Diversion plate and anti-vortex device integration based condenser

A deflector and condenser technology, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. problems such as low thermal efficiency, to achieve the effect of improving heat exchange efficiency and discharge capacity, simple structure, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

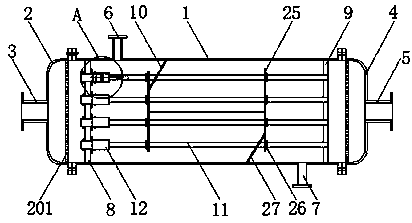

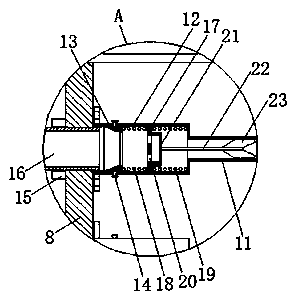

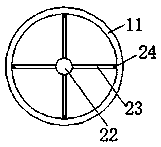

[0021] A condenser based on the integration of deflectors and anti-vortex devices, including a shell 1, the shell 1 is a cylindrical shell with both left and right ends open, the left port of the shell 1 is provided with a left end cover 2, and the left end cover 2 of the left end cover 2 The middle part of the side is provided with a refrigerant inlet pipe 3, the right port of the housing 1 is provided with a right end cover 4, the right side of the right end cover 4 is provided with a refrigerant outlet pipe 5, and the left end of the side of the housing 1 is provided with a fluid inlet pipe 6. The right end of the side is provided with a fluid outlet pipe 7, the left and right partitions of the inner cavity of the housing 1 are oppositely provided with a left partition 8 and a right partition 9, and the inner cavity of the casing 1 inside the left partition 8 and the right partition 9 is relatively provided with two stoppers. Plate 10, the middle part of the baffle plate 10 ...

Embodiment 2

[0023]A condenser based on the integration of deflectors and anti-vortex devices, including a shell 1, the shell 1 is a cylindrical shell with both left and right ends open, the left port of the shell 1 is provided with a left end cover 2, and the left end cover 2 of the left end cover 2 The middle part of the side is provided with a refrigerant inlet pipe 3, the right port of the housing 1 is provided with a right end cover 4, the right side of the right end cover 4 is provided with a refrigerant outlet pipe 5, and the left end of the side of the housing 1 is provided with a fluid inlet pipe 6. The right end of the side is provided with a fluid outlet pipe 7, the left and right partitions of the inner cavity of the housing 1 are oppositely provided with a left partition 8 and a right partition 9, and the inner cavity of the casing 1 inside the left partition 8 and the right partition 9 is relatively provided with two stoppers. Plate 10, the middle part of the baffle plate 10 i...

Embodiment 3

[0025] A condenser based on the integration of deflectors and anti-vortex devices, including a shell 1, the shell 1 is a cylindrical shell with both left and right ends open, the left port of the shell 1 is provided with a left end cover 2, and the left end cover 2 of the left end cover 2 The middle part of the side is provided with a refrigerant inlet pipe 3, the right port of the housing 1 is provided with a right end cover 4, the right side of the right end cover 4 is provided with a refrigerant outlet pipe 5, and the left end of the side of the housing 1 is provided with a fluid inlet pipe 6. The right end of the side is provided with a fluid outlet pipe 7, the left and right partitions of the inner cavity of the housing 1 are oppositely provided with a left partition 8 and a right partition 9, and the inner cavity of the casing 1 inside the left partition 8 and the right partition 9 is relatively provided with two stoppers. Plate 10, the middle part of the baffle plate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com