Cup type grinding wheel trimming device

A grinding wheel dresser and cup-shaped technology, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve the problems of large wear and limited use range of grinding wheel dressers, and improve dressing efficiency and performance Powerful, small and light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

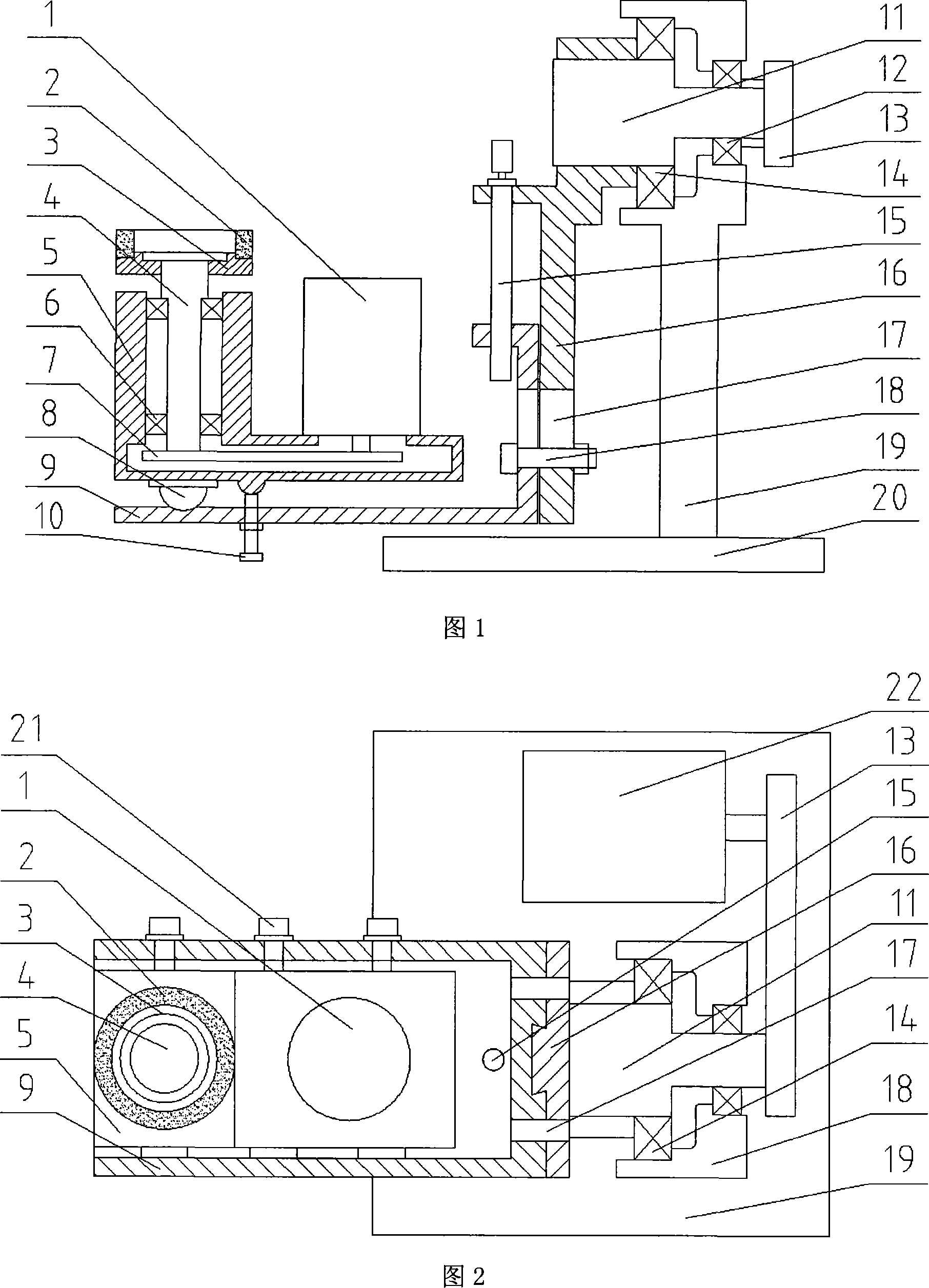

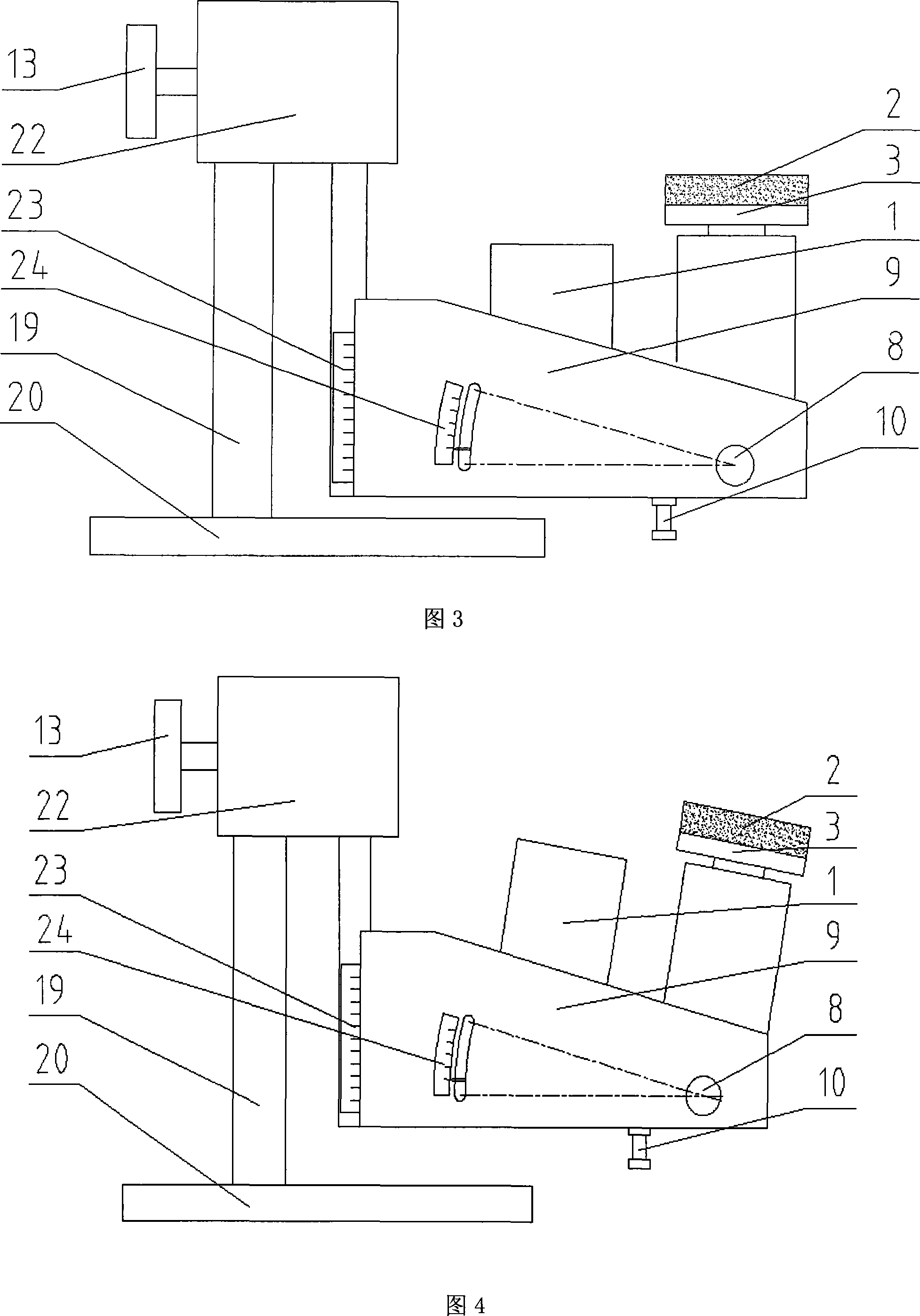

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Referring to Figures 1 to 4 and Figure 9, the present invention is provided with a base 20, a swing arm support 19, a swing arm shaft 11, a swing arm 16, a dressing wheel 2, a grinding wheel adapter 3, a main shaft 4, a main shaft pulley box 5, a first Servo motor 1, first transmission mechanism 7, second servo motor 22, second transmission mechanism 13, screw rod 15, bolts (10, 18 and 21), support round bar 8, triangular support 9, chute 17 and numerical control system .

[0032] The swing arm support 19 is installed on the base 20, the swing arm support 19 is connected with the swing arm rotating shaft 11 through the bearings 12, 14, and the swing arm 16 and the swing arm rotating shaft 11 are in interference fit. The dressing grinding wheel 2 is set on the grinding wheel connecting disc 3, the grinding wheel connecting disc 3 is installed on the main shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com