Combined precise trimming device and trimming method for ultrahard grinding sand wheel

A technology for superhard abrasives and dressing devices, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, grinding/polishing equipment, etc., and can solve problems such as difficult dressing of superabrasive grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

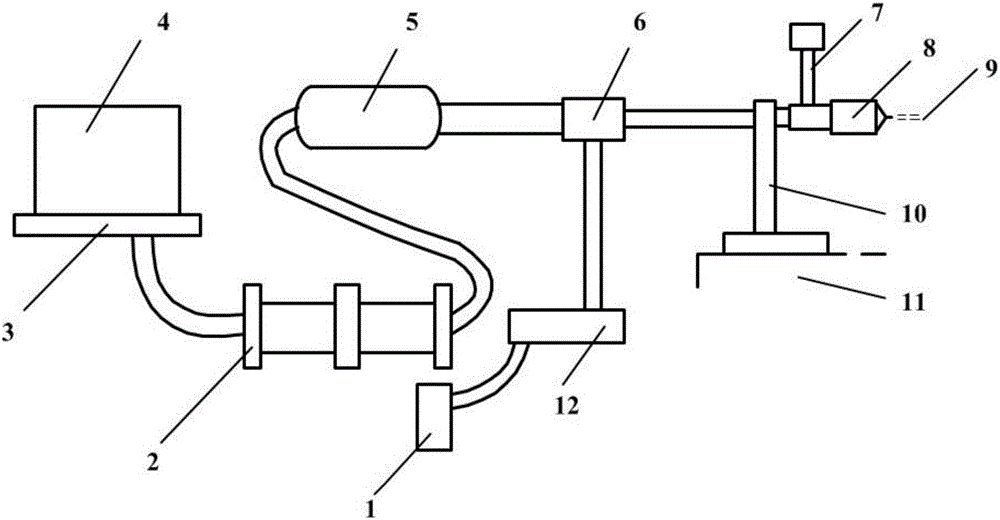

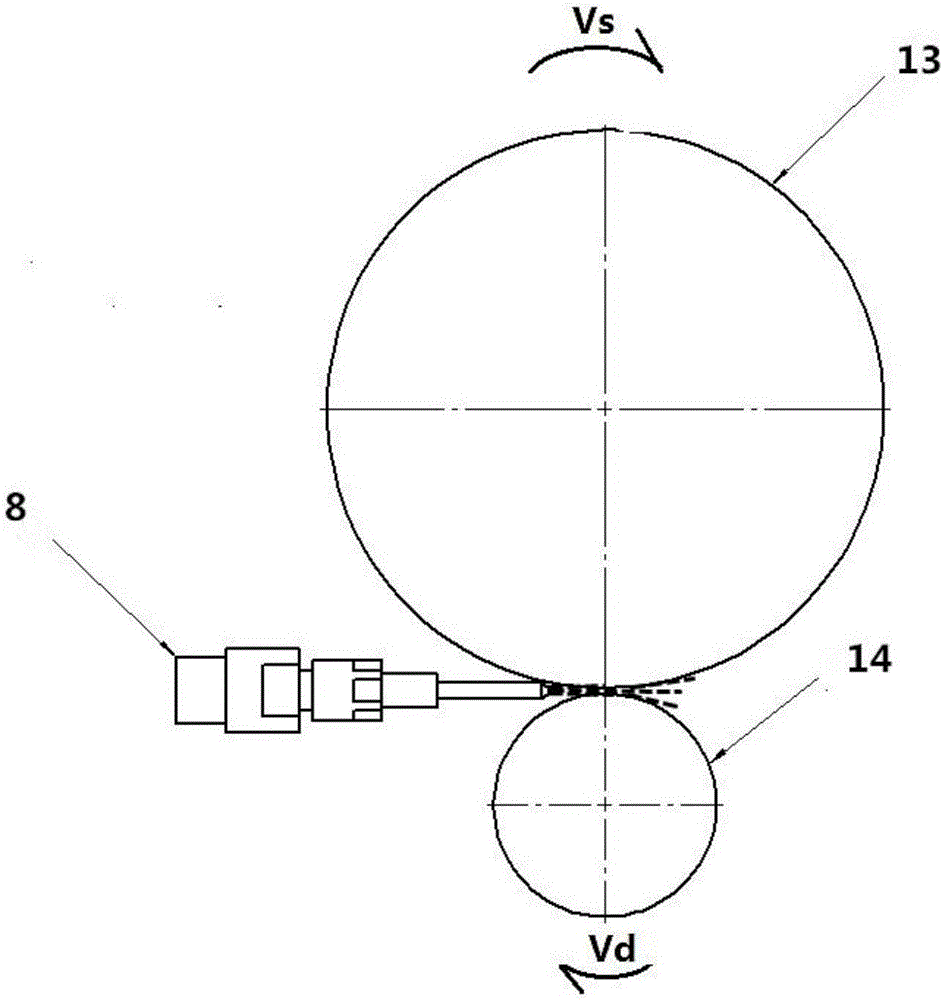

[0045] The invention will be further described in conjunction with the accompanying drawings.

[0046] Such as figure 1 , 2 As shown, a composite precision dressing device 11 for a superabrasive grinding wheel includes an abrasive water jet dressing device 11 installed on one side of the superabrasive grinding wheel and the dressing wheel, and the device is clamped by an abrasive water jet dressing clamping device 10 The abrasive water jet finishing device described in the abrasive water jet finishing clamping device includes an injection system 8, the inlet port of the injection system 8 communicates with an abrasive pot 7, and the injection system 8 is controlled by a controller 6, and the controller 6 is connected with the The accumulator 5 is connected to the air pressure device 12, and the accumulator 5 is connected to a water supply device 4; the air pressure device 12 is connected to the air compressor 1; a filter 3 and a booster Pressure pump 2.

[0047]The booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com