Mask ear band shearing device based on sliding groove mechanism and using method

A technology of shearing device and sliding device, which is applied in metal processing and other directions, can solve the problems of linkage mechanism wear, long stroke, continuous shearing, etc., and achieve the effect of ensuring reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

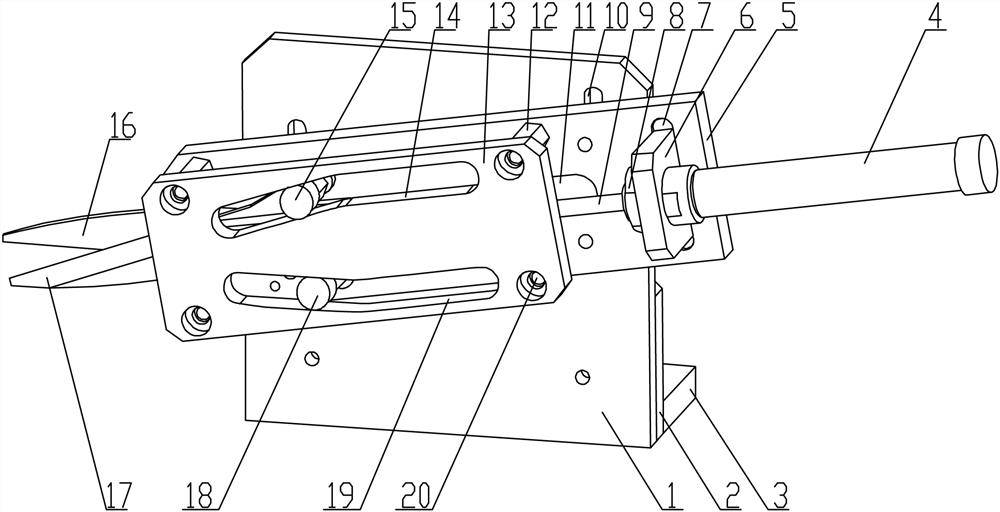

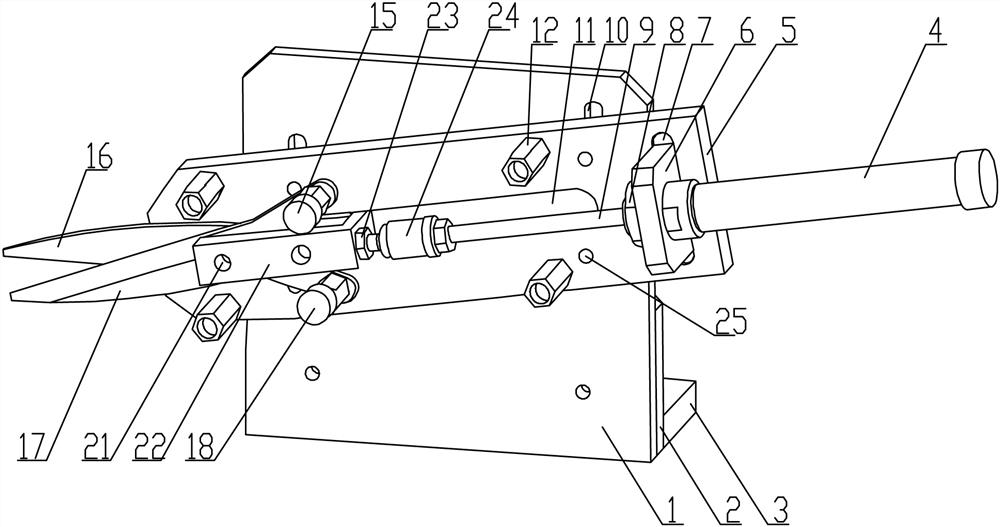

[0031] see Figure 1-2 , the mask earband cutting device based on the chute mechanism, which includes a vertical plate 1, the vertical plate 1 is fixedly installed on the frame of the mask machine through the vertical plate base, and the outer wall of the vertical plate 1 is equipped with a knife rest plate placed obliquely 5. A chute 11 is processed on the knife rest plate 5, and a sliding seat 22 is slidably fitted on the chute 11. The first scissor body 16 and the second scissor body 17 arranged crosswise are hinged on the sliding seat 22 through a pin shaft 21; The afterbody of a scissors body 16 and the second scissors body 17 cooperates with the roller guide mechanism, and is used to realize the closing and separating action of the scissors head; This shearing device adopts the chute mechanism as the transmission guide of the shearing power of the scissors, replacing the traditional multi-link mechanism, thereby ensuring the stability of the transmission and the reliabil...

Embodiment 2

[0040] The using method of the mask ear strap cutting device based on the chute mechanism comprises the following steps:

[0041] Step 1: Fix the whole device on the frame of the mask machine, and adjust the installation position of the whole device according to the position where the ear strap needs to be cut;

[0042]Step 2: Adjust the installation height and installation angle of the tool holder plate 5 on the installation groove 7, and ensure that the first scissors body 16 and the second scissors body 17 are just matched with the ear straps of the mask machine during the stretching and cutting process, and achieve its shearing;

[0043] Step 3, start the mask machine, and pull the ear strap line through the traction mechanism. During the traction process, start the sliding device, drive the piston rod 9 through the cylinder 4, and drive the sliding seat 22 through the piston rod 9, and the sliding seat 22 moves along the The chute 11 slides;

[0044] Step four, the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com