Digital controlled block cutting machine

The technology of last engraving machine and last head is applied in the field of numerical control last engraving machine, which can solve the problems of difficulty in meeting design requirements, large grinding workload and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

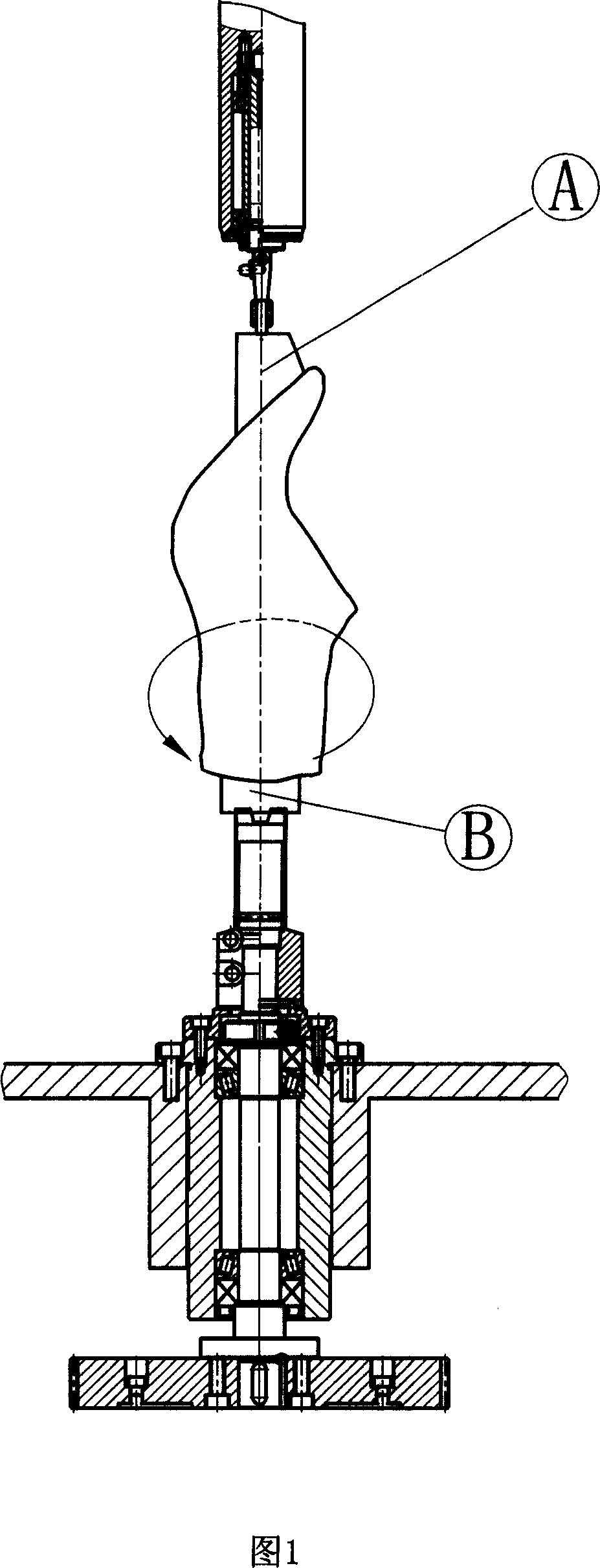

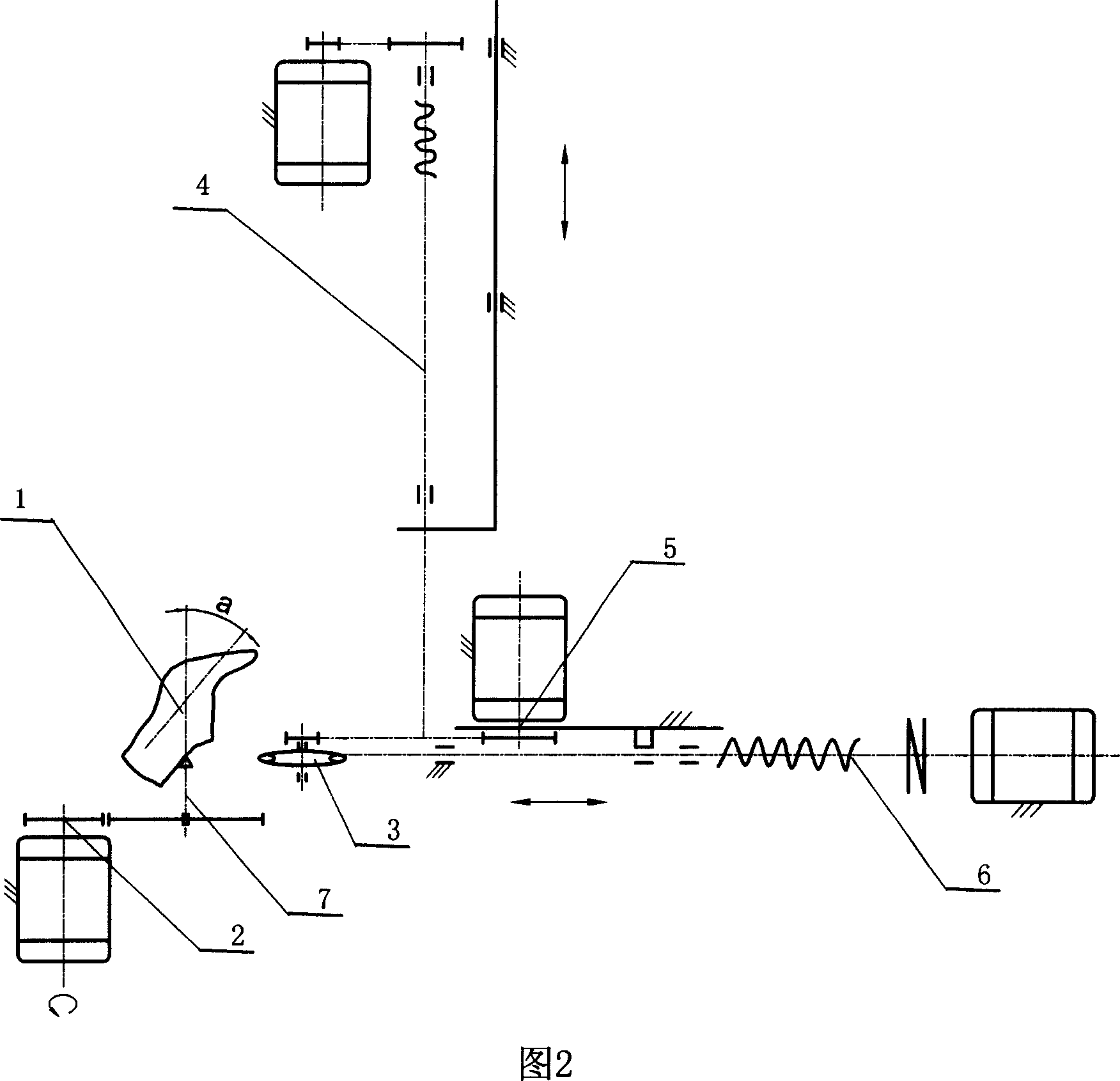

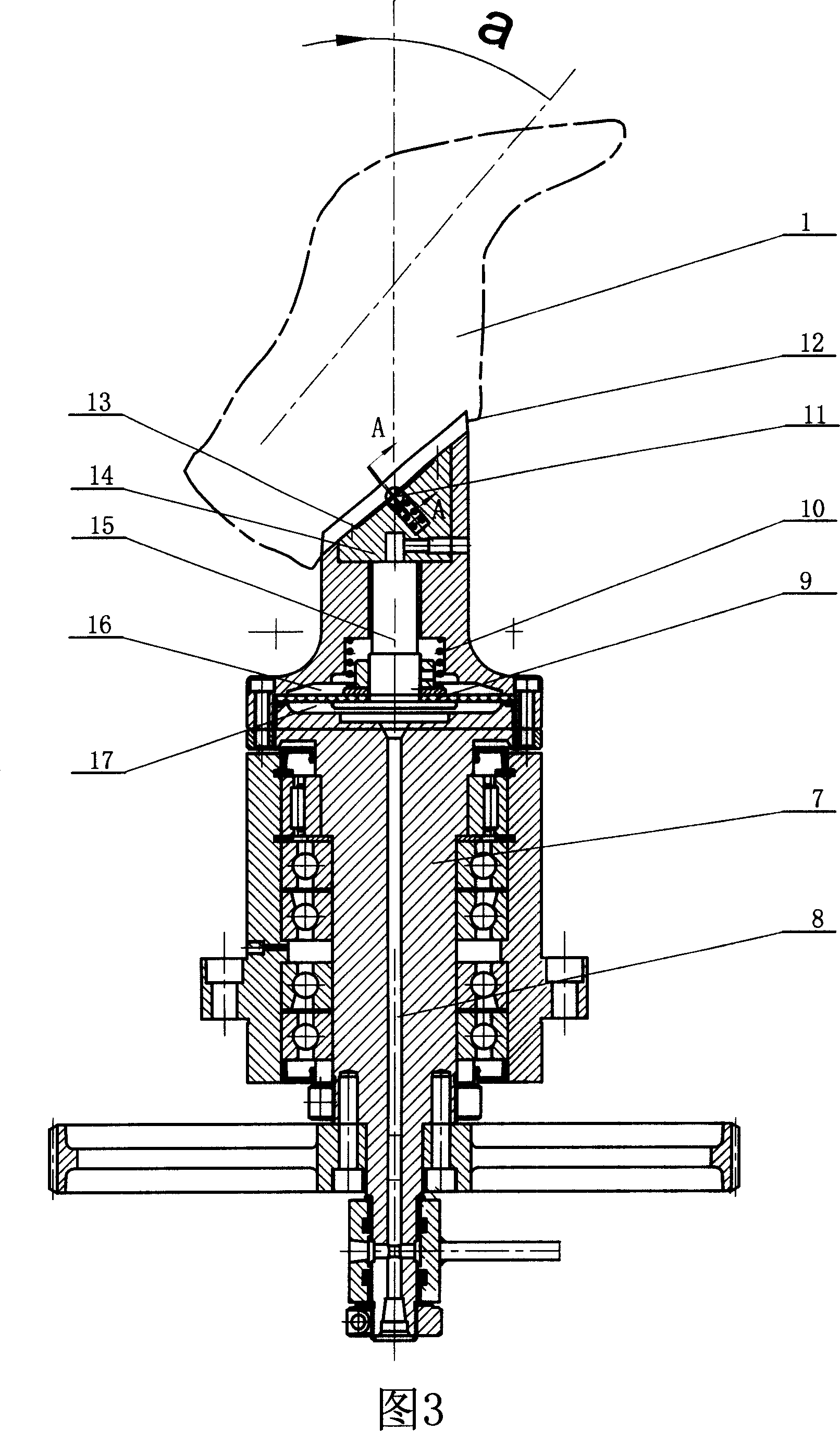

[0011] As shown in Figure 2, this embodiment includes a C-axis servo motor transmission system 2, a Y-axis servo motor transmission system 4, an X-axis servo motor transmission system 6, a cutterhead transmission system 5, a disc cutter 3, and a rotating shaft 7, wherein, The output end of the C-axis servo motor transmission system 2 is connected to the rotating shaft 7 . As shown in Figures 3-4, the top surface 13 of the rotating shaft is parallel to the last barrel surface 20 of the last blank 1, and forms a certain angle a with the center line of the rotating shaft, and the included angle a is 30°-50°, preferably 40°. A dovetail groove 18 is provided on the top surface 13 of the rotating shaft, which cooperates with the dovetail shaft 19 on the mouth surface of the last to form a last positioning device.

[0012] As shown in Figure 3 again, rotating shaft 7 is made of upper and lower two parts, separates with air bag 9 between the connection, forms upper and lower two cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com