Method of changing operating characteristics of an implement

a technology of operating characteristics and implements, applied in the direction of thinning machines, agriculture tools and machines, construction, etc., can solve the problems of increasing the overall cost of the implement, restricting the flexibility of the operation of the work machine,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

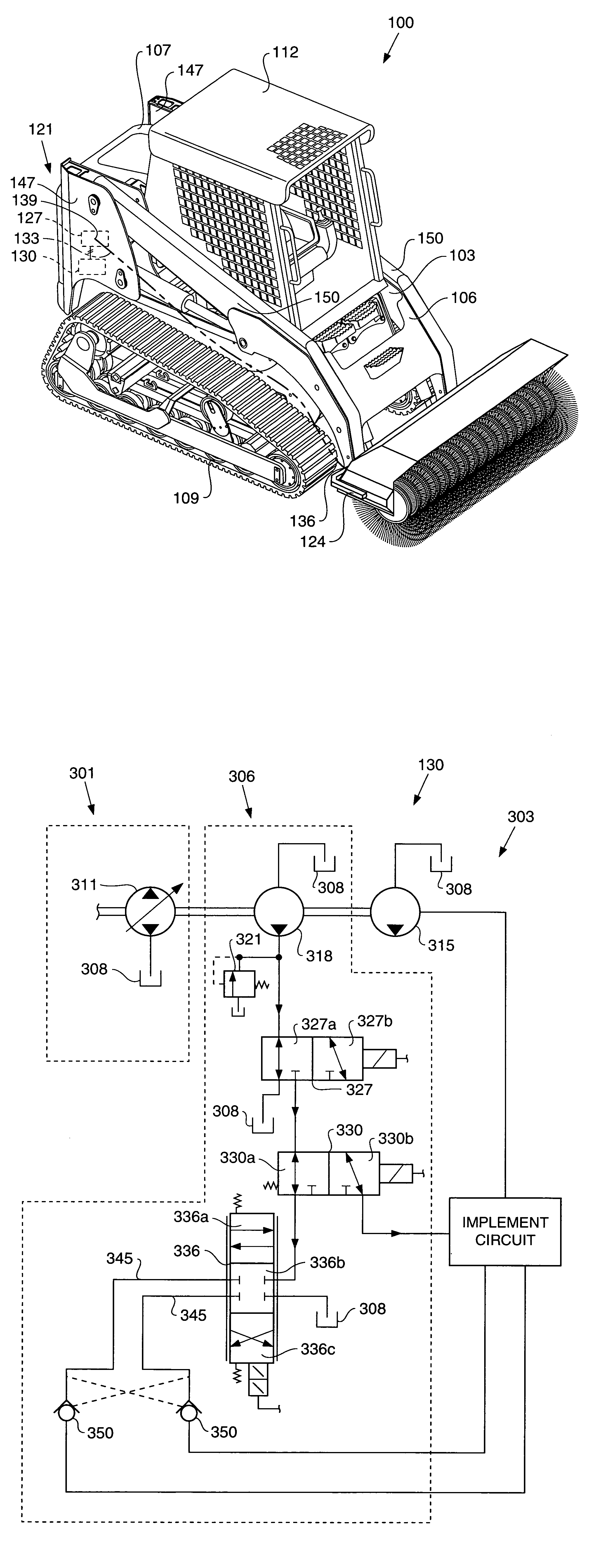

[0011]Referring to the drawings, a method and apparatus for changing operating characteristics of an implement for use with a work machine 100 is shown. With particular reference to FIG. 1, the work machine 100 is depicted as a tracked skid steer loader. It should be understood, however, that the work machine 100 could be any sort of work machine that has hydraulically controlled implements that are removably attached thereto and not just those enumerated above. The work machine 100 has a body portion 103 having a front-end portion 106 and a rear-end portion 107. The work machine includes a plurality of ground engaging support members 109 that support the body portion 103 and an operator's compartment 112 supported on the body portion 103. Further, the work machine 100 includes a lift member assembly 121 pivotally attached to the body portion 106 and an implement 124 pivotally connectable with the lift member assembly 121. The implement 124 has operating characteristics having a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com