Patents

Literature

57results about How to "Free play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

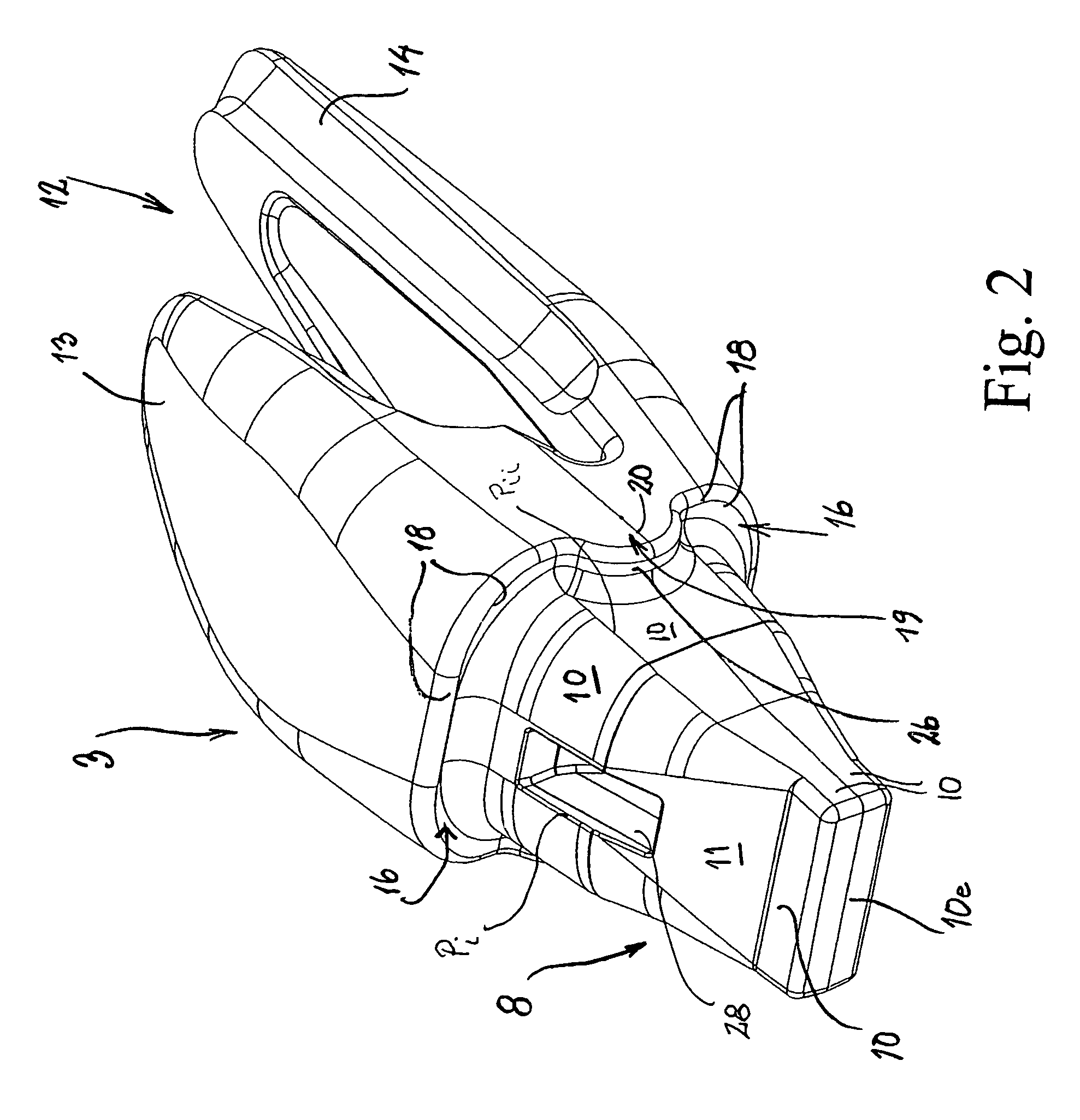

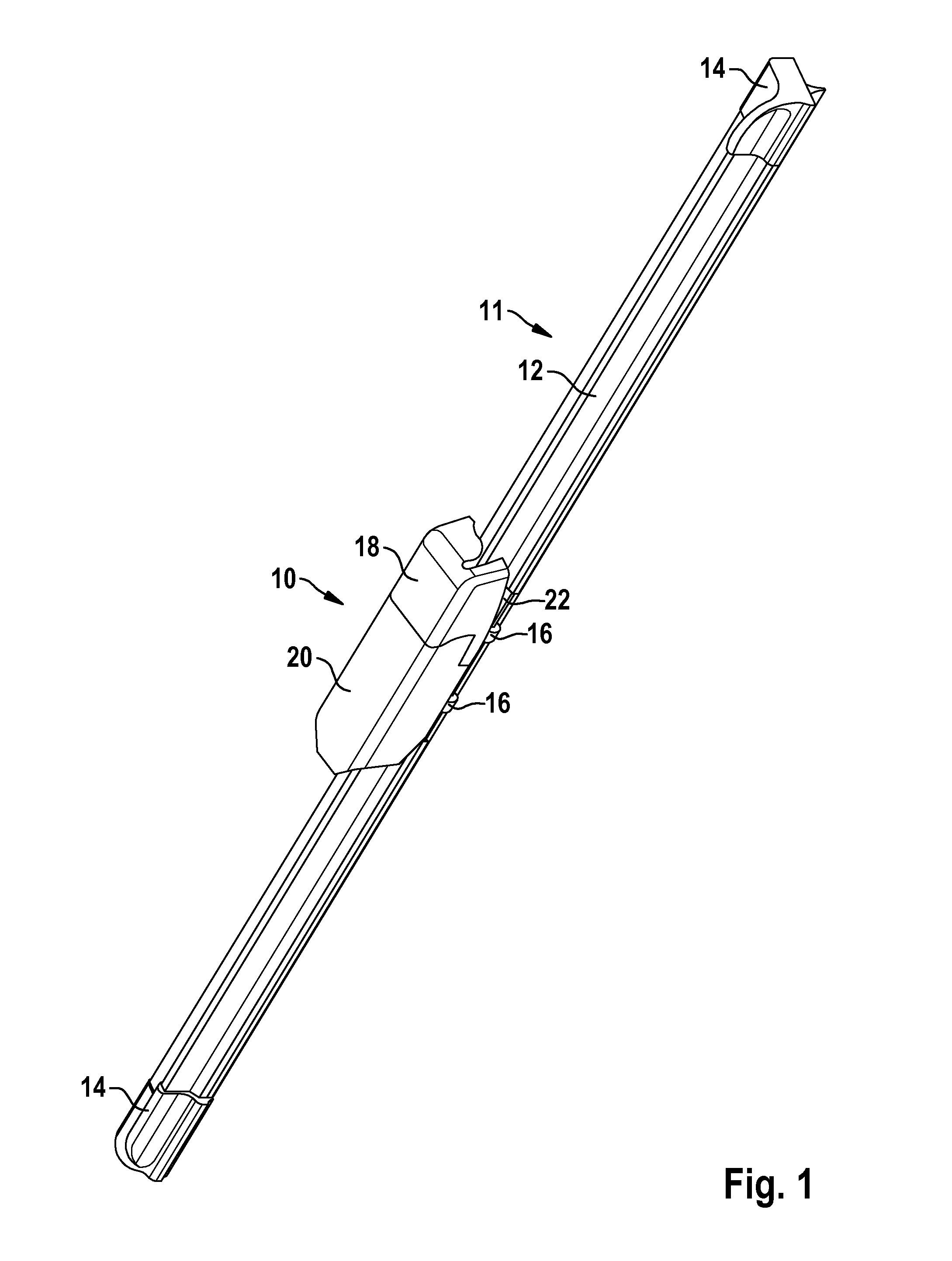

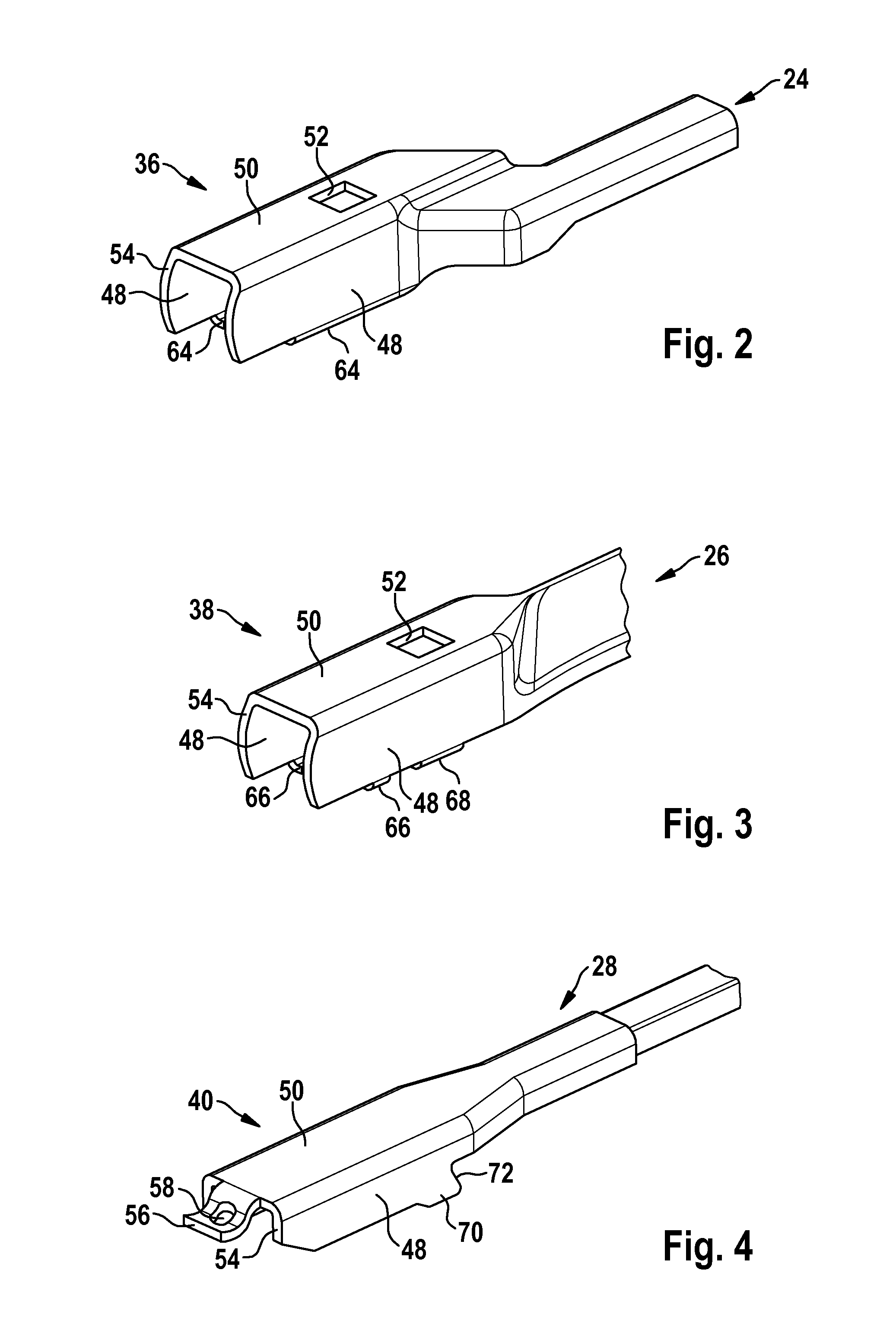

Device for detachably linking a wiper blade with a wiper arm

ActiveUS20040211021A1Accurate guidanceInhibition of activationWindow cleanersVehicle cleaningMechanical engineeringBand shape

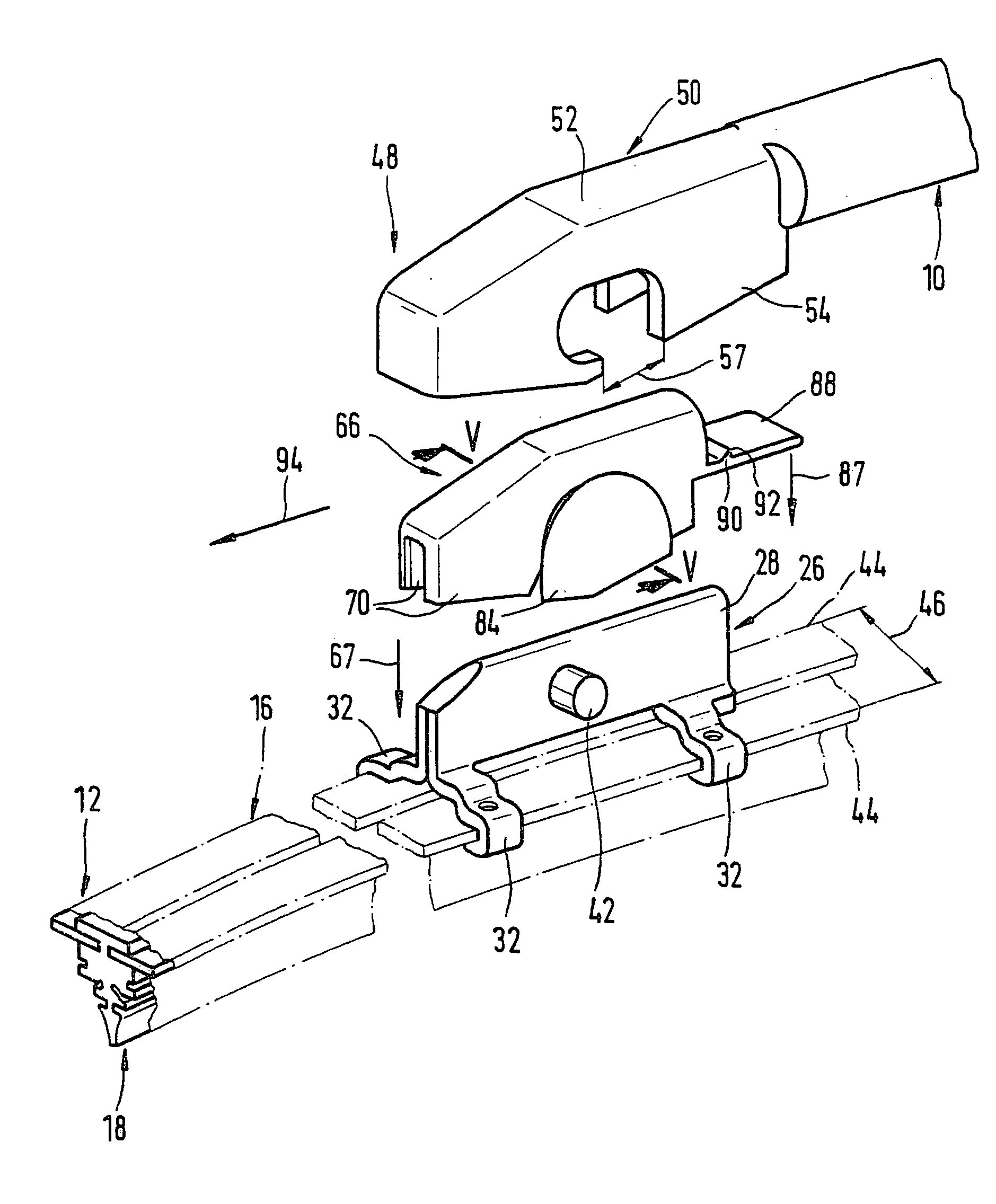

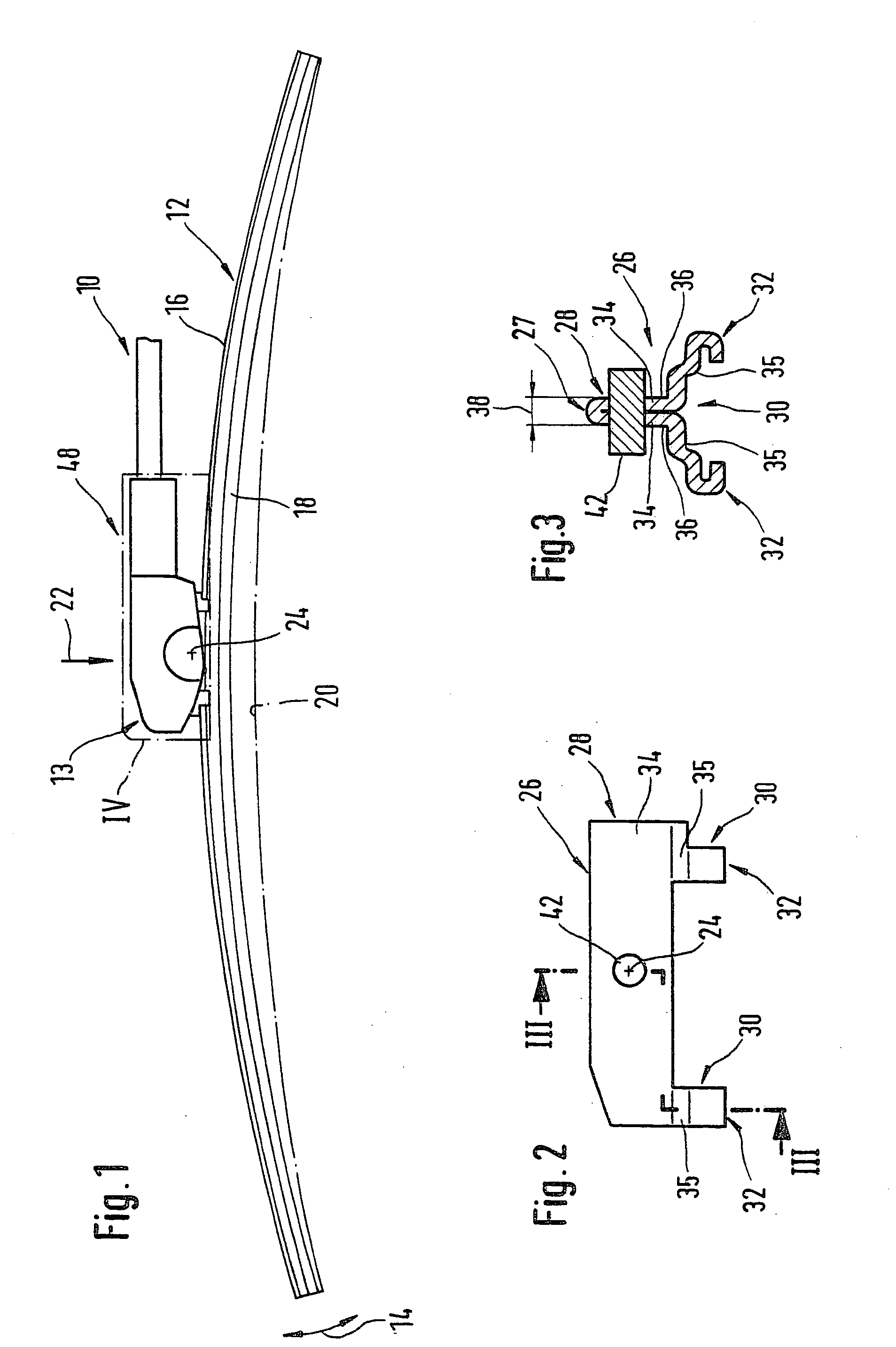

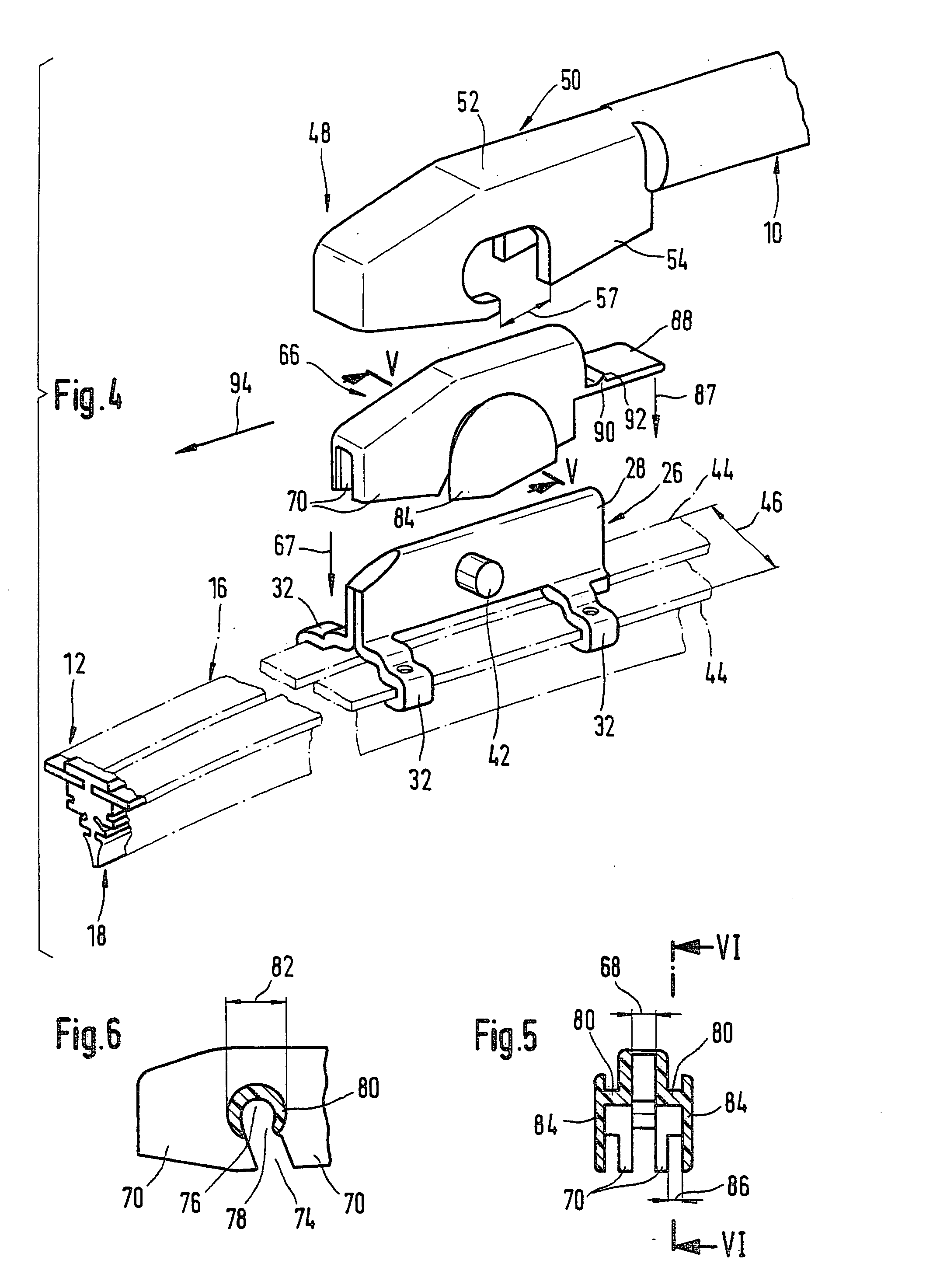

A device is proposed which is used to detachably connect a wiper blade (12) to clean windows, particularly of motor vehicles, to a driven wiper arm (10) featuring a wiper blade holder (50 or 150), whereby the wiper blade (12) that can be placed on the window (20) with a long-stretched-out, rubber elastic wiper strip (18) features a band-like, long-stretched-out elastic supporting element (16) that is curved in the longitudinal direction over its band surfaces (15, 17) on whose lower, concave band surface (17) the wiper strip (18) is arranged parallel to the longitudinal axis. On the outer convex band surface (15) of the supporting element (16) sits a connecting element (26), which features two parallel wall surfaces (36) that are aligned in a vertical plane on the band surface and extend in the longitudinal direction of the wiper blade and that a pivot pin (42) projects from each wall surface, whereby the longitudinal axes of the two pivot pins are aligned with one another. An especially simple embodiment of the articulated connection with an integrated connecting device is achieved if an adapter (66 or 166) that can move in a pendulum fashion is positioned on the two pivot pins of the connecting element (26), and said adapter features means to connect to the wiper blade holder (50 or 150) of the wiper arm (10).

Owner:ROBERT BOSCH GMBH

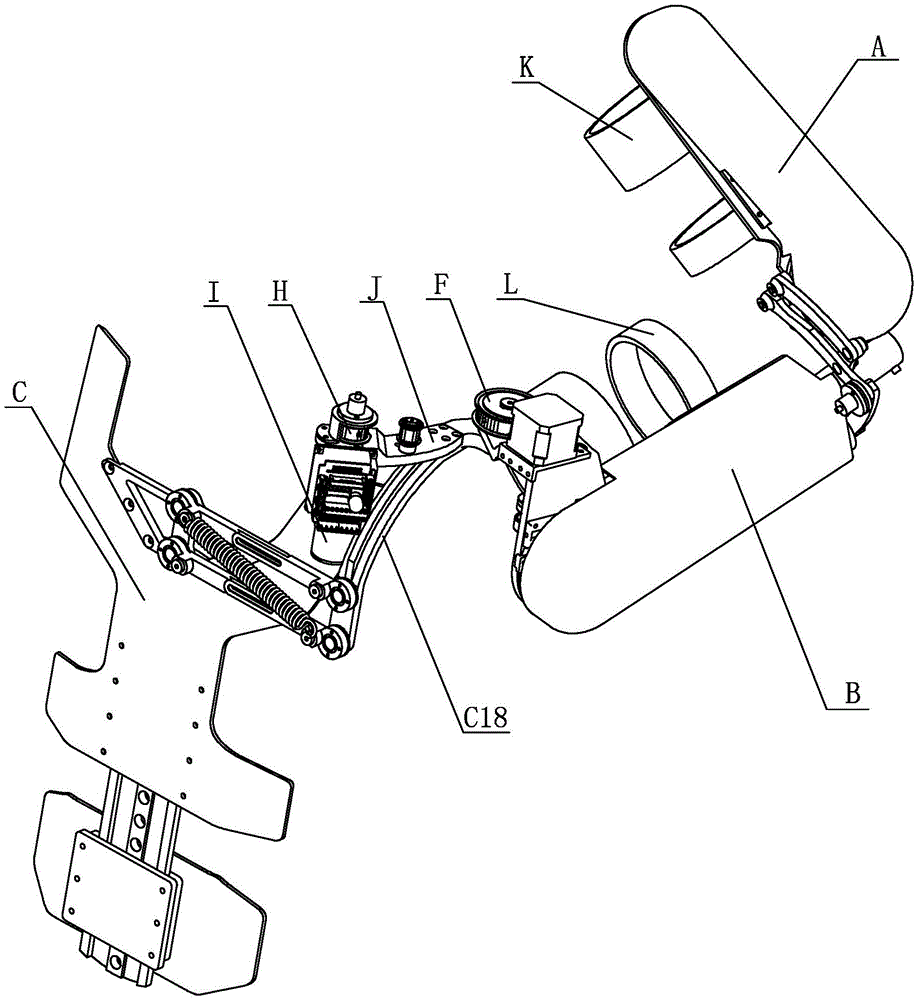

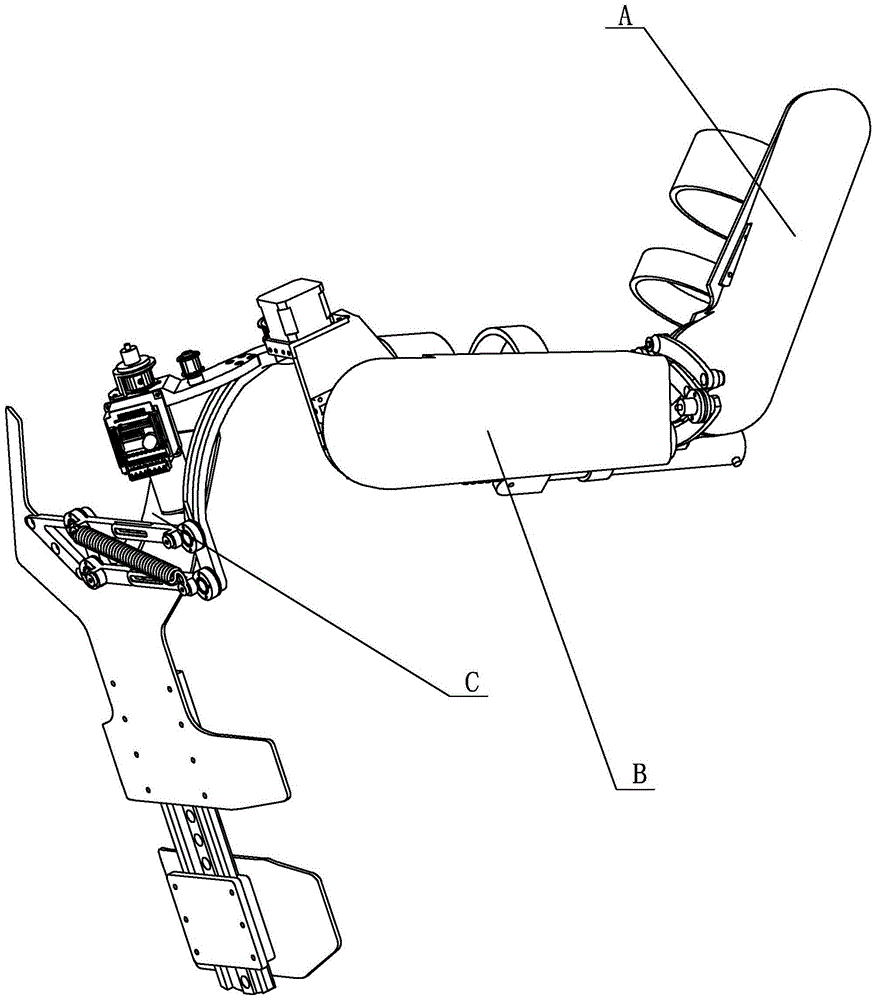

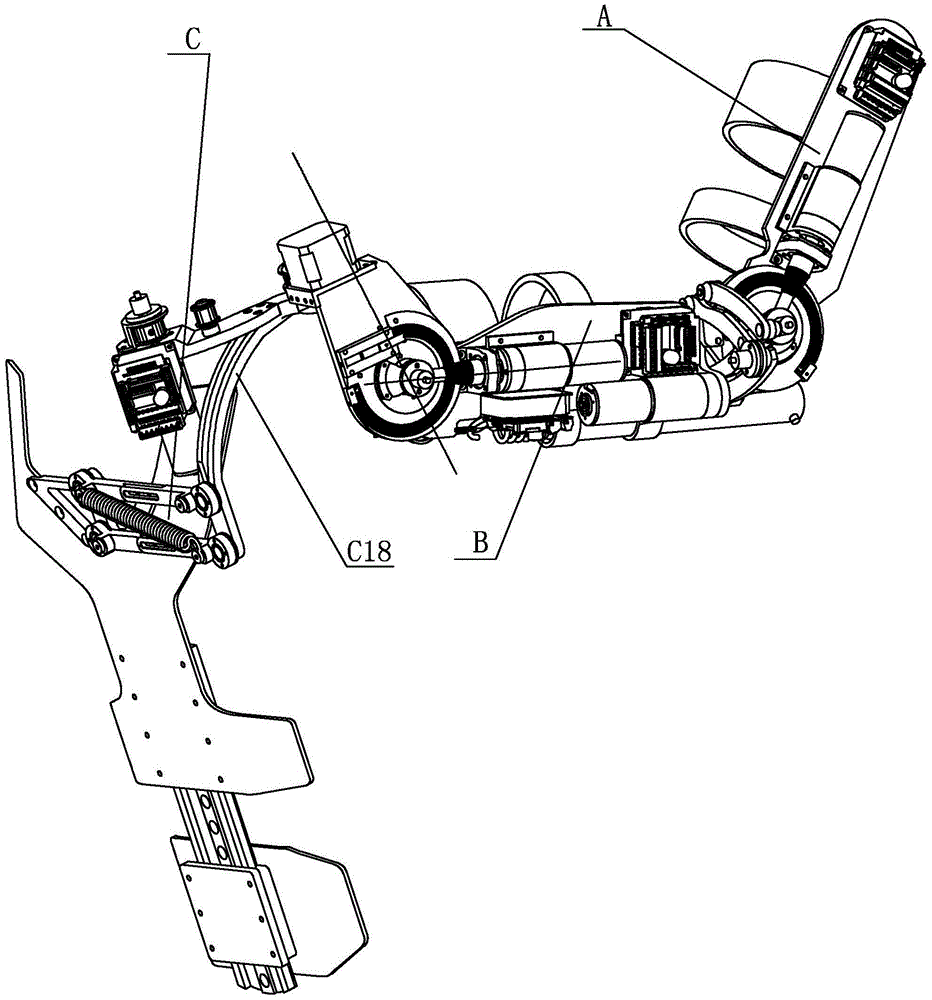

Active-passive upper limb rehabilitation training exoskeleton

ActiveCN105597280AFree playSatisfy freedom of movementProgramme-controlled manipulatorResilient force resistorsDrive motorSacroiliac joint

The invention discloses an active-passive upper limb rehabilitation training exoskeleton. An elbow joint connecting base on a big arm is fixedly connected with an elbow joint output wheel on a forearm, one end of an outward turning shaft is hinged to a crossarm of a shoulder joint skeleton, and the other end of the outward turning shaft is connected with a bearing inner race; a driving belt wheel is fixedly installed on the outward turning shaft and sleeved with one end of a synchronous belt, a driven belt wheel is sleeved with the other end of the synchronous belt and fixedly installed on an output shaft of a back driving motor, the back driving motor is fixedly connected with a back driving motor base, the back driving motor base is fixedly connected with an arched connecting rod on the back, a back driving motor driver is fixedly connected with the back driving motor base through a back driving motor driver bracket, the back driving motor driver is electrically connected with the back driving motor, a forearm binding mechanism is hinged to an exoskeleton substrate on the forearm, and a big arm binding mechanism is hinged to an exoskeleton upper arm on the big arm. The active-passive upper limb rehabilitation training exoskeleton is applied to rehabilitation medicine, large-scale engineering construction and material handling.

