Roller bearing raceway crown grinding machine grinding wheel dresser

A grinding wheel dresser and raceway convexity technology, which is applied to grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as affecting the processing quality of workpieces, and achieve simple structure, high dressing accuracy and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

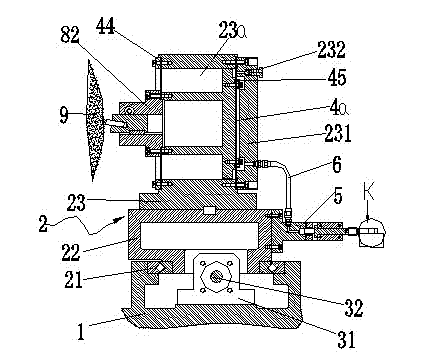

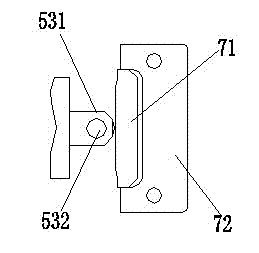

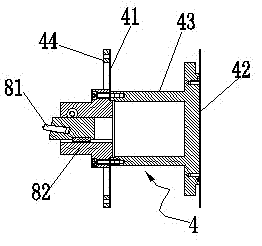

[0023] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0024] The reference signs are: base 1, trimming reciprocating mechanism 2, rolling guide rail 21, trimming reciprocating carriage 22, diamond pen bracket 23, installation cavity 23a, rear cover 231, large hydraulic chamber exhaust plug 232, hydraulic cylinder block 31 , oil cylinder piston 32, axial elastic moving element 4, large hydraulic chamber 4a, front elastic diaphragm 41, rear elastic diaphragm 42, connecting shaft 43, front pressure plate 44, rear pressure plate 45, small plunger pump valve combination element 5, Valve body 51, first oil passage 51a, second oil passage 51b, first check valve 511, second check valve 512, pump body 52, fastening bolt 521, preload plunger cylinder 522, preload plunger 523, pressure rod 524, support connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com