Tin soldering device for commutator and armature wire

A commutator and armature technology, used in tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems of low welding efficiency, poor quality reliability, insulation damage, etc., and achieve the effect of high welding efficiency and good welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

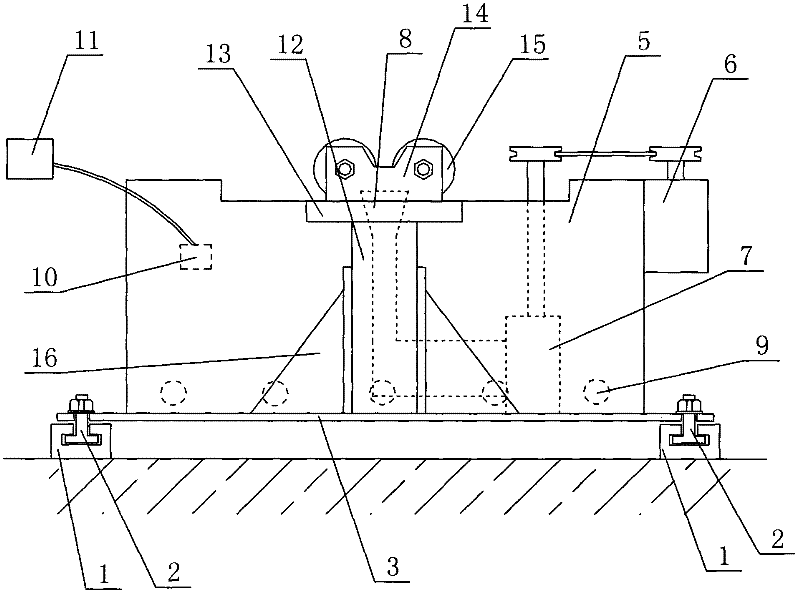

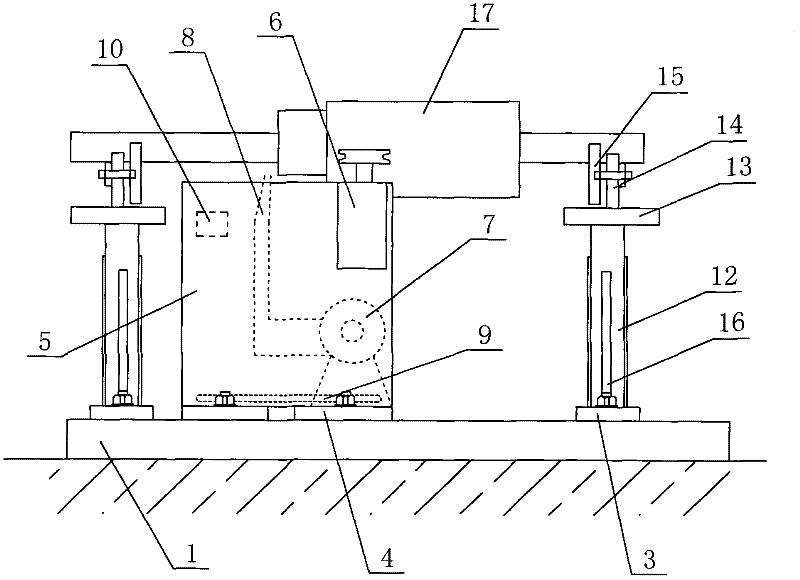

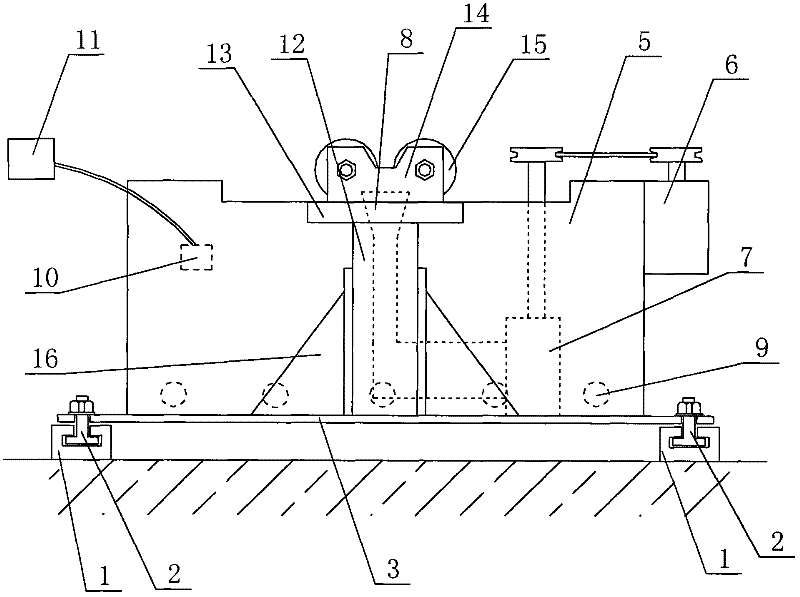

[0016] Please refer to Figure 1 to Figure 2 as shown, figure 1 It is a side view of the commutator and armature wire soldering device of the present invention; figure 2 It is a schematic diagram of the specific use of the commutator and armature wire soldering device of the present invention.

[0017] In this embodiment, a commutator and armature wire soldering device includes two supporting rails 1 arranged in parallel and at intervals, T-shaped grooves are opened on the supporting rails 1, and the tin basin 5 is arranged on the tin basin. On the bottom plate 4, the tin basin bottom plate 4 is installed on the support rail 1 by T-shaped bolts 2, and a support is installed on the support rail 1 on both sides of the tin basin 5, and the support is arranged on the support bottom plate 3 , the bracket bottom plate 3 is installed on the support rail 1 through T-shaped bolts 2, and the bracket includes a support rod 12 whose bottom is fixed on the bracket bottom plate 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com