Owner:HARBIN INST OF TECH

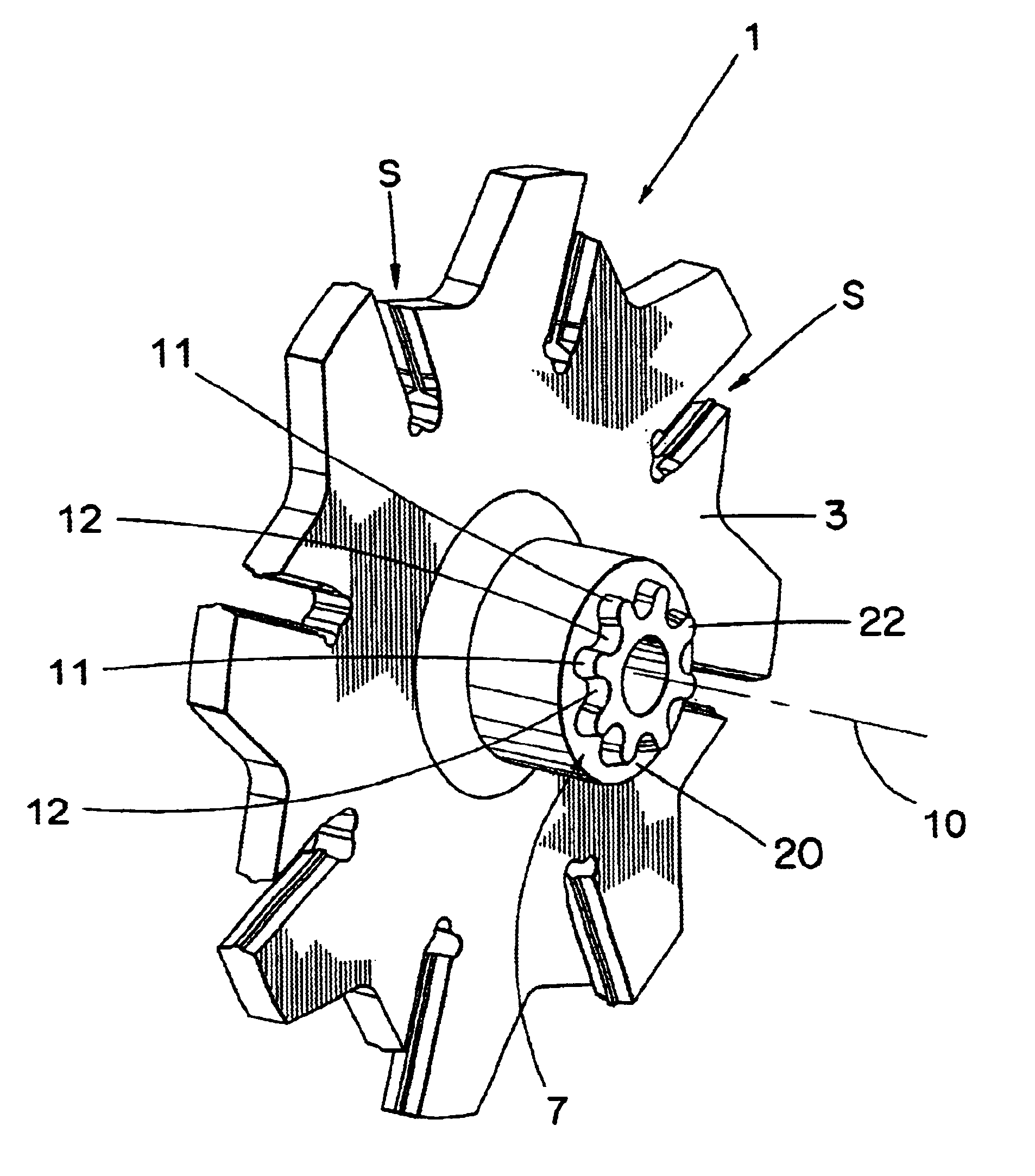

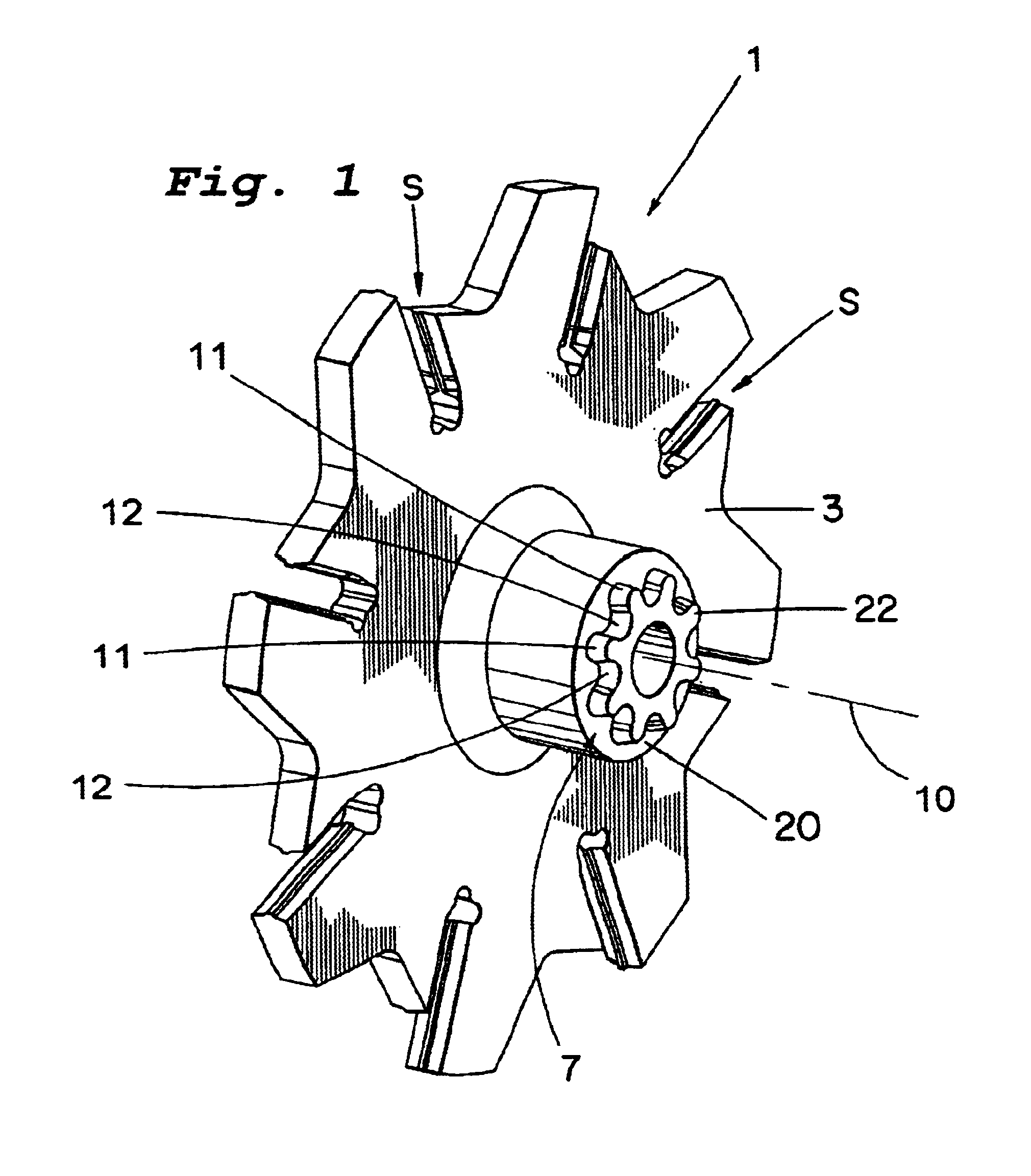

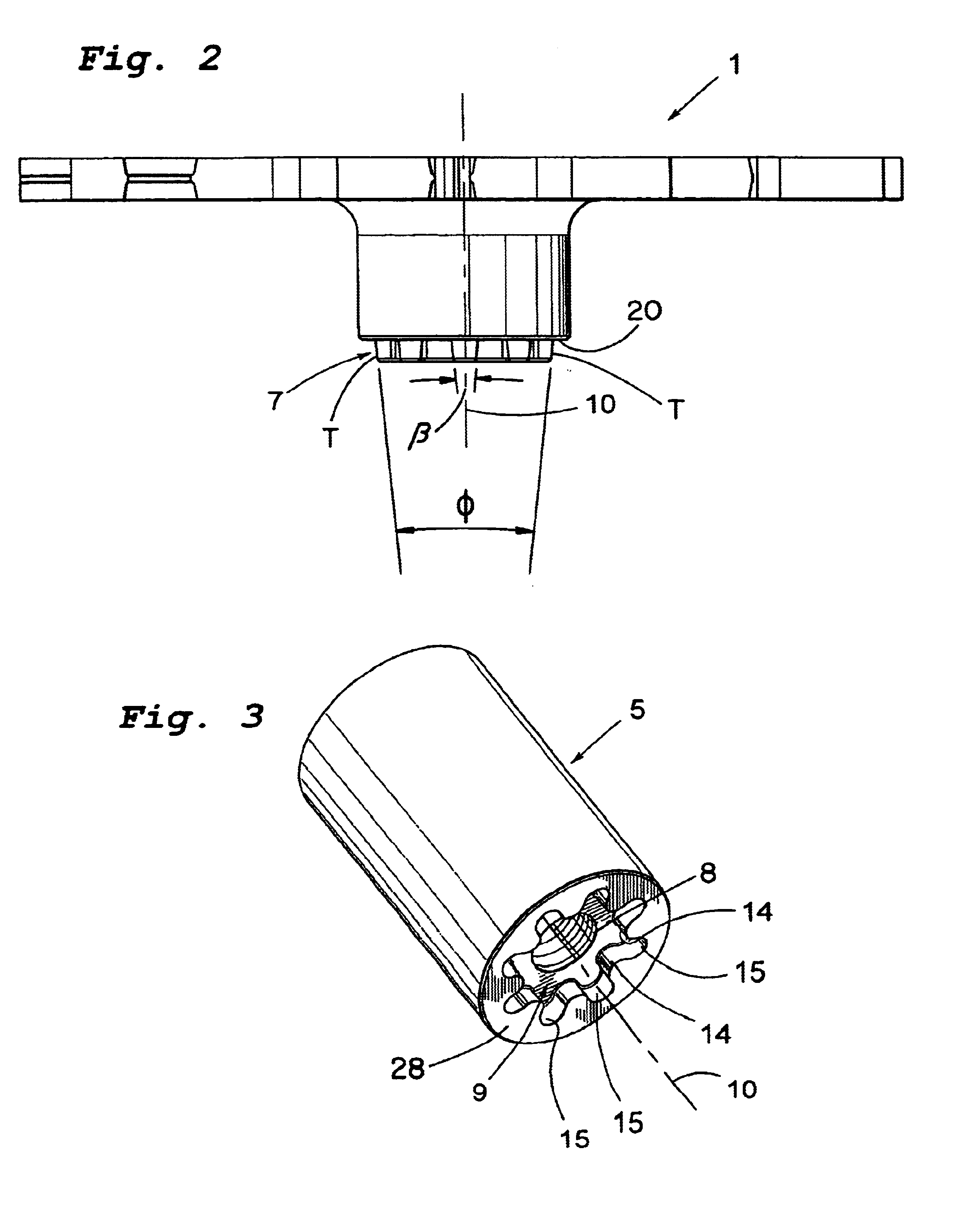

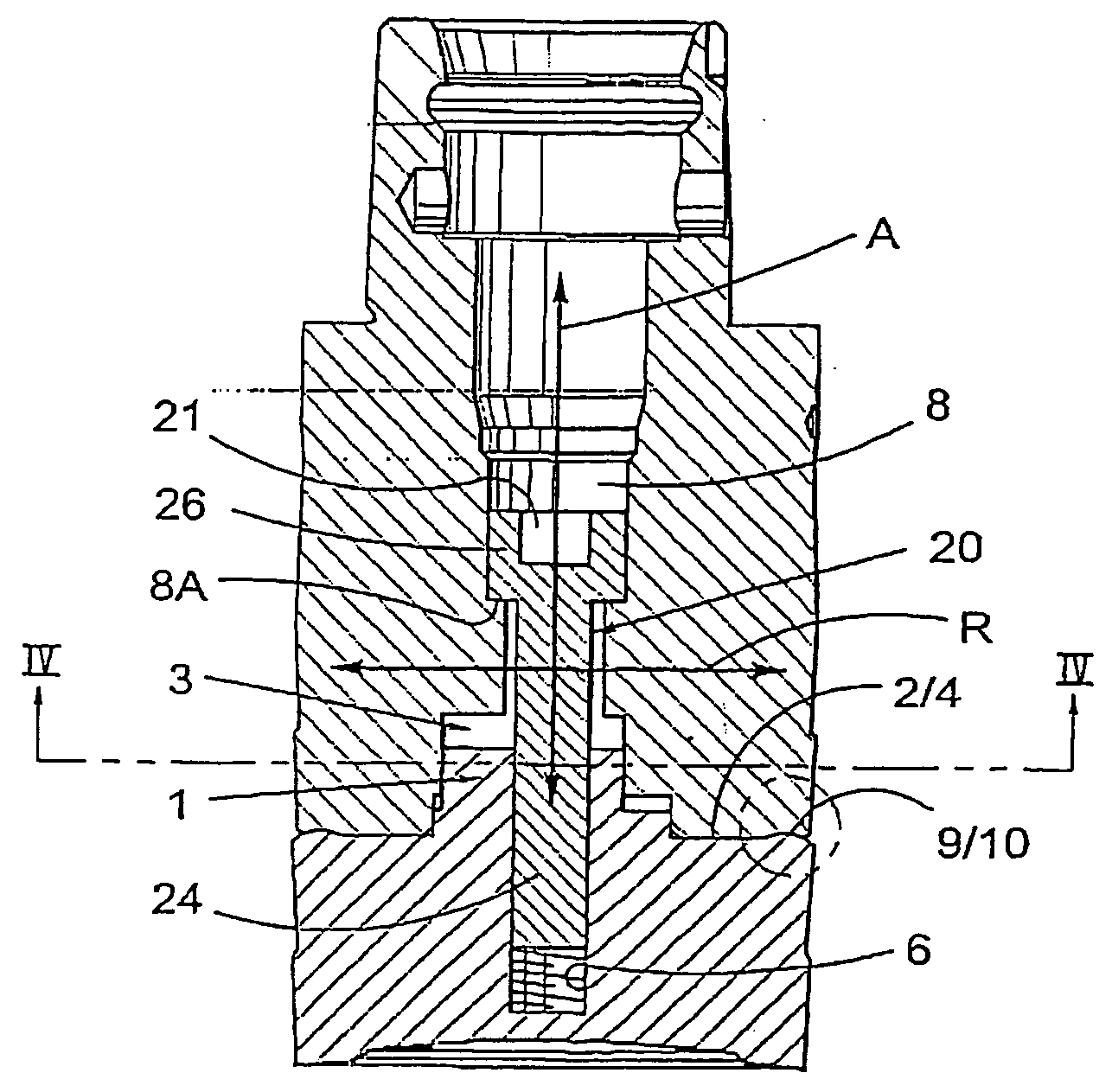

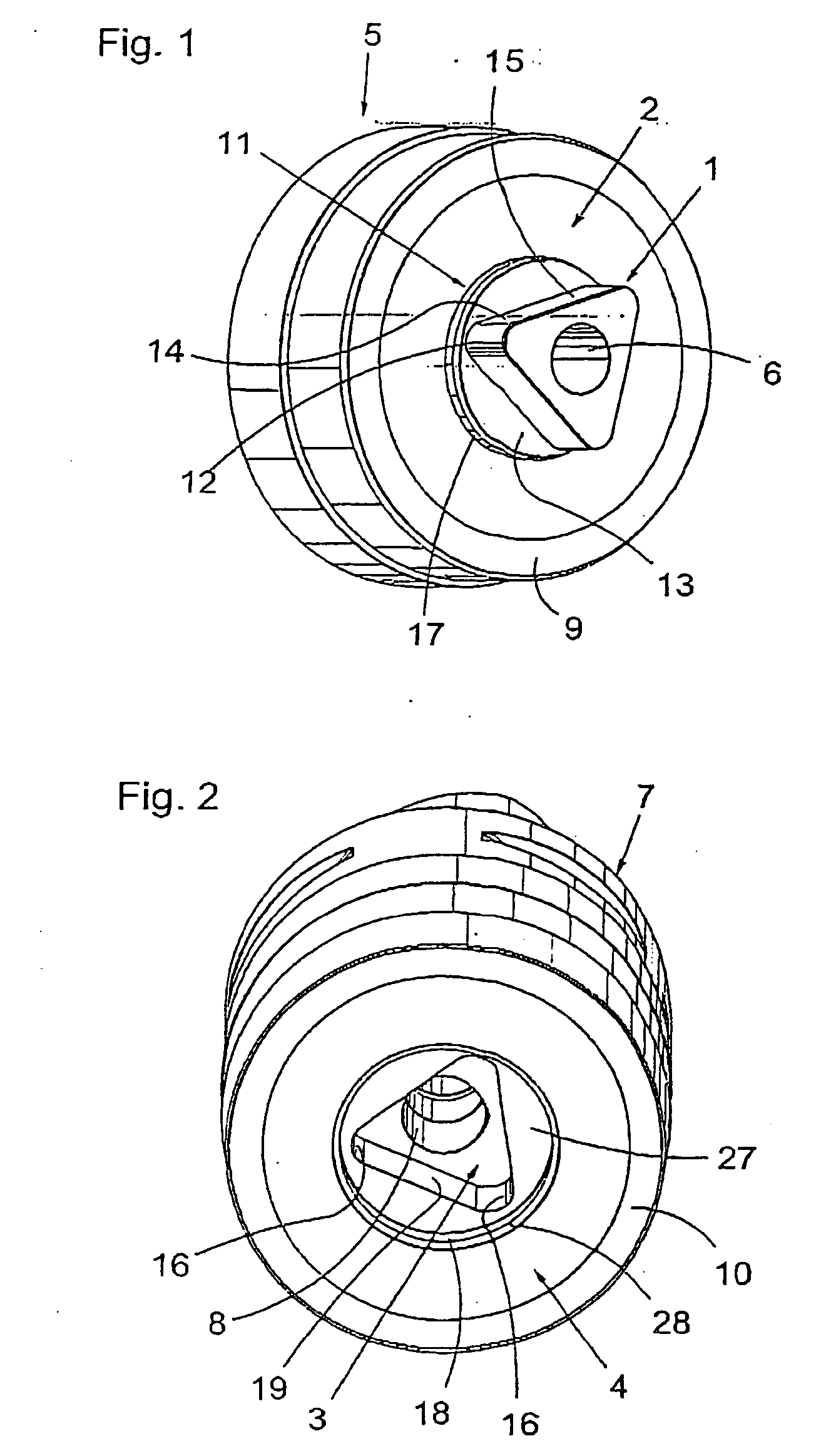

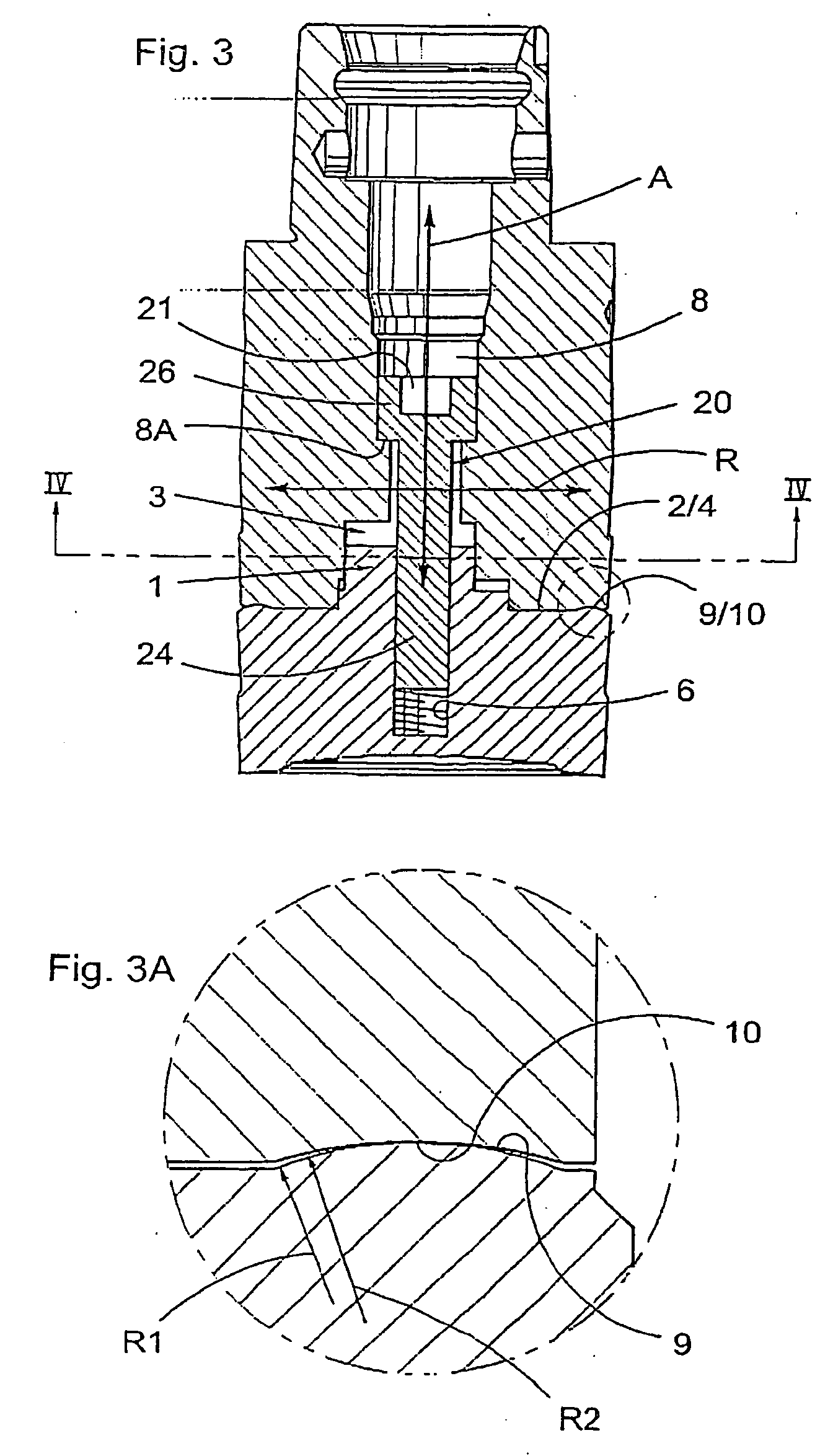

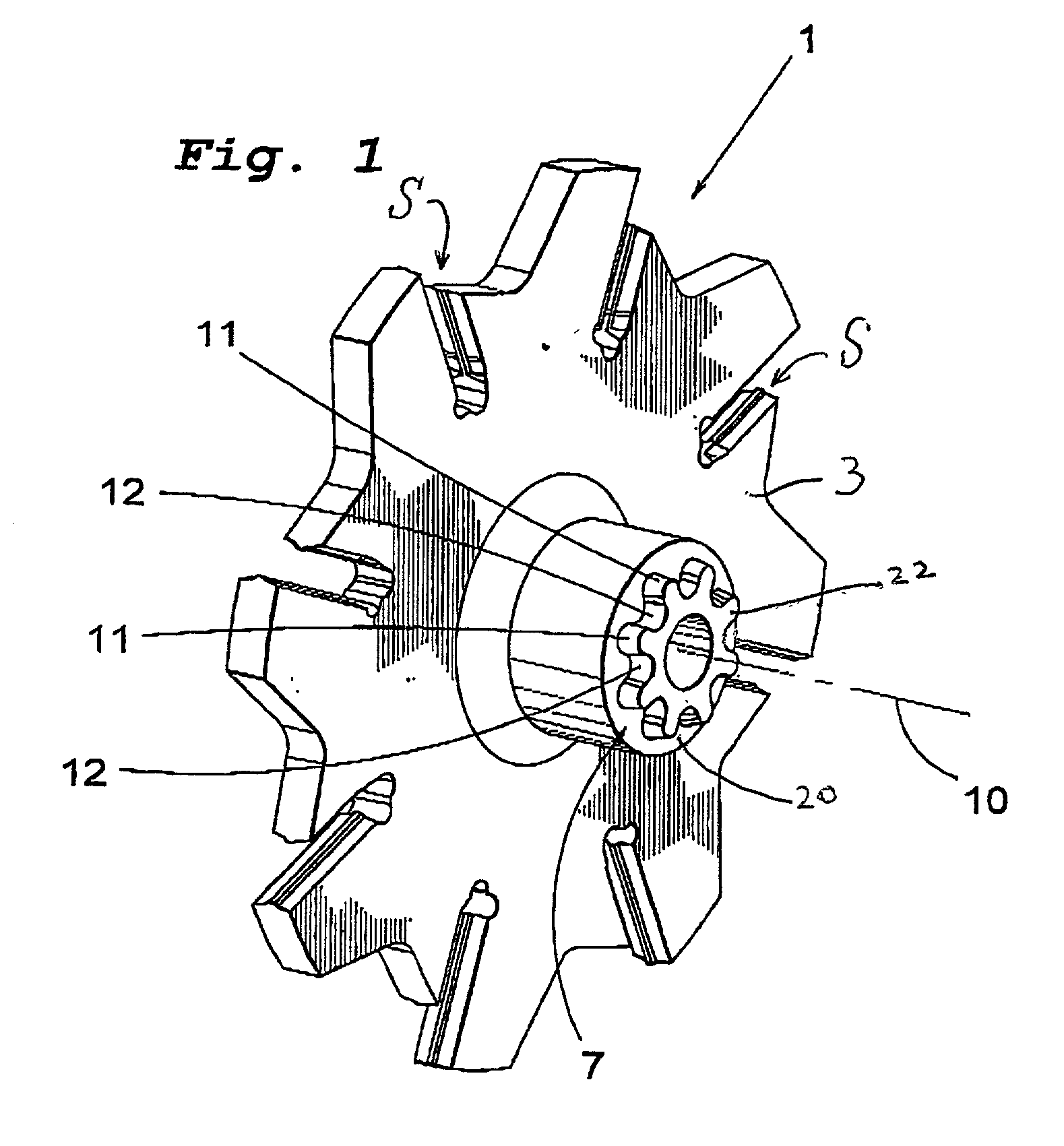

Toothed tool coupling for rotating a rotary tool

A driven tool includes a driven part which is rotatably driven by a drive part. The driven part and the drive part are coaxially arranged one inside of the other. The drive part and the driven part are conical as viewed in a longitudinal section plane containing the axis. The driven part includes driven teeth projecting generally radially with respect to the axis and received in respective radially-open recesses formed in the drive part. Each of the driven teeth makes contact with a wall of the respective recess at first and second contact places which are respectively situated on opposite sides of a generally radial line of symmetry of the driven tooth. The contact places are operable to transmit a drive force from the drive part to the driven part in respective directions of rotation. A driving angle in the range of -5° to +45° is formed at each contact place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

