Convenient-to-mount edging device applied to glass production line

A production line, casual wear technology, used in grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, grinders, etc. The effect of side processing, speeding up work progress, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

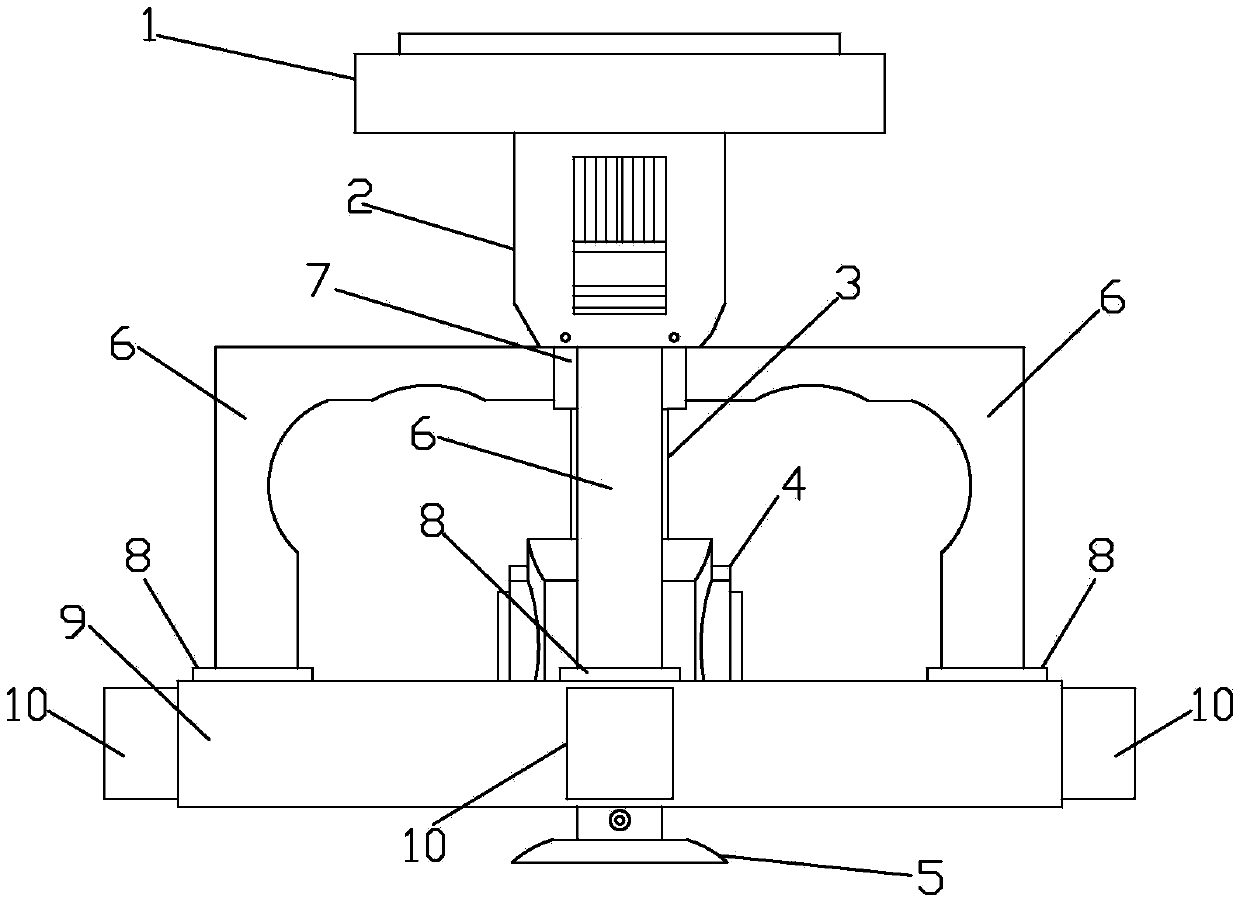

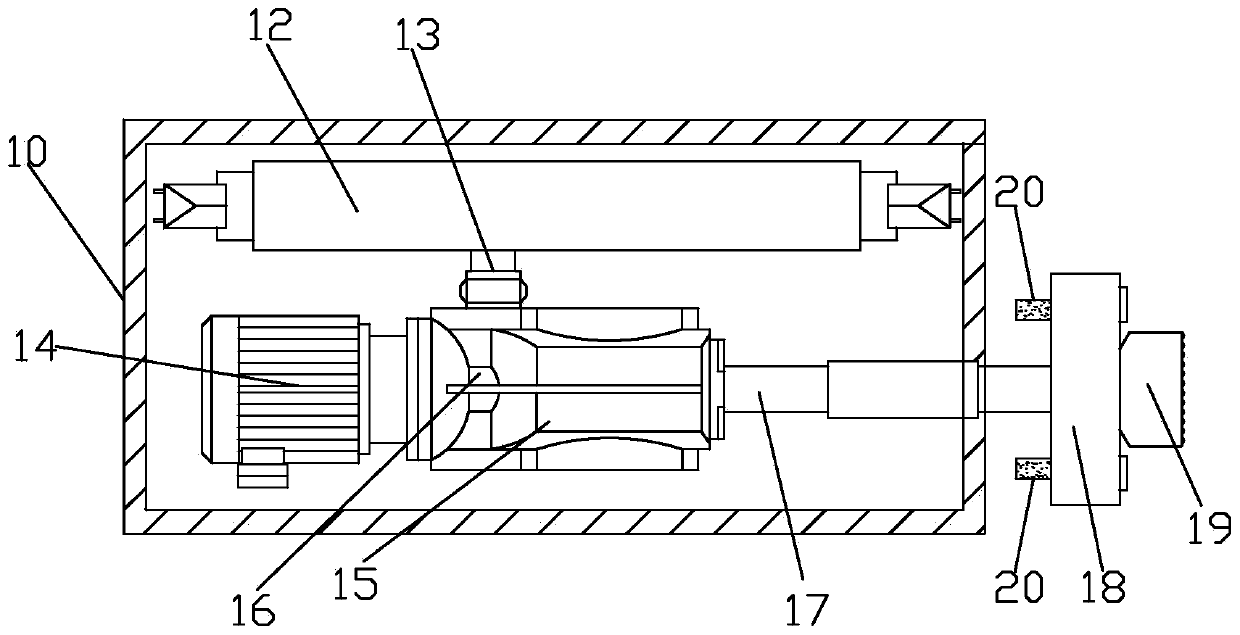

[0031] A portable edging device applied to a glass production line, comprising a grasping mechanism and an edging mechanism. An electromagnetic chuck 1 is installed on the upper end of the grasping mechanism, and the electromagnetic chuck 1 is installed on the grasping mechanism by welding. After the electromagnetic chuck 1 is energized, a strong