Manufacture method of ultra-low-temperature, high-strength and long-fatigue life automobile bridge seamless heterotype axle steel tube

A fatigue life, seamless special-shaped technology, applied in the direction of manufacturing tools, shafts, furnace types, etc., can solve the problems that the corners of the welded and formed axle steel pipes cannot be thickened, the comprehensive performance cannot be improved and guaranteed, and the overall rigidity of the steel pipes is not high. , to achieve the effect of having overall performance advantages, conducive to precise molding and avoiding welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

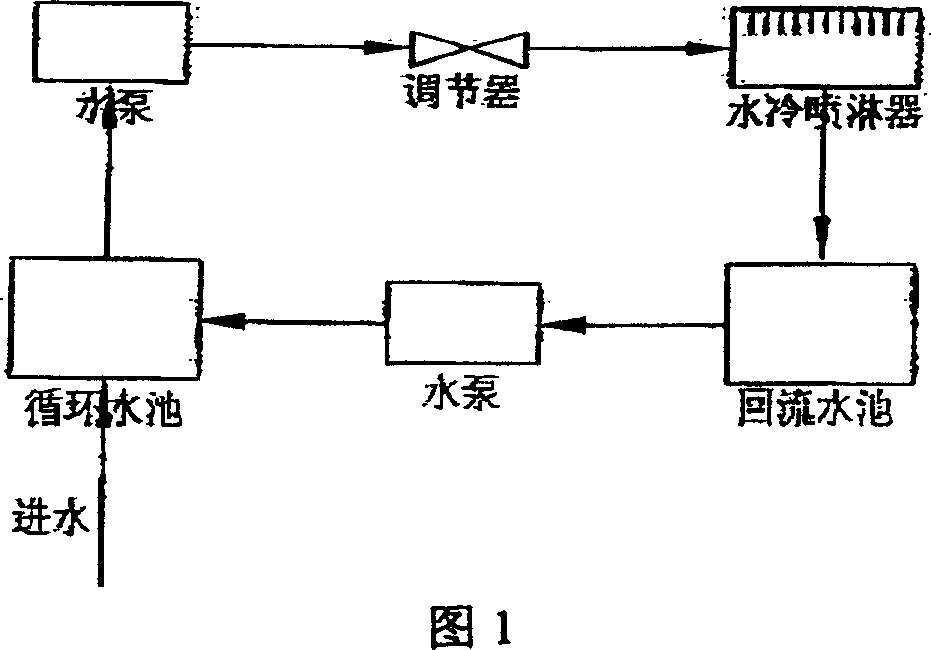

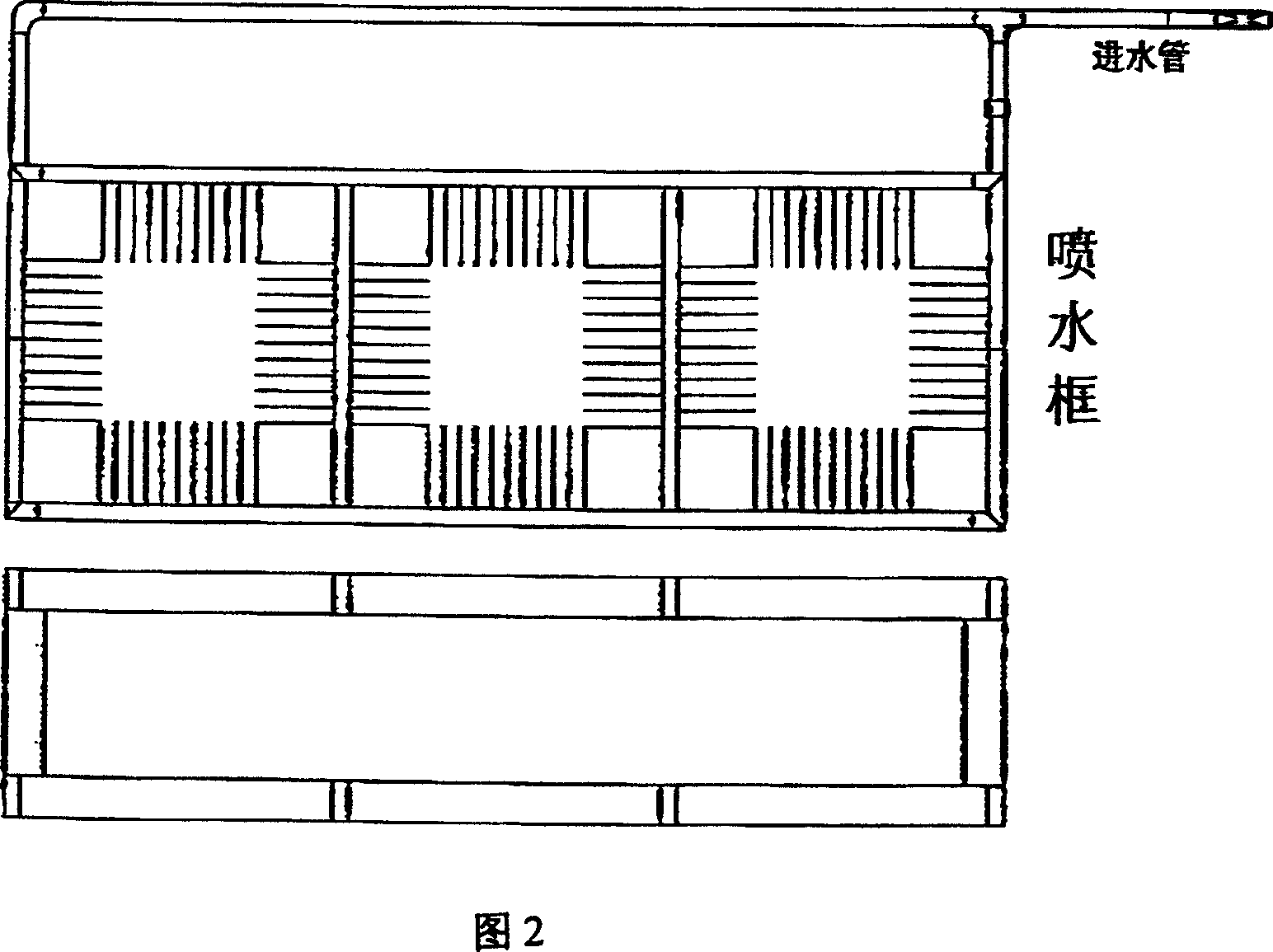

Method used

Image

Examples

Embodiment 1

[0043] The invention discloses a method for manufacturing an ultra-low temperature, high-strength and long-fatigue-life seamless special-shaped axle steel pipe for automobile bridges. Low-carbon micro-alloy high-strength structural steel (450DJZ, 450EJZ) is used as the material, and the weight percentage of each chemical element in the material is: C 0.15%, Si 0.5%, Mn 1.7%, and trace elements V 0.05%, Nb 0.05%, Ti 0.05 % and Al 0.02%, the balance is Fe and unavoidable impurities, the specific process steps are as follows:

[0044] Step 1. Normalizing heat treatment

[0045] Normalizing heat treatment heating temperature 900~920℃, holding time 25 minutes, air cooling,

[0046] Step 2. Pickling and lubrication

[0047] Pickling to remove the oxide film, after rinsing, the internal and external surface phosphating process,

[0048] Step 3. Hydraulic cold drawing

[0049] The cold drawing of the shape adopts the hydraulic cold drawing liner core drawing method. The outer mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com