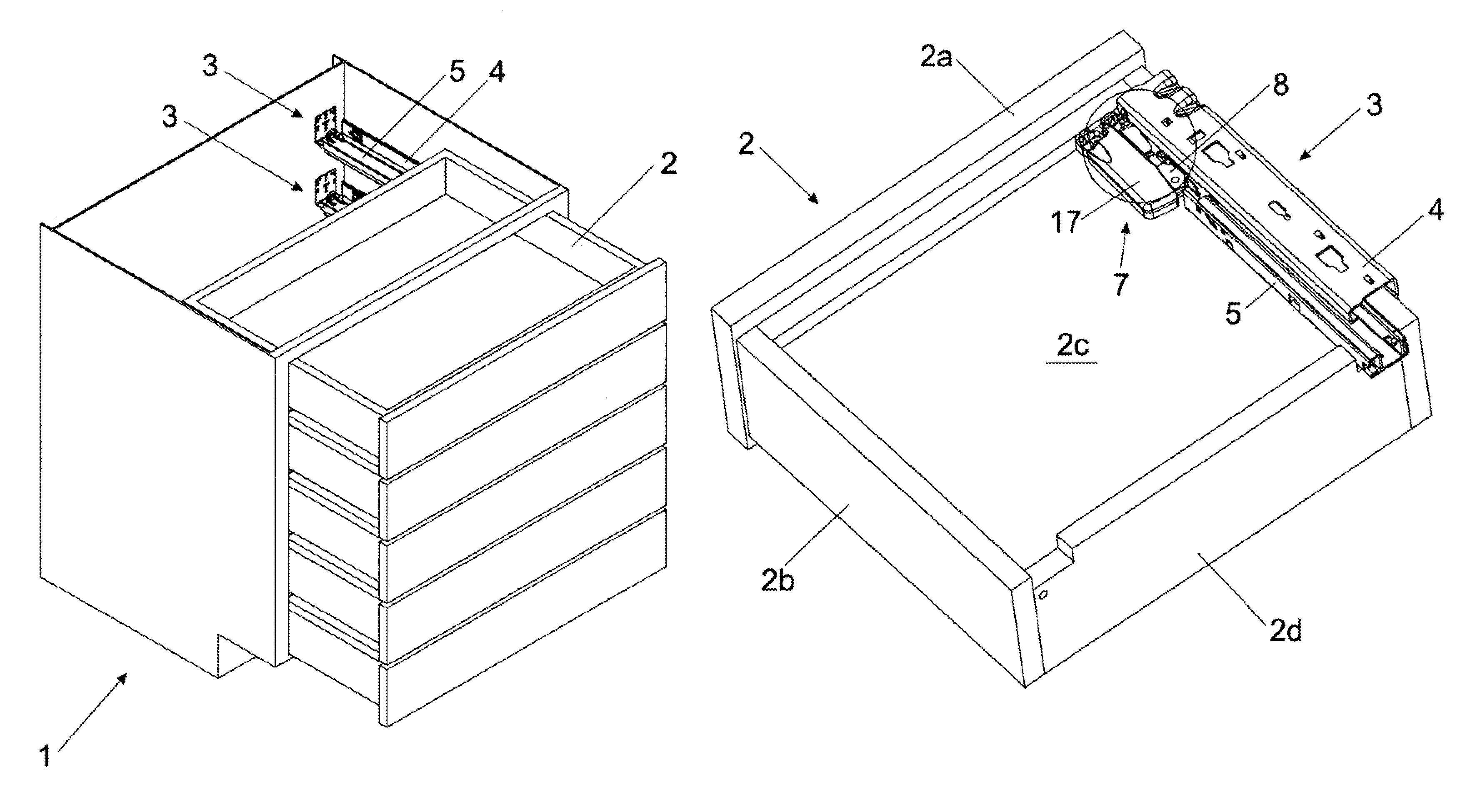

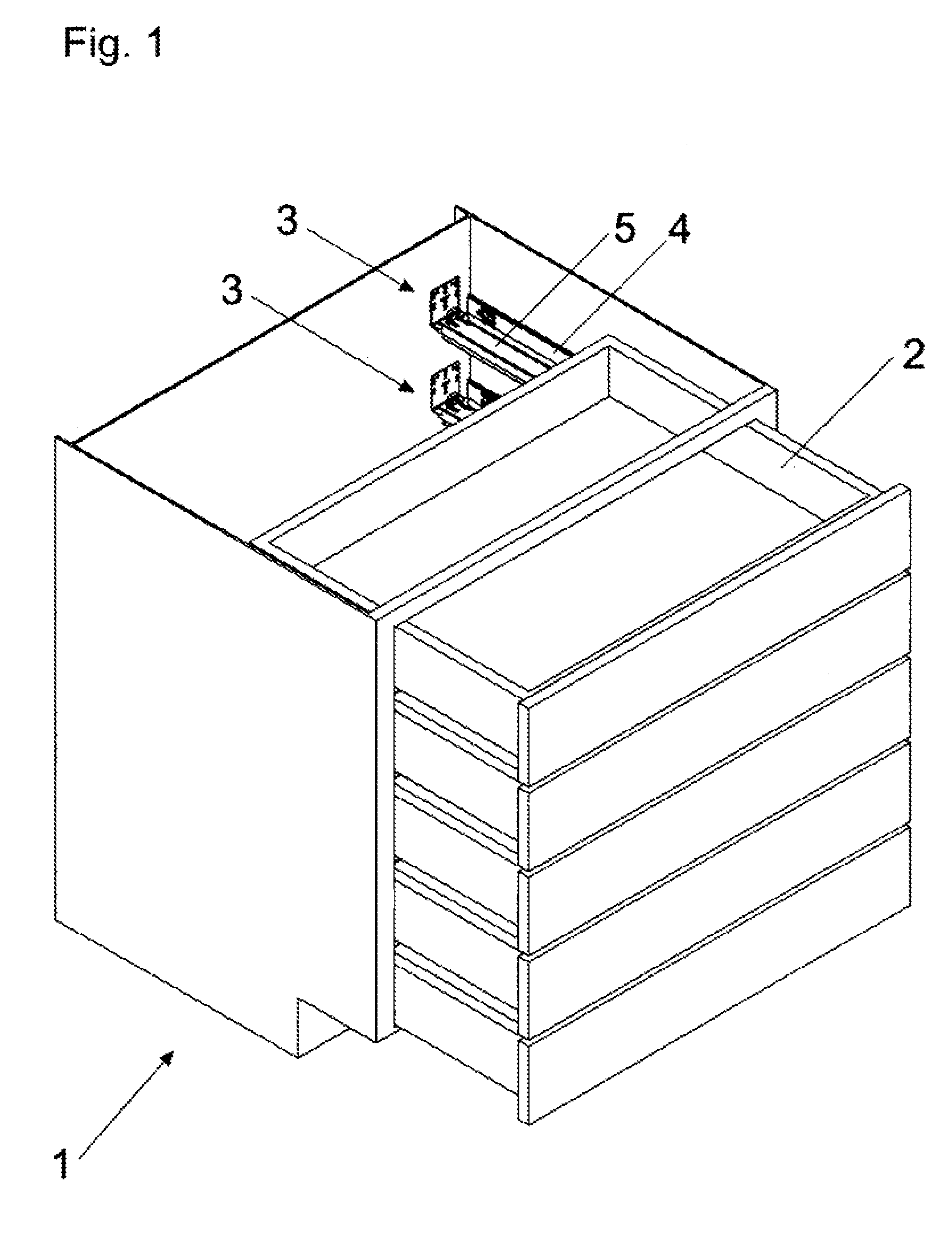

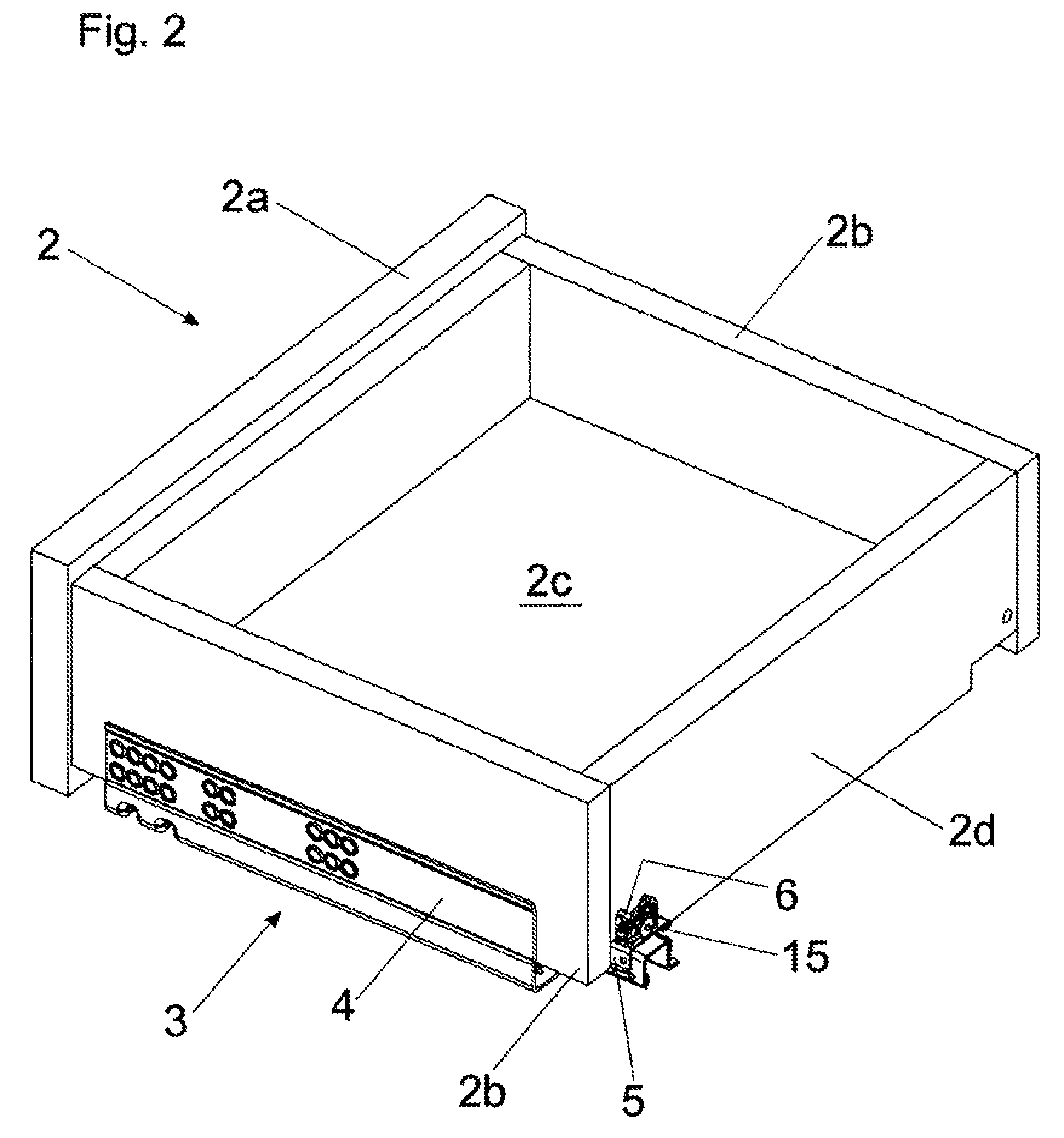

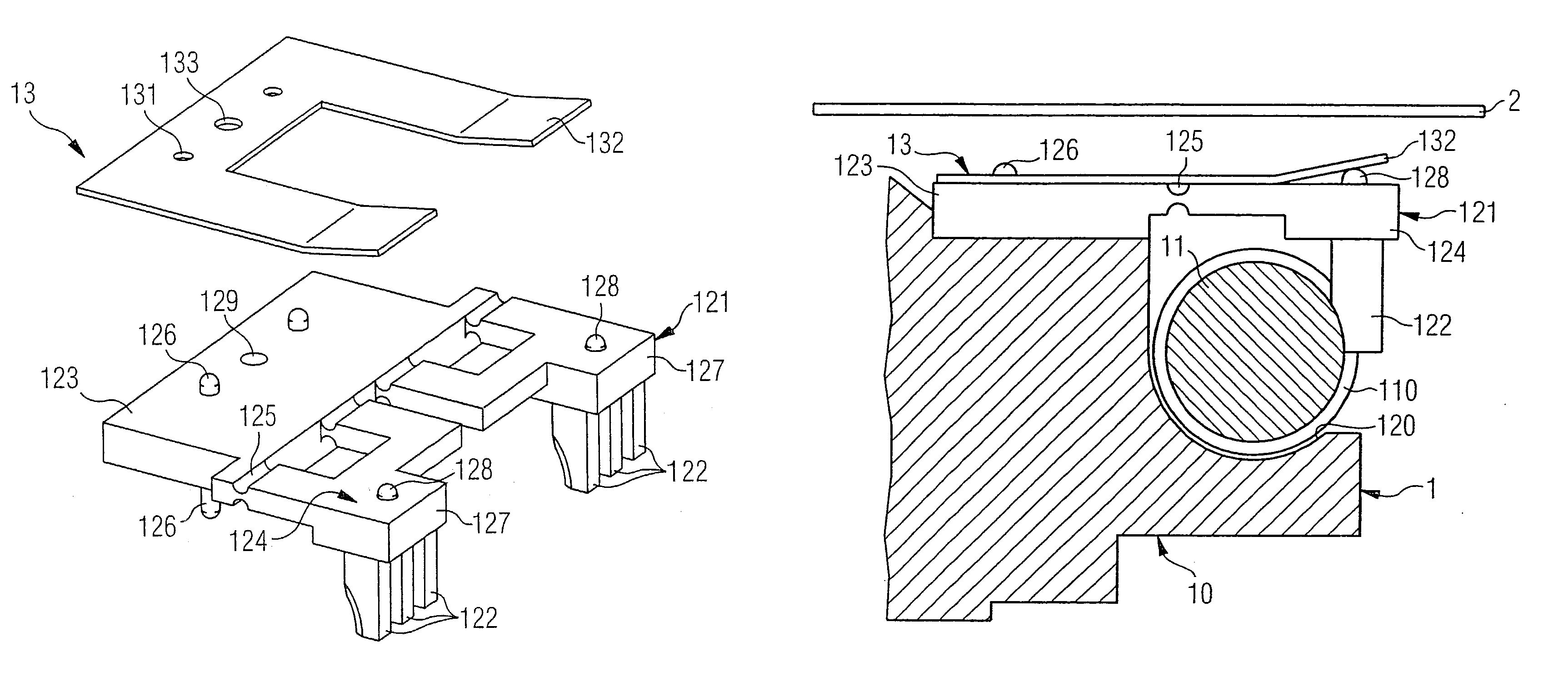

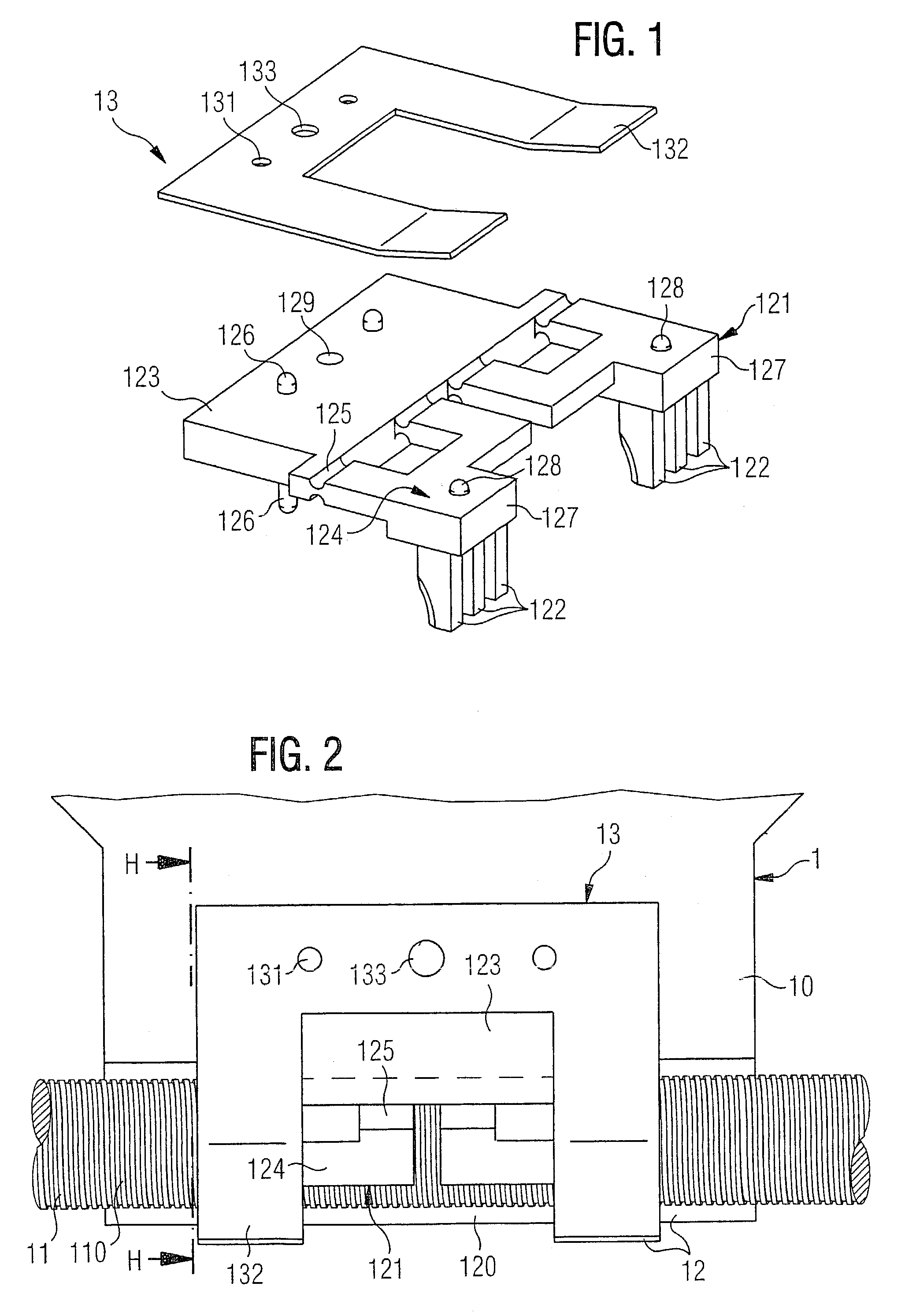

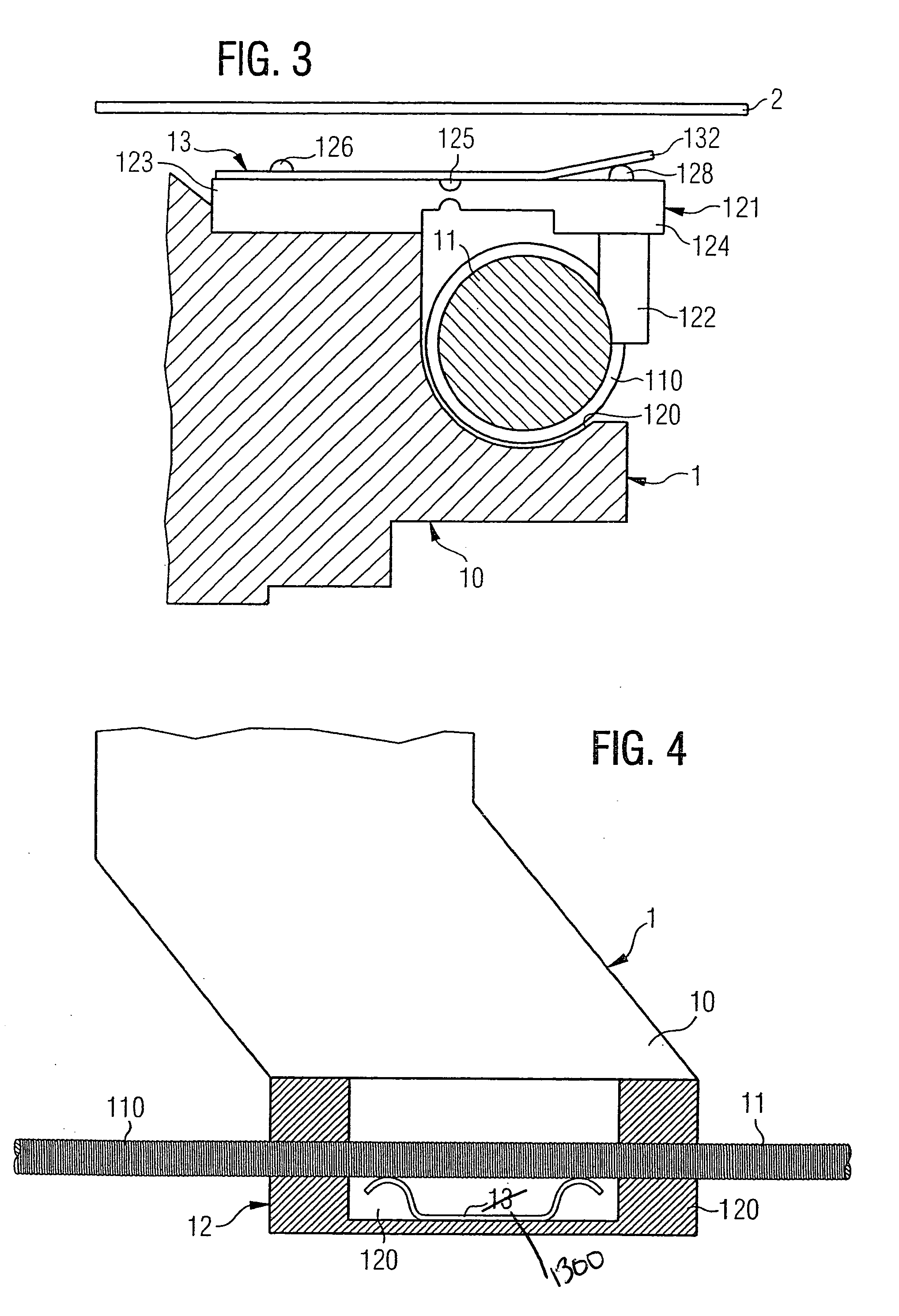

Apparatus for releasably coupling a drawer to a drawer pull-out guide

An apparatus is provided for releasably coupling a drawer to a rail, which can be pulled out in a longitudinal direction, of a drawer pull-out guide. The apparatus has a holding part which interacts with a mating holding part in the coupled state in order to establish the releasable connection. At least that region of the holding part which comes into contact with the mating holding part is made flexible, preferably by attaching a flexible piece of material, so that any longitudinal play of the drawer which may occur in relation to the rail can be compensated.

