Light emitting device and lighting device

A technology of light-emitting devices and light-emitting elements, which is applied in the direction of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., which can solve problems such as the difficulty in improving the intensity and brightness of light emitted by light-emitting devices, and the attenuation of reflected light intensity, so as to improve the emission The effect of high light intensity, brightness and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

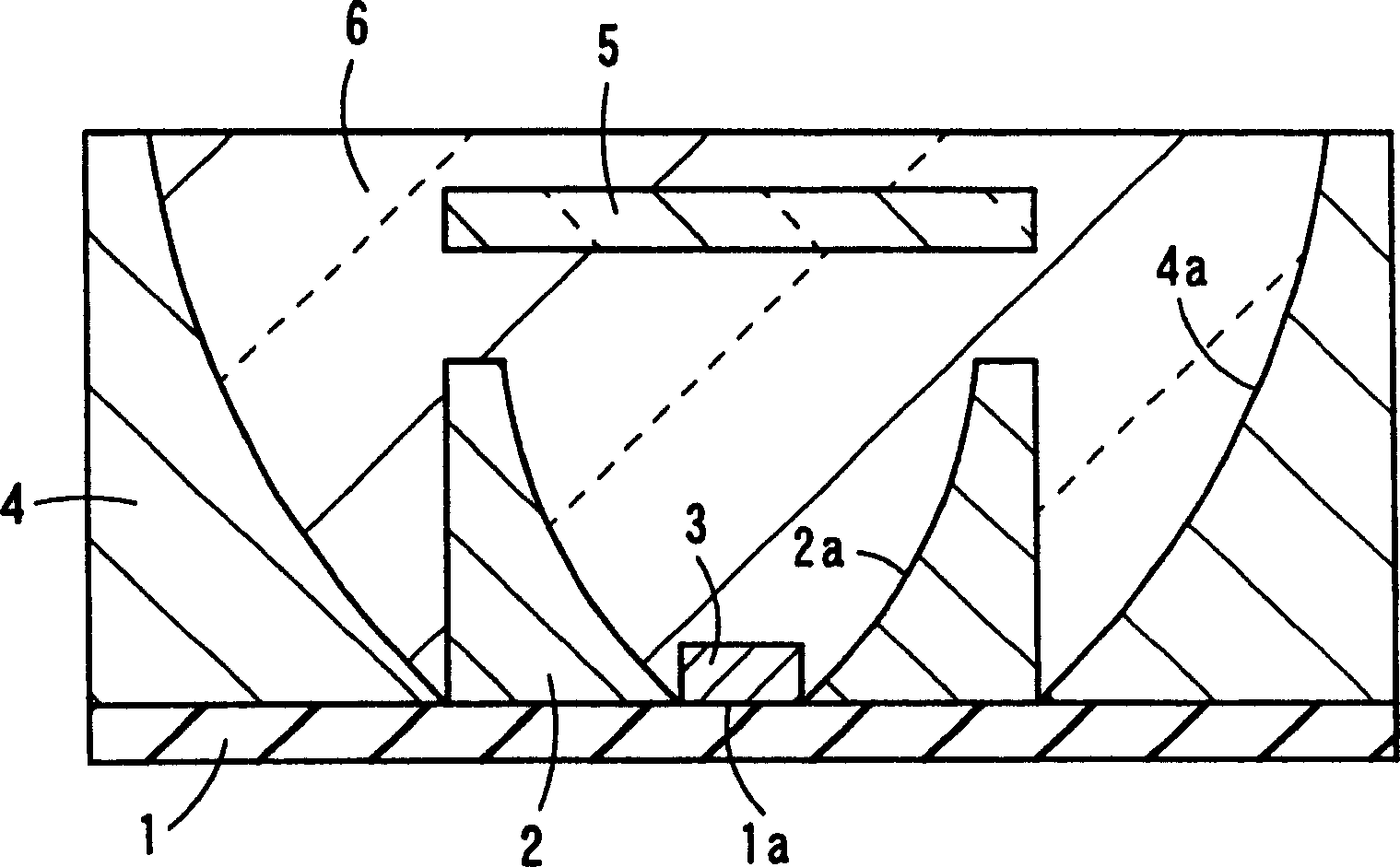

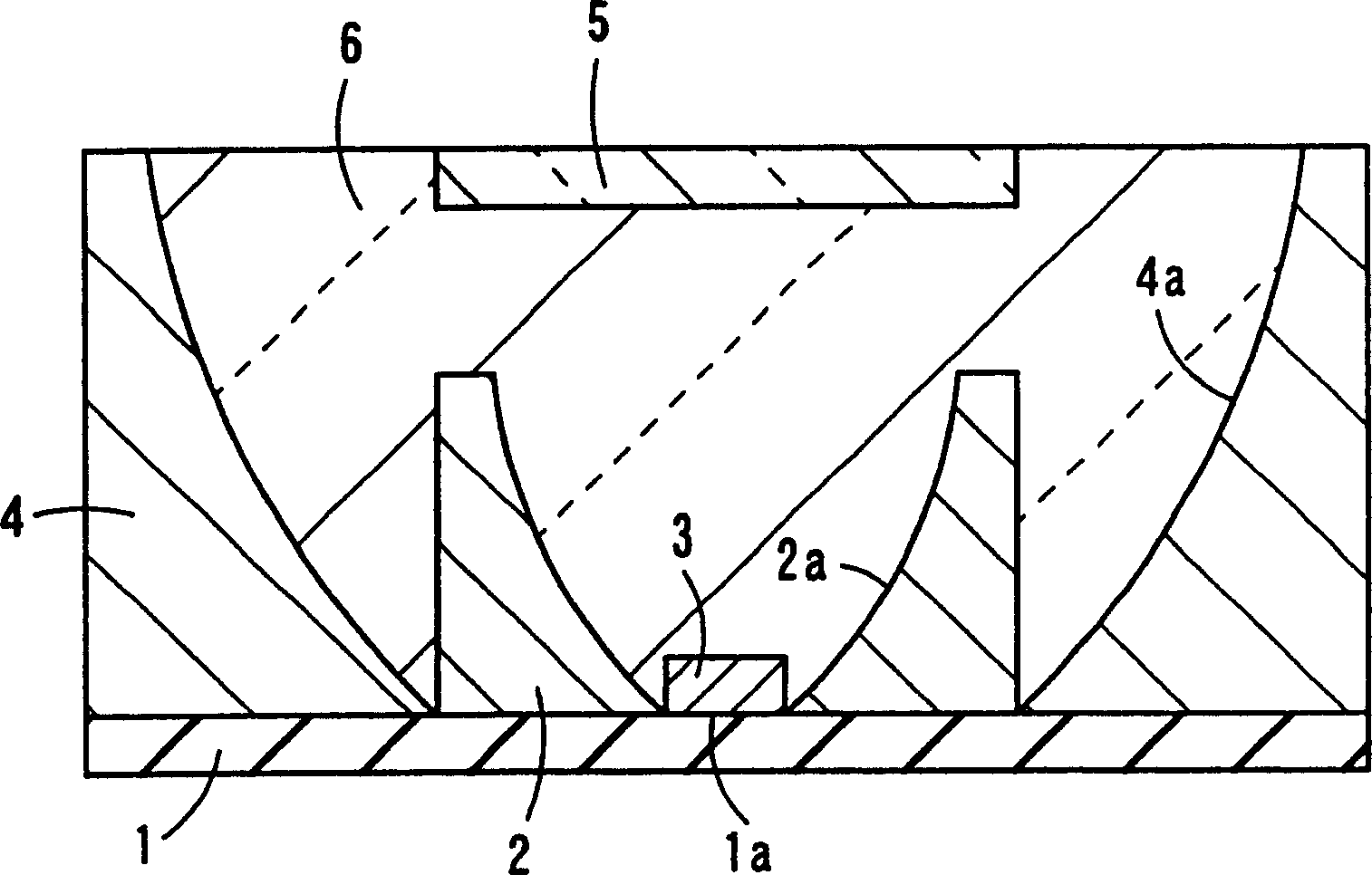

[0165] For the light-emitting device of the present invention, examples will be shown below. First, a base 1 made of alumina ceramics to be the base 1 was prepared. Moreover, substrate 1 such as image 3 As shown, it is integrally formed so that the placement portion 1a protrudes, and the upper surface of the placement portion 1a is parallel to the upper surface of the base body 1 other than the placement portion 1a.

[0166] The base 1 is a member in which a cuboid mounting part 1a of width 0.35 mm x depth 0.35 mm x thickness 0.15 mm is formed on the upper central part of a cuboid of width 17 mm x depth 17 mm x thickness 0.5 mm.

[0167] In addition, a wiring conductor for electrically connecting the light emitting element 3 and the external circuit board via internal wiring formed inside the base body 1 is formed at the portion where the light emitting element 3 is mounted on the placement portion 1a. The wiring conductor is made of a metallization layer made of Mo-Mn powd...

