Electric servo linear loading testing system

A test system, electric servo technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of inconvenient manufacturing and maintenance, limited active loading, and affecting loading accuracy, etc., to achieve loading control Convenience, simple structure, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

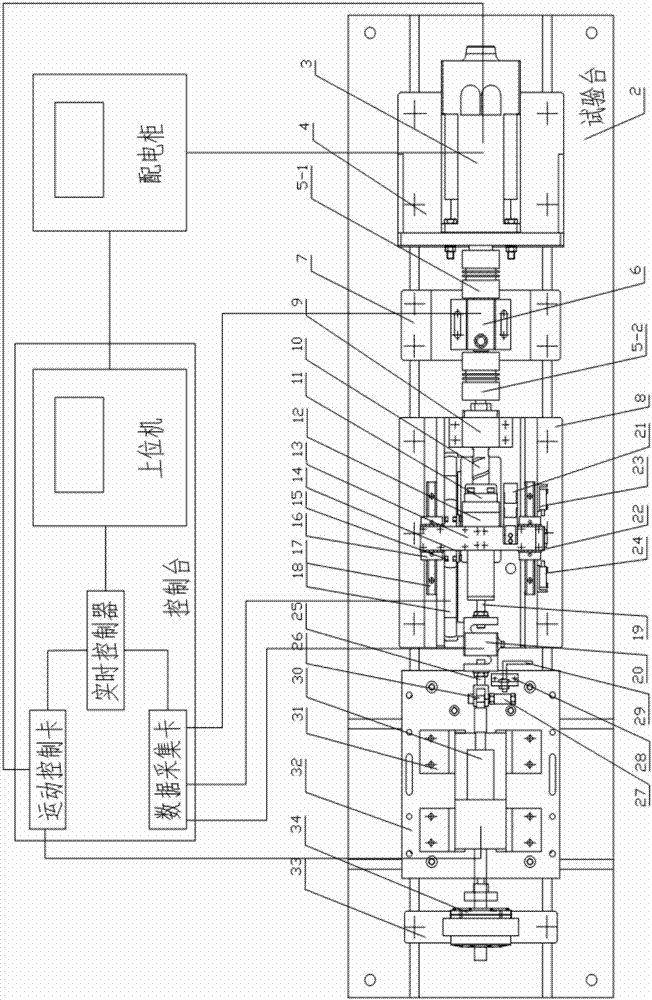

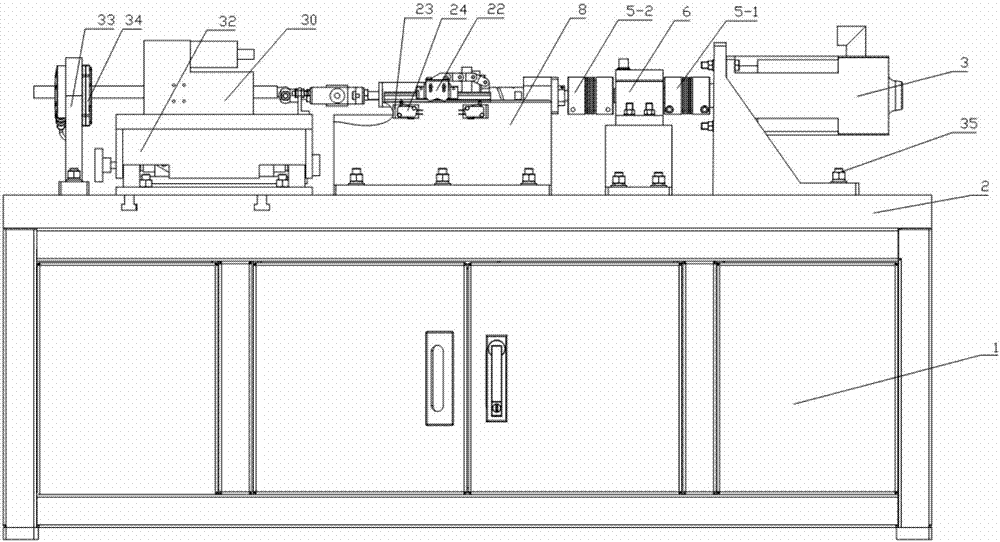

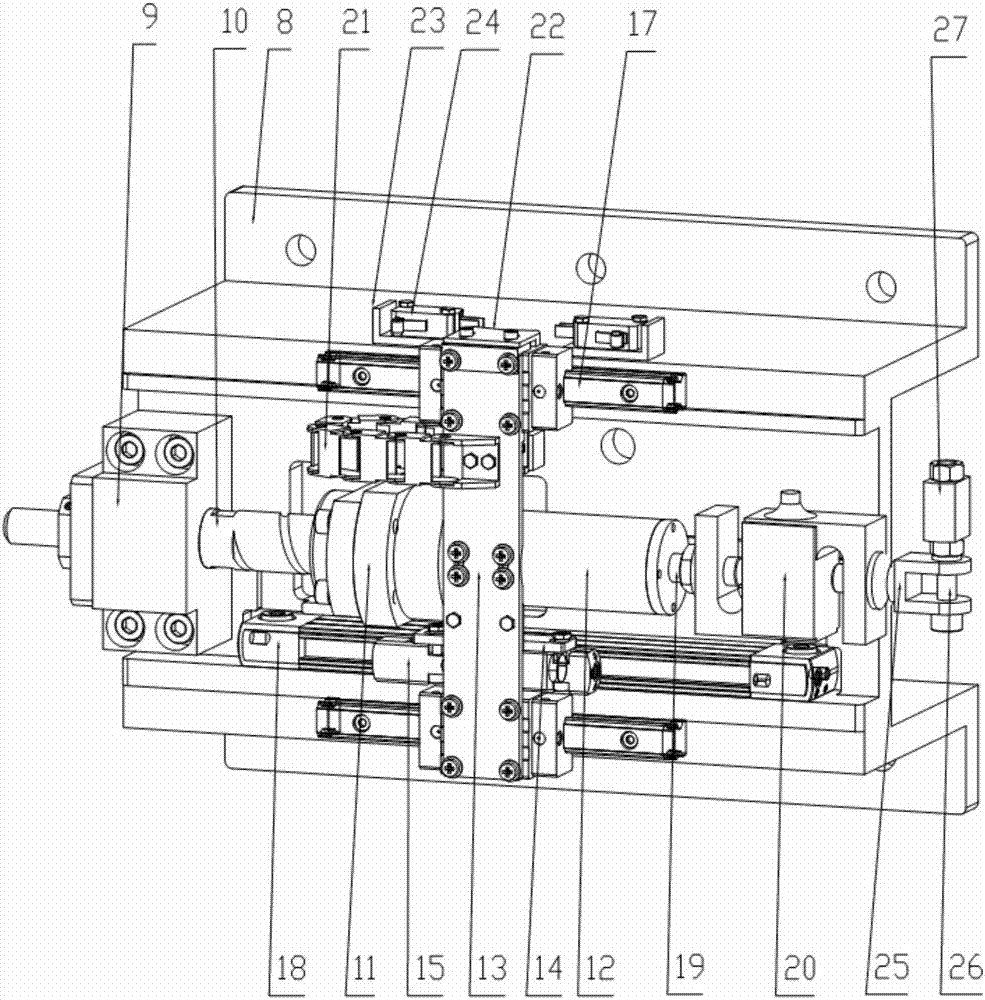

[0049] An electric servo linear loading test system, including a test bench, a console and a power distribution cabinet, wherein the console is used to perform closed-loop loading control on the test bench and realize human-computer interaction functions, and the power distribution cabinet provides power for the test bench and the console And isolate each part of the power module through the isolation circuit. The test bench includes a basic bench, a servo loading system, a motion conversion system and a servo system under test. The basic bench includes a base 1 and a T-slot plate 2. The servo loading The system includes servo loading motor 3, servo loading motor support 4, bellows coupling 5-1, bellows coupling 5-2, torque speed sensor 6 and torque speed sensor support 7, and the motion conversion system includes Support platform 8, ball screw auxiliary support unit 9, ball screw 10, ball screw auxiliary nut 11, sleeve 12, connecting plate 13, grating ruler connecting plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com