Self-locking auto-centering target ball mounting seat

A self-centering and mounting seat technology, which is applied in the direction of measuring devices, optical devices, electromagnetic wave reradiation, etc., can solve the problems of low-precision measuring holes and the inability to realize the cooperation between the guide column and the measured hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

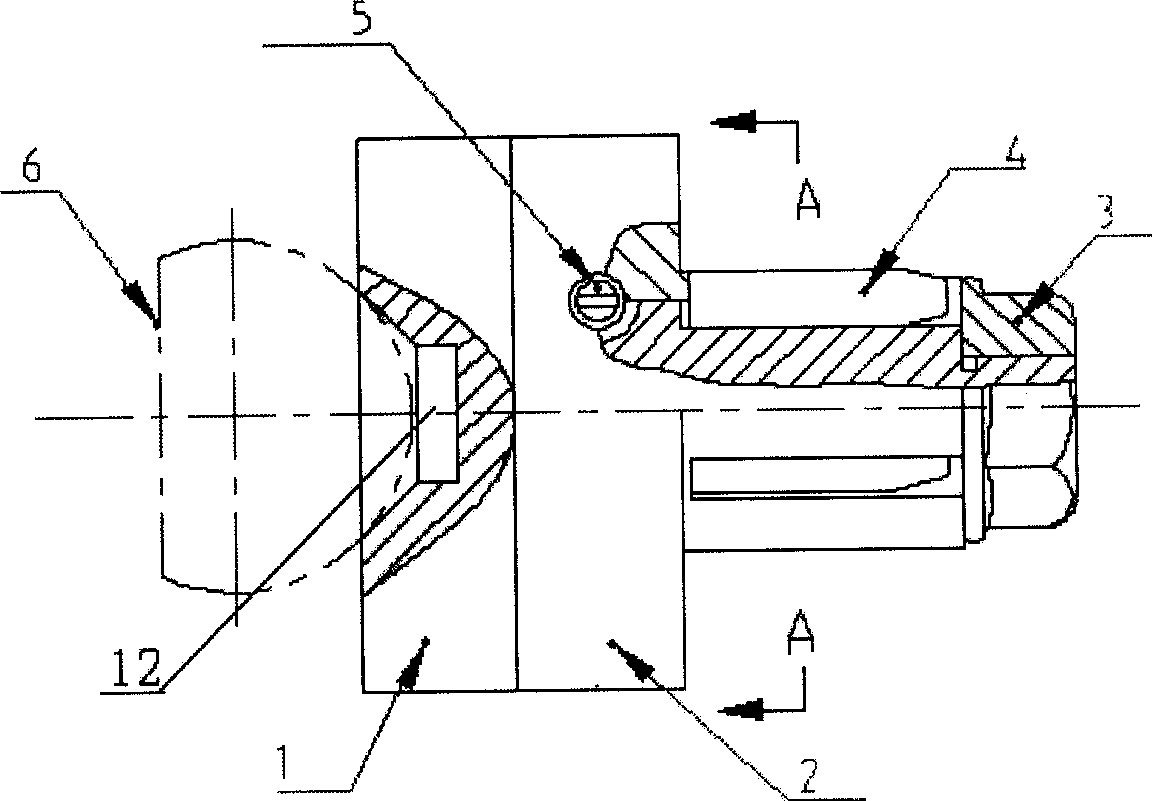

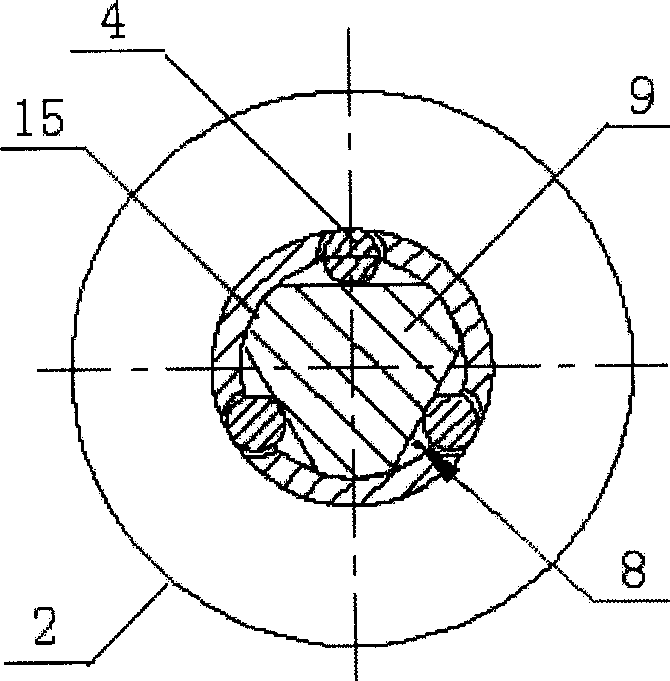

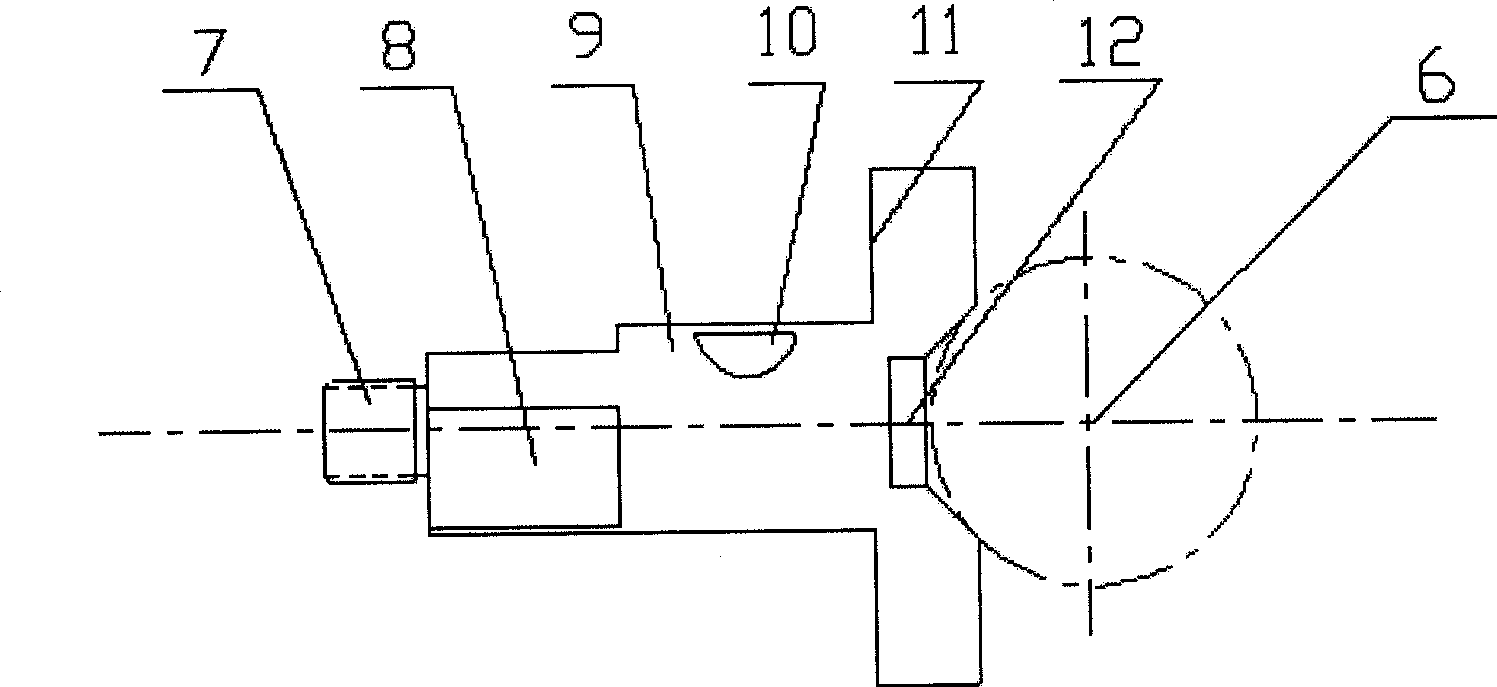

[0015] Figure 1 to Figure 5 A best embodiment of the target ball installation seat composed of the target ball center support 1 and the target ball seat cover 2 coaxially assembled together is described. The target ball center support 1 and the target ball seat cover 2 have a step joint surface, and the target ball center support 1 with the positioning guide post 9 is concentrically assembled in the positioning center hole 15 of the target ball seat cover 2 . The positioning guide post 9 of the vertical target center support 1 step has a polygonal cylinder. figure 2 Shown in is an equilateral triangular prism with arcs. The triangular column is formed at the end away from the positioning surface 11, which is a preferred embodiment of the present invention. A locking groove 10 is formed on the cylindrical surface of the small end step shaft of the polygonal cylinder 9, and the locking groove 10 corresponds to the fastening screw hole 13. The fastening screw 5 locks the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com