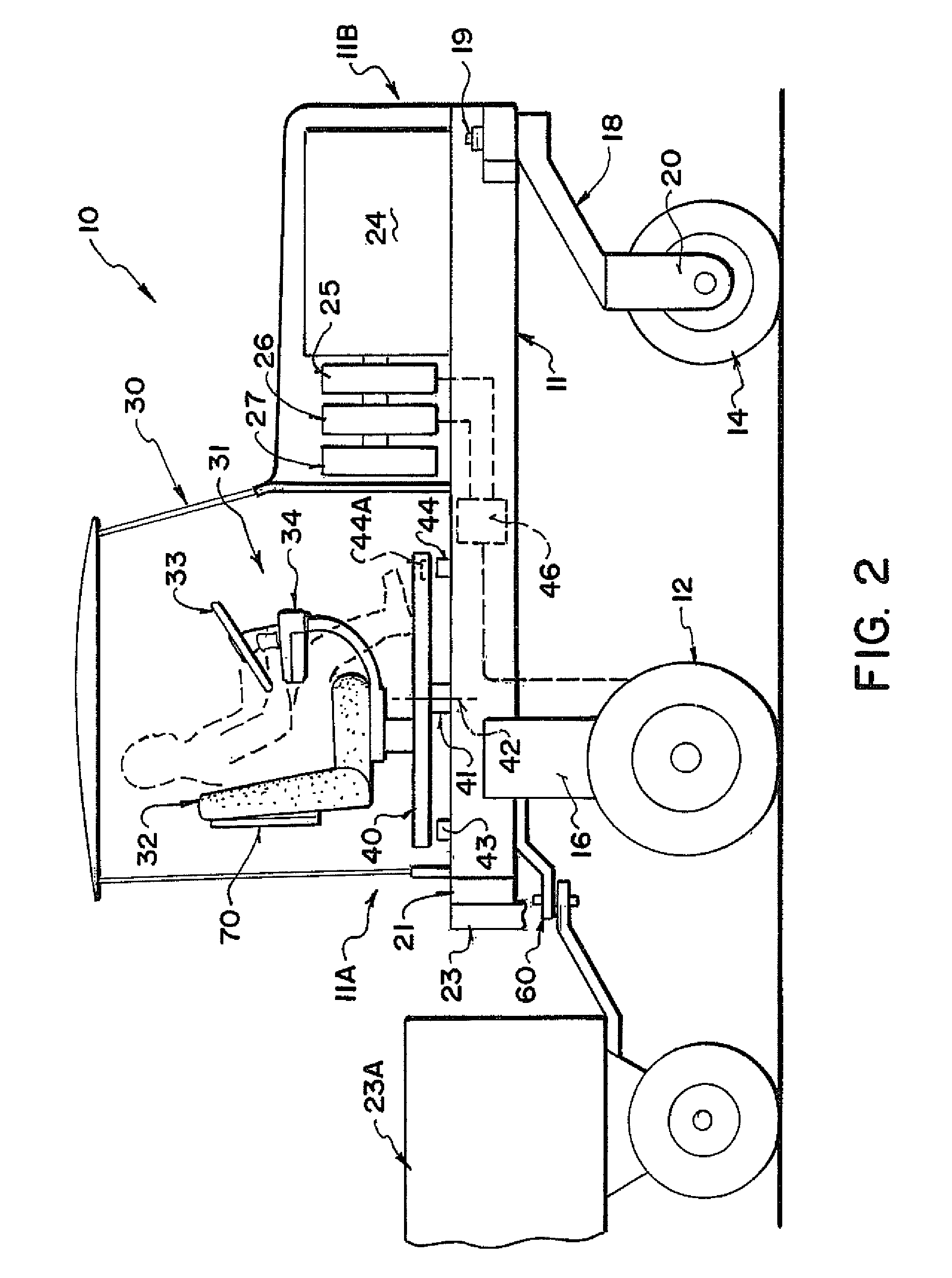

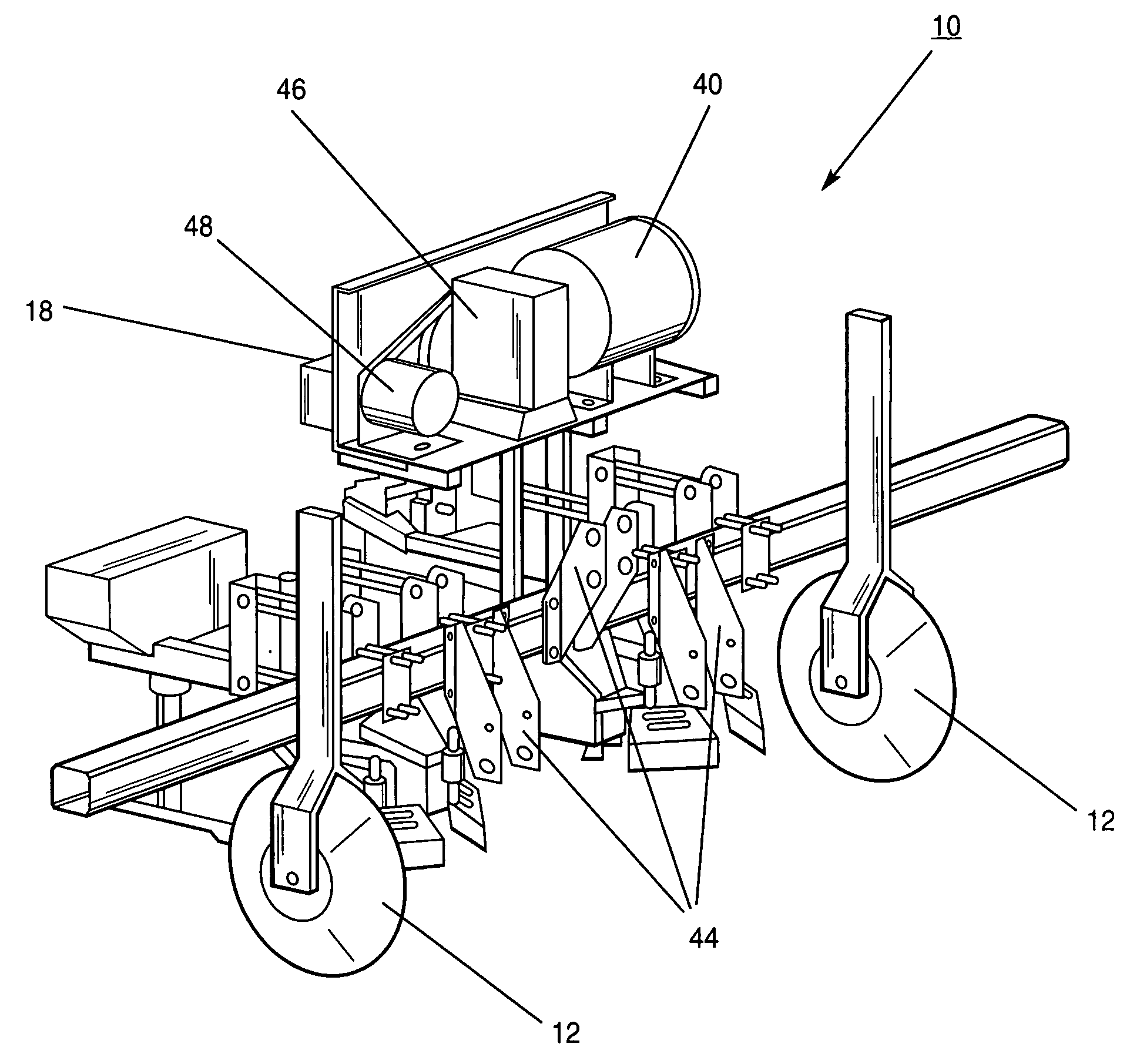

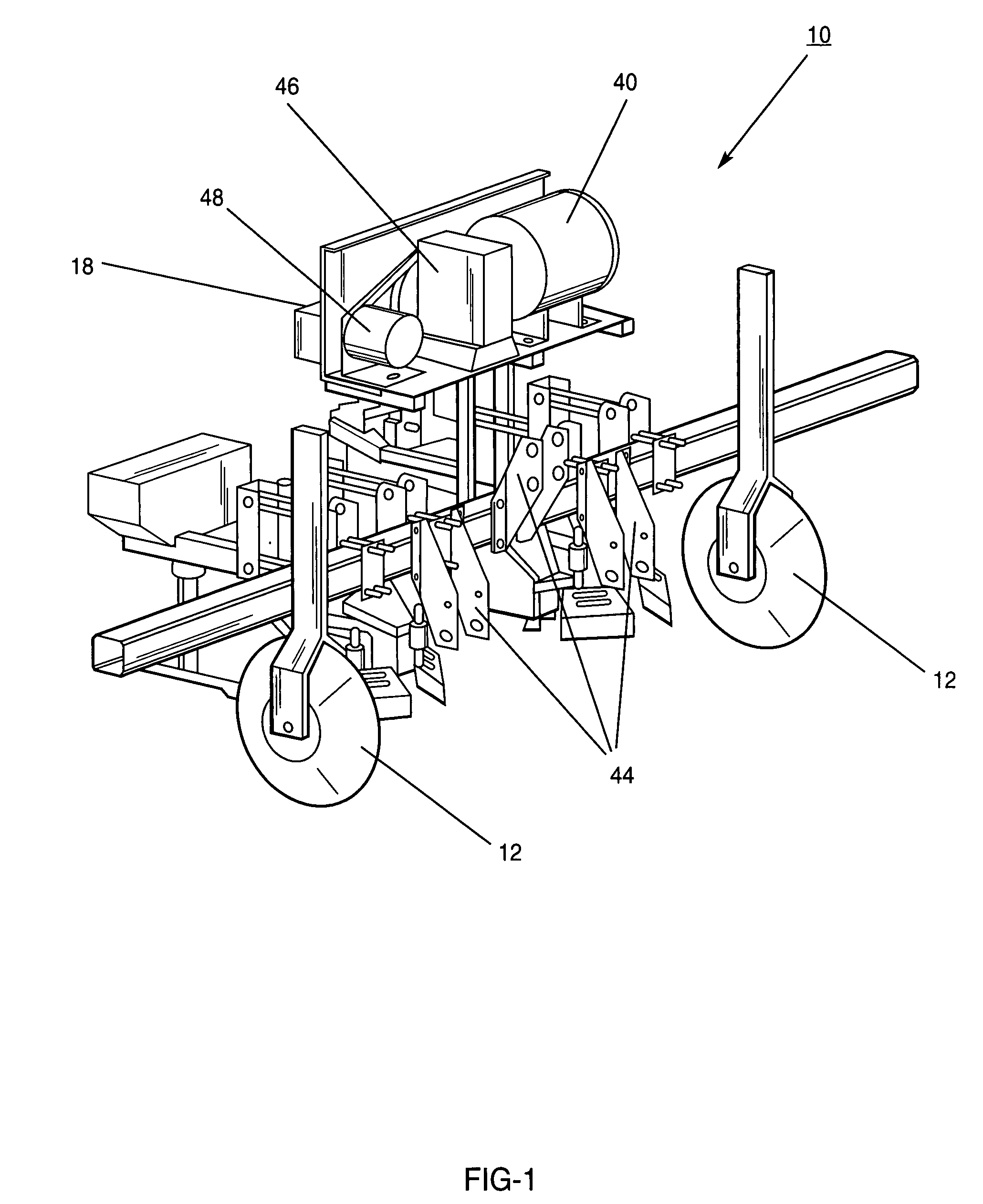

Crop thinning apparatus and method

InactiveUS7032369B1Agricultural machinesHedge trimming apparatusElectronic control systemControl system

A method and apparatus for mechanically thinning crops, particularly those planted in rows. One or more crop thinning units are connected to the back of a tractor or other vehicle. Each of the units has the ability to sense plants and activate an arm which has a blade disposed thereon. An electronic control system enables data from several sensors to be evaluated such that plants may be selectively removed based on pre-established criteria. Sensors differentiate between weeds and plants, and maintain the cutting units above the crop rows.