Owner:JULIUS BLUM GMBH

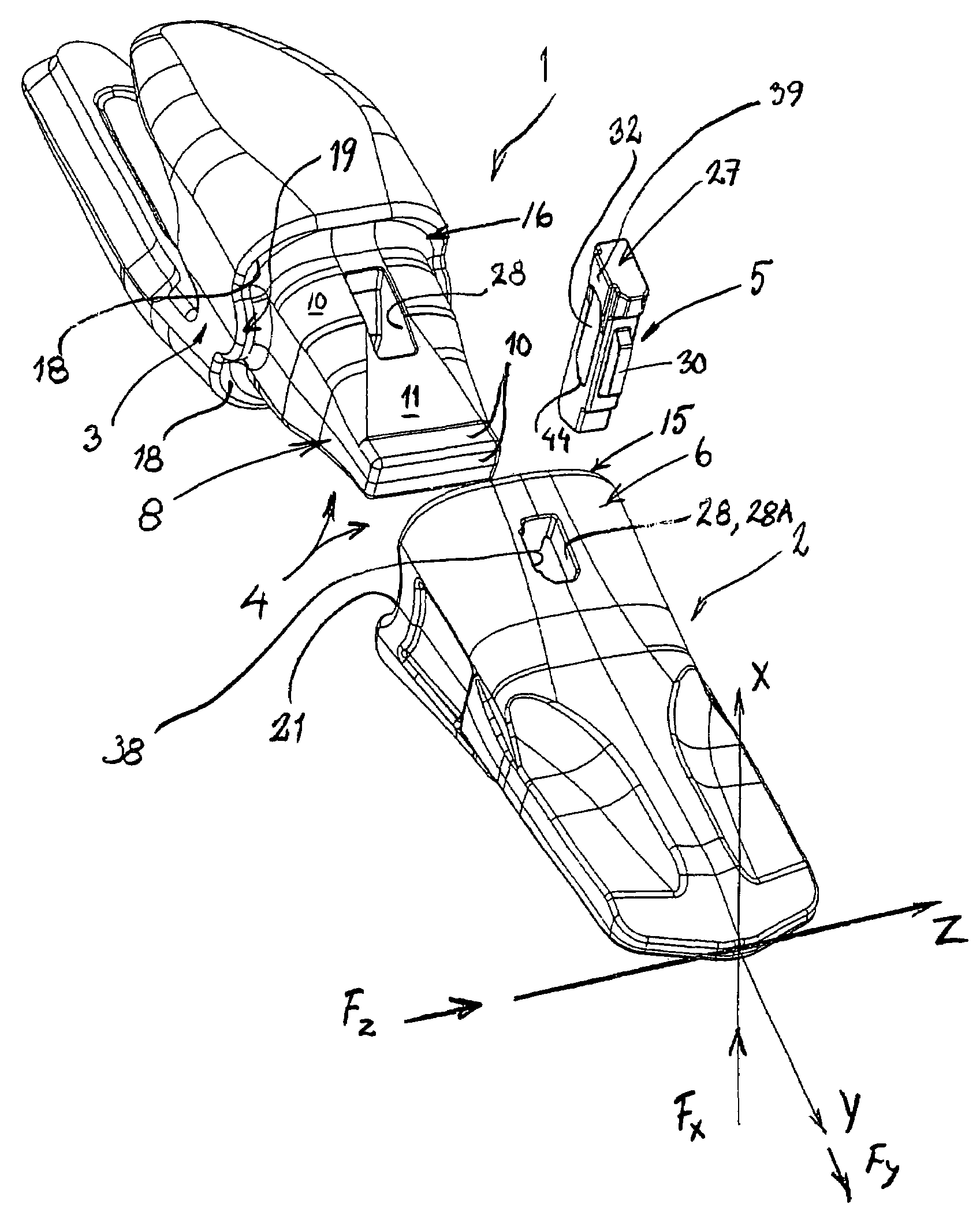

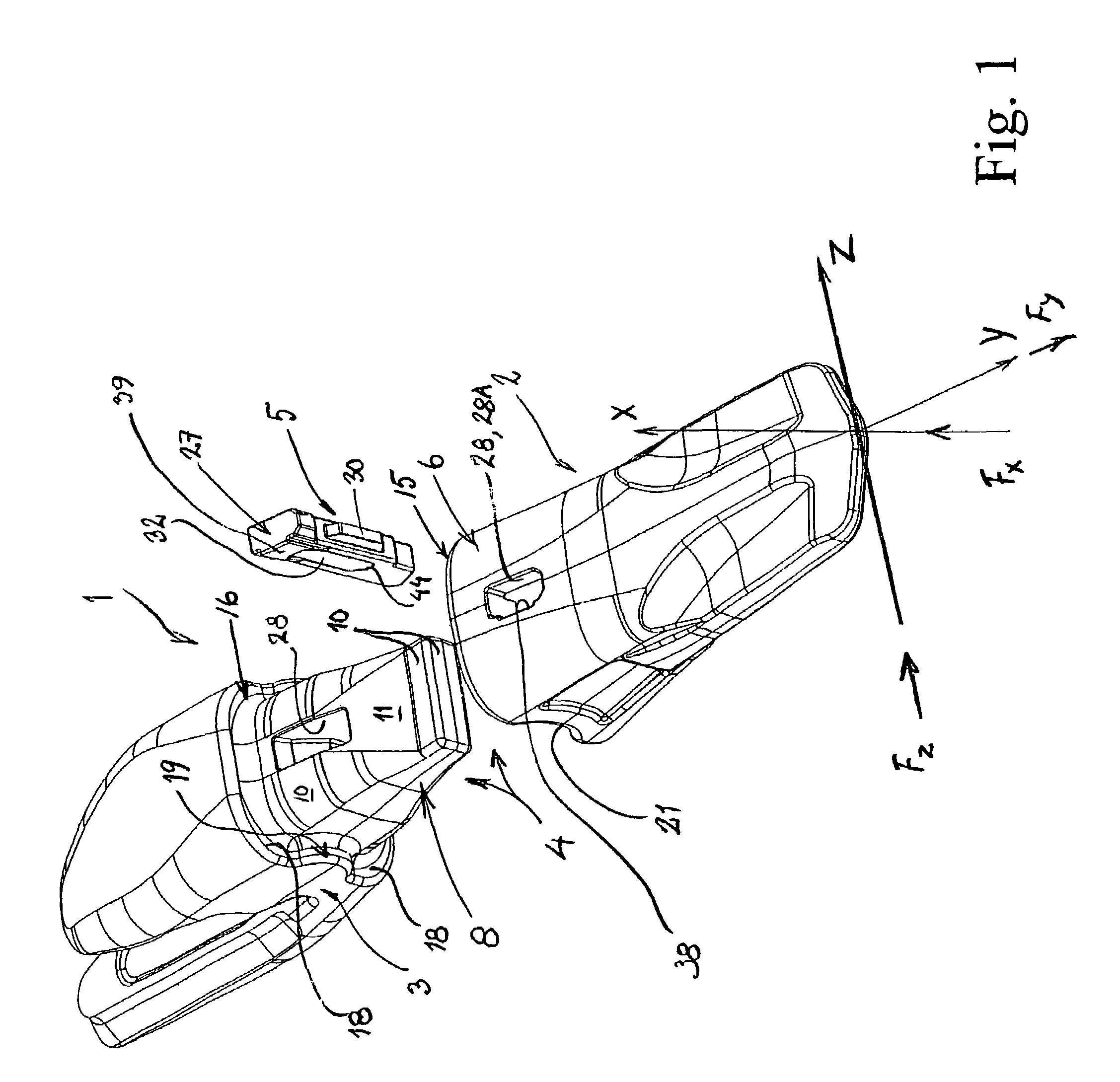

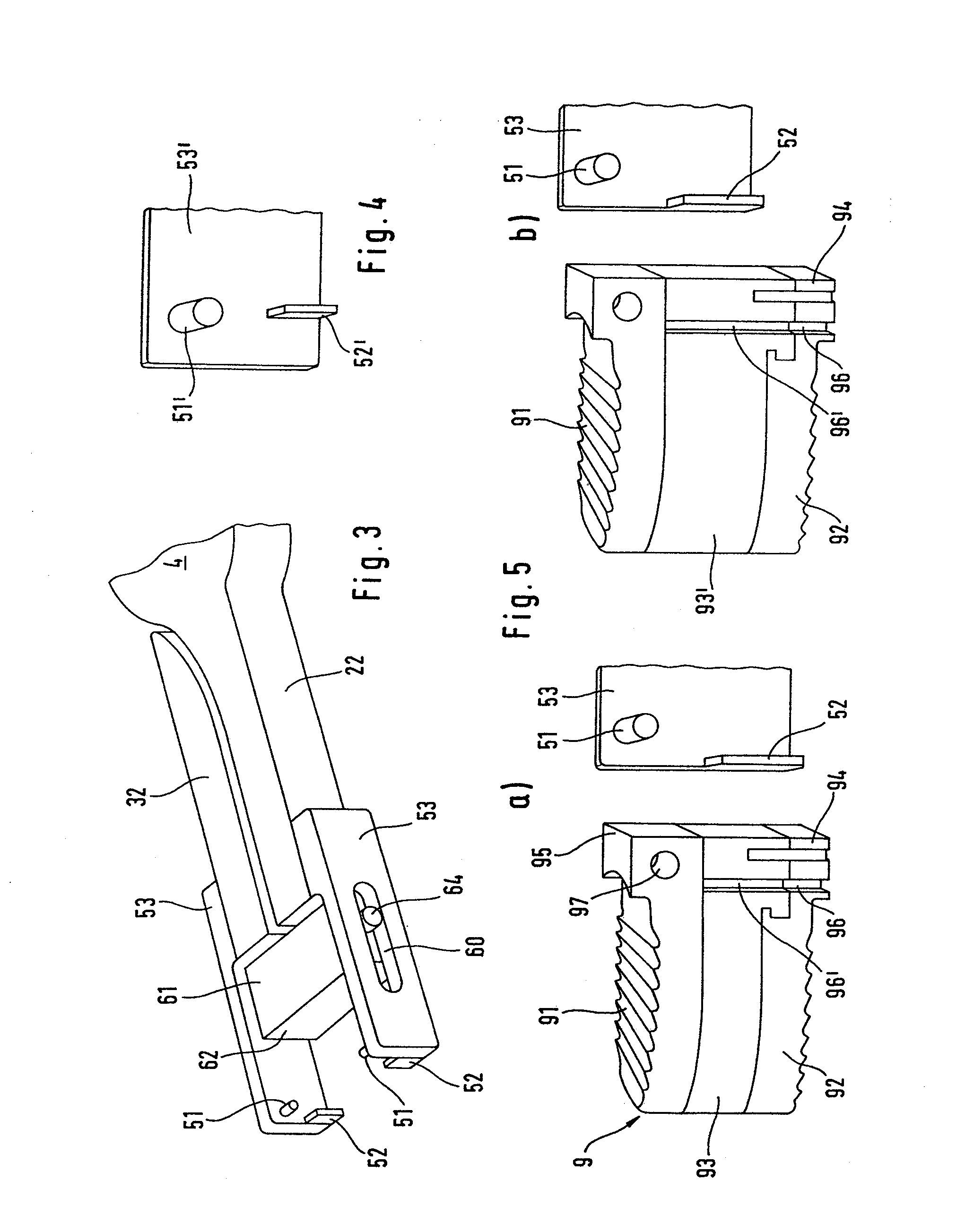

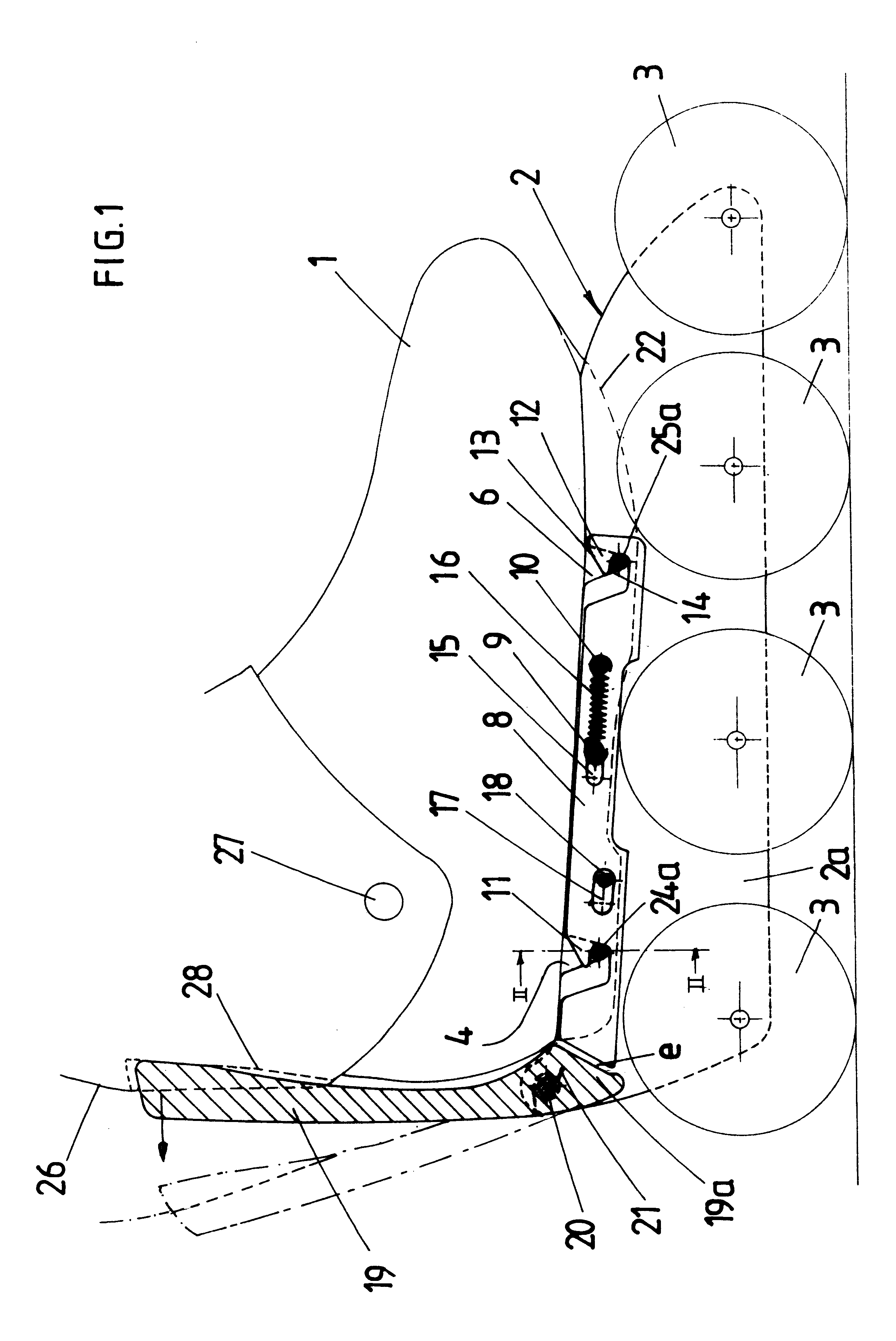

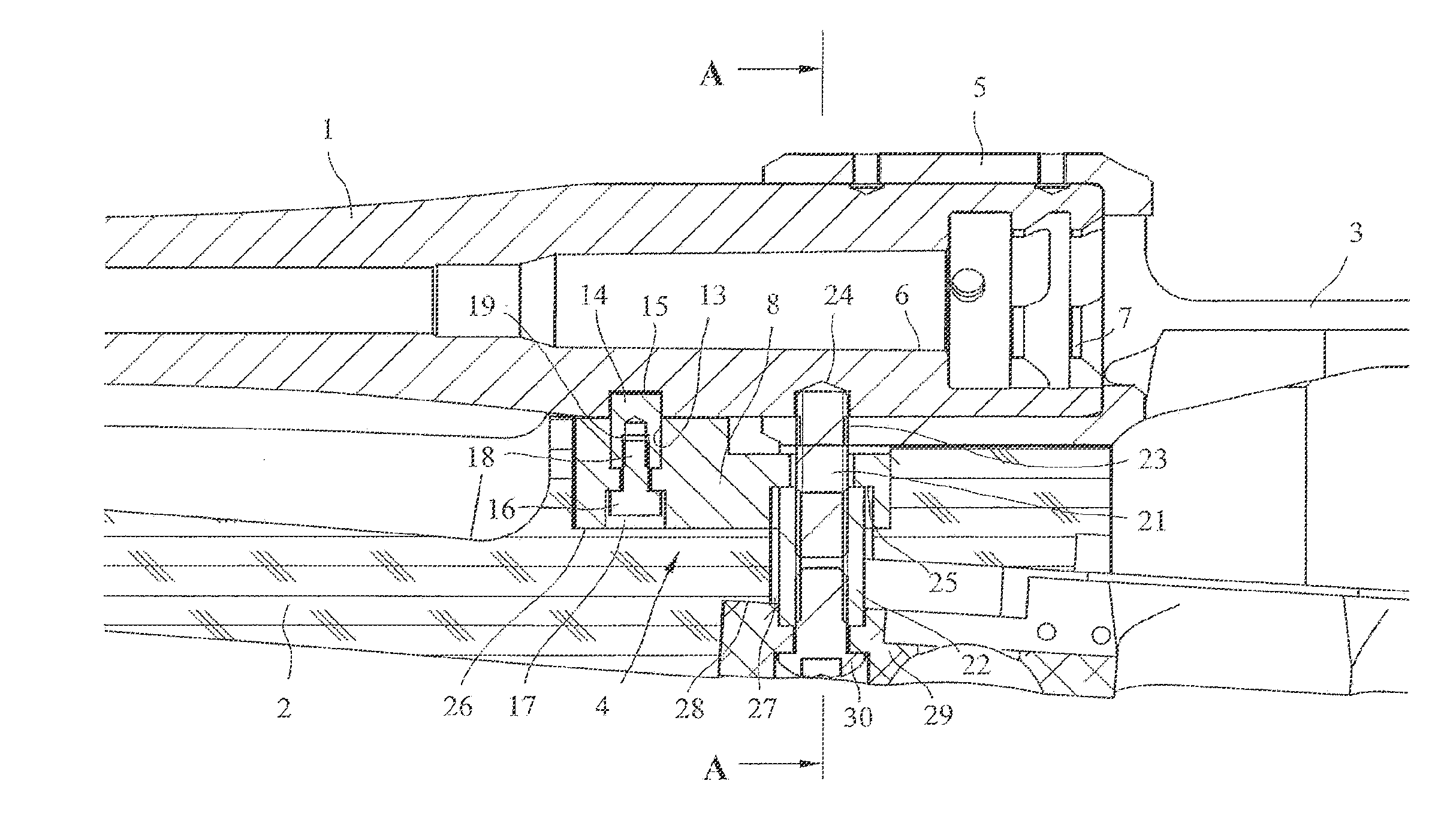

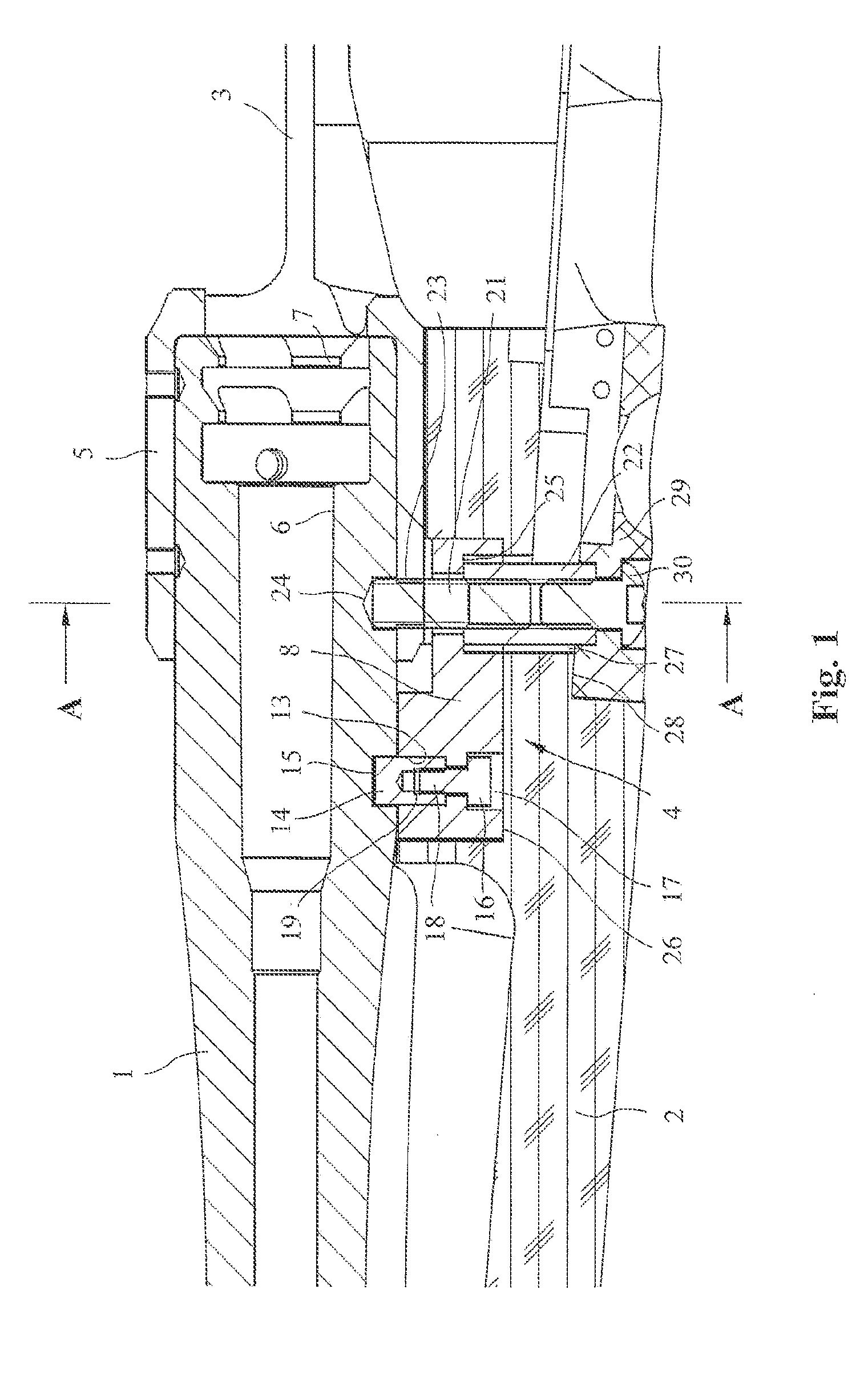

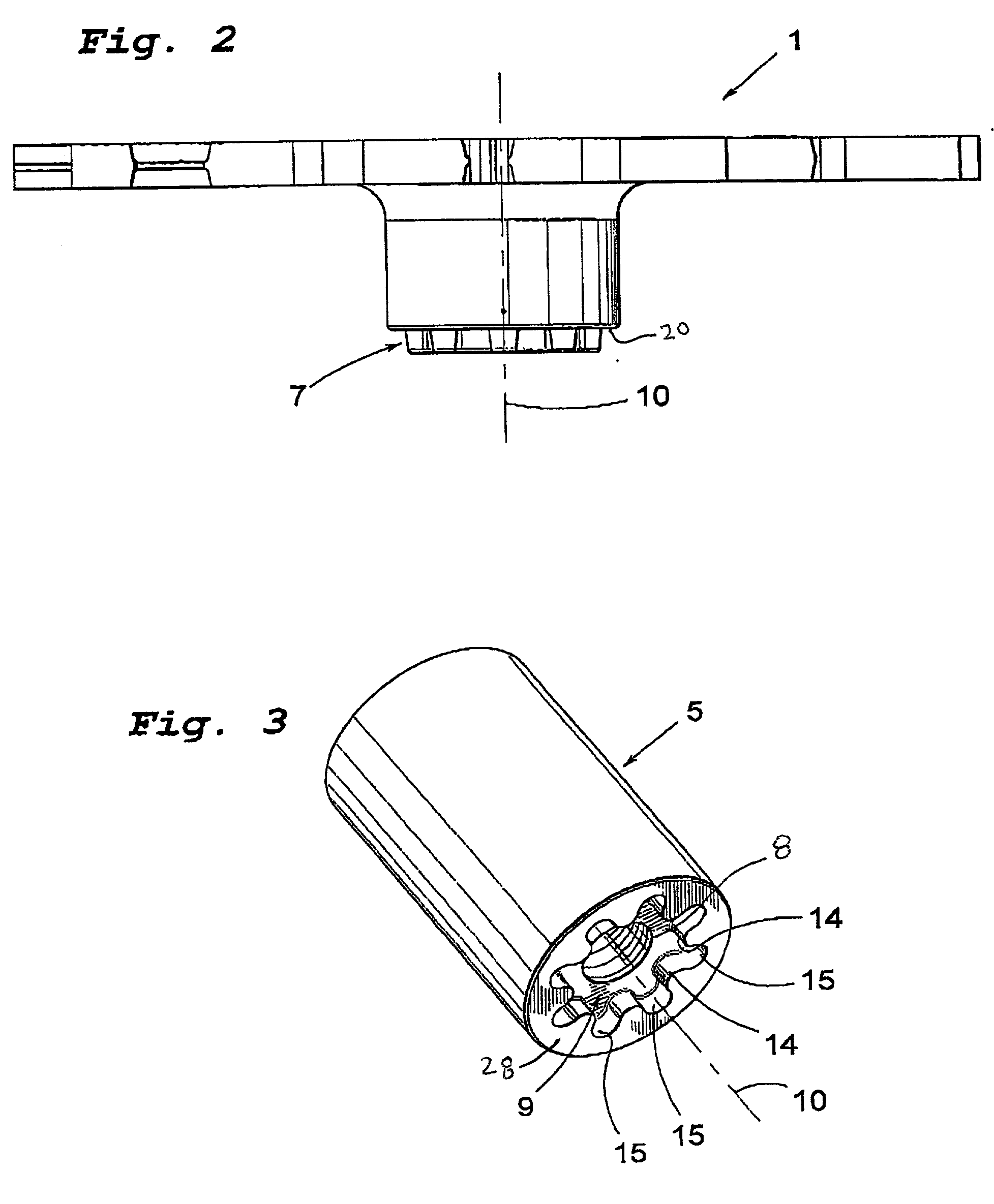

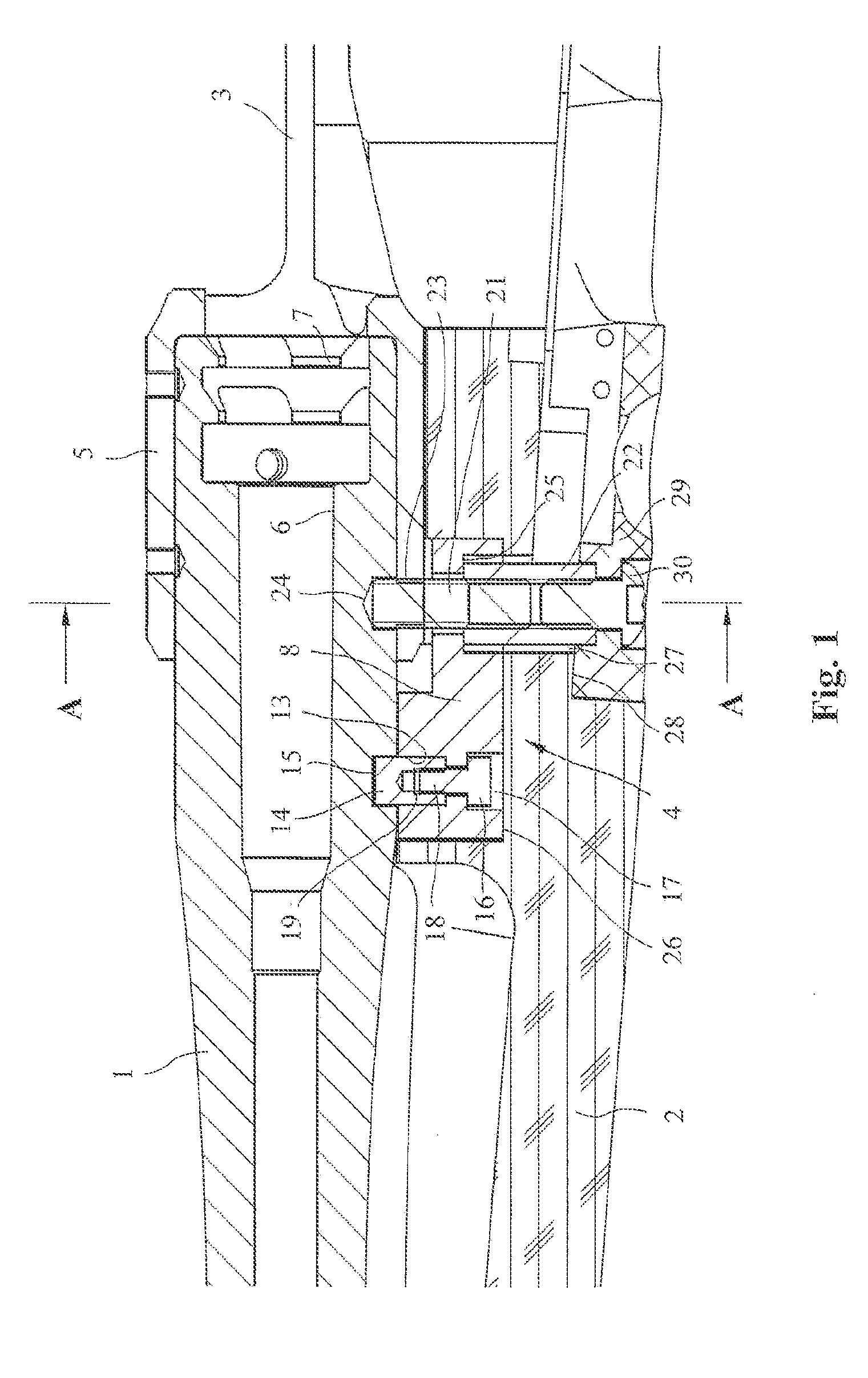

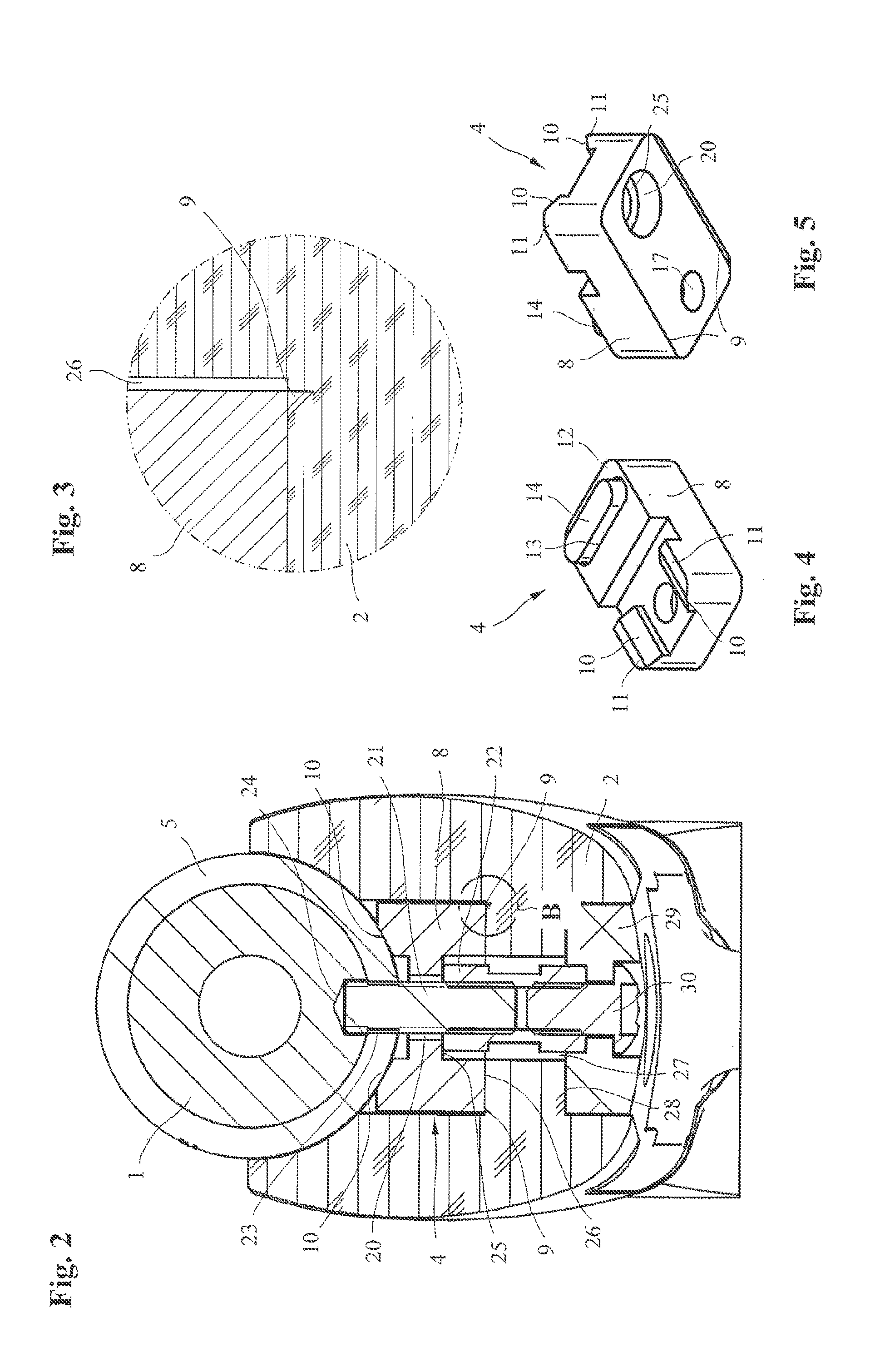

Wearing parts system for detachable fitting of wearing parts for the tool of a cultivating machine

