High-voltage LED chip structure and manufacturing method thereof

A technology of LED chip and manufacturing method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low output efficiency of high-voltage LED chips, and achieve the effect of providing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

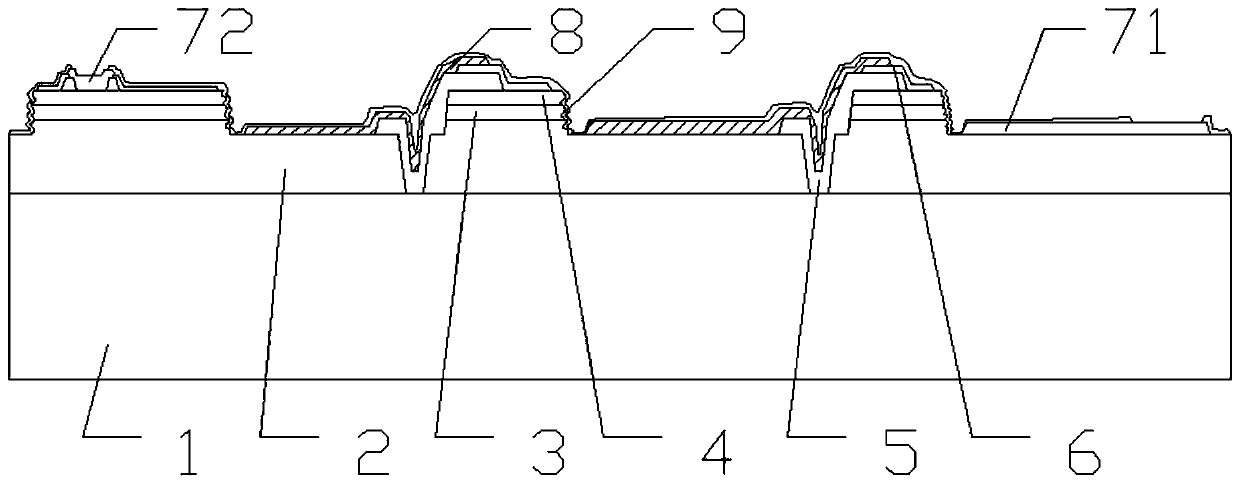

[0044] As mentioned in the background art section, the output efficiency of the high-voltage LED chips in the prior art is relatively low and needs to be improved.

[0045] The inventor found that the reason for the above phenomenon is that the side wall of the high-voltage LED chip is a smooth plane. When the active layer emits light, there will be light emitted from the side. Since the high-voltage LED chip includes multiple adjacent LED sub-chips , if the light emitted from the side cannot be effectively utilized, the high-voltage LED chip will cause a large loss of light efficiency, resulting in a lower luminous output efficiency of the entire high-voltage LED chip compared to a single LED chip.

