Modular wind tube machine and air conditioner

A duct machine, modular technology, applied in air-conditioning systems, space heating and ventilation, space heating and ventilation details, etc. Applicable places, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

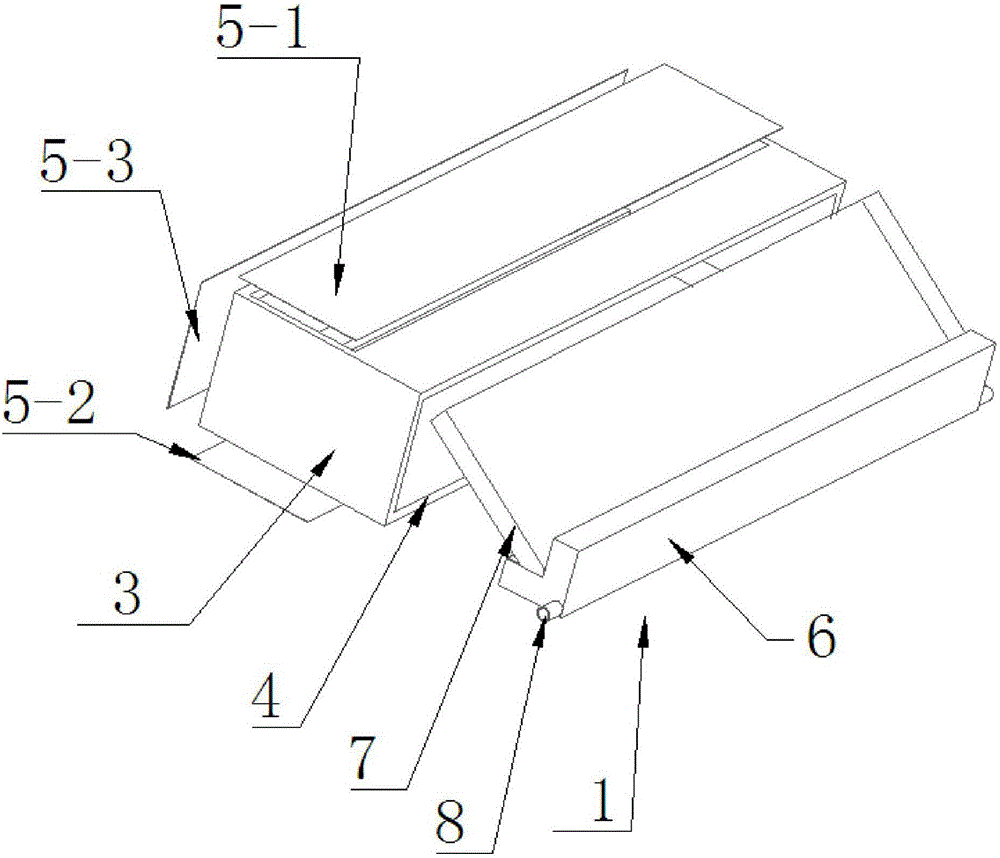

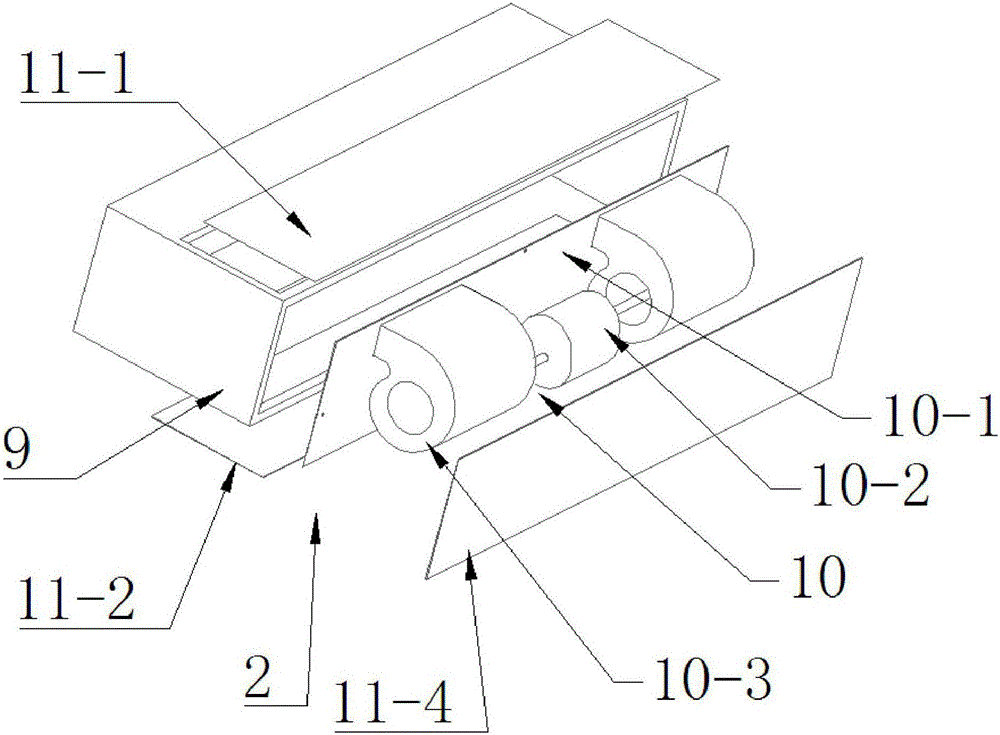

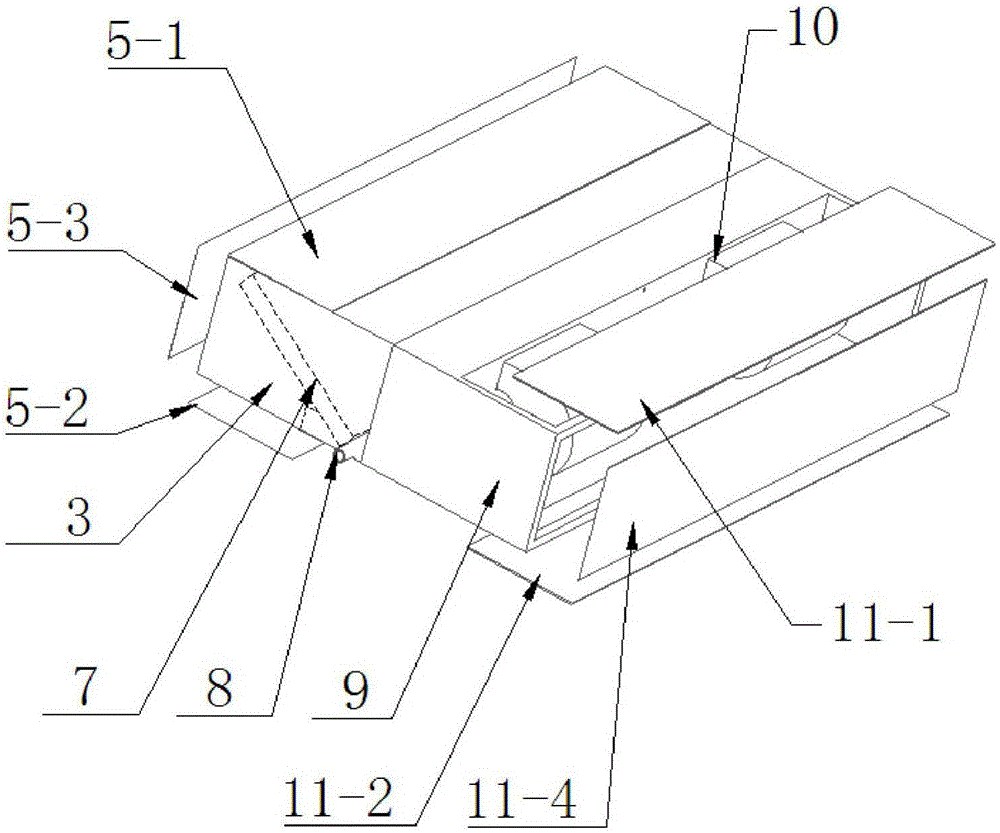

[0042] Such as Figure 5 , Figure 6 As shown, the air outlet box body 3 is rotated 180 degrees along the vertical axis, so that the air outlet box front baffle 5-3 is located at the rear end of the air outlet box body 3, and the air outlet box rear baffle 5-4 is located at the air outlet box body 3; remove the front baffle 5-3 of the air outlet box, remove the front baffle 11-3 of the air return box, and install the partition 10-1 on the front baffle 11-3 of the original air return box, so that the volute wind wheel 10-3 The air outlet of the air outlet is facing the outside of the air return box body 9, and the end face of the air outlet box body 3 provided with the opening 4 and the end face of the air return box body 9 provided with the fan assembly 10 are fixedly connected by screws. After the two are installed, the overall width is 2D, and the overall The height is H, the fan assembly 10 is fixed on the opening 4 of the air outlet box body 3 by screws or buckles, the wa...

Embodiment 3

[0044] Such as Figure 7 , Figure 8 As shown, the air outlet box body 3 is rotated 90 degrees clockwise along the horizontal axis, so that the air outlet box lower baffle 5-2 is located at the front end of the air outlet box body 3, and the air outlet box front baffle 5-3 is located at the front end of the air outlet box body 3. The upper end, the upper baffle plate 5-1 of the air outlet box is located at the rear end of the air outlet box body 3, and the rear baffle plate 5-4 of the air outlet box is located at the lower end of the air outlet box body 3; the air return box body 9 is rotated 90 degrees clockwise along the horizontal axis , so that the lower baffle plate 11-2 of the air return box is located at the front end of the air return box body 9, the front baffle plate 11-3 of the air return box is located at the upper end of the air return box body 9, and the upper baffle plate 11-1 of the air return box is located at the main body of the air return box 9, the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com