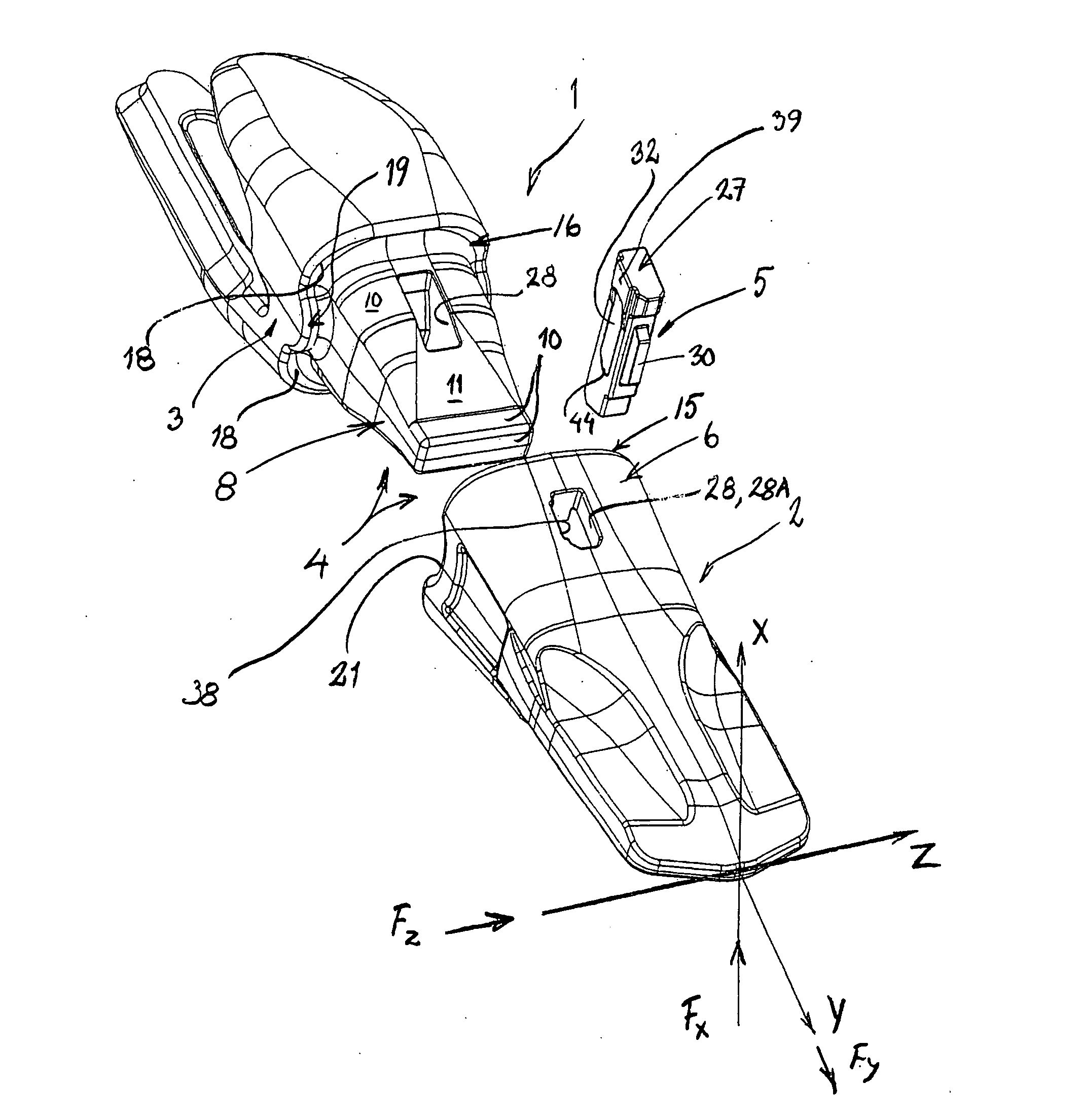

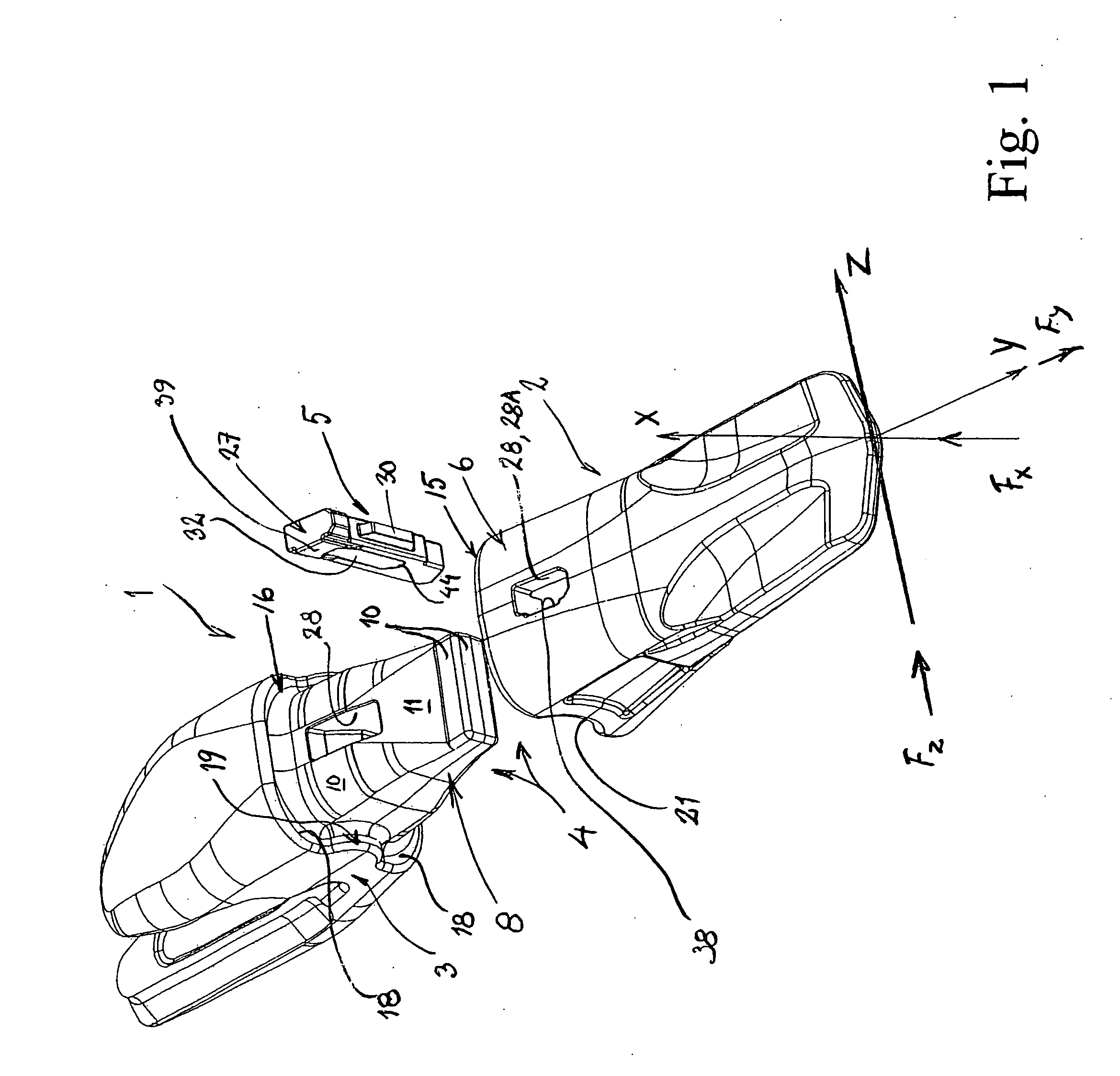

ActiveUS7703224B2Effective strikeImprove stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention relates to a wearing parts system (1) intended for the tool of a tilling machine of the type which comprises a holder part (3), having a front end part (8), and an exchangeable wearing and / or replacement part (2), arranged over this end part and comprising a hood-shaped (6) hollow (7) which, when the wearing part (2) is fitted in place, is designed to grip over the end part and is fixed thereto by means of at least one locking device (27) placed through interacting openings (28), the end part and the hollow having front, rear and collateral contact zones (9, 22, 23), each comprising contact faces (10, 25, 26), disposed one on the holder part and one on the wearing part, for the absorption of acting vertical, horizontal and collateral forces Fx, Fy and Fz. The contact faces (25, 26) are designed to interact so as, on the one hand, to limit the pushing-on of the wearing part over the holder part and, on the other hand, to ensure that the contact between the contact faces will be made, primarily, at the common centre M0, of the two radii (of a recess and a projection) essentially in the horizontal plane YZ and secondarily, as the wear has progressed, symmetrically about this mid contact point as an increasingly large contact zone (22′, 23′).

Owner:COMBI WEAR PARTS AB

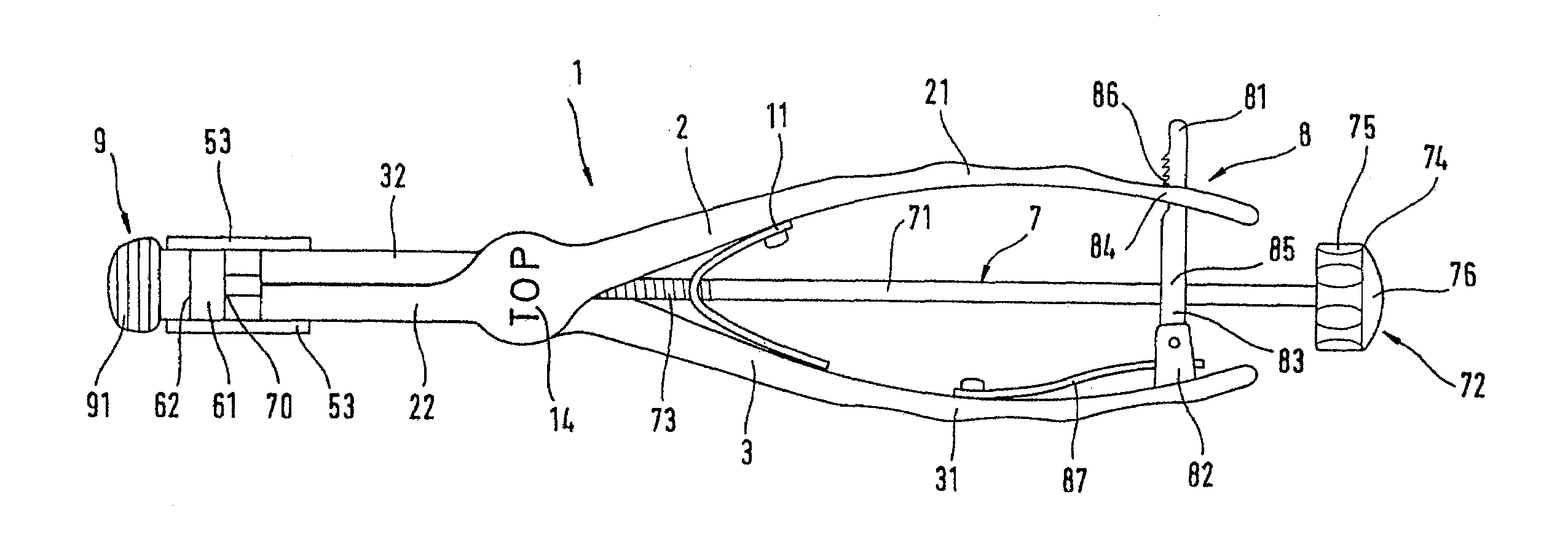

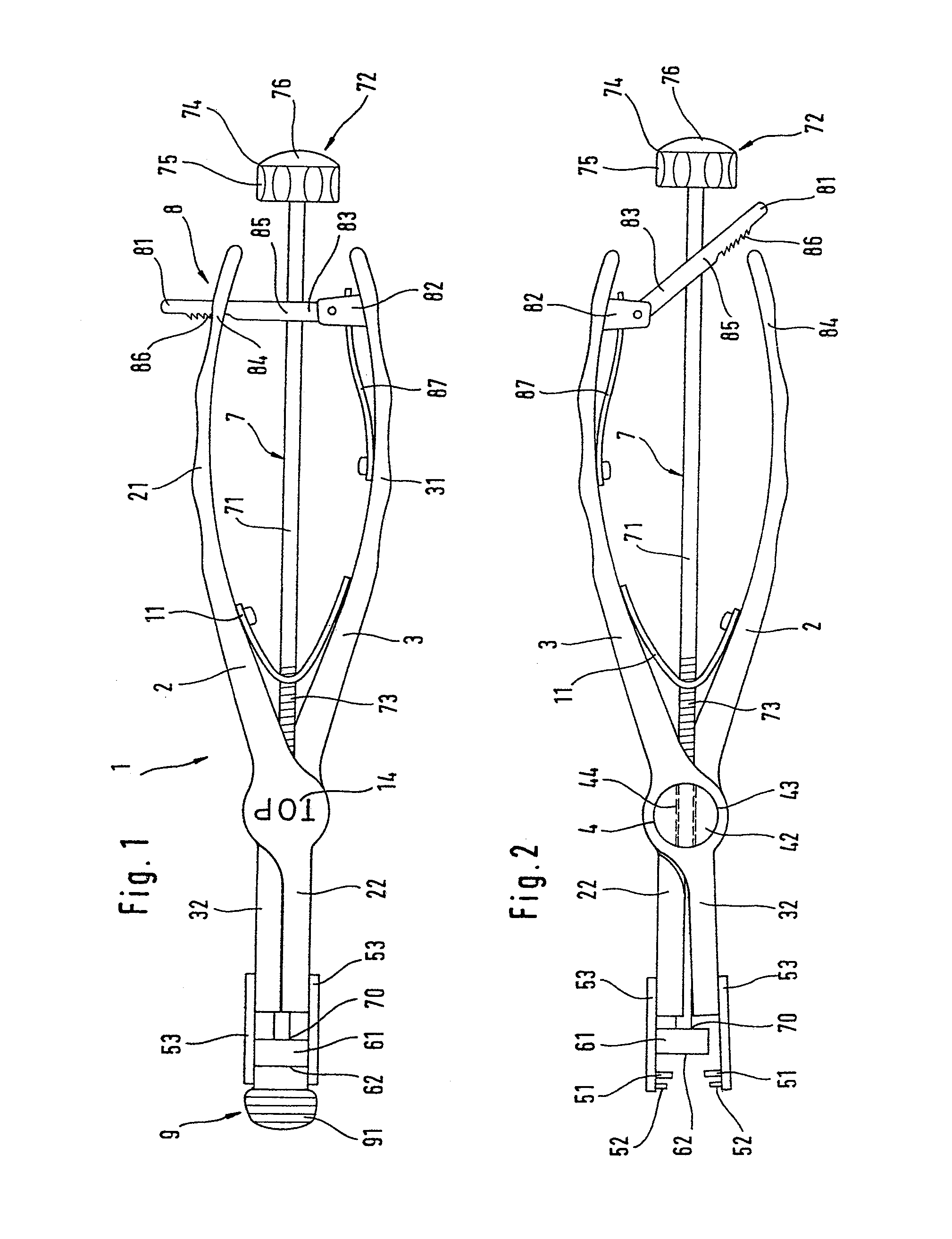

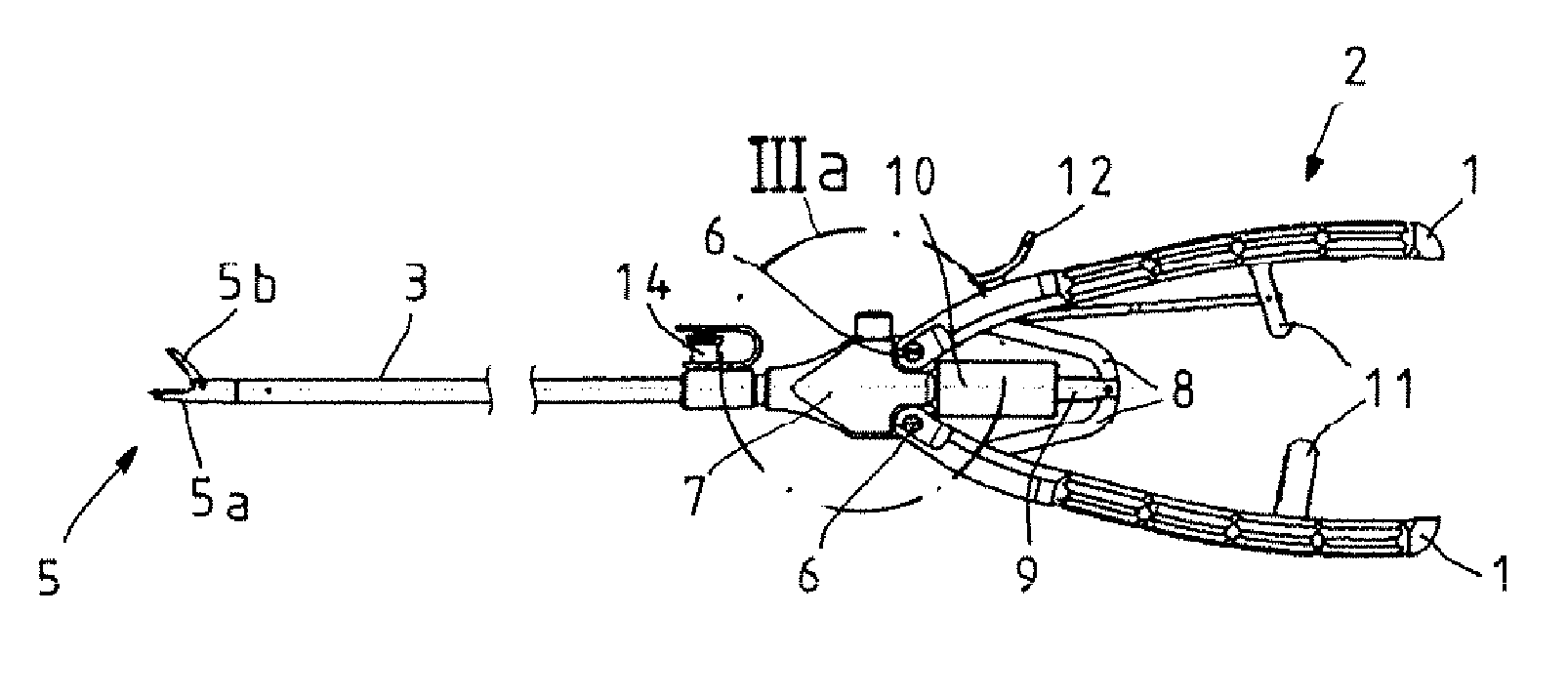

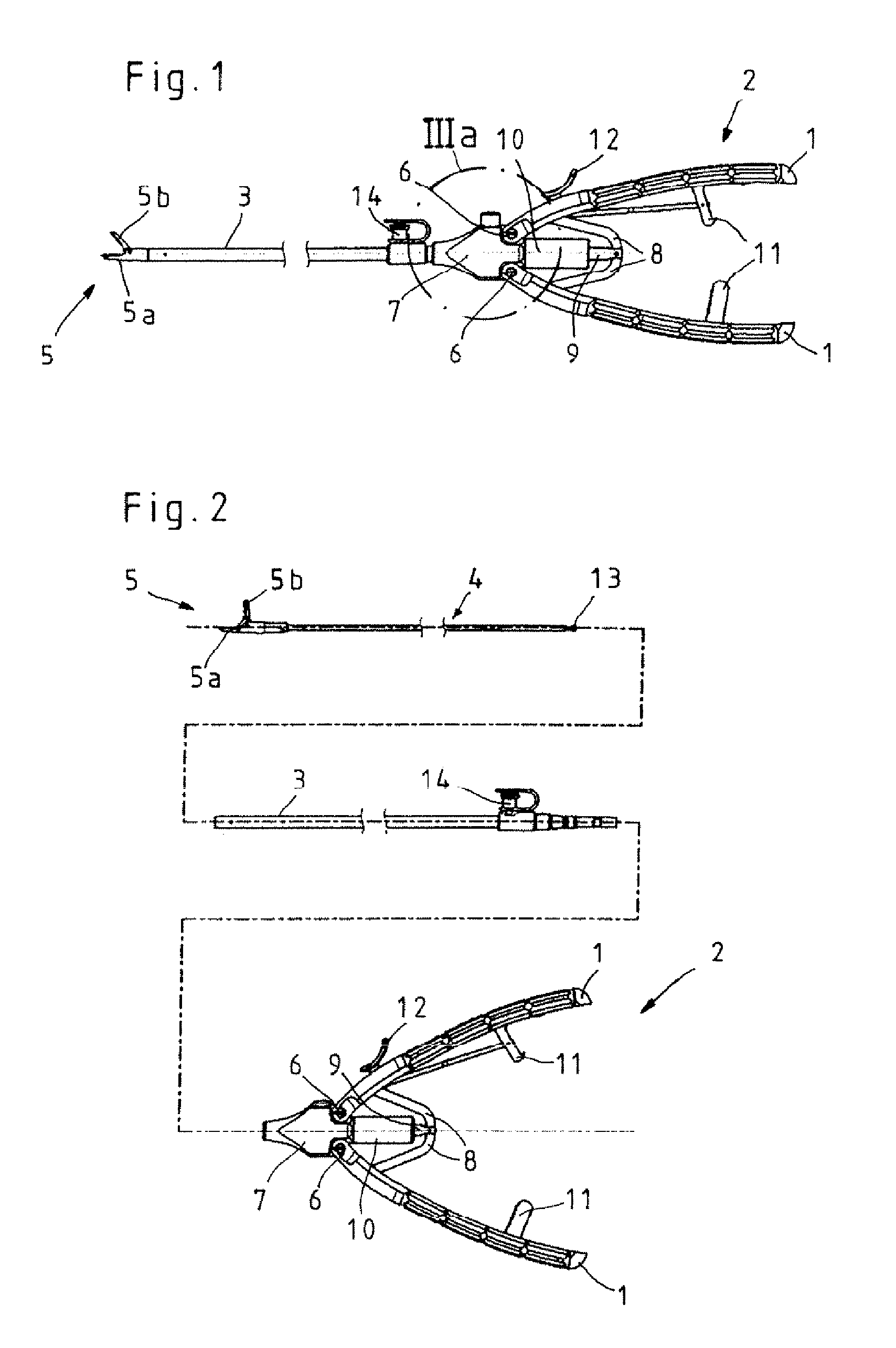

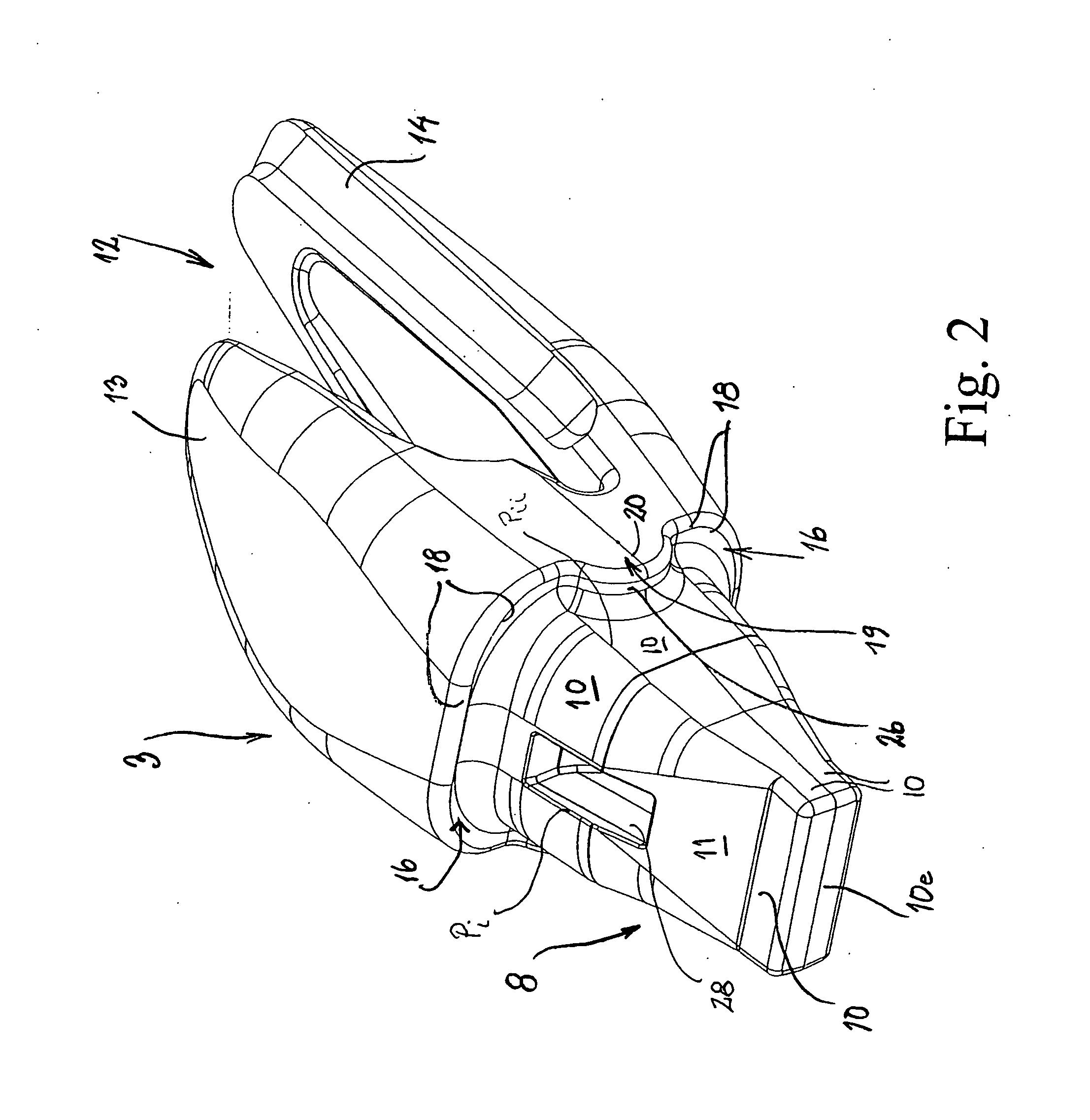

Insertion instrument for cervical prostheses

ActiveUS7569067B2Easy to handleSave construction spaceJoint implantsSpinal implantsProsthesisHinge angle

An insertion instrument for a multi-part intervertebral endoprosthesis includes two closure plates and a sliding core arranged between these, said insertion instrument having a handgrip part, gripping members which hold the closure plates between them, and a force-receiving part for applying an insertion force to the intervertebral endoprosthesis, the gripping members being guided movably toward and away from one another via a hinge and being able to be tensioned against the intervertebral endoprosthesis, projections pointing in the tensioning direction or recesses for holding the intevertebral endoprosthesis with form-fit being provided on the gripping members, and a block guided in the longitudinal axis direction and with an abutment surface being provided which can be moved by means of an actuating device so as to bear on the intervertebral endoprosthesis and, in its forward position, secures the intevertebral endoprosthesis against the projections or recesses.

