Full-automatic grinding machine for ultrasonic vibration auxiliary grinding of outer circle of hard and brittle single crystal cylinder

An ultrasonic vibration, fully automatic technology, applied in the direction of grinding machine bed, grinding feed movement, grinding machine tool parts, etc., can solve the problems of corrosion of machine tools, labor, workpiece clamping accuracy reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

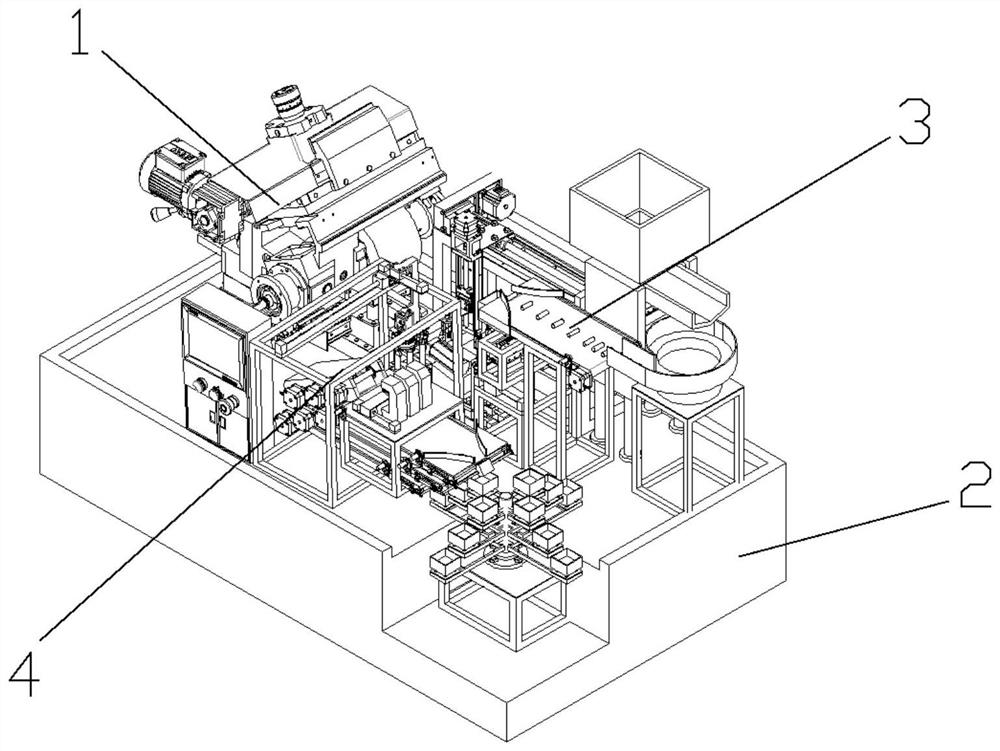

[0051] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a fully automatic grinding machine for ultrasonic vibration-assisted grinding of hard and brittle single crystal cylindrical outer circles described in this embodiment includes a fully automatic grinding machine 1, a grinding machine base 2, an automatic feeding mechanism 3 and an automatic classification And storage mechanism 4, the upper surface of grinder base 2 is provided with grinder 1, automatic feeding mechanism 3, automatic classification and storage mechanism 4 and storage mechanism abutment 11, automatic feeding mechanism 3 and automatic classification and storage mechanism 4 are mutual Distributed in parallel, the automatic grinding machine 1 is vertically distributed with the automatic feeding mechanism 3 and the automatic classification and storage mechanism 4 respectively, and a corner of the upper surface of the grinding machine base 2 is provided with a storage mechanism ab...