adsorption force can be obtained. When installing, the electromagnetic chuck 1 is initially installed on the iron workpiece, and then the electromagnetic chuck 1 is powered on. At this time, the electromagnetic chuck 1 is firmly adsorbed on the iron workpiece; Therefore, the present invention can adjust the installation position at will, thereby obtaining a wider application range, simple structure, and convenient installation.

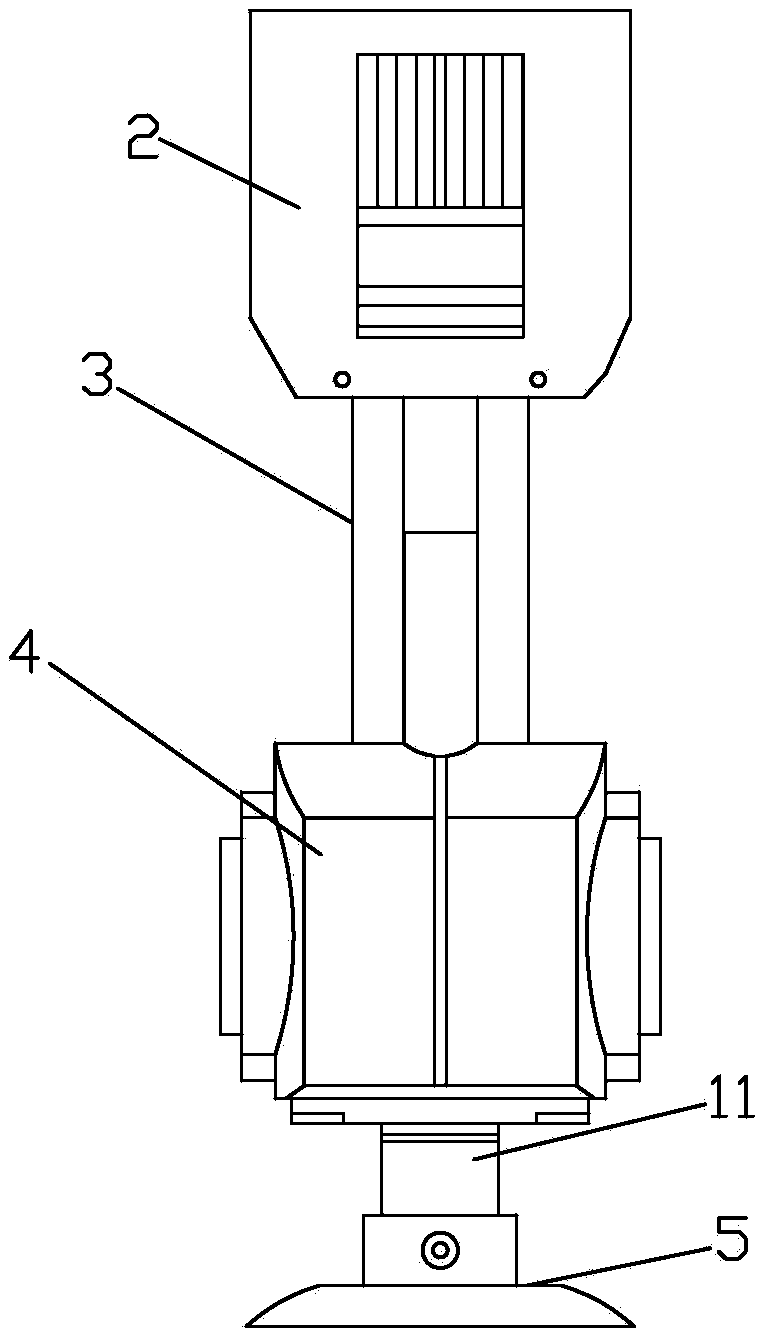

[0032] The grabbing mechanism includes a lifting motor 2, a lifting connecting rod 3, a hydraulic cylinder 4 and a hydraulic sucker 5. The upper end of the lifting motor 2 is equipped with an electromagnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com