Owner:ARROWHEAD CENT +1

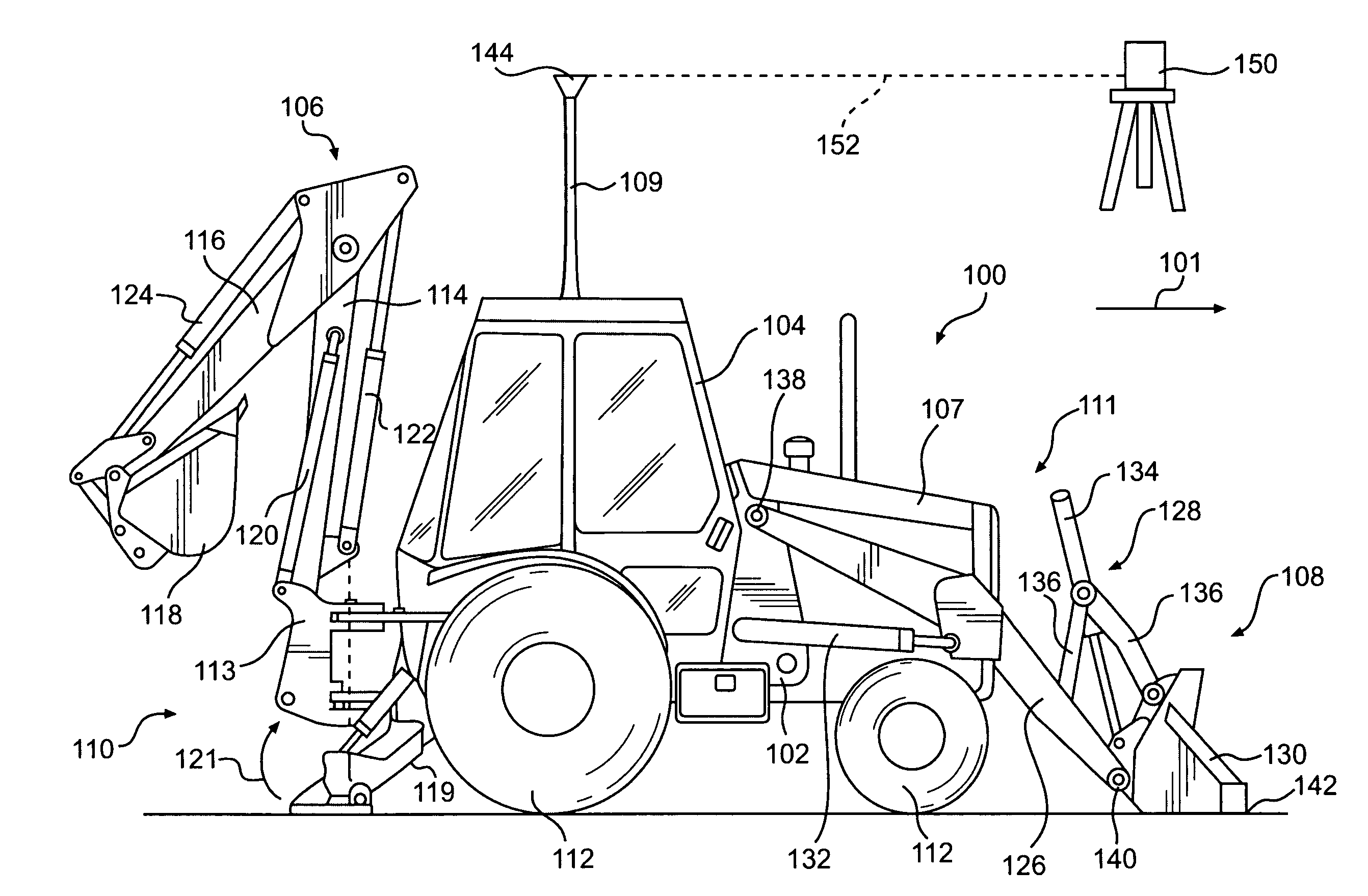

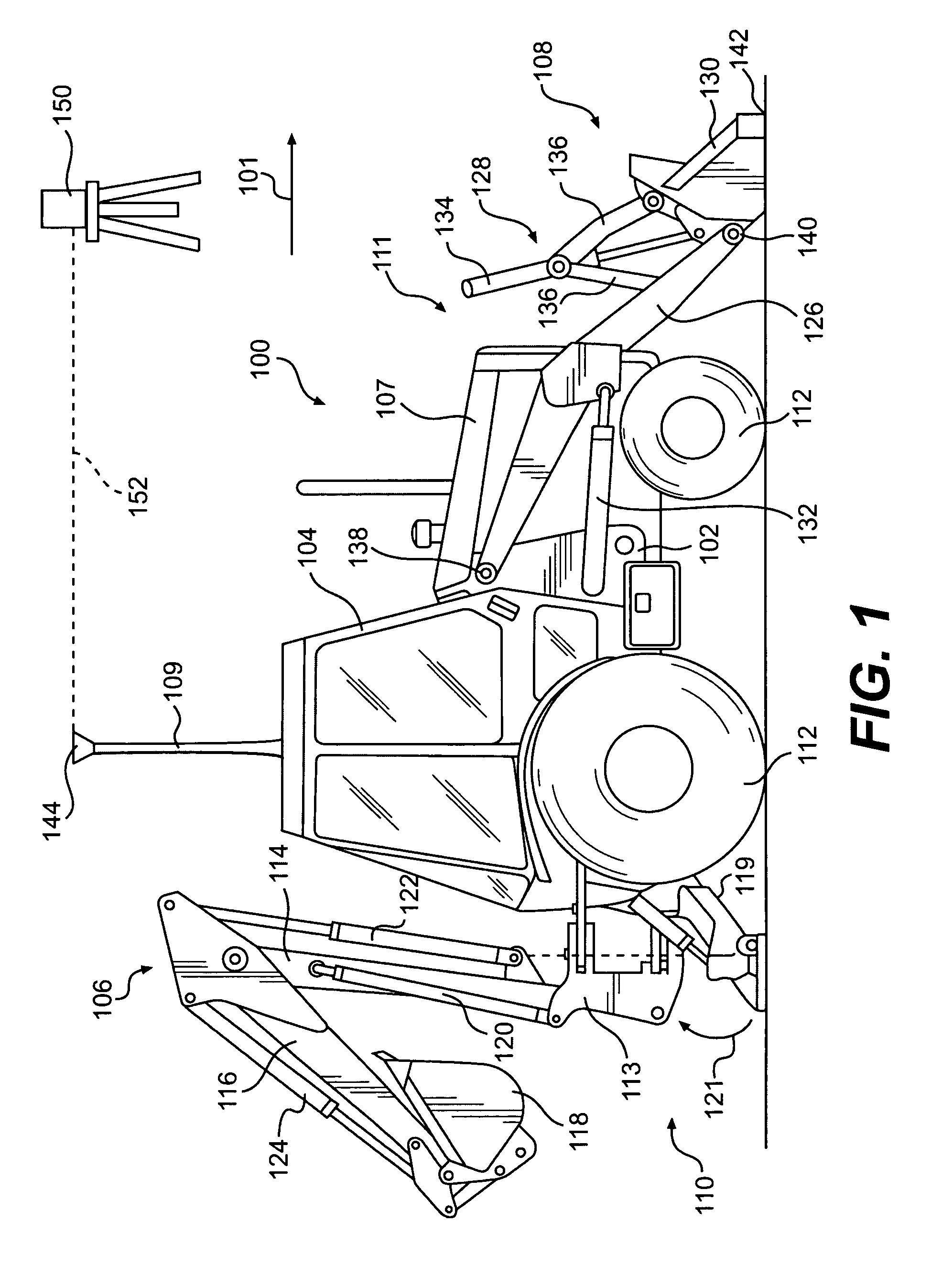

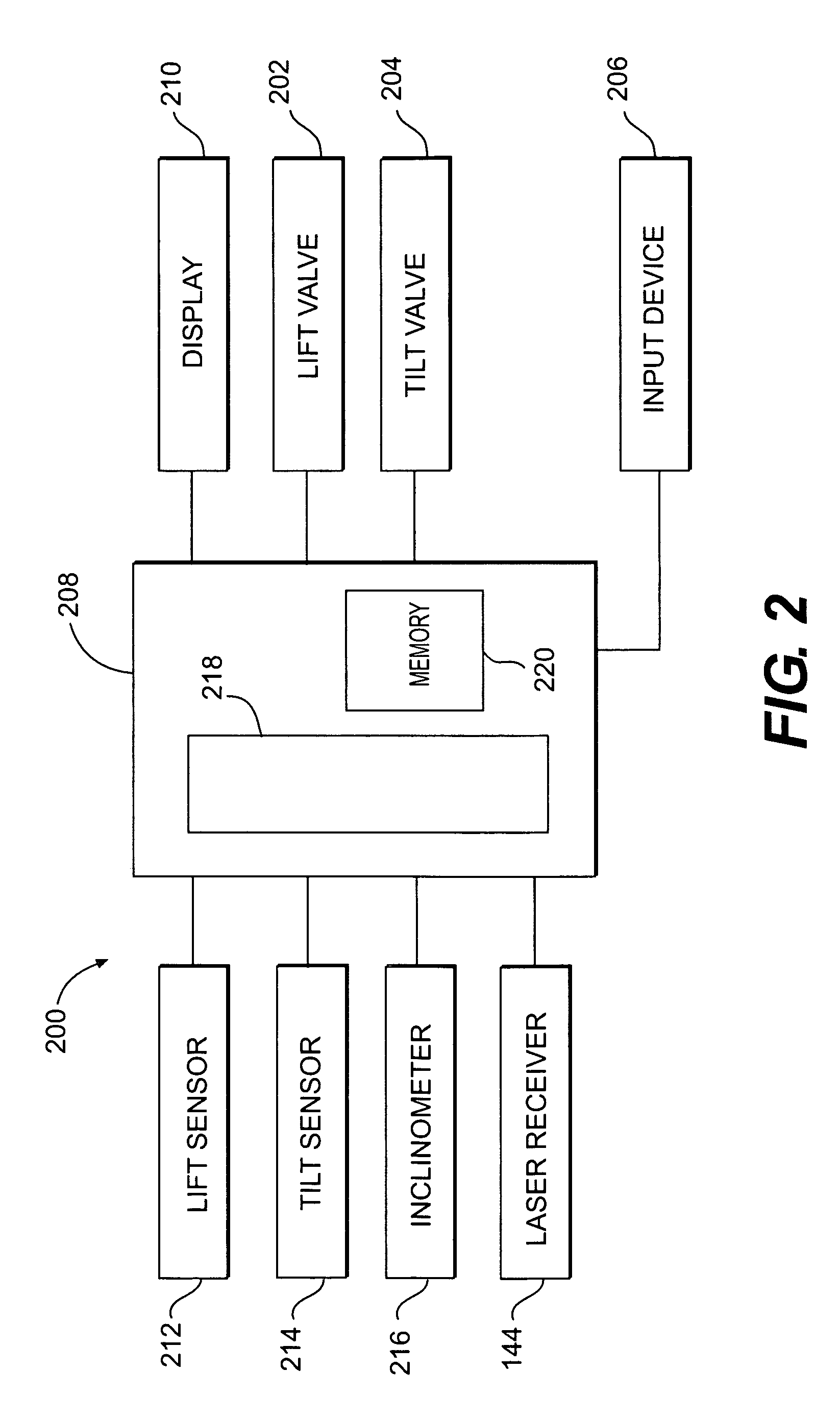

Grading control system

ActiveUS7293376B2Analogue computers for trafficMechanical machines/dredgersMarine engineeringControl system

A grading control system for a work machine having a work implement for grading along a grade defined by a laser plane generator is disclosed. The system includes tilt and lift actuators associated with the work implement and configured to selectively tilt, raise and lower the work implement. A laser receiver is configured to receive a laser signal indicative of a desired grade. The laser receiver is configured to communicate a height signal indicative of a position of the work machine relative to the laser plane. A lift sensor is configured to communicate a lift signal indicative of a lift position of the work implement. A control module is configured to generate and communicate a control signal based on the height and lift signals to actuate at least one of the lift and tilt actuators to maintain the work implement at a position substantially corresponding to the desired grade.