specific Embodiment approach 2

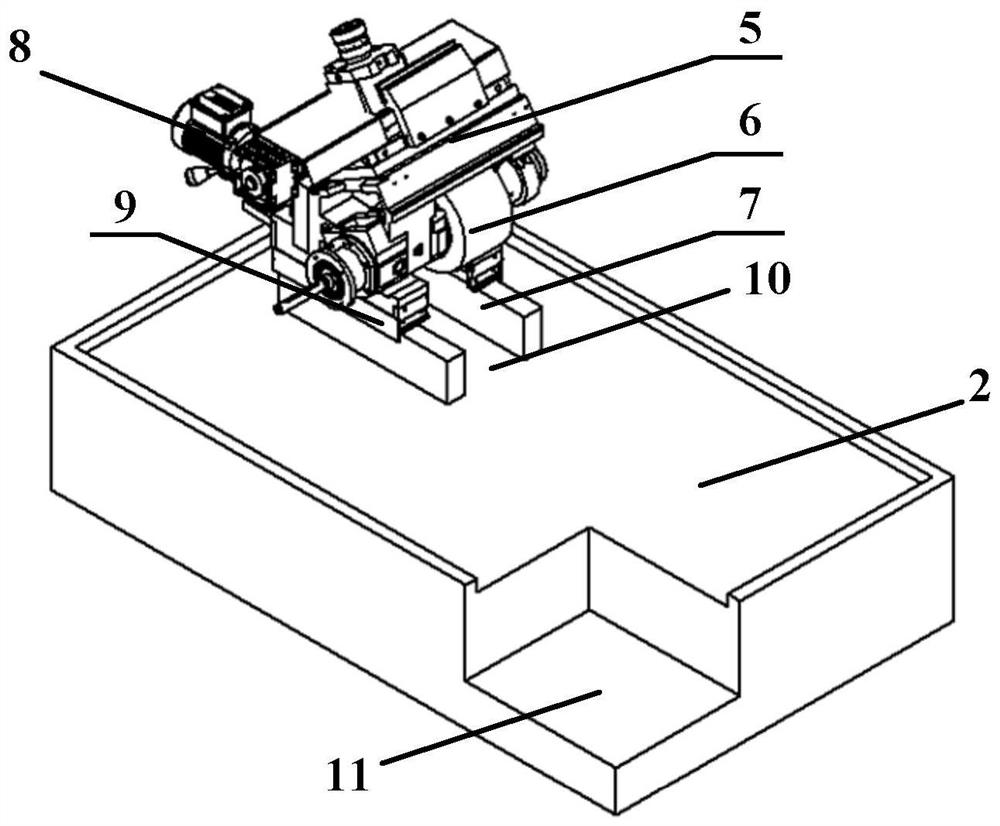

[0054] Specific implementation mode two: combination figure 2 Describe this embodiment. This embodiment is a further limitation on the fully automatic grinding machine described in Embodiment 1. A fully automatic grinding machine for hard and brittle single crystal cylindrical outer circle ultrasonic vibration assisted grinding described in this embodiment. Grinder, described automatic grinder 1 comprises grinder frame 5, grinder emery wheel 6, support base 7, grinder motor 8 and grinder base 9; Grinder emery wheel 6 and grinder motor 8 are fixed on the top of grinder frame 5, grinder machine The grinder base 9 below the frame 5 is fixed on the upper surface of the support base 7 by bolts, the middle part of the side of the support base 7 is provided with a grinding device placement groove 10, and the lower bottom surface of the support base 7 is connected to the upper surface of the grinder base 2. Surface fixed connection.

specific Embodiment approach 3

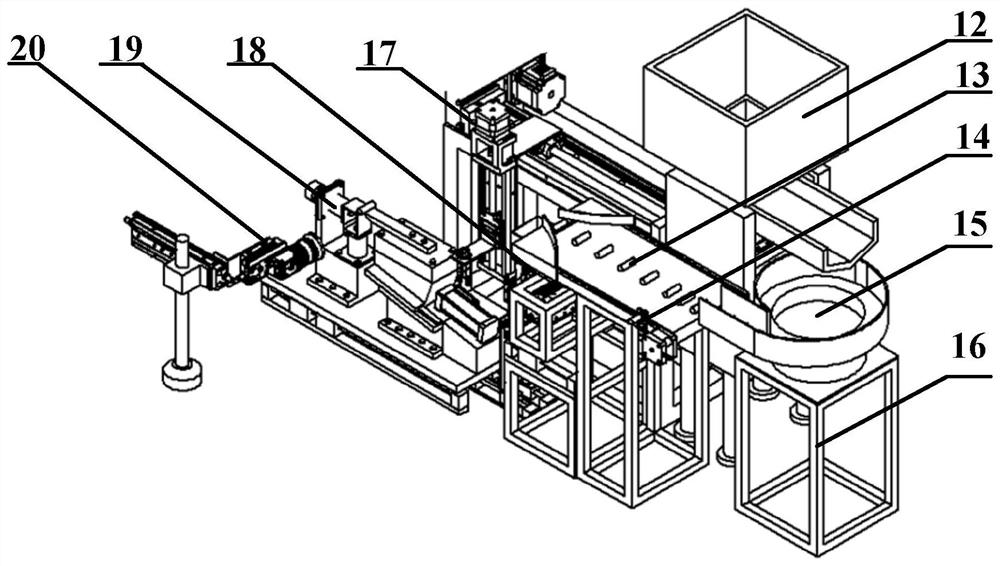

[0055] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment. This embodiment is a further limitation on the fully automatic grinding machine described in Embodiment 1. A fully automatic grinding machine for hard and brittle single crystal cylindrical outer circle ultrasonic vibration assisted grinding described in this embodiment. Grinding machine, the automatic feeding mechanism 3 includes a hopper device 12, a first photoelectric sensor 14, a vibrating tray 15, a vibrating tray bracket 16, a feeding mechanism 17, a workpiece separation mechanism 18, and an ultrasonic elliptical vibration auxiliary grinding device 19 And on-line proofreading camera device 20, hopper device 12 is arranged on the top of vibrating material pan 15, and the discharge port of hopper device 12 faces vibrating material pan 15, and vibrating material pan 15 is installed on the vibrating material pan support 16, vibrating material pan 15 The outlet is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com