Metal base spherical diamond abrasive wheel dressing device

A technology of diamond grinding wheel and dressing device, which is applied in metal processing equipment, abrasive surface adjustment device, parts of grinding machine tools, etc., can solve the problems of low dressing precision and incapable of spherical grinding wheel dressing, etc., to achieve simple and convenient control and meet dressing requirements. Angle requirements, reducing the effect of repeated clamping errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

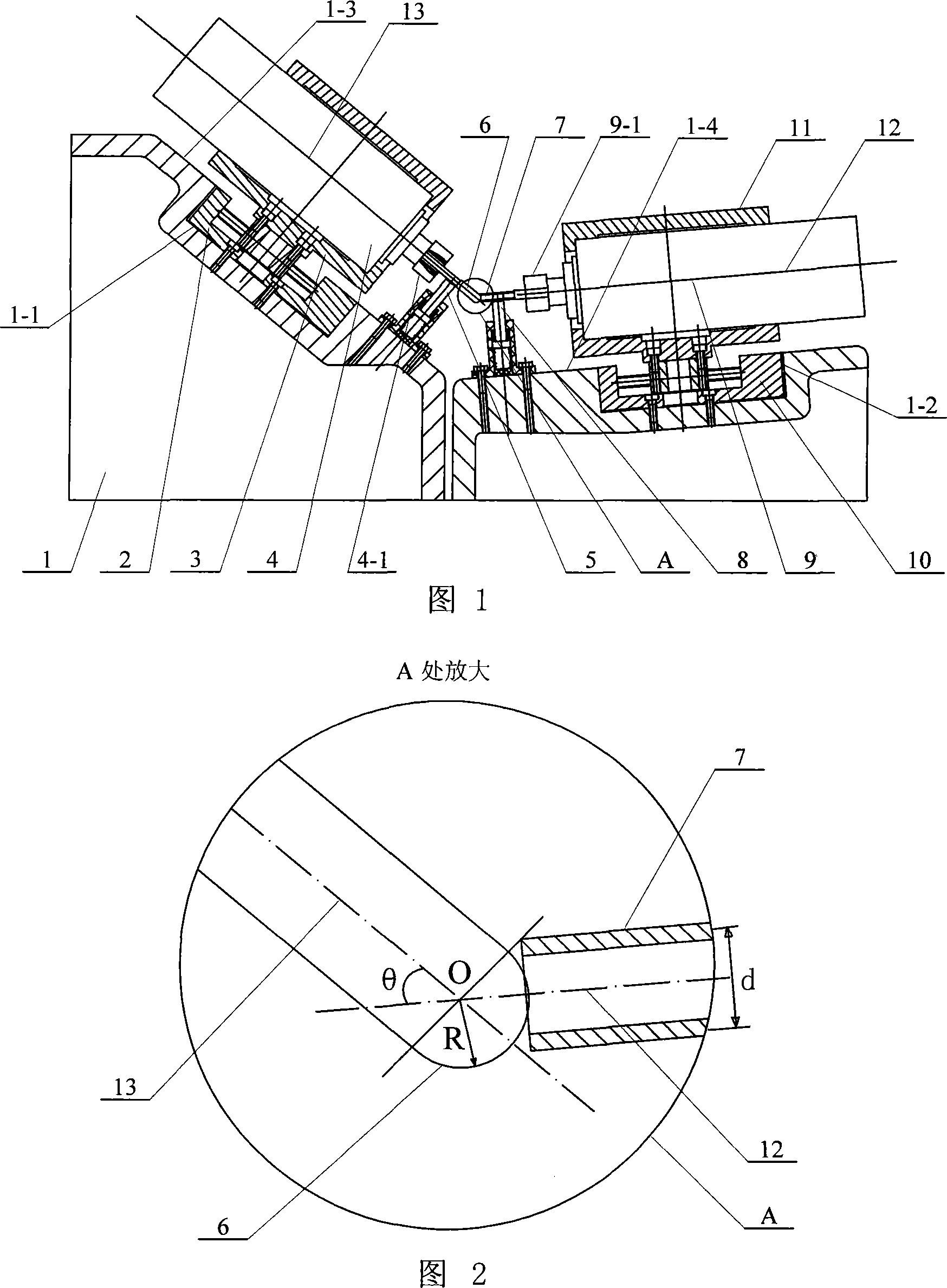

[0006] Specific embodiment one: (see Figure 1 and Figure 2) This embodiment consists of a worktable 1, a grinding wheel positioning drive system 2, a grinding wheel spindle holder 3, a grinding wheel spindle 4, a grinding wheel locker 4-1, and a grinding wheel brush 5. , Electrode 7, electrode brush 8, electrode spindle 9, electrode locker 9-1, electrode positioning drive system 10 and electrode spindle holder 11, the first inclined surface 1-3 of the worktable 1 is provided with a first Groove 1-1, the grinding wheel positioning drive system 2 is fixed in the first groove 1-1 of the worktable 1, the lower end of the grinding wheel spindle holder 3 is connected with the grinding wheel positioning drive system 2, and the grinding wheel spindle 4 is arranged on the grinding wheel spindle In the holder 3, one end of the grinding wheel spindle 4 is provided with a grinding wheel locker 4-1, and the lower end of the grinding wheel brush 5 is fixed on the first inclined surface 1-3 in t...

specific Embodiment approach 2

[0007] Specific embodiment two; (see Figure 1 and Figure 2) In this embodiment, the supplementary angle θ between the axis 13 of the grinding wheel spindle 4 and the axis 12 of the electrode spindle 9 is 40-50°. Others are the same as the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation three: (see Figure 1 and Figure 2) In this embodiment, the supplementary angle θ between the axis 13 of the grinding wheel spindle 4 and the axis 12 of the electrode spindle 9 is 45°. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com