Embodiment 2

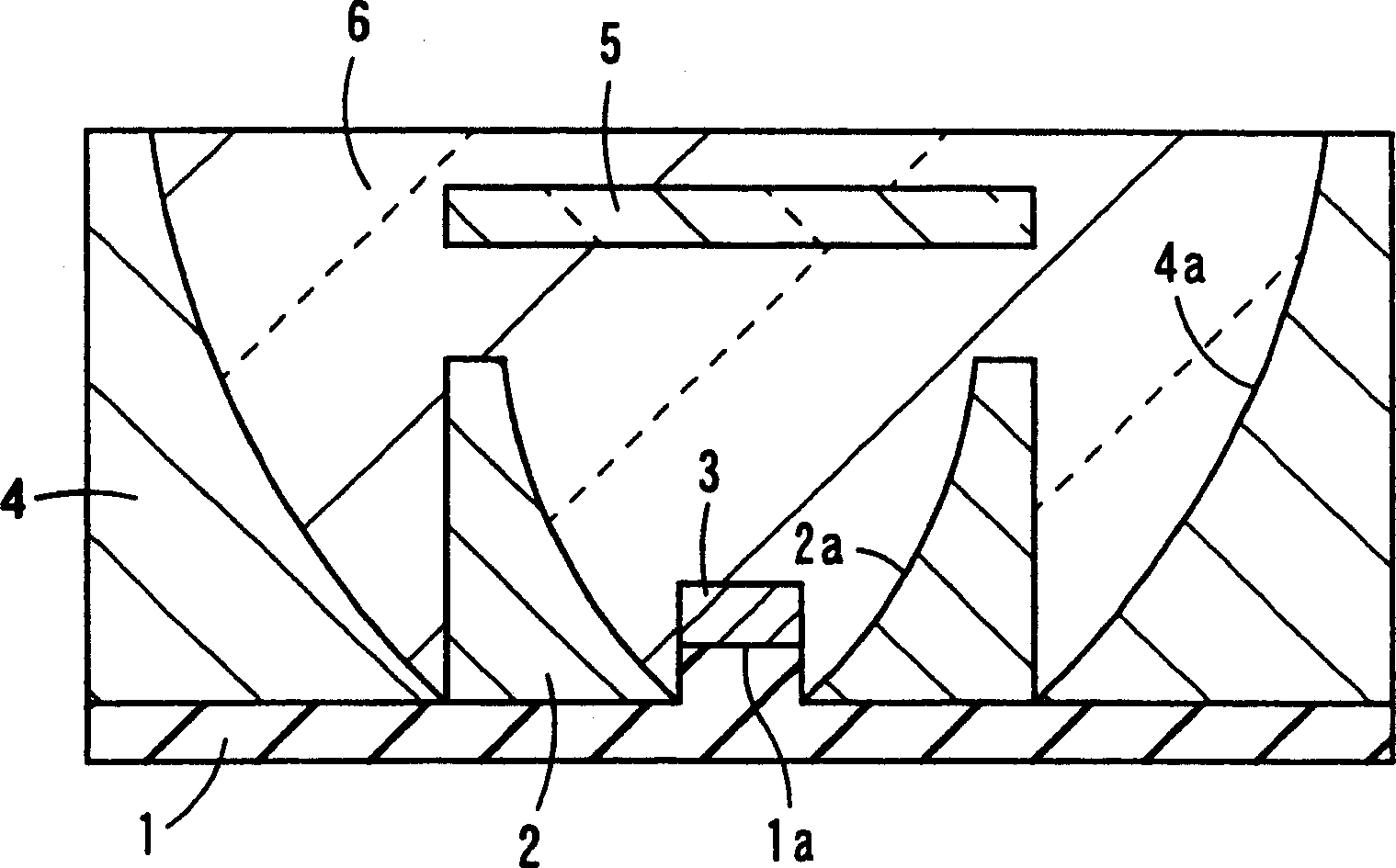

[0187] For the light-emitting device of the present invention, examples will be shown below. First, a substrate 1 made of alumina ceramics to be a substrate 1 was prepared. Moreover, substrate 1 such as Figure 16 As shown, it is integrally formed so that the placement portion 1a protrudes, and the upper surface of the placement portion 1a is parallel to the upper surface of the base body 1 other than the placement portion 1a.

[0188] The base 1 is a member in which a cuboid mounting part 1a of width 0.35 mm x depth 0.35 mm x thickness 0.15 mm is formed on the upper central part of a cuboid of width 17 mm x depth 17 mm x thickness 0.5 mm.

[0189] In addition, a wiring conductor for electrically connecting the light emitting element 3 and the external circuit board via internal wiring formed inside the base body 1 is formed at the portion where the light emitting element 3 is mounted on the placement portion 1a. The wiring conductor is made of a metallization layer made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com