Ink jet printing apparatus and ink jet printing method

A technology of an inkjet printing device and a printing head, which is applied in printing devices, printing, etc., and can solve problems such as color unevenness, print quality degradation, and color tone differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

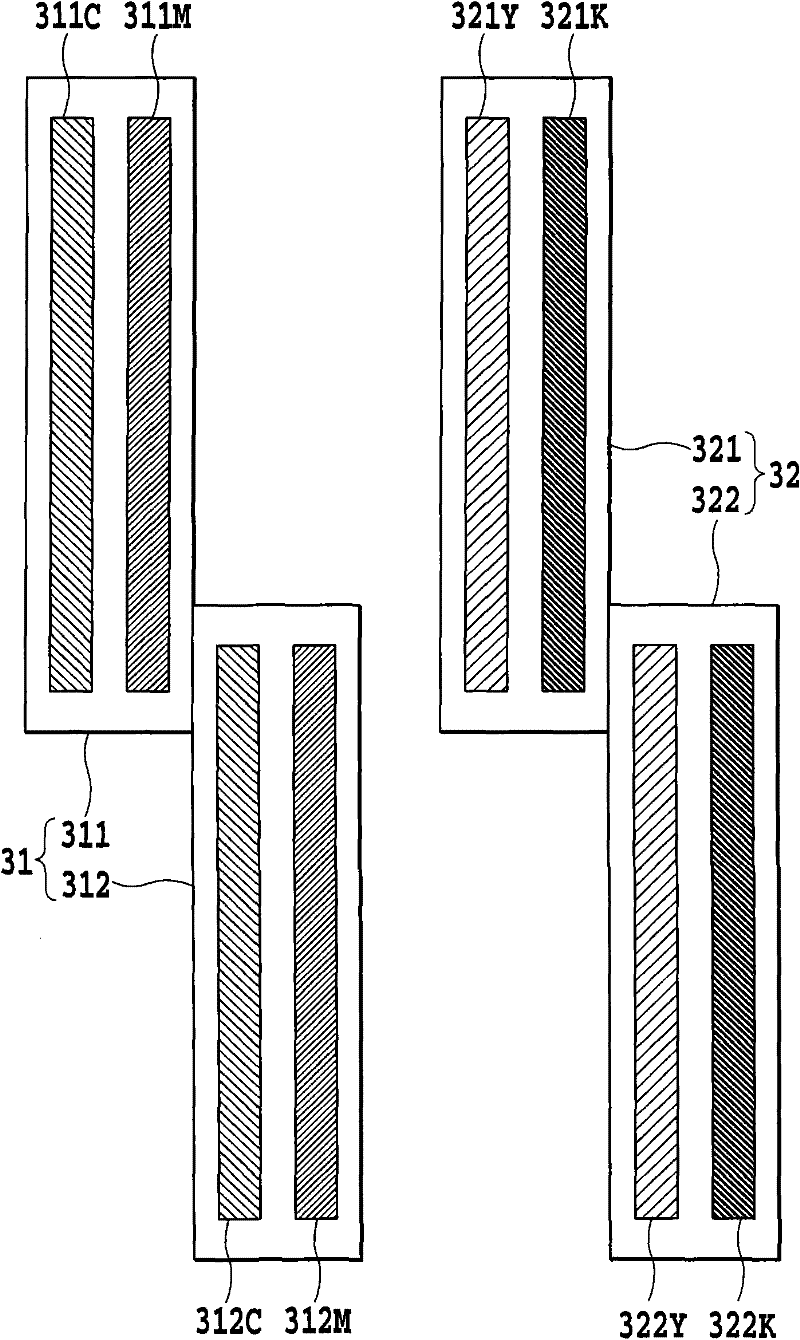

[0093] A second embodiment of the present invention will now be described. The second embodiment corresponds to the structure shown in the above-mentioned embodiments, and in which the threshold for controlling the overlap area mask is increased if the number of main scans per unit area is large. The 2nd embodiment is also constructed as Figure 1 to Figure 7 shown.

[0094] The second embodiment enables selective two-pass printing or 8-pass printing described in the first embodiment; in 8-pass printing, an image is completed by performing 8 main scans per unit area. That is, in the second embodiment, as masks corresponding to the number of passes, a mask pattern for two-pass printing and a mask pattern for eight-pass printing are stored in the mask pattern storage section 621 . In addition, the mask M and the mask N are stored in the overlapping area B mask pattern storage section 622 as in the case of the above-described embodiment. However, if Figure 15 As shown in , t...

no. 3 Embodiment

[0101] A third embodiment will now be described.

[0102] The first and second embodiments use a connection head including head chips (nozzle arrays) for two colors arranged side by side in one print head. However, the present embodiment uses a connection head including head chips (nozzle arrays) for 3 colors arranged side by side in 1 print head. In this embodiment, such a connector is used to print an image by two-pass printing.

[0103] Figure 16 The structure of the connector that can be used in this embodiment is shown. exist Figure 16 Among them, the connection head 33 includes two print heads 331 and 332 . The print head 331 includes: a head chip 331c having arranged therein a plurality of nozzles for ejecting cyan ink, a head chip 331M having arranged therein a plurality of nozzles for ejecting magenta ink, and a head chip 331c having arranged therein a plurality of nozzles for ejecting magenta ink. A head chip 331Y of a plurality of nozzles for ejecting yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com