Light conducting plate and backlight module using the same

A technology of backlight module and light guide plate, which is applied in optics, light guide, optical components, etc., can solve the problems of low luminance and poor optical performance of light guide plate, and achieve the effects of small energy loss, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

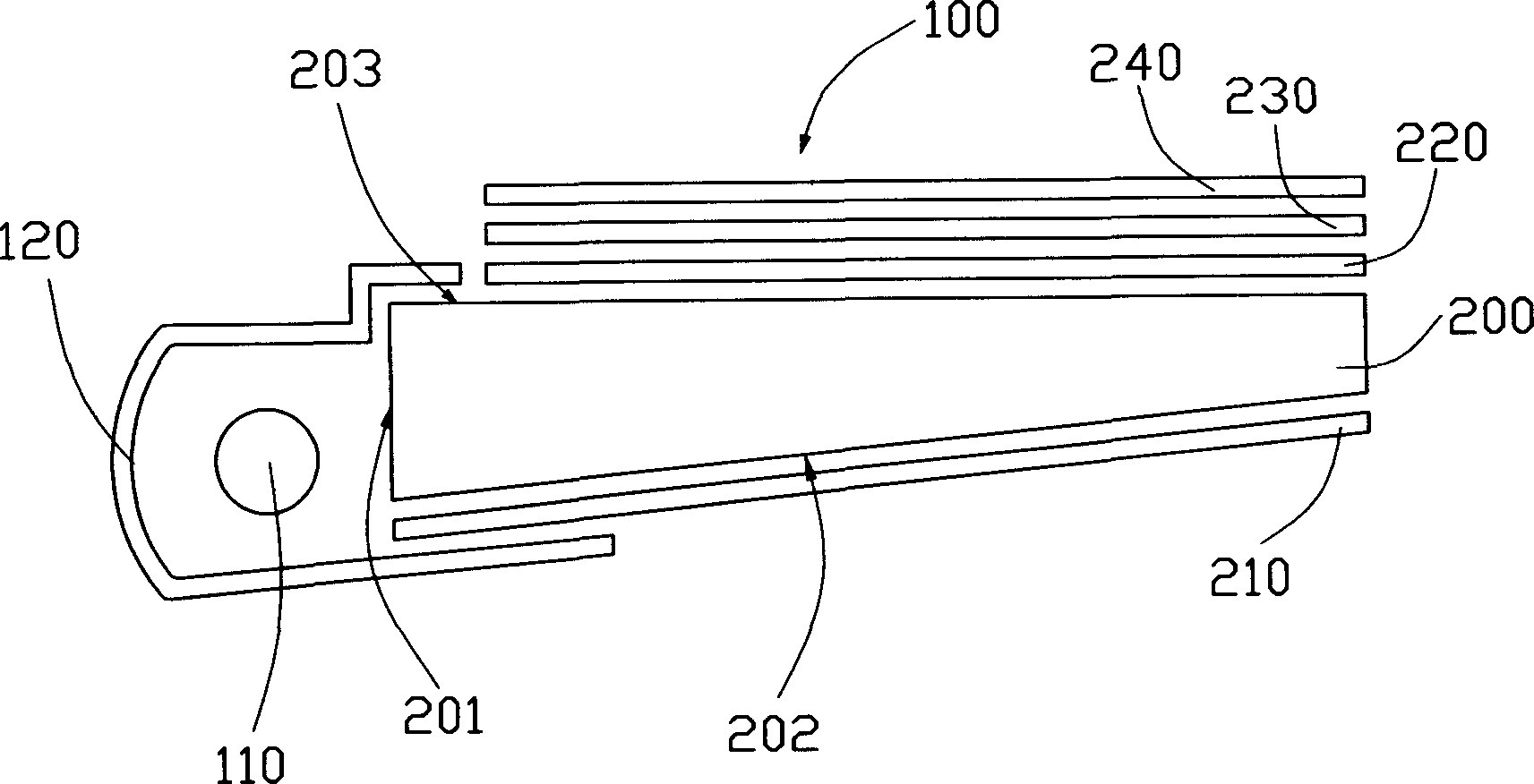

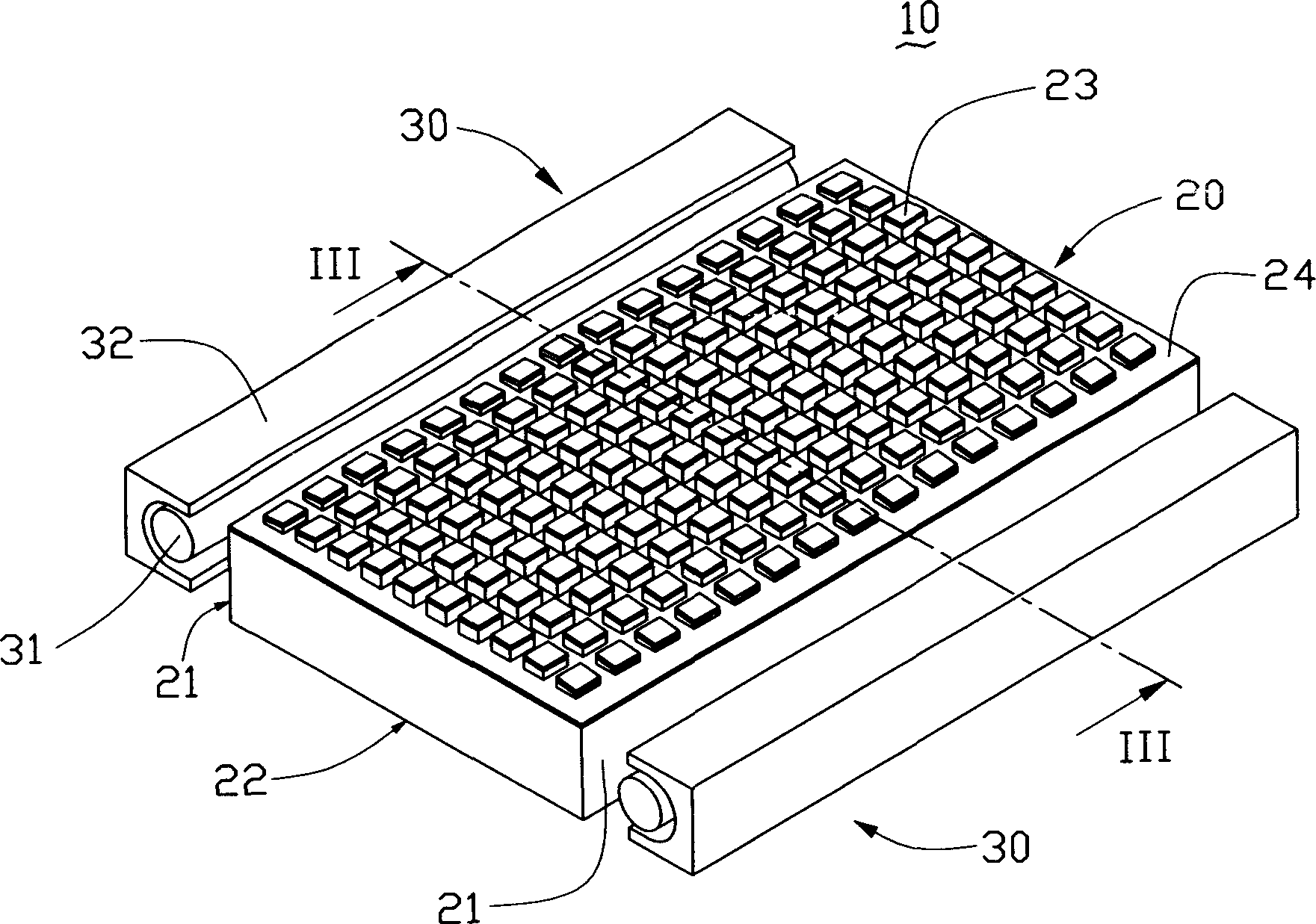