Owner:CERVITECH

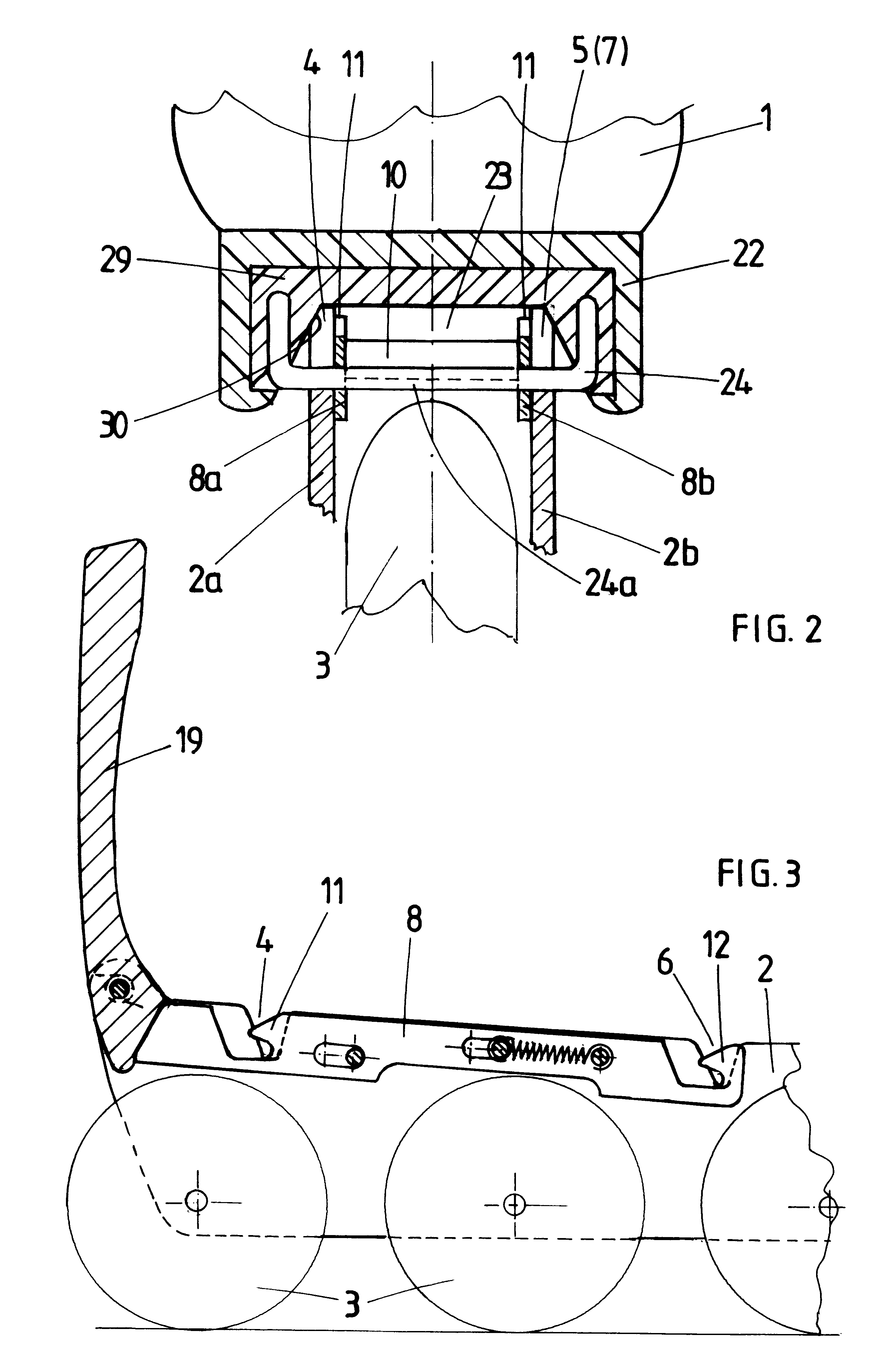

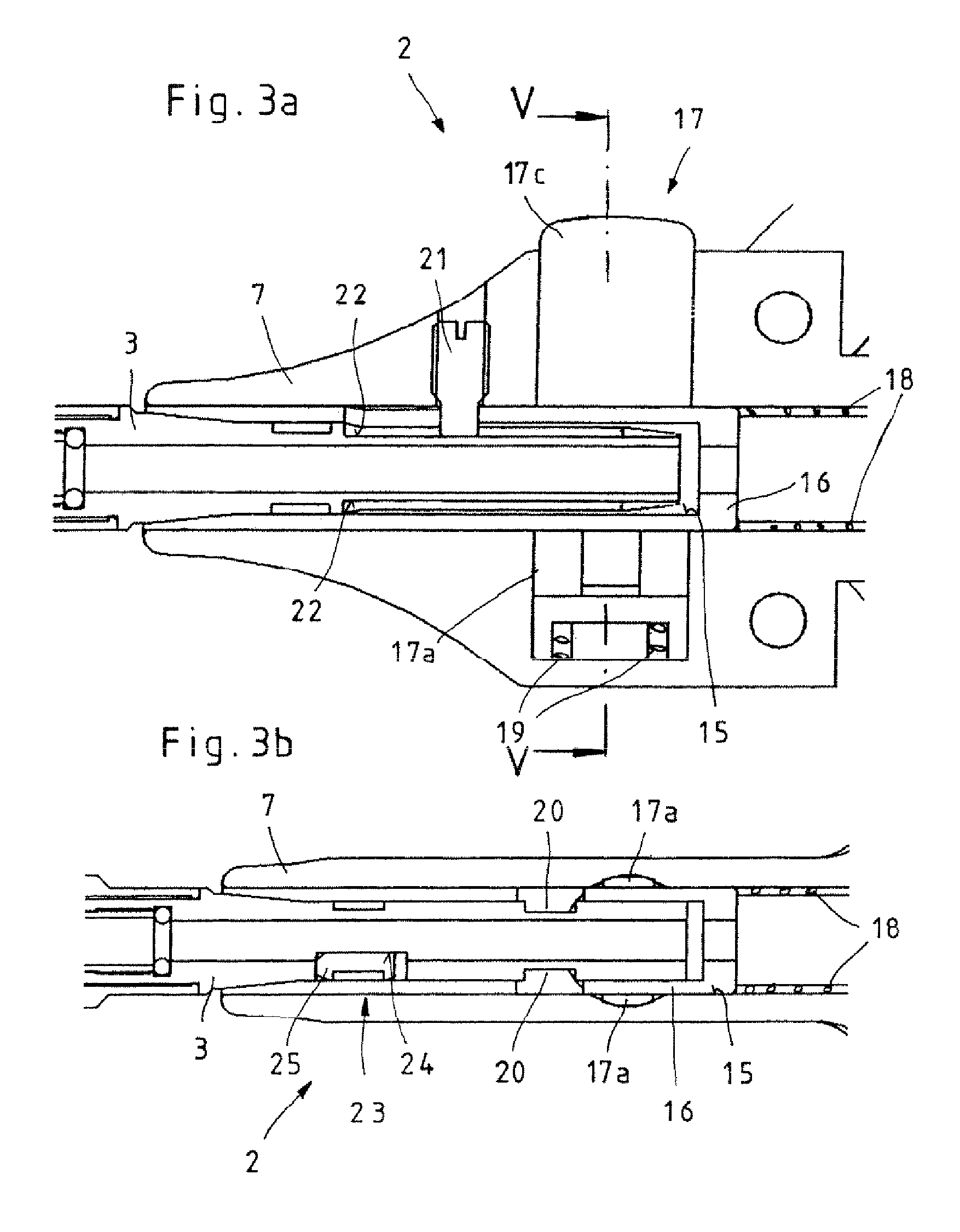

Guiding system for a sliding door

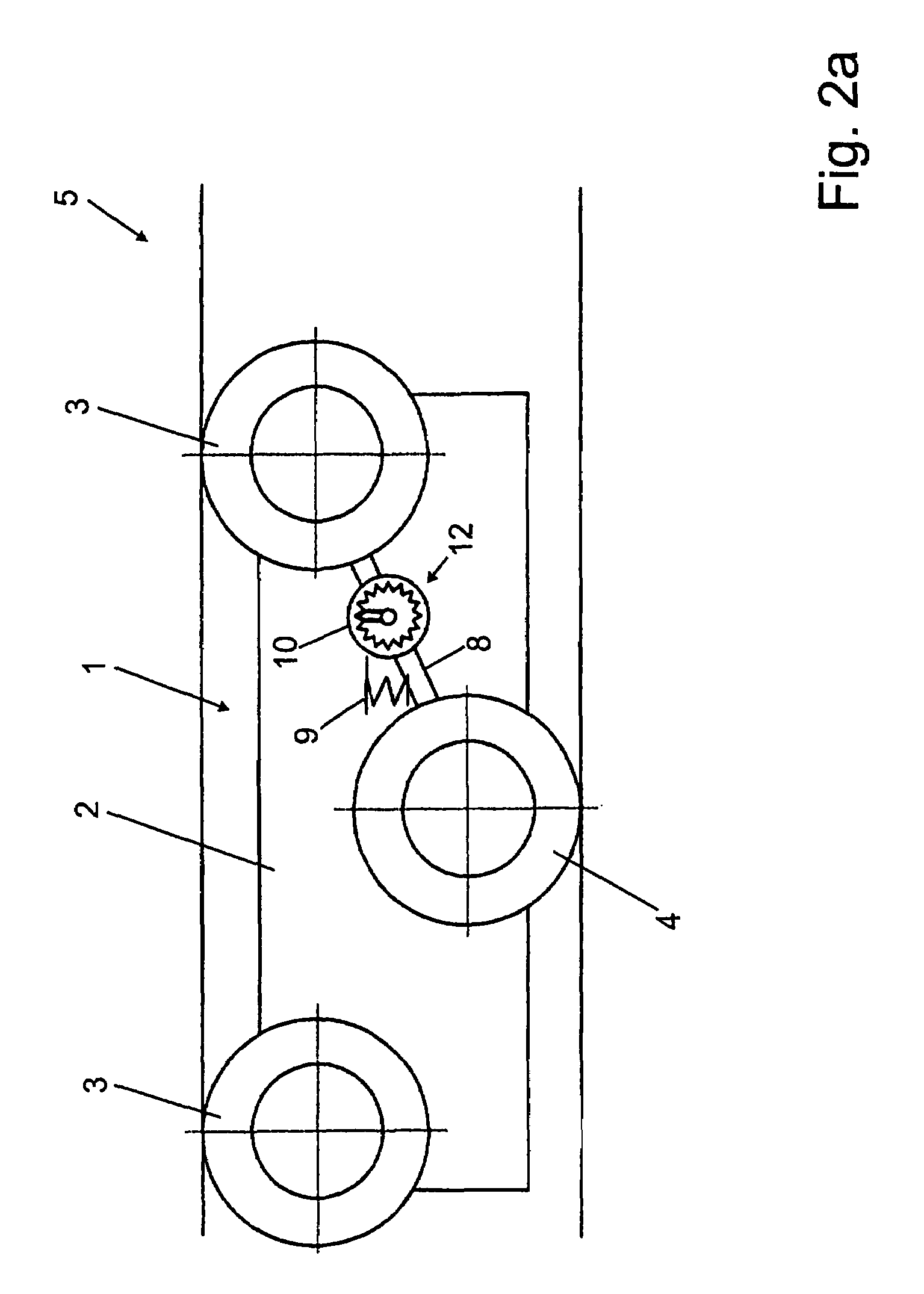

ActiveUS7703242B2Free playLittle noiseCurtain accessoriesMan-operated mechanismEngineeringMechanical engineering

A guiding system for a sliding door, especially a motor vehicle, comprising a sliding rail (5) with an upper cover (6) and a lower edge (7) arranged opposite the upper cover (6), and a roller element (101) which is guided in the sliding rail (5) and comprises a roller element housing (102) is presented. Three rollers (103, 104) are rotatably fixed to the roller element housing (102), two rollers (103) extending along the upper cover (6) of the sliding rail (5) and the third roller (104) extending along the lower edge (7). The invention creates one such guiding system in such a way that there is no play, it operates quietly, and has a taut system characteristic. To this end, a spring element (109) is fixed to the roller element housing (102), said spring element pressing on of the first two roller (103) and the third roller (104) against the sliding rail (5).

Owner:EDSCHA ENG GMBH

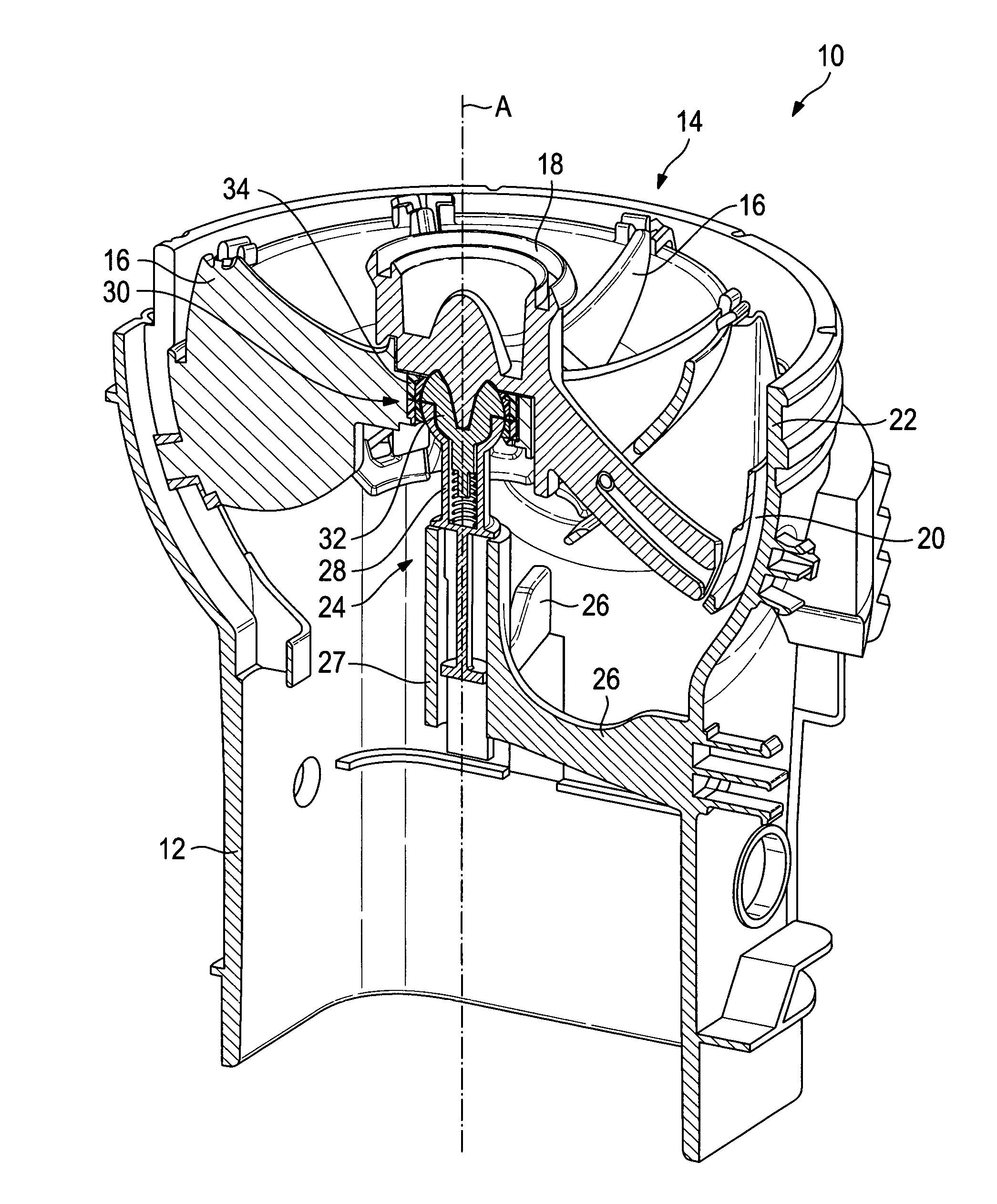

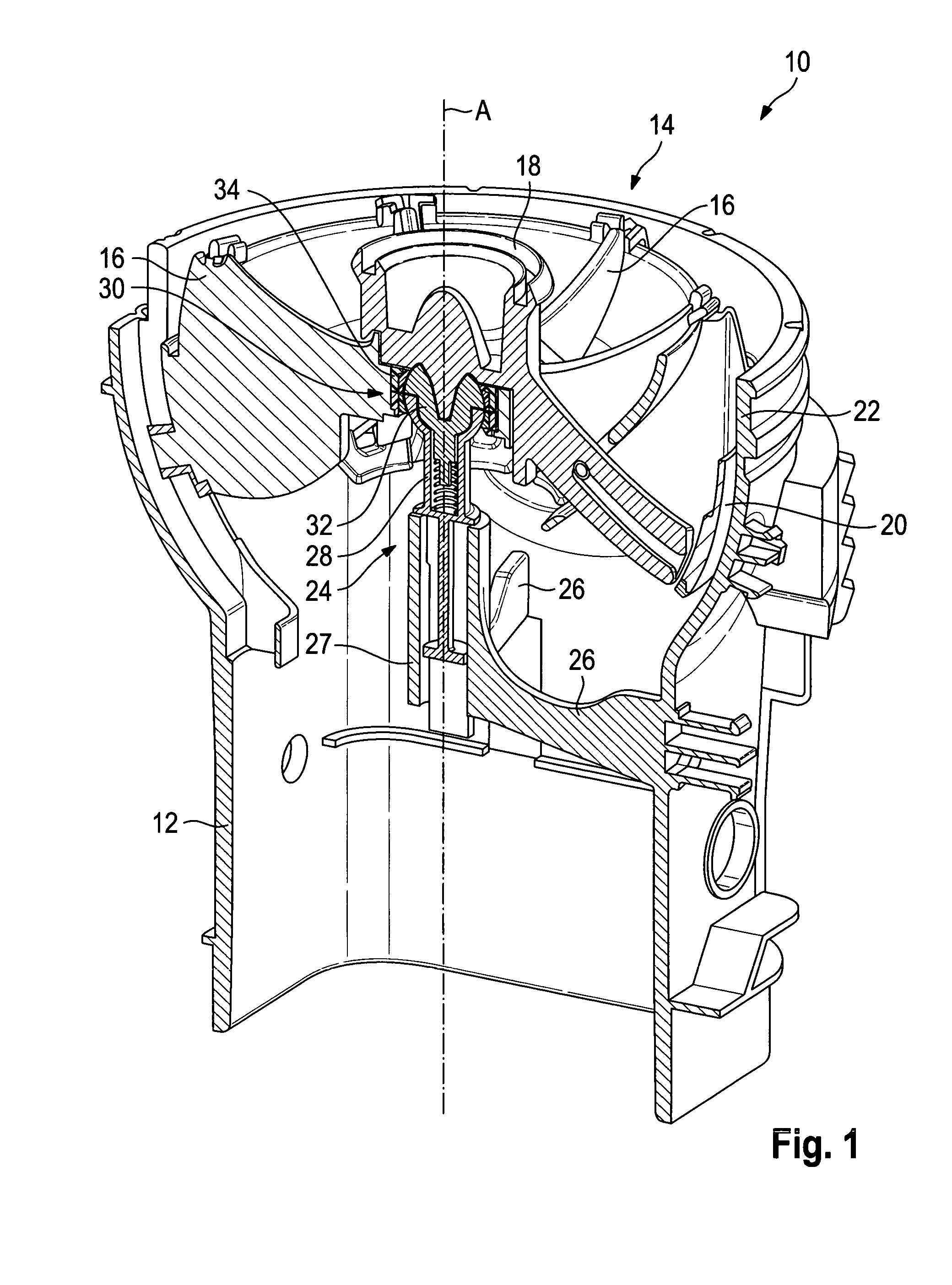

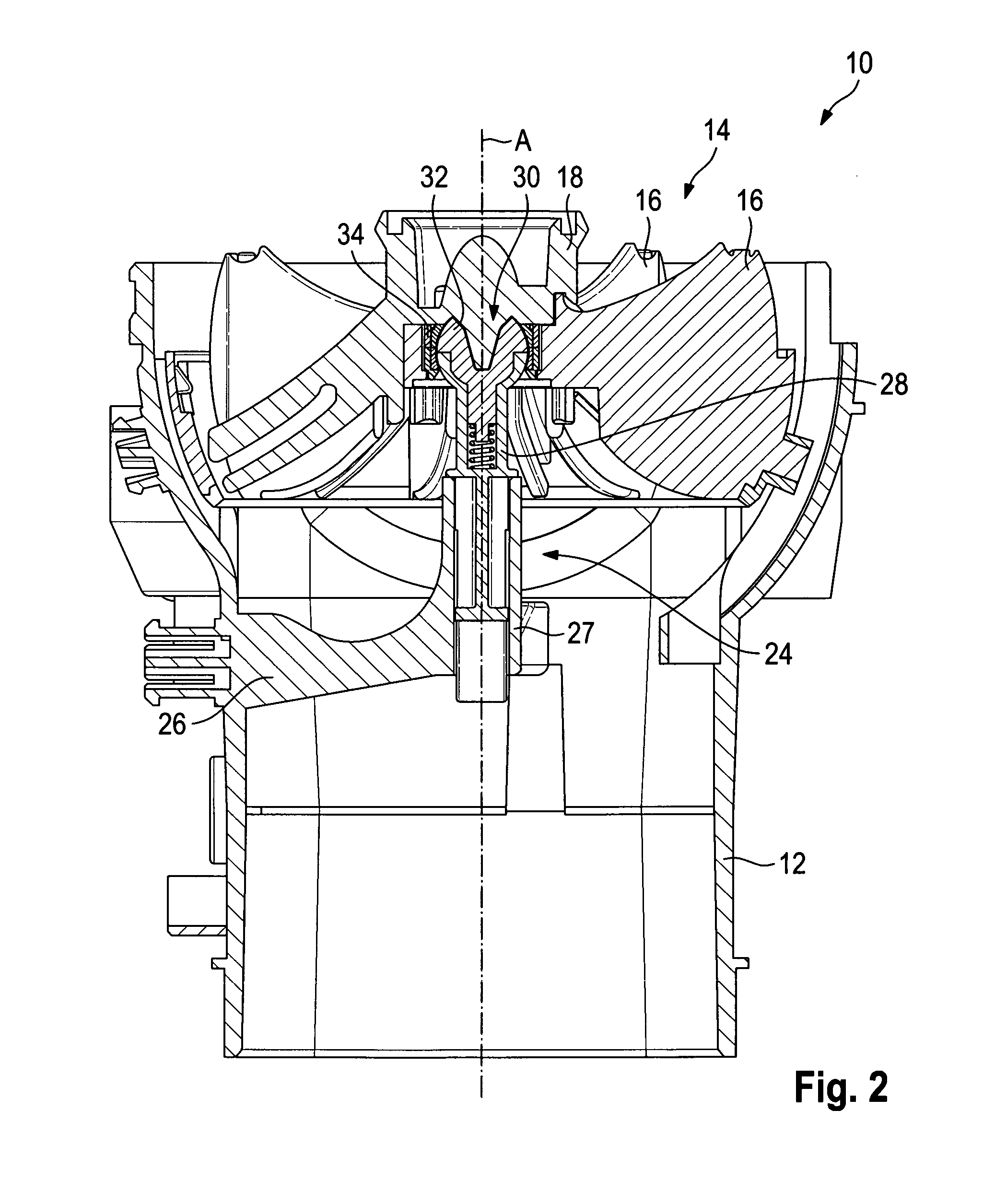

Air diffuser

ActiveUS20130210333A1Produce frictionSufficient forceAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

An air vent (10) having a housing (12) and an air guiding means (14) that is swivel-mounted in the housing (12) includes a mounting (24) by means of which the air guiding means (14) is mounted on the housing (12) for swiveling about at least one swivel axis, the mounting (24) being formed by a ball joint (30) having a bearing shell (34) and a ball head (32) mounted in the bearing shell (34), and the ball head (32) being of a multipart configuration with at least two spherical segments (50, 52), and a spring member (54) being provided that acts upon the spherical segments (50, 52) of the ball head (32) with a force that seeks to push the spherical segments (50, 52) apart.