Owner:CATERPILLAR INC

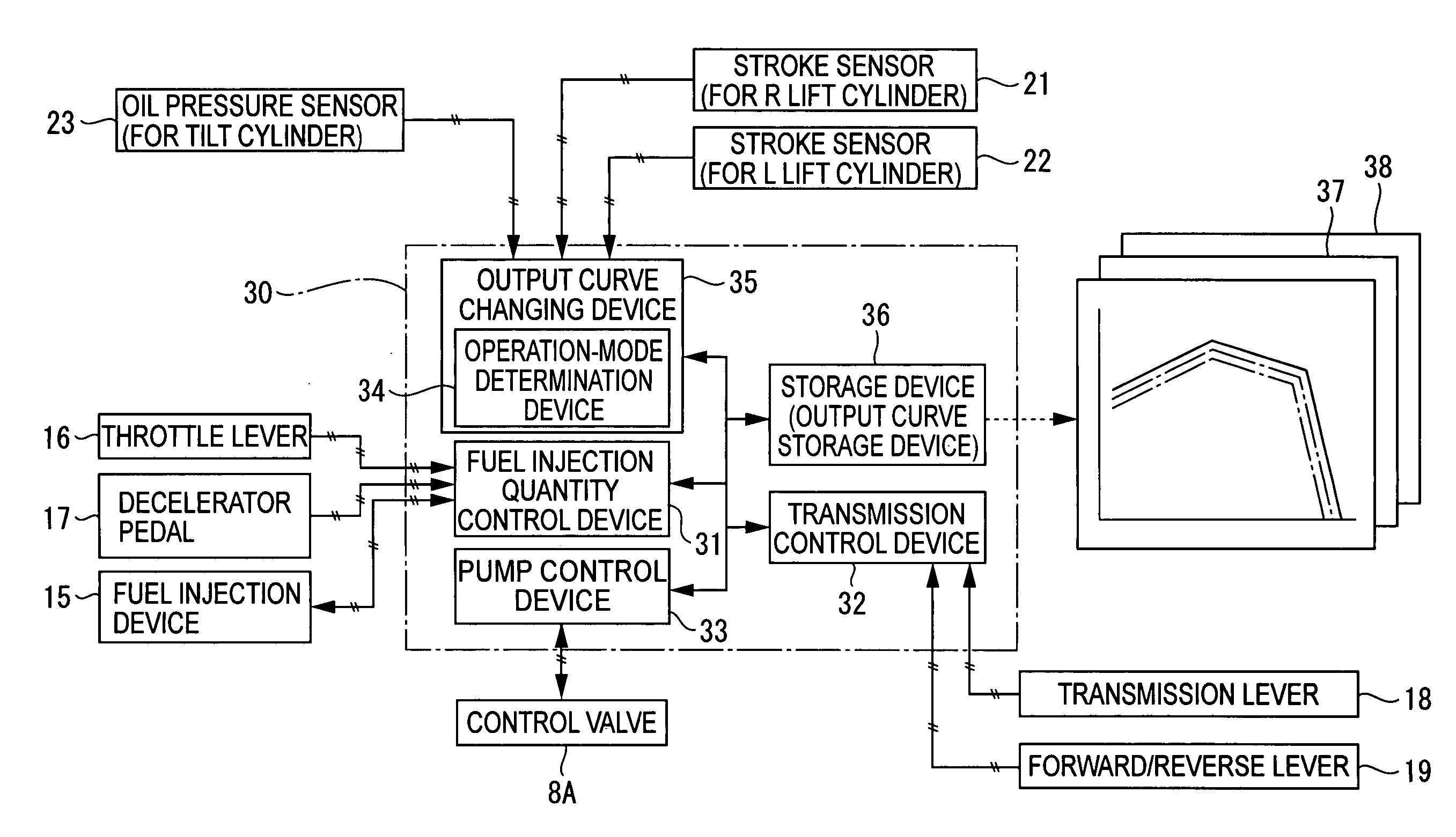

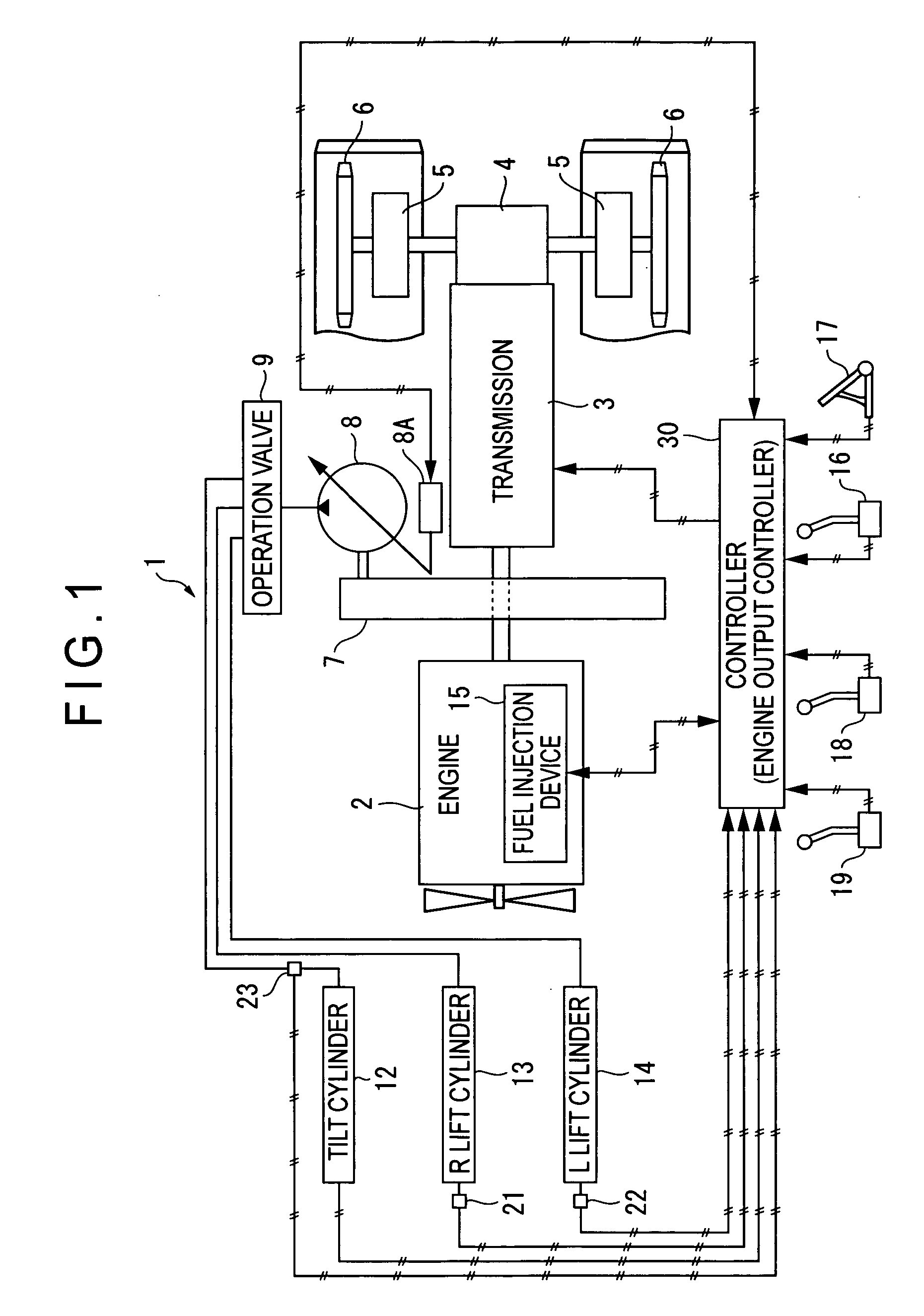

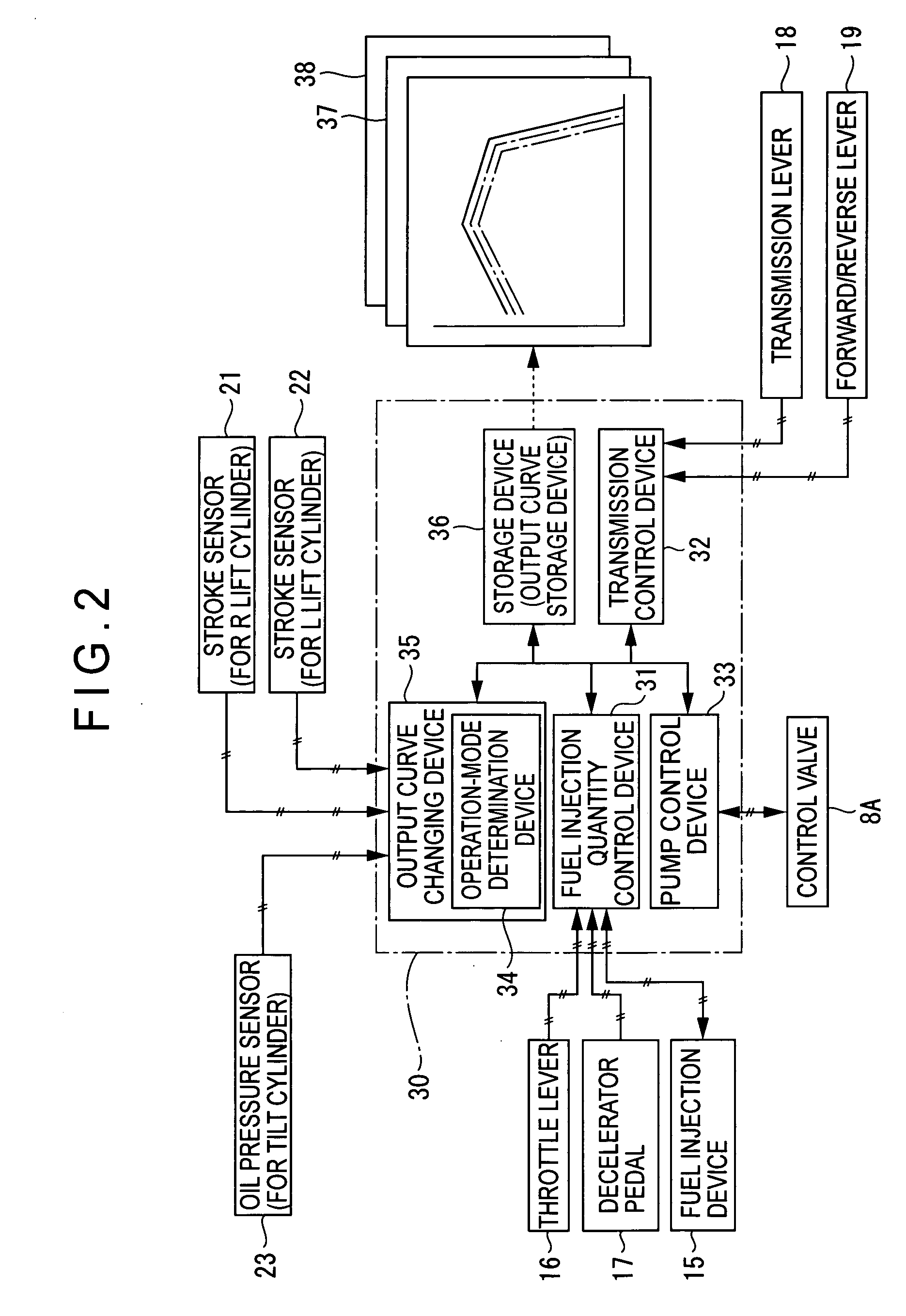

Engine output controller

InactiveUS20060161324A1Engine output decreaseIncrease fuel consumptionAnalogue computers for vehiclesAgricultural machinesEngineeringMechanical engineering