[0020] see figure 2 In the first embodiment of the backlight module of the present invention, the backlight module 10 includes a light guide plate 20 and two light sources 30 . The light guide plate 20 includes two incident surfaces 21 , an outgoing surface 22 connected to the incoming surfaces 21 , and a bottom surface 24 opposite to the outgoing surfaces 22 . The light source 30 includes a lamp tube 31 and a part of a reflector 32 surrounding the lamp tube 31 . The two light sources 30 are respectively disposed opposite to the two incident surfaces 21 of the light guide plate 20 .

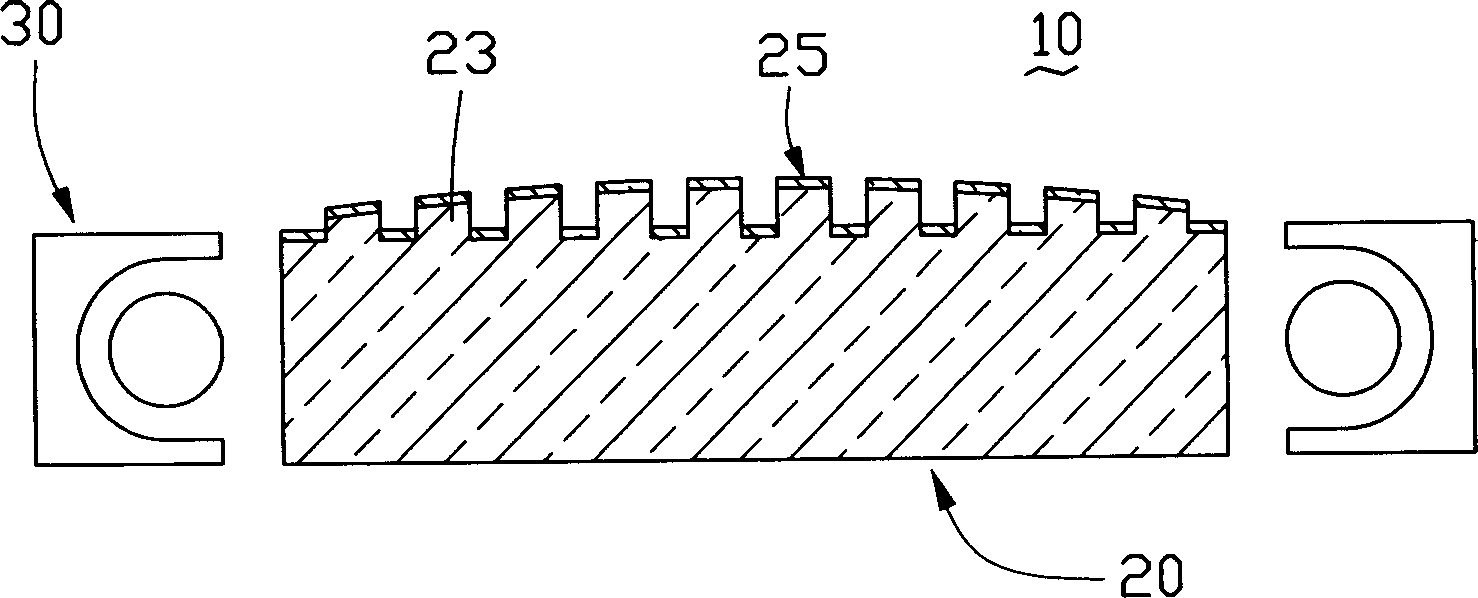

[0021] see together figure 2 and image 3 , a plurality of protrusions 23 are distributed on the bottom surface 24 of the light guide plate 20 . The plurality of protrusions 23 are used to scatter the light beams, destroy the total reflection condition for the light beams entering from the incident surface 21 to transmit inside the light guide plate 20 , and improve the brightness and unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com