Luminous device and illuminator

一种发光装置、照明装置的技术,应用在照明装置、照明装置的零部件、照明和加热设备等方向,能够解决发光装置发光强度以及亮度恶化、减少波长变换等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

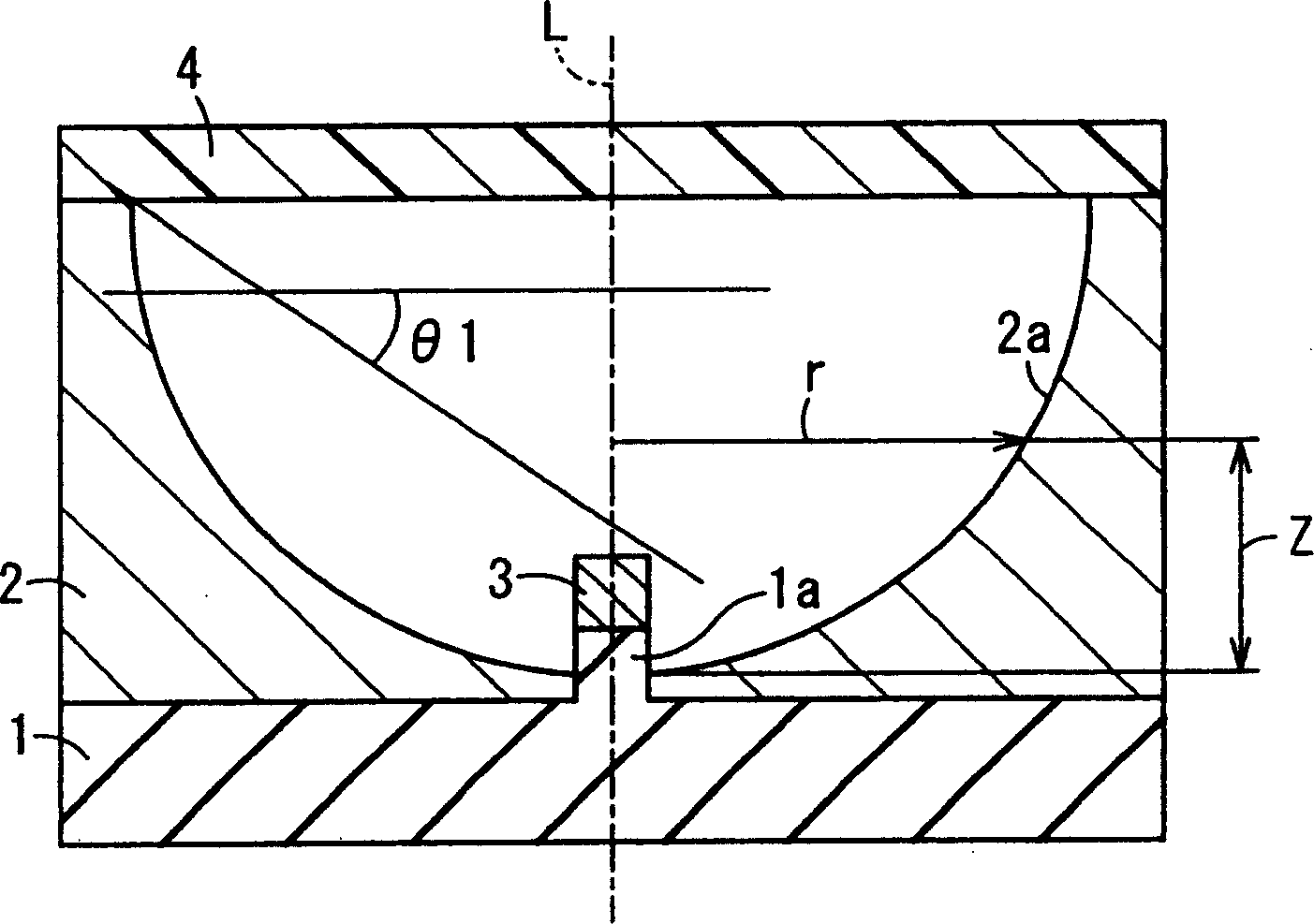

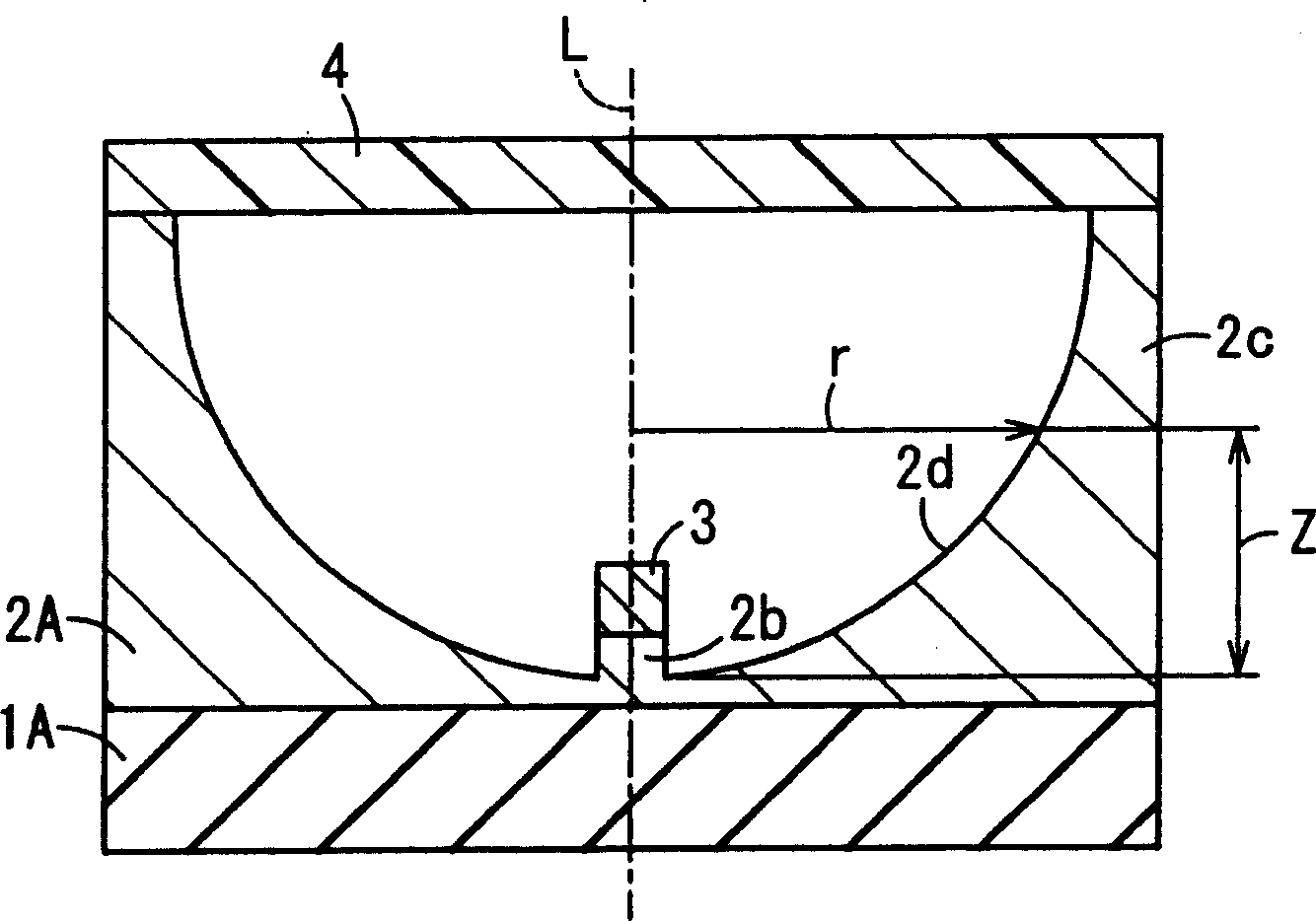

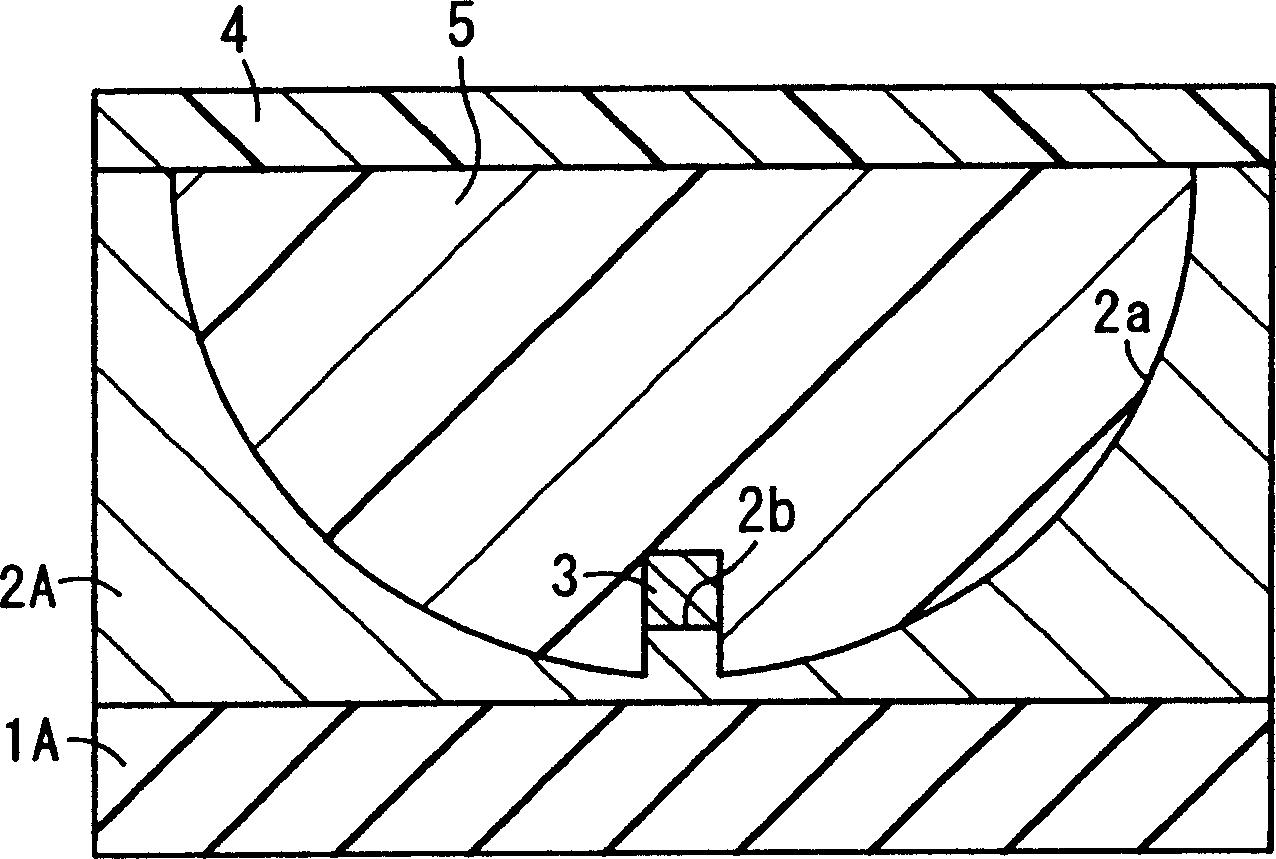

[0063] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a cross-sectional view illustrating the light emitting device according to Embodiment 1 of the present invention. In the figure, the light emitting device includes a substrate 1 , a reflective component 2 , a light emitting device 3 and a phosphor layer 4 . A phosphor layer 4 for converting the wavelength of light emitted by the light emitting device 3 is provided on the upper part of the reflective member 2 .

[0064] The substrate 1 has a convex portion 1 a on its upper surface for mounting the light emitting device 3 . Also, wiring conductors (not shown) including lead terminals and metal-clad wiring for electrically connecting the inside and outside of the light-emitting device from the mounting portion 1b and its periphery are formed on the base body 1 . The reflective member 2 surrounds the convex portion 1a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com