Composite wavelength conversion powder, resin composition containing composite wavelength conversion powder, and light emitting device

A technology of resin composition and multiple wavelengths, which is applied in luminescent materials, lighting devices, electroluminescent light sources, etc., can solve problems such as insufficient performance of wavelength conversion materials, reduced luminous efficiency of nano-phosphors, and influence of humidity to achieve high-efficiency luminescence Reliability, high utilization efficiency, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0064] Embodiments for implementing the composite wavelength conversion powder and the resin composition containing the composite wavelength conversion powder of the present invention will be described.

[0065] In addition, the following embodiments are specifically described for a better understanding of the gist of the invention, and unless otherwise specified, do not limit the present invention.

[0066] [Composite wavelength conversion powder]

[0067] The composite wavelength converting powder of this embodiment is a powder formed by dispersing phosphor particles having a refractive index of 1.6 or more in matrix particles containing magnesium fluoride fine particles or calcium fluoride fine particles.

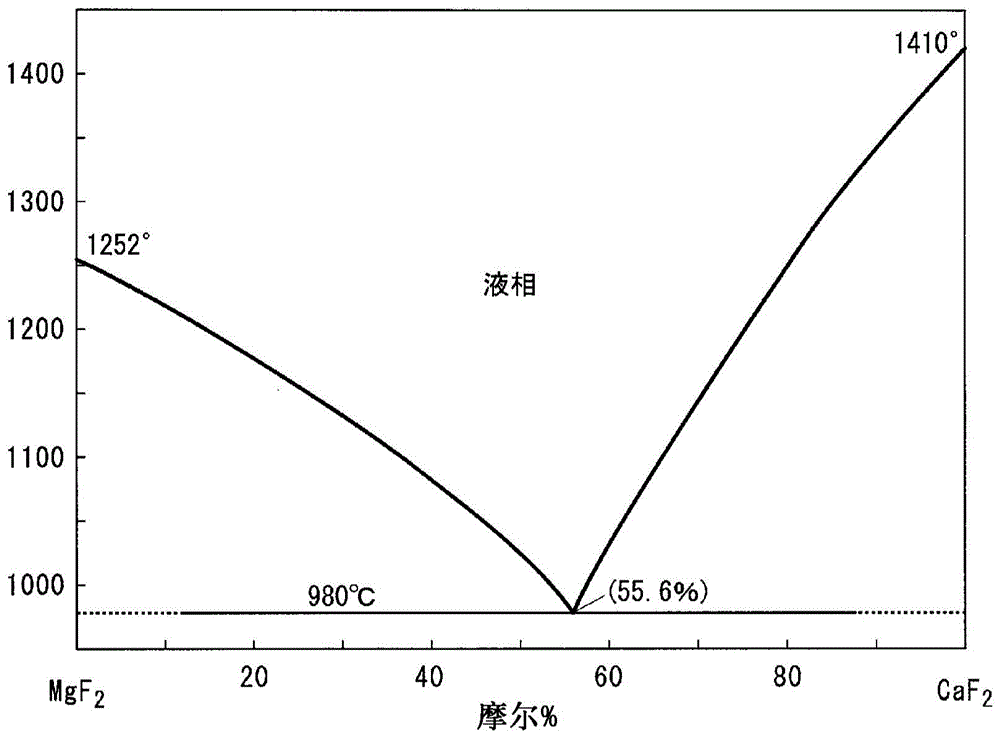

[0068] Here, the reason for using magnesium fluoride fine particles (refractive index: 1.38) or calcium fluoride fine particles (refractive index: 1.43) as the material constituting the above-mentioned matrix particles is that the refractive index is low, and heat resist...

Embodiment 1

[0126] [Example 1] (preparation of magnesium fluoride colloid)

[0127] Magnesium chloride hexahydrate (MgCl 2 ·6H 2 O) 406.6g was dissolved in 2000g of pure water (room temperature: 25 degreeC), and the magnesium chloride aqueous solution was prepared. Next, ammonium fluoride (NH 4 F) Magnesium fluoride particles were produced by stirring an aqueous ammonium fluoride solution obtained by dissolving 148.2 g in 2000 g of pure water (room temperature: 25° C.).

[0128] Next, the solution containing the magnesium fluoride particles is cleaned by ultrafiltration to remove impurity ions in the solution, and then concentrated to prepare a solution containing 2% by mass of magnesium fluoride (MgF 2 ) particles of magnesium fluoride colloid.

[0129] The dispersed particle diameter of this magnesium fluoride colloid is 30nm, magnesium fluoride (MgF 2 ) The crystal particle size of the particles is 8nm.

[0130] (Preparation of phosphor precursor solution with garnet structure) ...

Embodiment 2

[0144] [Example 2] (preparation of calcium fluoride colloid)

[0145] Calcium chloride dihydrate (CaCl 2 2H 2 O) 376.6g was dissolved in 9624g (room temperature: 25 degreeC) of pure water, and the calcium chloride aqueous solution was prepared. Next, ammonium fluoride (NH 4 F) An ammonium fluoride aqueous solution obtained by dissolving 190 g in 9810 g of pure water (room temperature: 25° C.) was stirred to produce calcium fluoride particles.

[0146] Next, the solution containing the calcium fluoride particles is cleaned by ultrafiltration to remove impurity ions in the solution, and then concentrated to prepare a solution containing 2% by mass of calcium fluoride (CaF 2 ) particles of calcium fluoride colloid.

[0147] The dispersed particle diameter of this calcium fluoride colloid is 80nm, calcium fluoride (CaF 2 ) The crystal particle size of the particles is 20nm.

[0148] ]

[0149] (Preparation of phosphor precursor solution with garnet structure)

[0150] Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com