Owner:AUDI AG +1

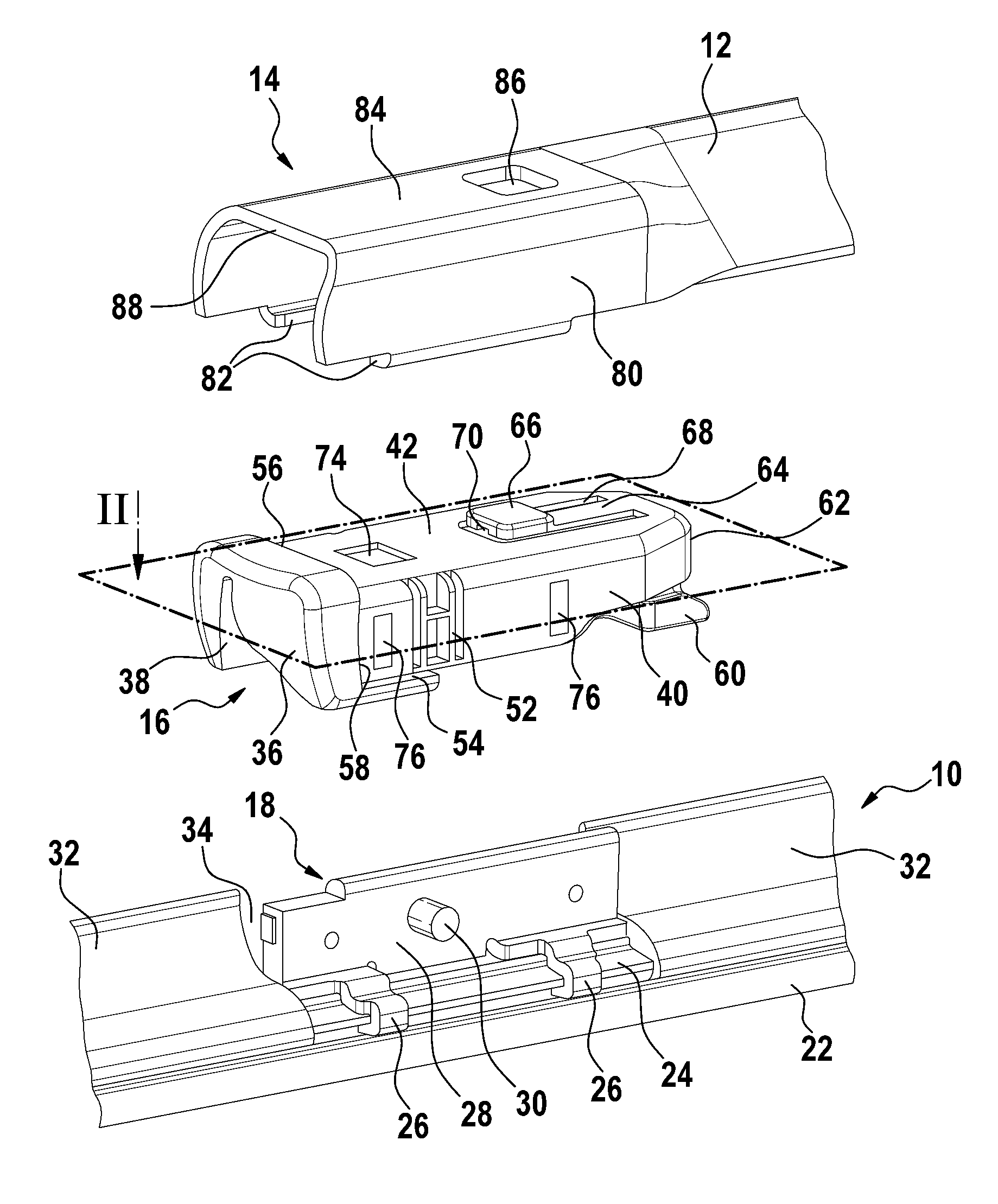

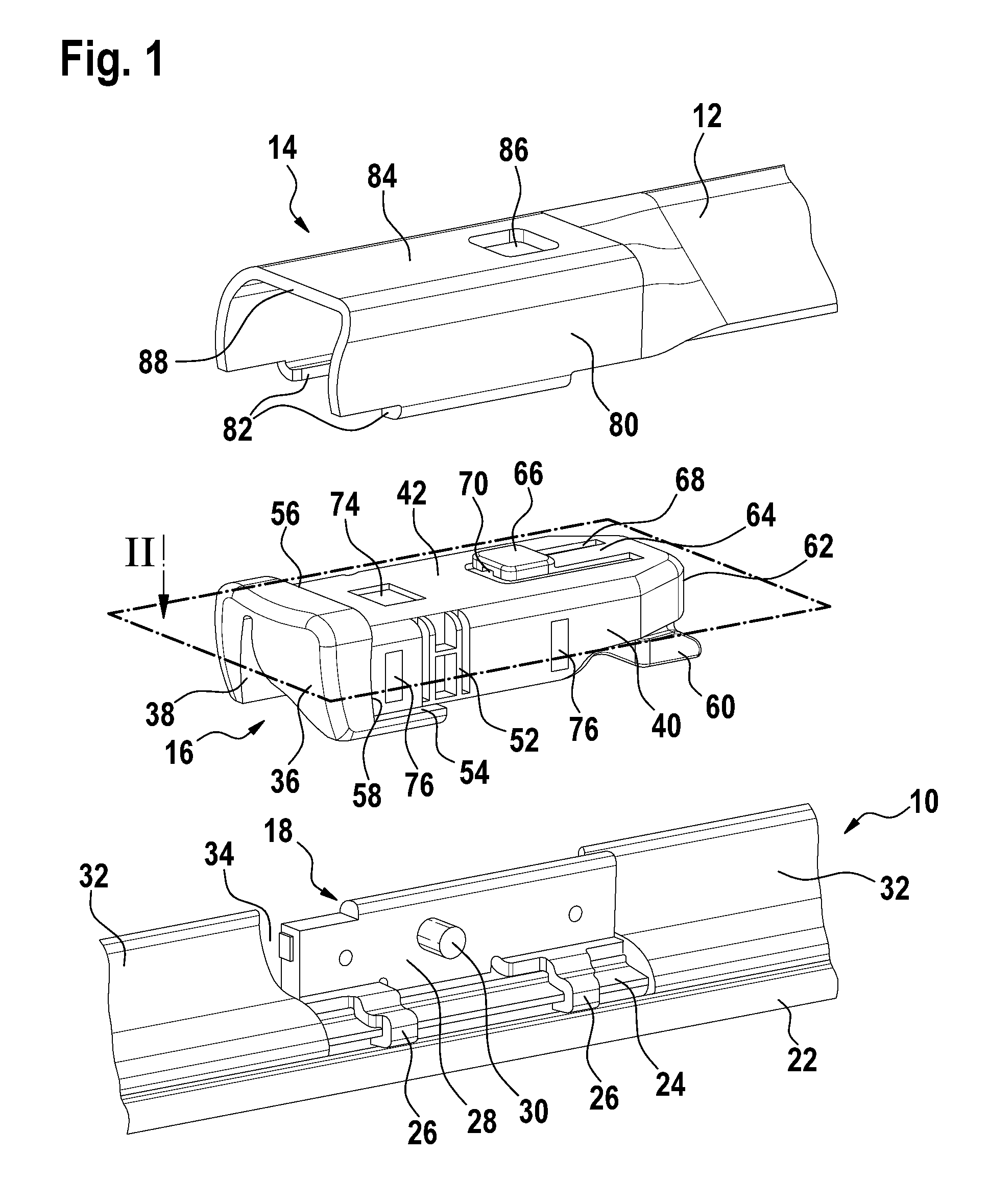

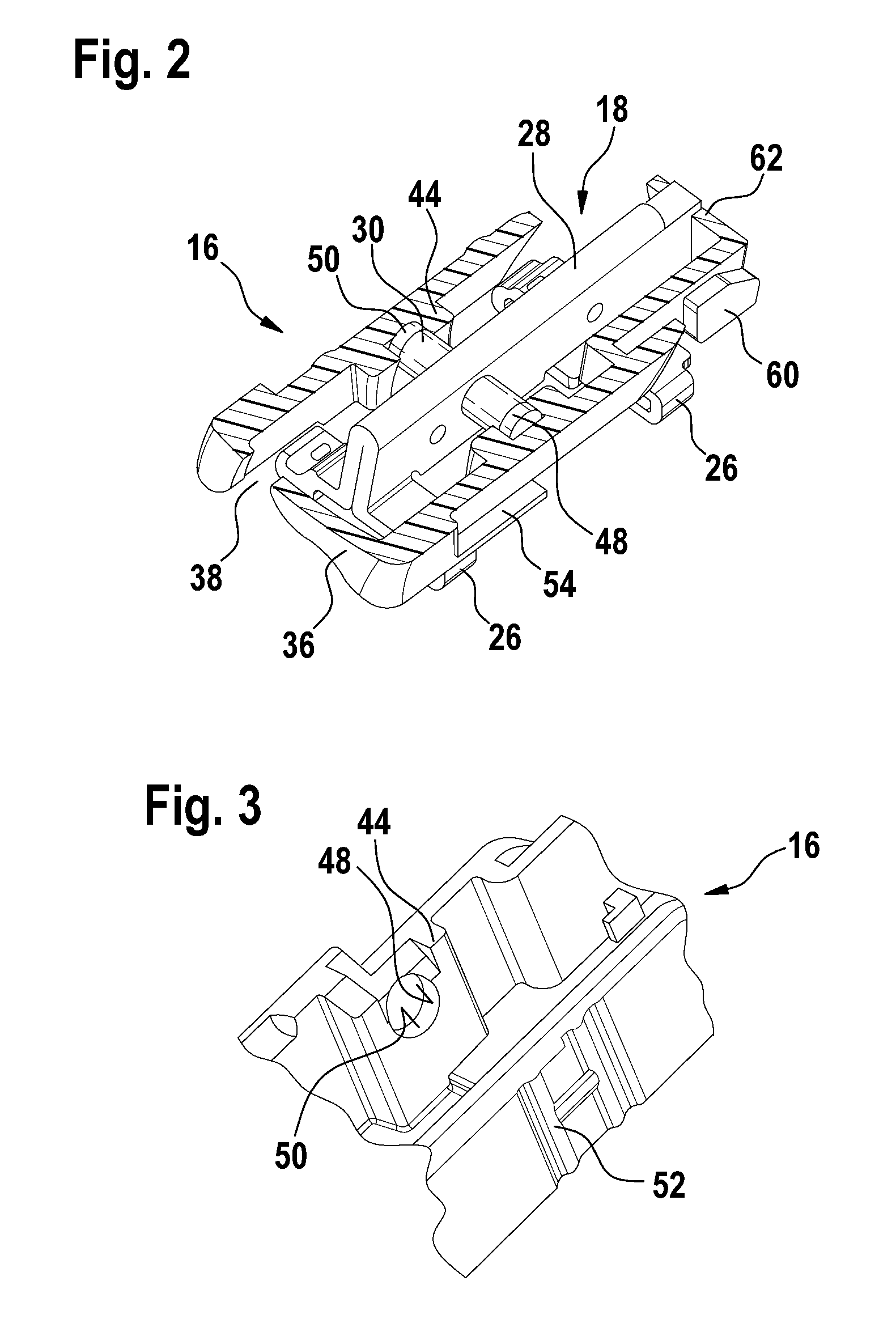

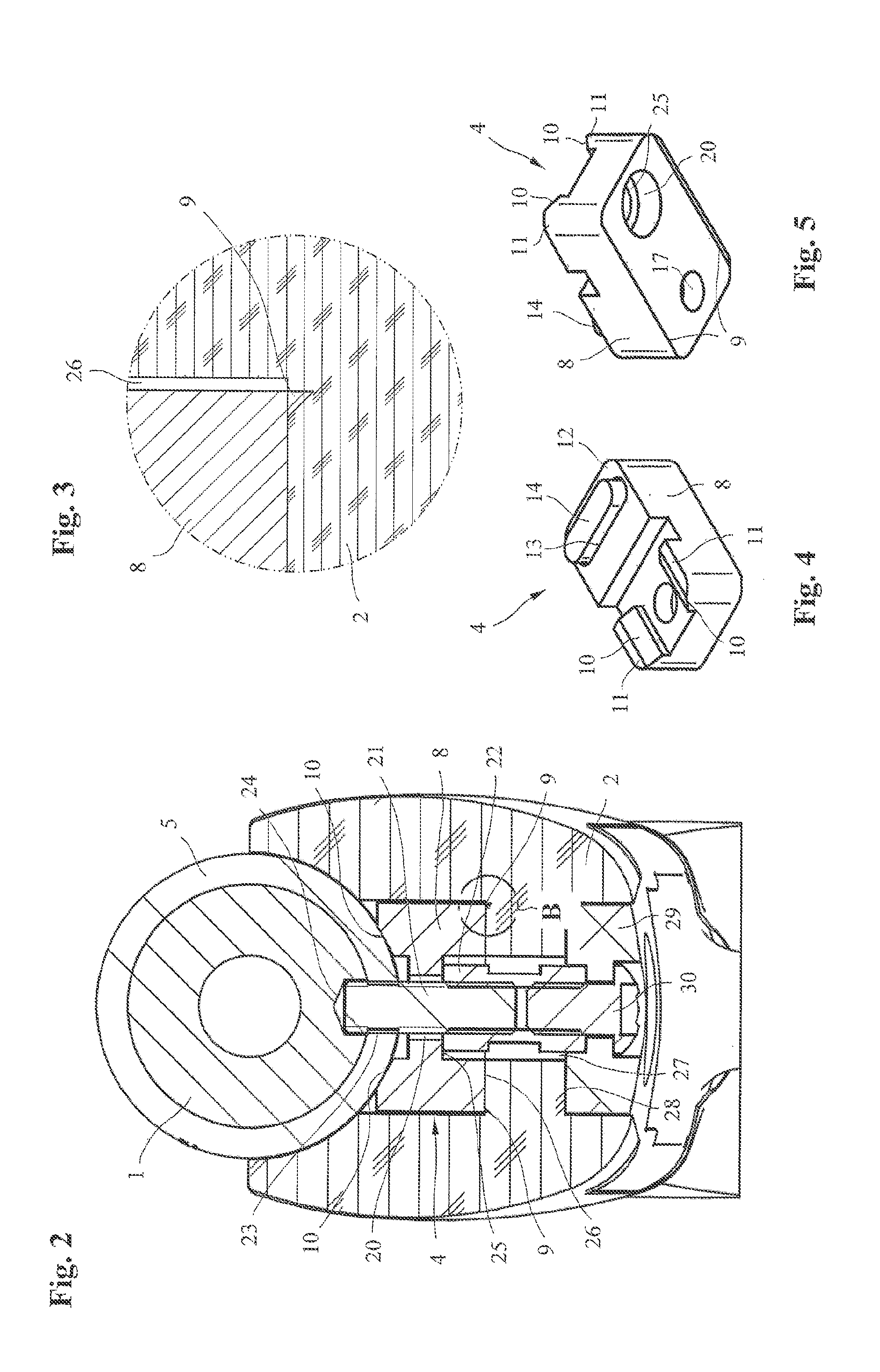

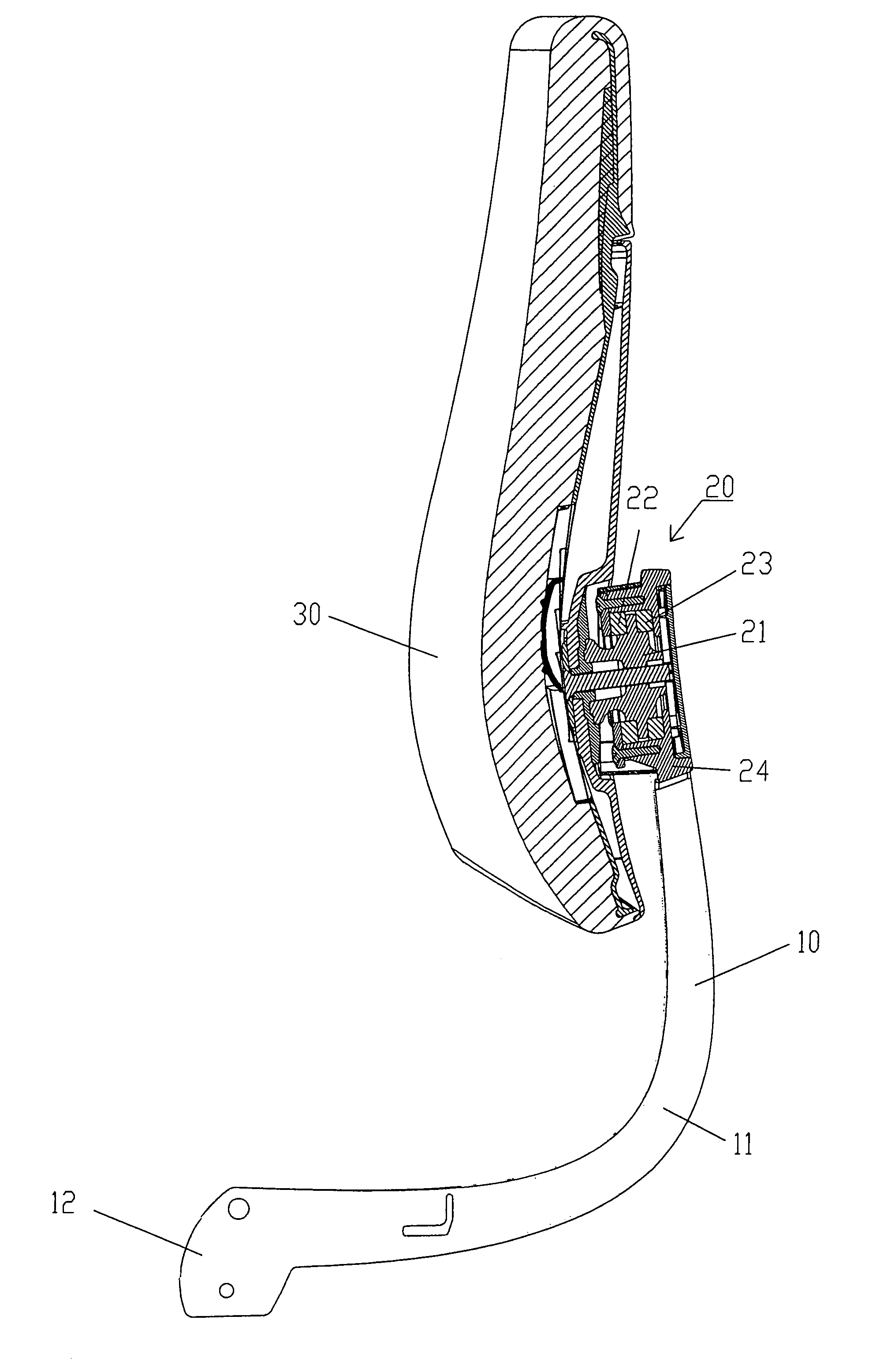

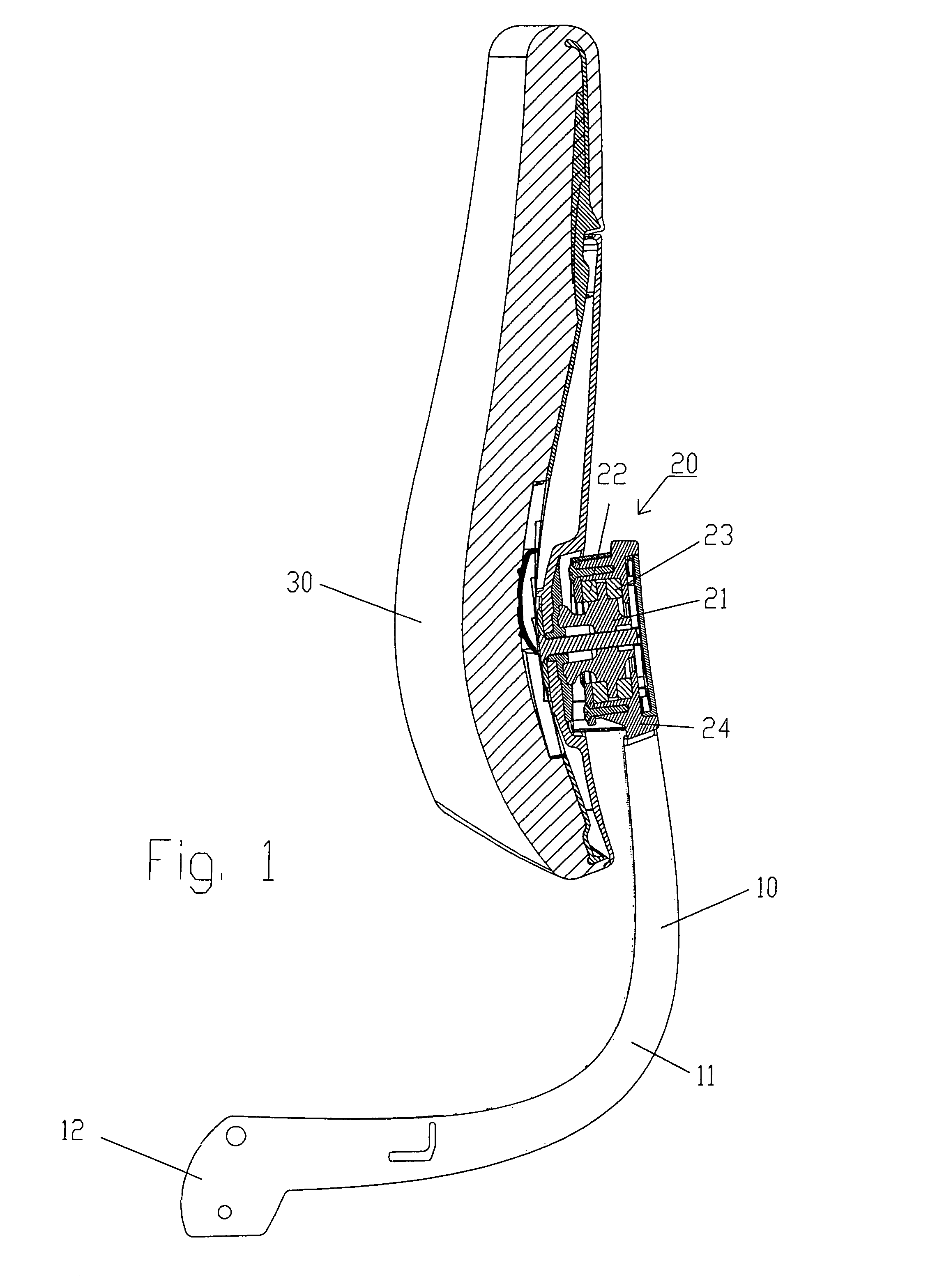

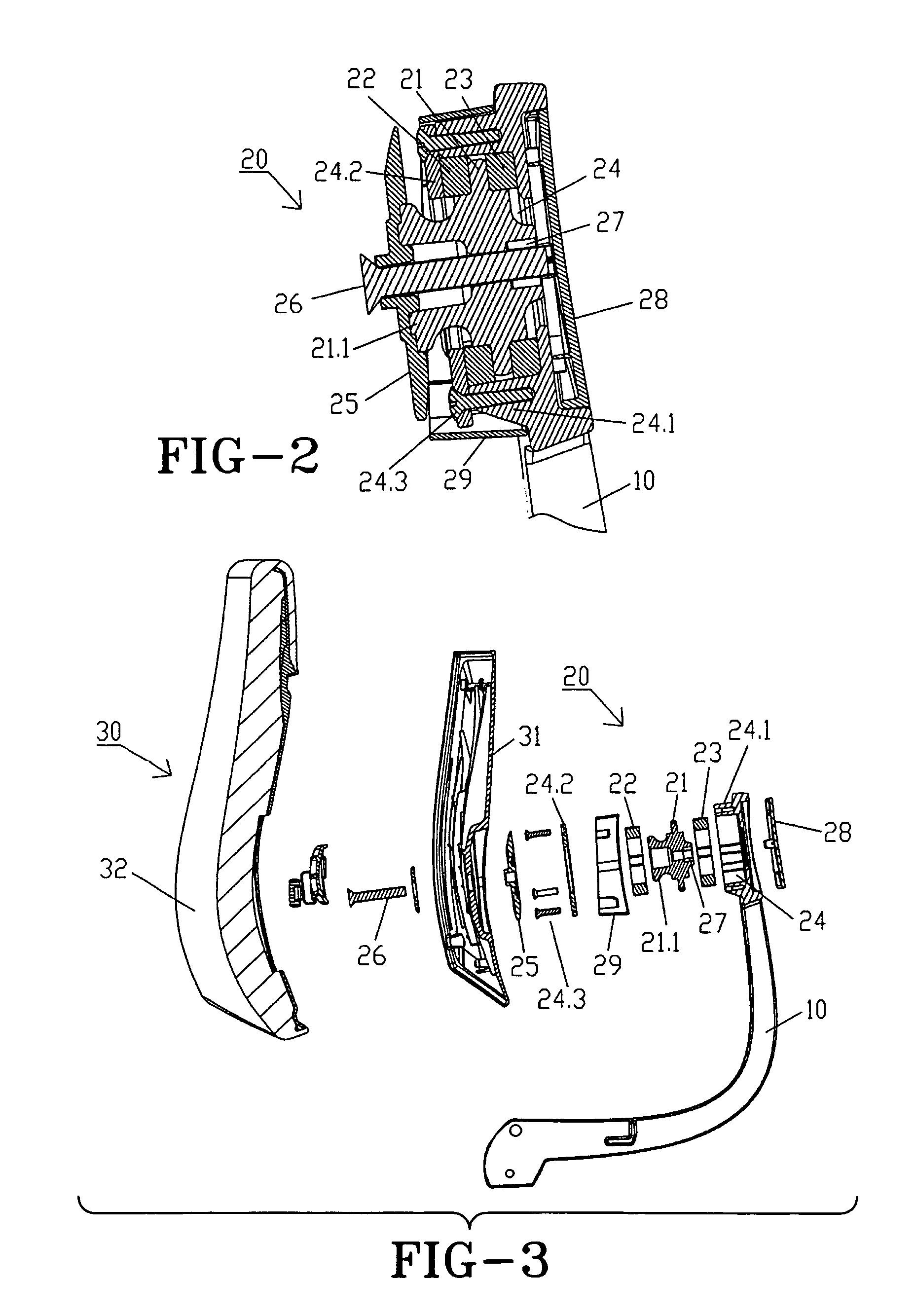

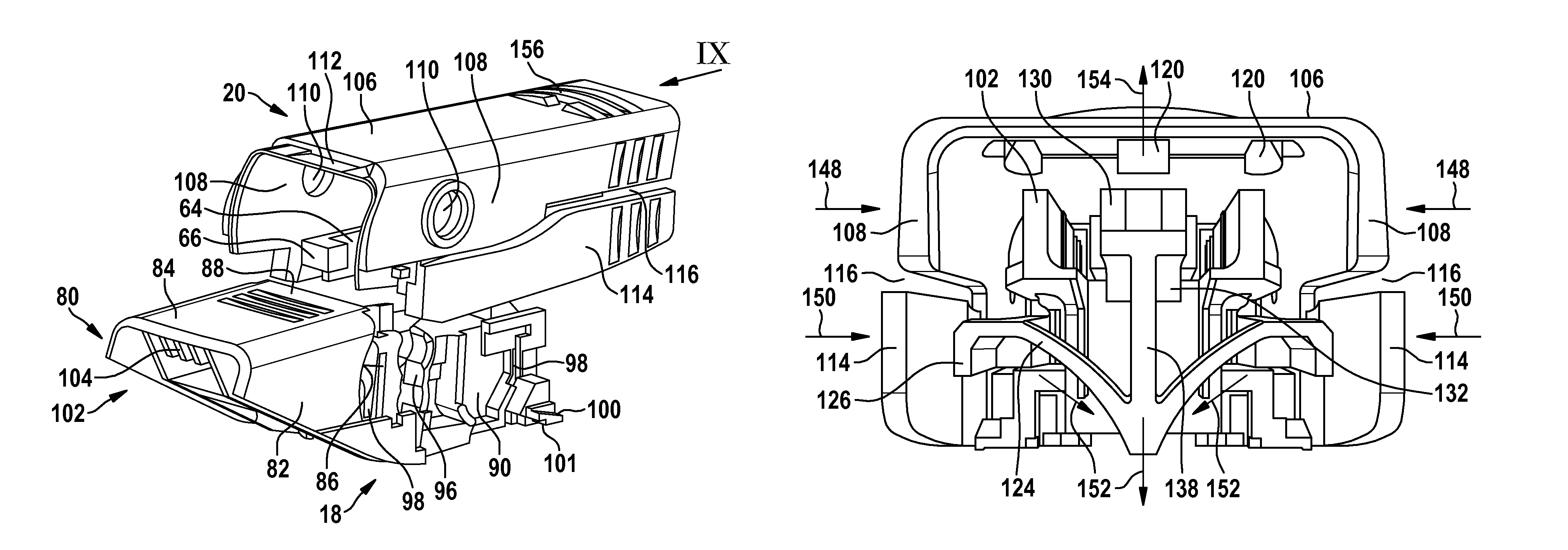

Connecting device

ActiveUS8931133B2Low bearing frictionReduce stiffnessWindow cleanersVehicle cleaningEngineeringBlind hole

Owner:ROBERT BOSCH GMBH

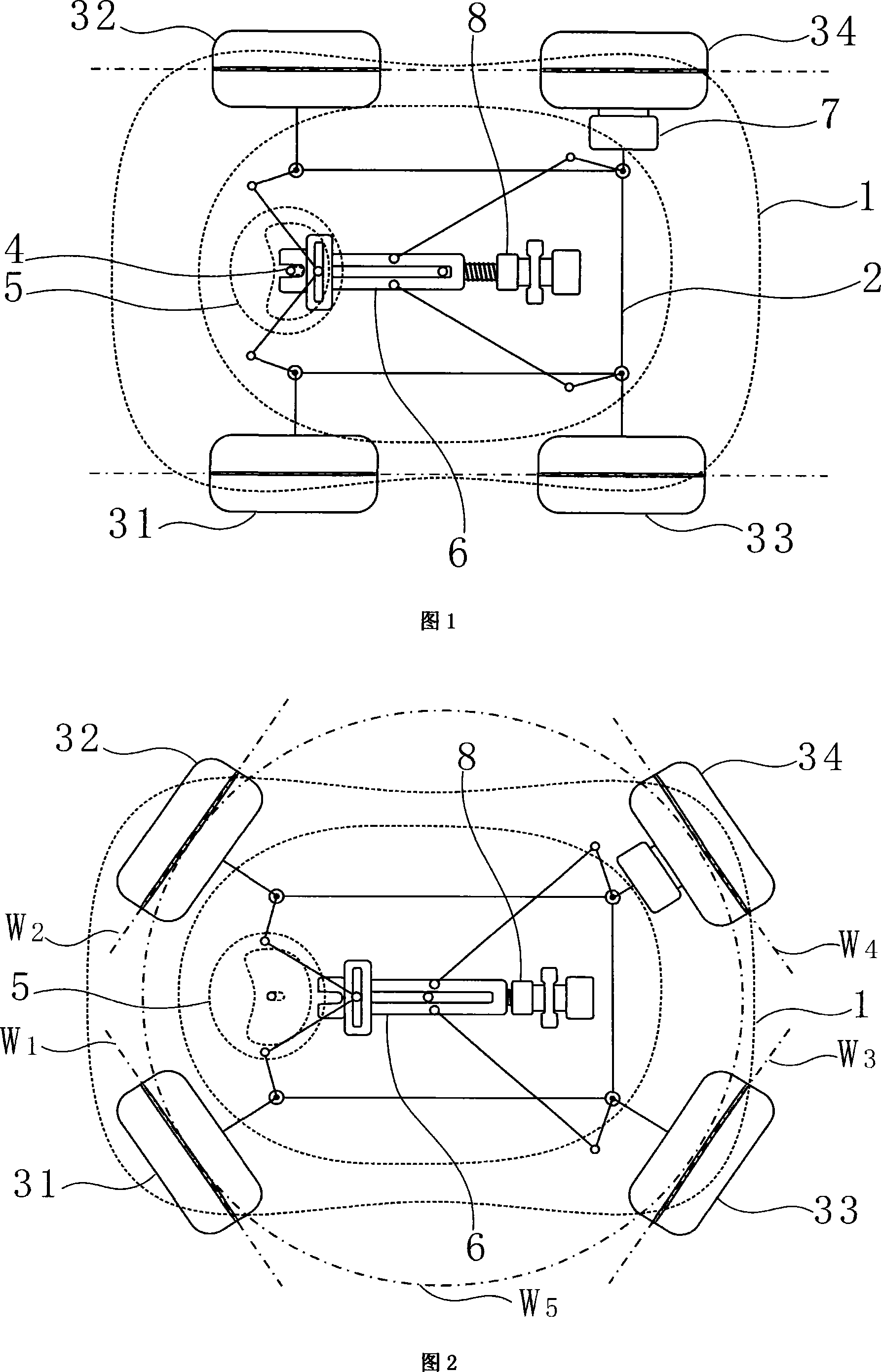

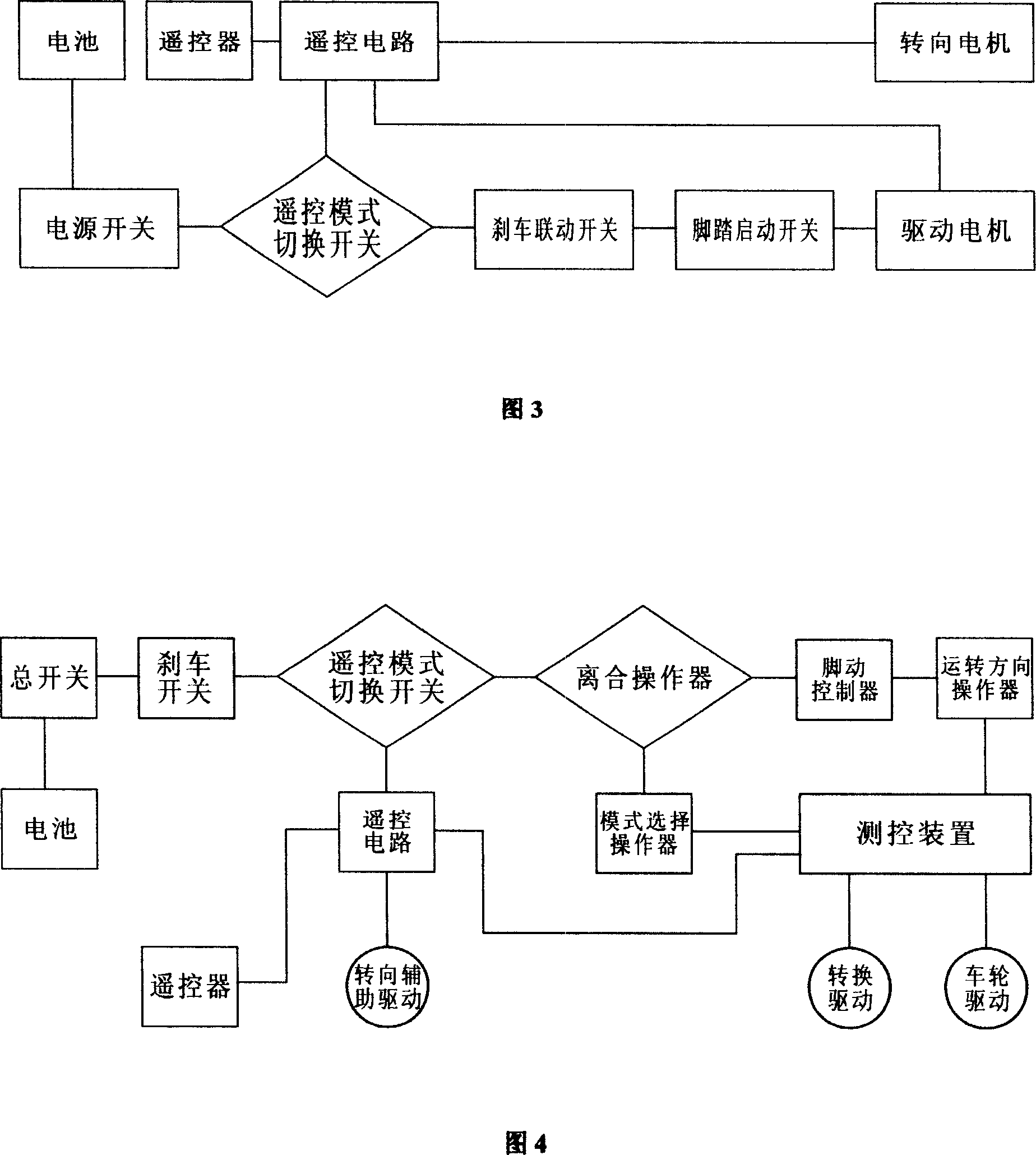

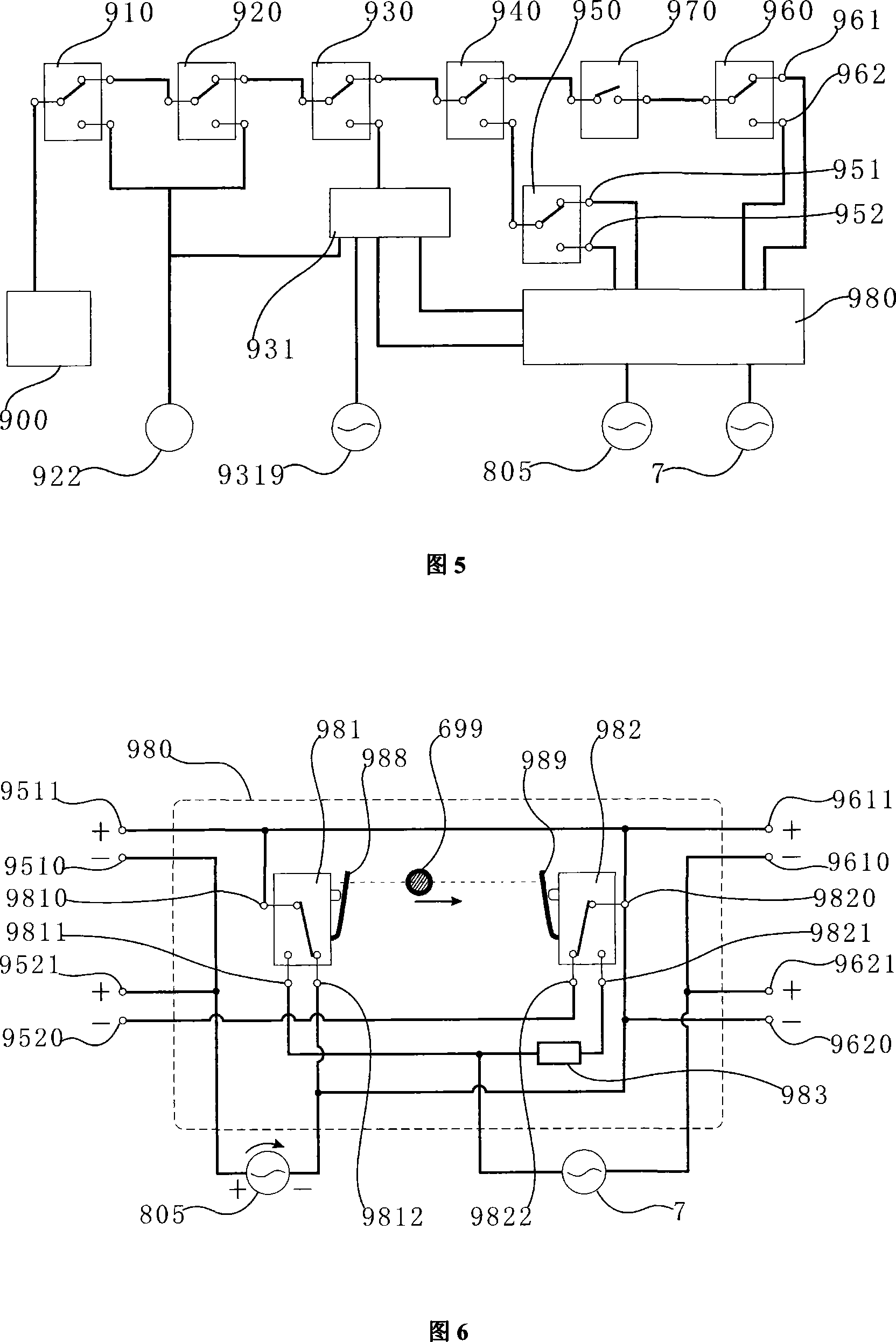

Rotatable carriage for children and operational control system for the same

InactiveCN101085406ASatisfy driving pleasureVarious forms of exerciseSteering linkagesToy vehiclesPush and pullVehicle frame

The invention discloses a windmilling children vehicle and its control system. The said quadricycle is composed of a body, a frame, front and rear brake bands,a driving device,a turning shifter lever,and a steering wheel. Axles are arranged between each wheel and frame. Each axle connects with the frame through a vertical shaft and is provided with an orientation shifter lever angled with the axle. Slipper group is arranged inside the frame. Rigidity pitman and push-and-pull device acting on the slipper group are arranged between the slipper group and each orientation shifter lever. The push-and-pull device is lead screw. Said vehicular control system also has a braking device,a clutch, connection mode selection operator, a running orientation operator,and a control system. The invention can safely switch the children vehicle between general pattern and rotation pattern and supply reliable guarantee for the said children vehicle original game form.

