Novel tool cylinder for wood shaving machine

A new type of planing technology, which is applied in the field of new cutter barrels for wood planers, can solve the problems of increased labor costs, space limitations of the fuselage, troublesome maintenance operations, etc., and achieve the effects of reducing labor costs, realizing quick adjustment, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

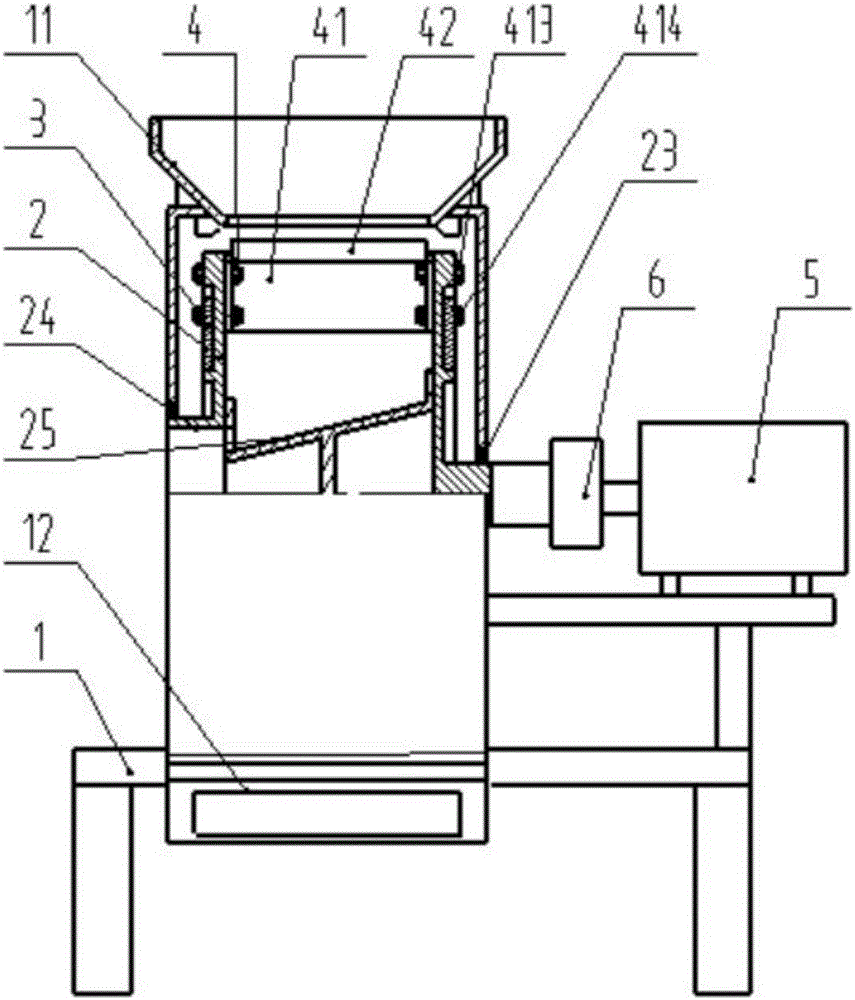

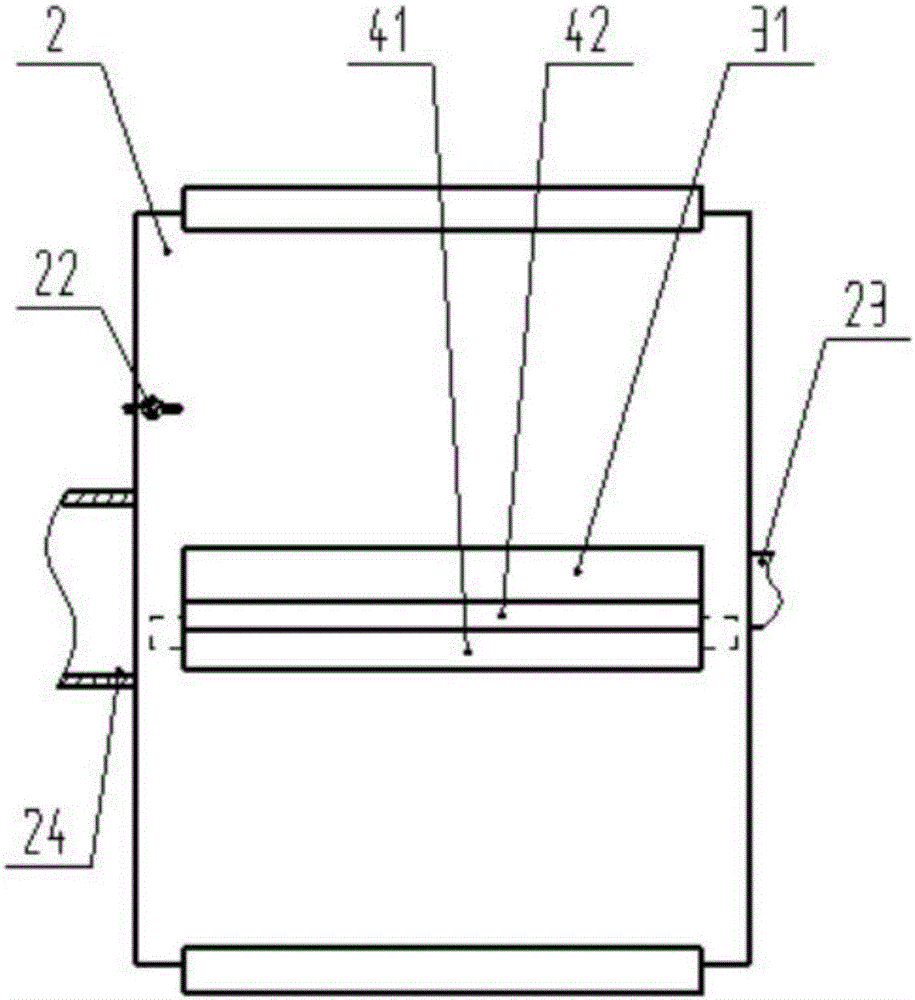

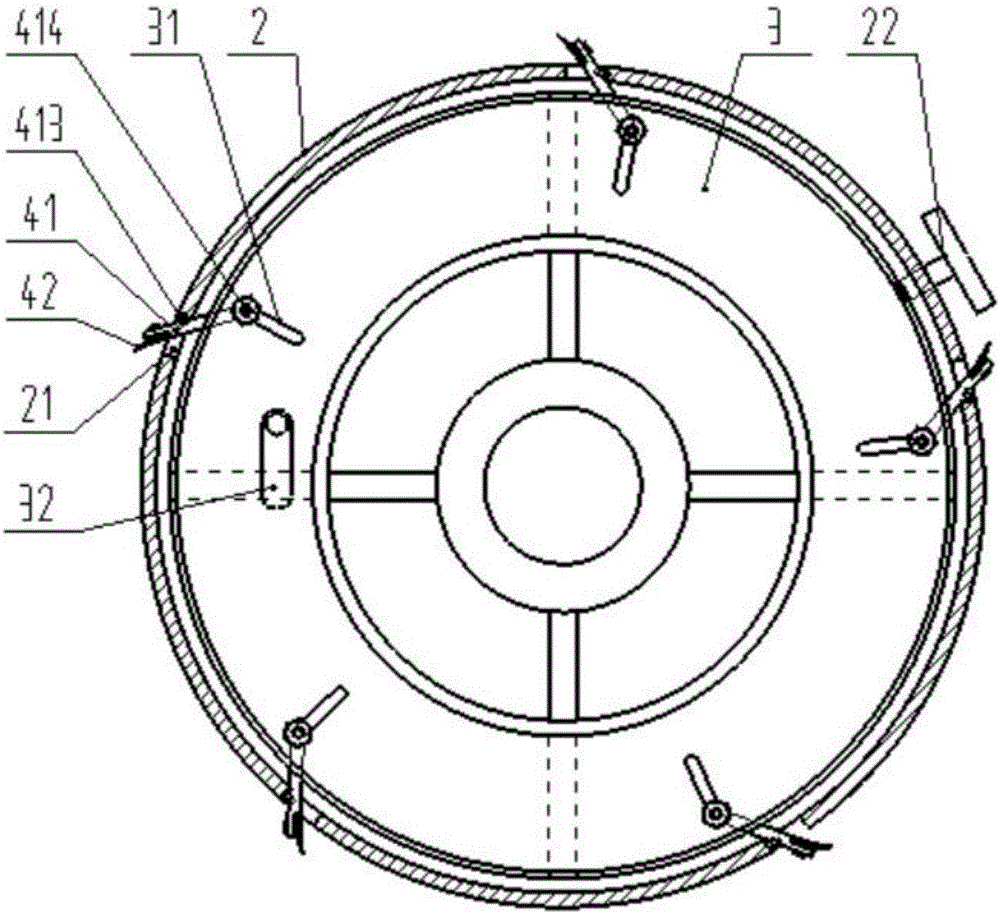

[0024] Such as Figure 1-5 As shown, a novel cutter cylinder for wood planer includes a rotary cutter cylinder. The rotary cutter cylinder includes a hollow cylinder body 2, two swivel rings 3 and a plurality of cutter assemblies 4. The circumferential wall of the cylinder body is evenly distributed along the axial direction There are a plurality of material guide holes 21, and the swivel ring is clamped with both ends of the cylinder body and can rotate around the axis of the cylinder body. A plurality of guide holes 31 are evenly distributed in the radial direction on the swivel ring. On the outer wall of the swivel ring 3 There is a handle 32 for rotating the swivel, the cylinder body is hollow so that the shavings can be exported from the inner cavity, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com