Technology for controlling coaxiality precision of U-shaped support combination

A technology of precision control and bracket group, which is applied in the field of coaxial precision control process of step holes at both ends of U-shaped brackets, can solve the problems of increasing installation error, reducing machining accuracy, and low machining accuracy, so as to reduce installation error and provide Processing accuracy, the effect of high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

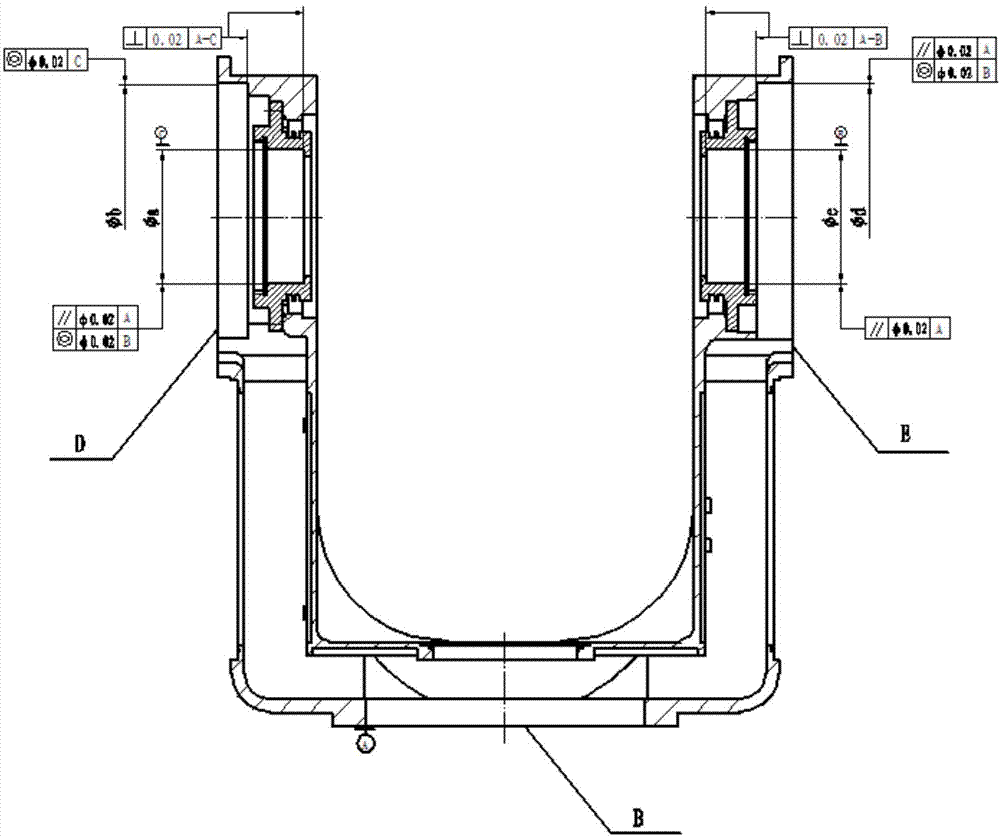

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] The present invention comprises the following steps: 1), during casting, add five process tables for positioning during processing on the side of the part, four of which are 20x20 square; 2.

[0019] 2) Each processing surface is rough processed, and each size is reserved. The fitter shovels, repairs and polishes each non-processed surface to be smooth.

[0020] 3) Carry out heat treatment - low temperature aging treatment to remove the processing stress generated by a large number of processing.

[0021] 4) For the surface A of fine milling process, leave the scraping amount, the fitter finely scrapes and grinds this surface, and the flatness is not greater than 0.01mm.

[0022] 5) With the craft table A as the base surface, the amount of the milling surface B is positioned at one time, the semi-finish boring φc is used for positioning with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com