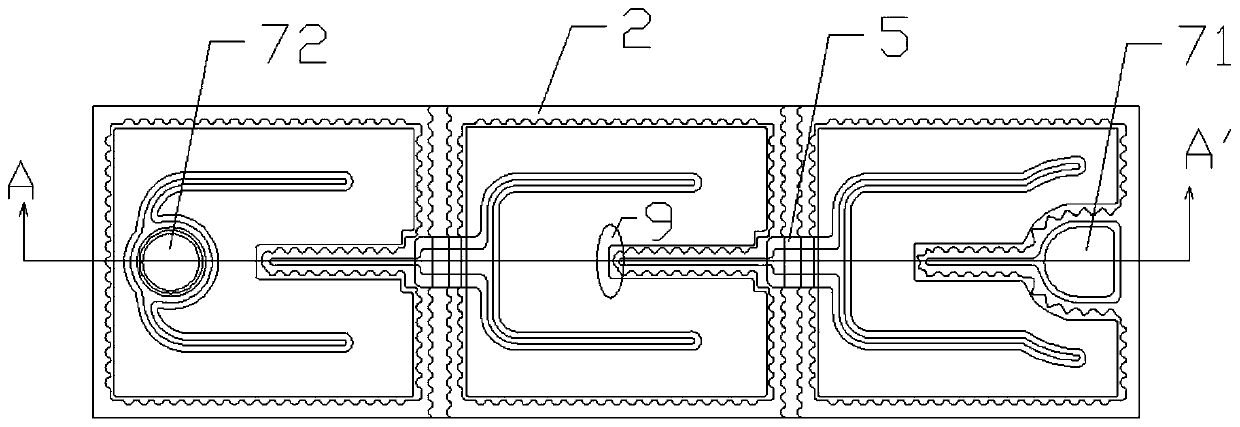

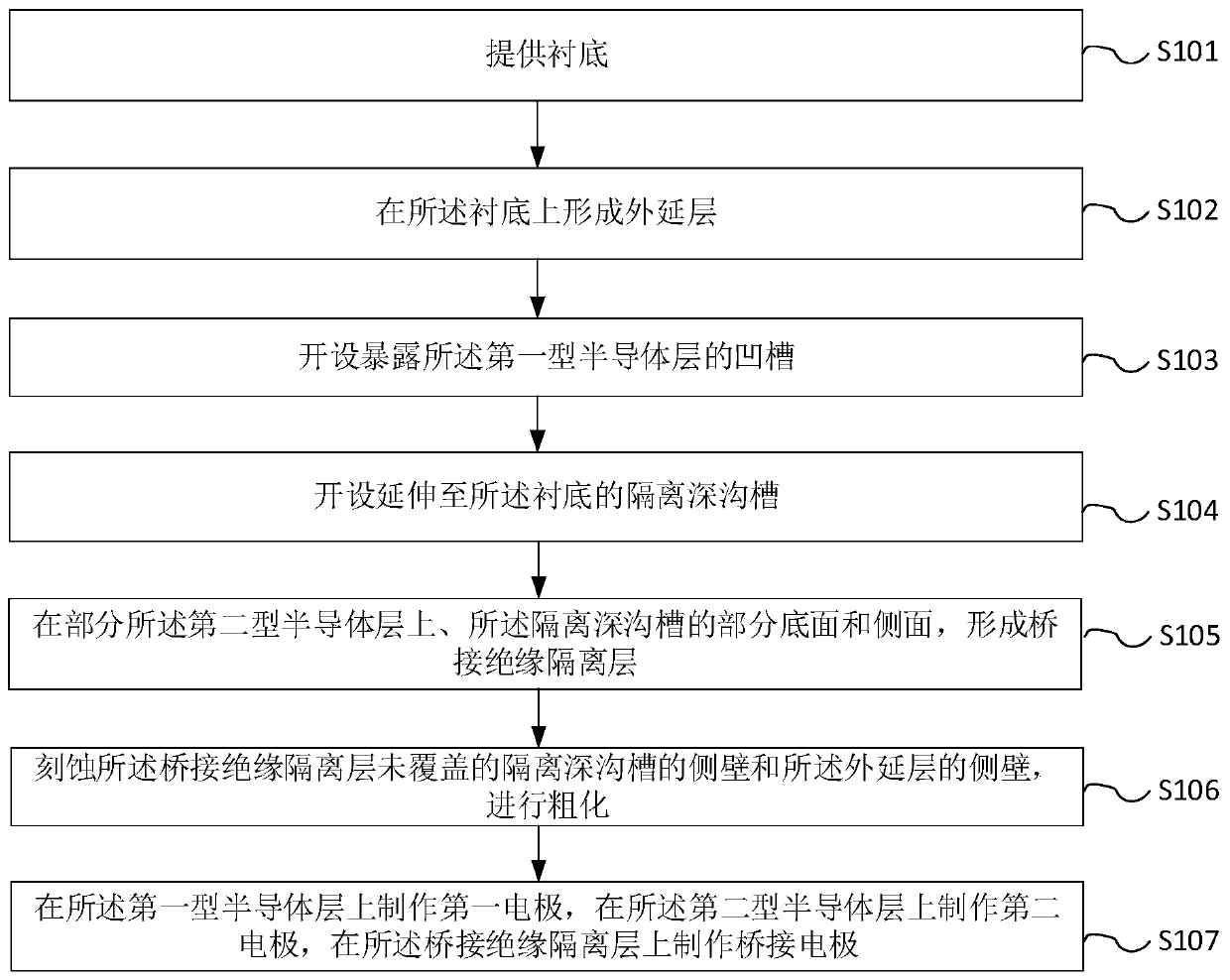

[0046] Based on this, the present invention provides a high-voltage LED chip structure, including:

[0047] Multiple LED sub-chips;

[0048] Each of the LED sub-chips includes:

[0049] Substrate;

[0050] an epitaxial layer located on the substrate, the epitaxial layer compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com