Transversely self-driven three-dimensional copying machining method and three-dimensional copying machine

A technology of three-dimensional profiling and processing methods, which is applied in metal processing equipment, manufacturing tools, and replication process control systems, etc., can solve the problems of inaccurate profiling size, enlargement of processing errors, large and complex overall structure of profiling machine tools, etc. Simplified structure and processing method, and the effect of high profiling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

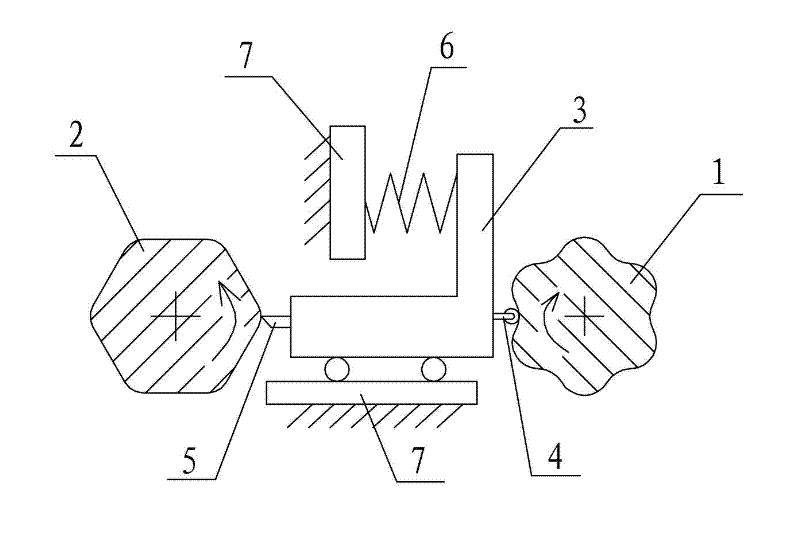

[0039] refer to figure 2 , the workpiece 2 to be processed is in the shape of a regular hexagonal prism with rounded edges, and its cross-section is a regular hexagon with rounded corners. For mold 1, the finished size of the workpiece is used as the design basis, that is, in figure 2 The size of the workpiece to be processed in 2 is regarded as the size of the standard finished product.

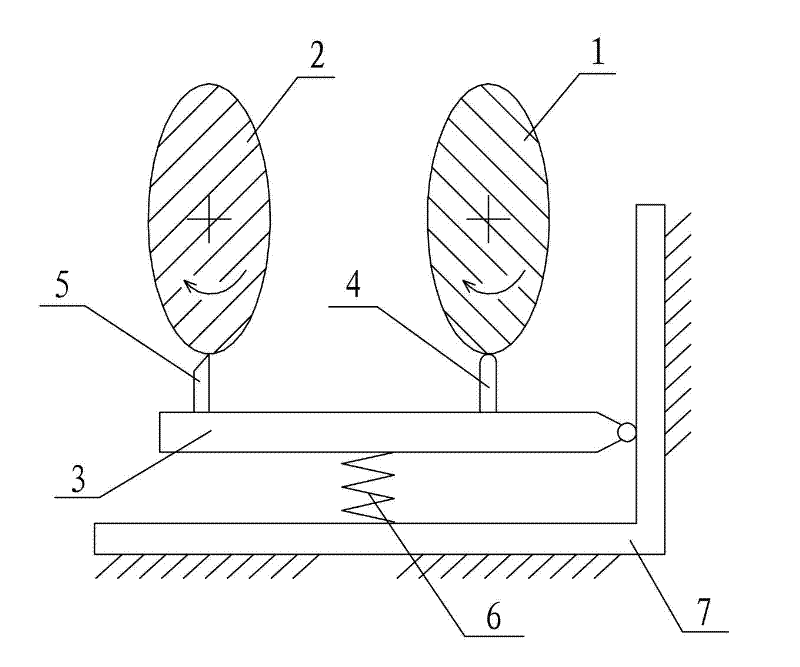

[0040]1) Prepare the profiling machine tool, adjust the profiling frame 3 of the profiling machine tool to be located between the main shaft of the profiling machine tool and the master axis, and adjust the contact 4 on the profiling frame 3 to face the direction of the profiling axis , the processing head 5 is adjusted to face the direction of the main shaft, and its specific structure is as follows figure 2 In addition, cutting processing is adopted here, so the processing head 5 is a turning tool, and the contact 4 is a roller (if the horizontal self-driven three-dimensional profilin...

Embodiment 2

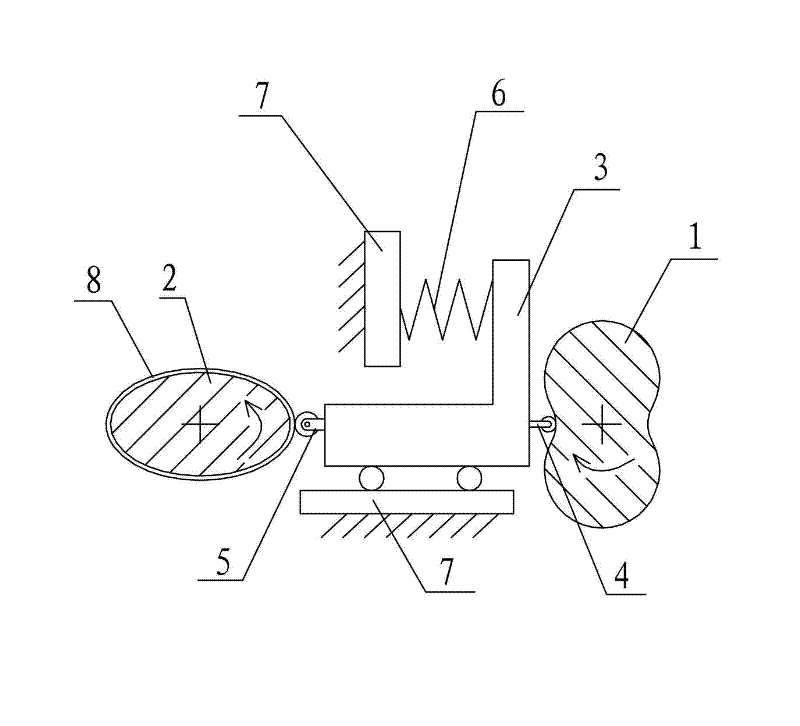

[0046] refer to image 3 , the workpiece 2 to be processed is a hollow cone part with an elliptical cross-section, because it is in the shape of a cone, it has a large end and a small end, and the central axis is coaxial with the spindle axis during installation. The cone angle of the part is 15°, the height is 50mm, the major axis of the ellipse is 250mm, the minor axis is 145mm, and the distance between the main axis and the model axis is 400mm. For spinning processing, the actual processing blank of the workpiece 2 to be processed is a flat plate with the same thickness as the workpiece, but when designing the profile 1, the finished size of the workpiece is used as the design basis, that is, in image 3 The size of the workpiece to be processed in 2 is regarded as the size of the standard finished product.

[0047] 1), prepare the profiling machine tool, set the profiling frame 3 of the profiling machine tool between the main shaft of the profiling machine tool and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com