Owner:KOMATSU LTD

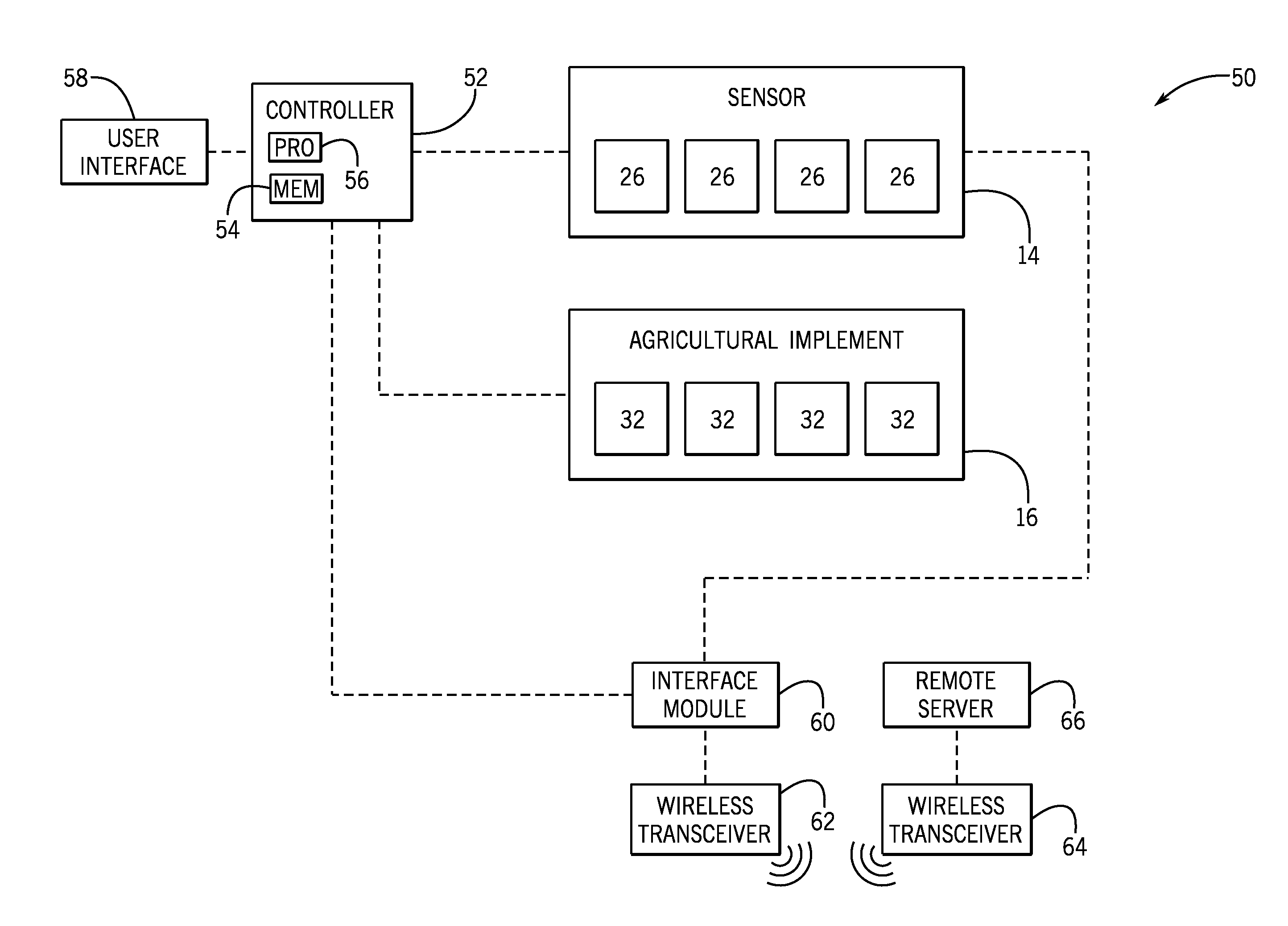

System and method for sensor-based crop management

InactiveUS20150305226A1Agricultural machinesAnalogue computers for trafficCrop managementSoil properties

An agricultural system includes a sensor positioned forward of an agricultural implement relative to a direction of travel of the agricultural system. The sensor is configured to output a first signal indicative of at least one soil property associated with an operation of the agricultural implement. The system also includes a controller communicatively coupled to the sensor. The controller is configured to output a second signal indicative of instructions to control the operation of the agricultural implement based on the first signal.

Owner:CNH IND AMERICA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com