Ultrasonic food cutter device

A cutting knife and ultrasonic technology, applied in the direction of metal processing, etc., can solve the problems of insufficient production capacity, dirty factory environment, poor cutting effect, etc., and achieve the effect of accurate edge cutting, high cutting precision, and good finish of the cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

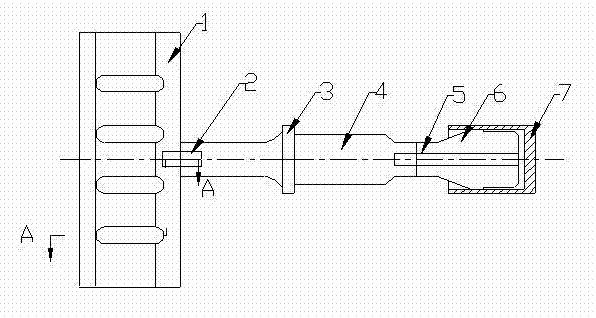

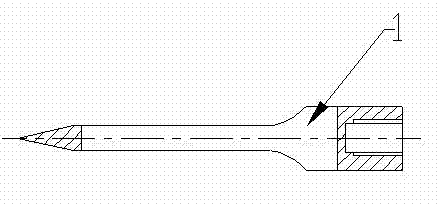

[0016] figure 1 figure 2 image 3 Middle: Ultrasonic food cutter device, mainly composed of cutter 1, screw rod Ⅰ2, front ring 3, horn 4, screw rod Ⅱ5, transducer 6, shell 7 and digital power control box 8, the cutter 1 One end of the screw rod I2 is connected, the other end of the screw rod I2 is connected to the horn 4, the other end of the horn 4 is connected to the screw rod II5, the other end of the screw rod II5 is connected to the transducer 6, the front ring 3 is set in the middle of the horn 4, and the The transducer 6 is arranged inside the shell 7, and the transducer 6 is electrically connected with the digital power control box 8. In the ultrasonic food cutting knife device, the cutting knife 1 is rectangular, the middle part of the right side of the rectangle is provided with a threaded hole, the left side is provided with a blade, and the middle part of the rectangle is evenly arranged with four oval through holes. The horn 4 is cylindrical, and the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com