Owner:陈华胜

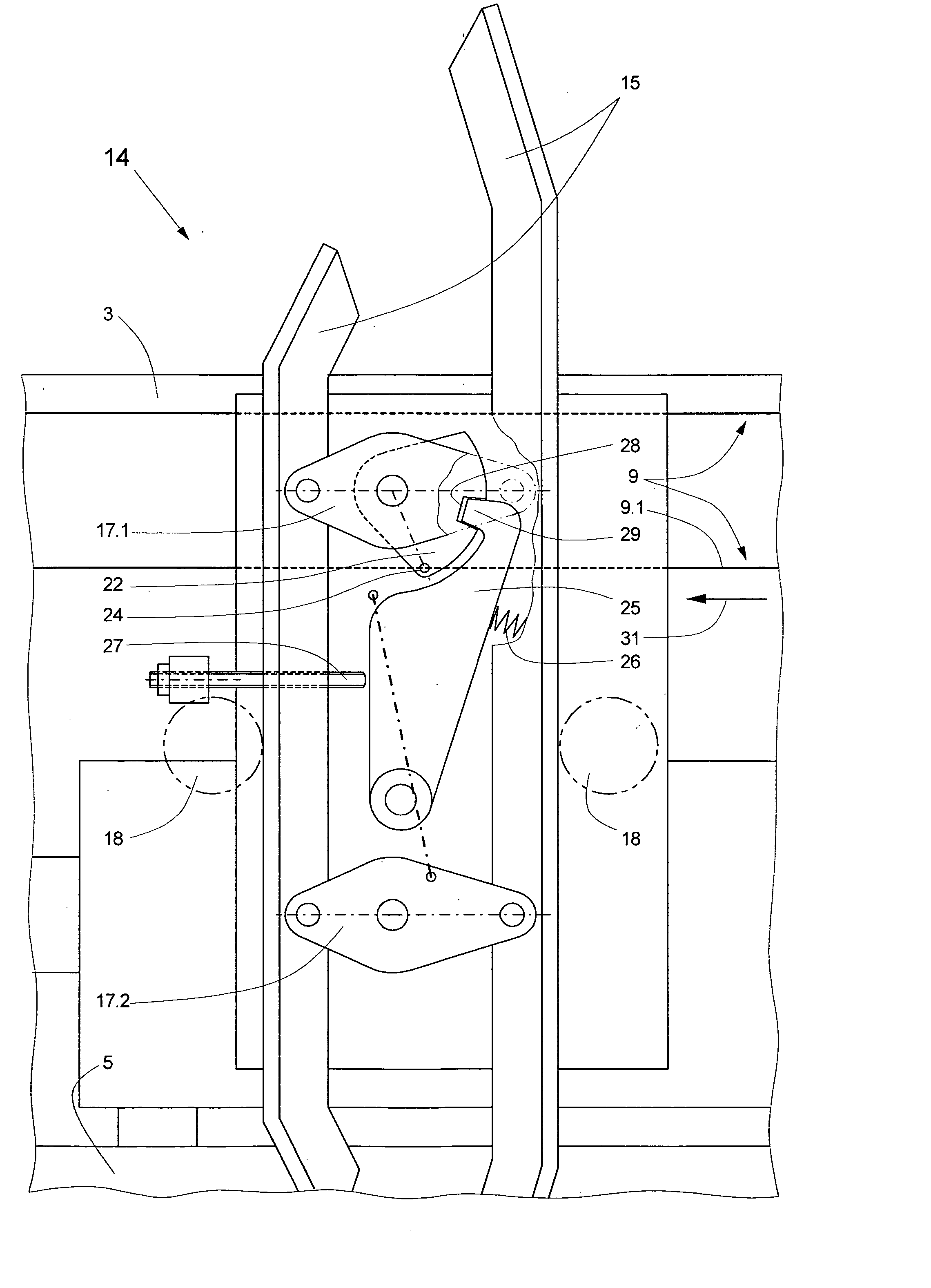

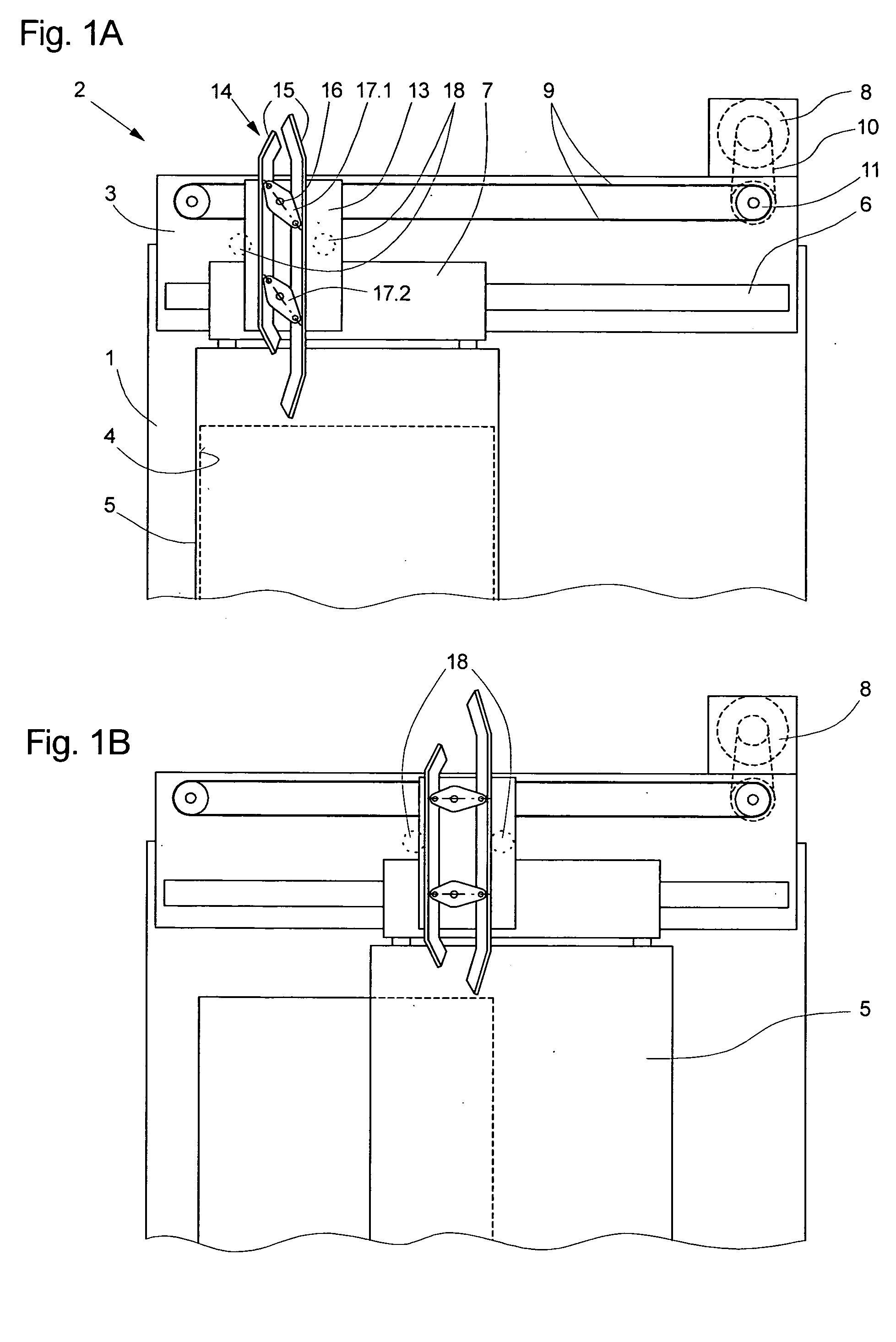

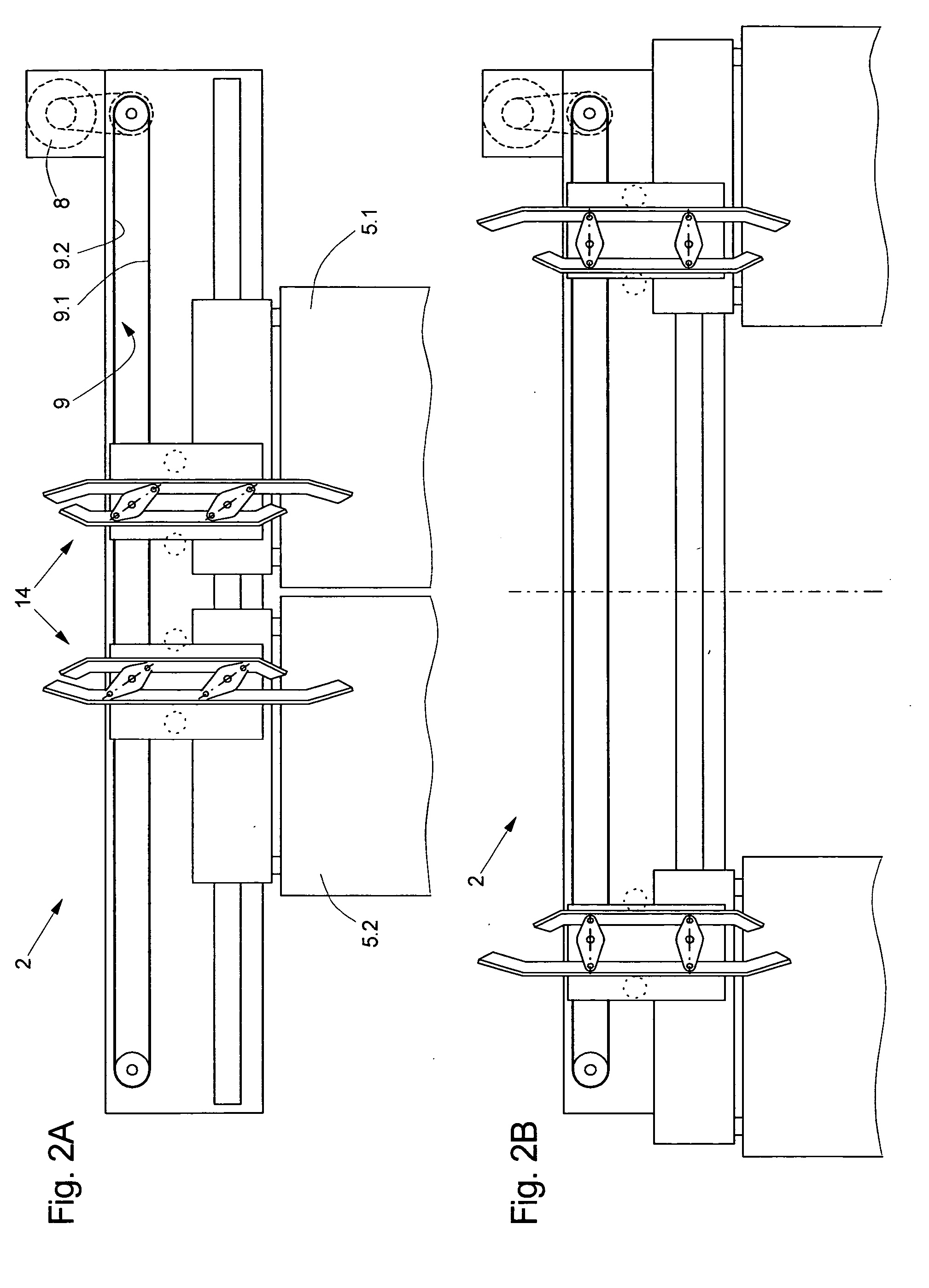

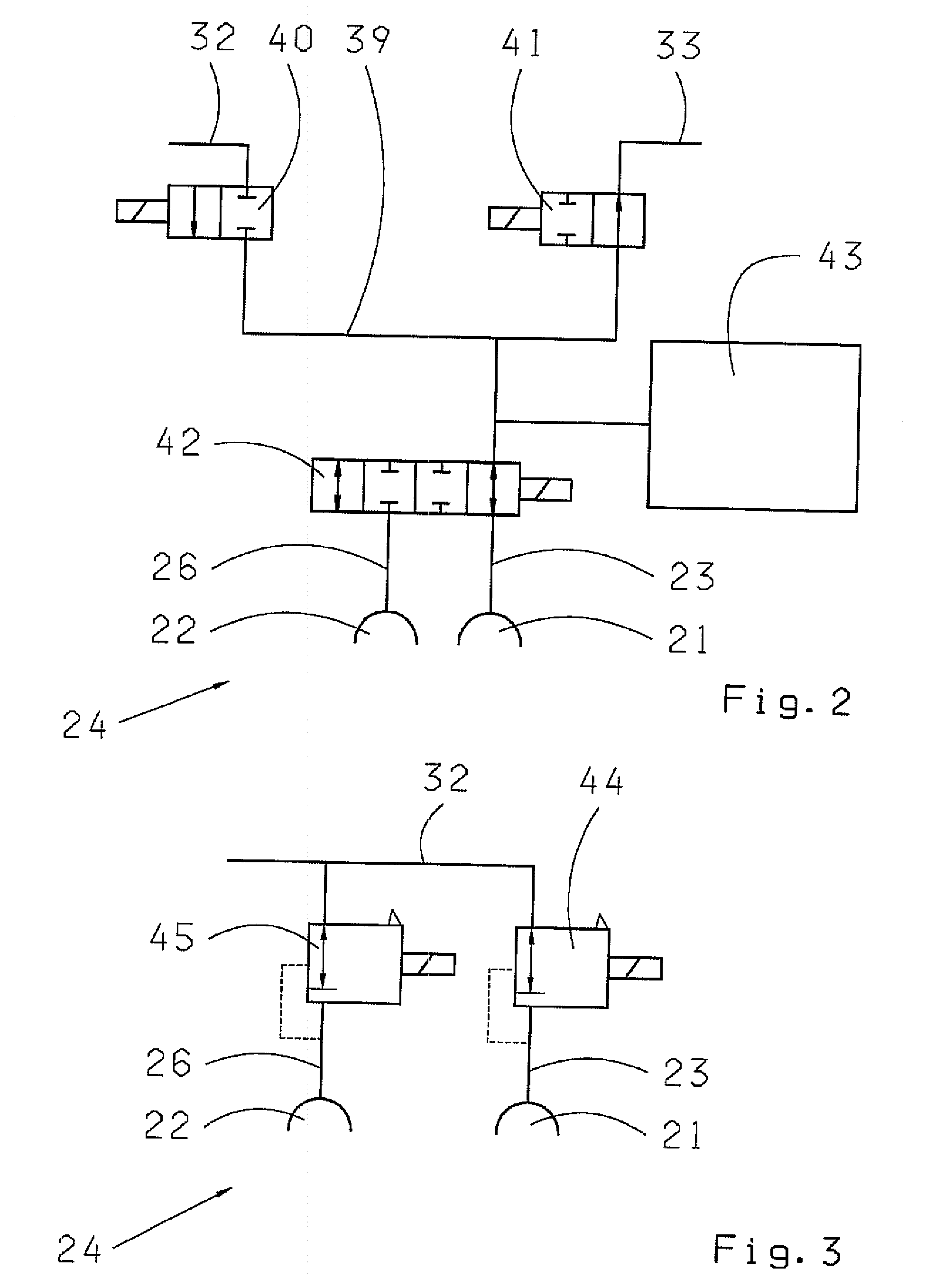

Elevator door drive device

An elevator door drive device, which opens and closes at least one car door leaf and a corresponding shaft door leaf, includes a coupling mechanism mounted at the car door leaf for transmitting the car door leaf movement to the shaft door leaf with two parallel entraining runners mounted on pivotable adjusting elements. The spacing between the runners is adjustable and a drive unit transmits closing and opening movements to the car door leaf by way of a drive apparatus that leads the entraining runners to a coupling element at the shaft door leaf before the start of the opening movement and moves them away from the coupling element after the end of the closing movement. The pivotable adjusting elements, during opening or closing the door leaf are blocked by means of a catch acting in both pivot directions.

Owner:INVENTIO AG

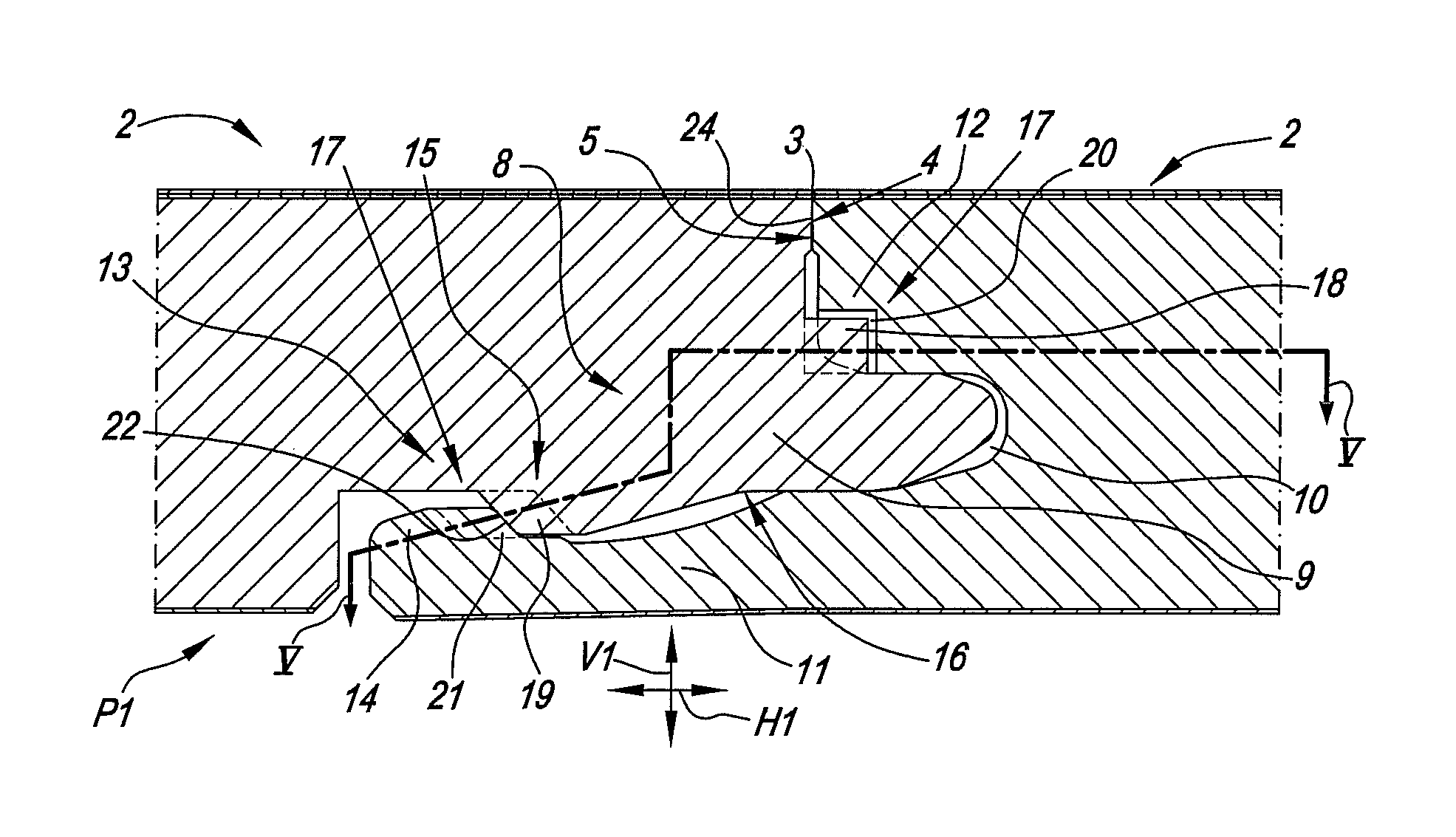

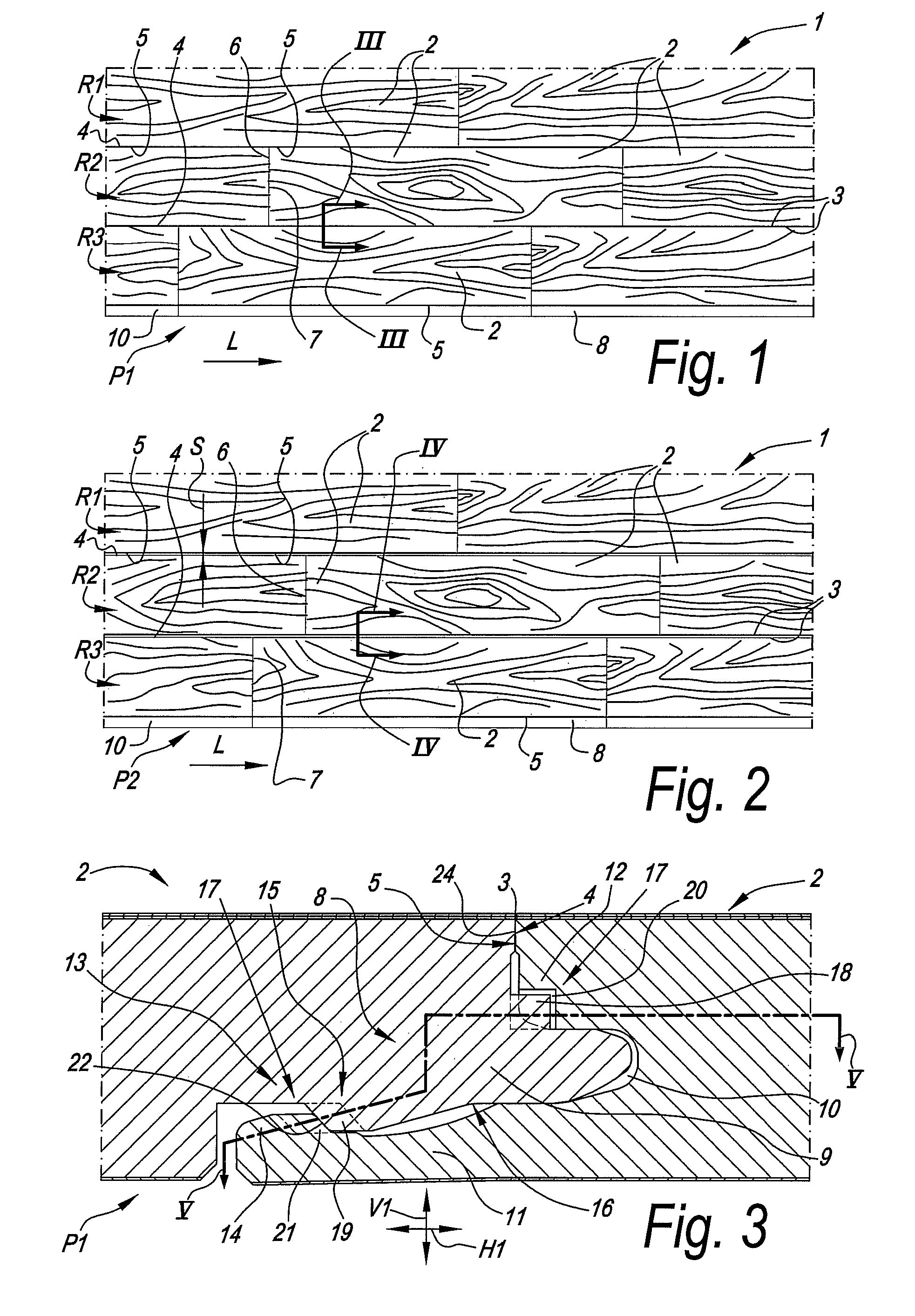

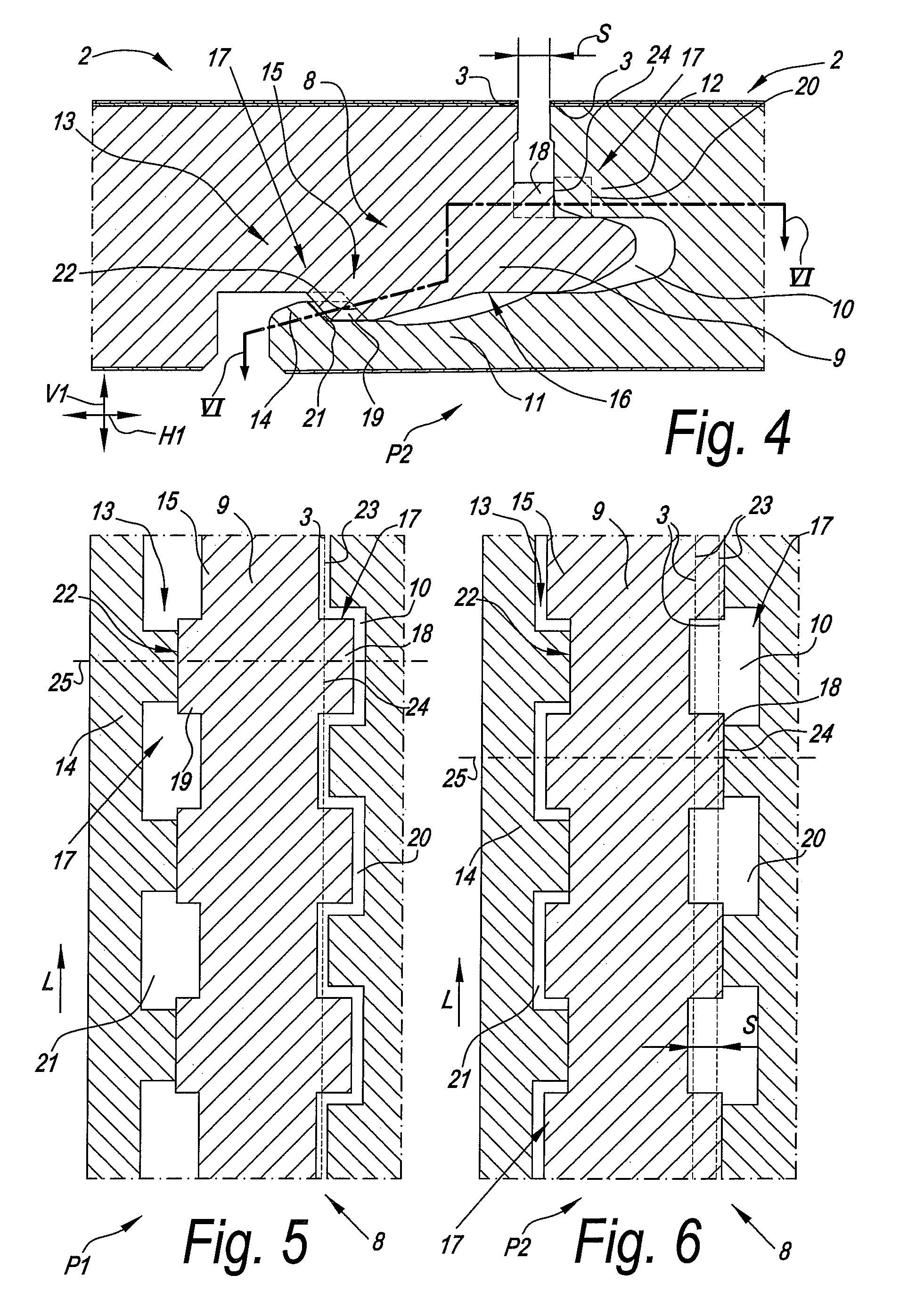

Floor panels, floor covering composed thereof, and method for manufacturing such floor panels

Floor panel comprising coupling parts enabling two floor panels to adopt two or more different mutually locked positions (P1-P2) when coupled, wherein the two or more mutual positions (P1-P2) differ from each other in that they, at the coupled sides, define two or more different distances (S) between the upper side edges of the floor panels, and adapter elements are provided with the coupling parts, so that the use or non-use of these adapter elements enables setting the mutually locked position (P1-P2).

Owner:FLOORING IND LTD

Male/female tool coupling for rotary tools

InactiveUS20040213642A1Free playHigh precisionSleeve/socket jointsTransportation and packagingCouplingEngineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

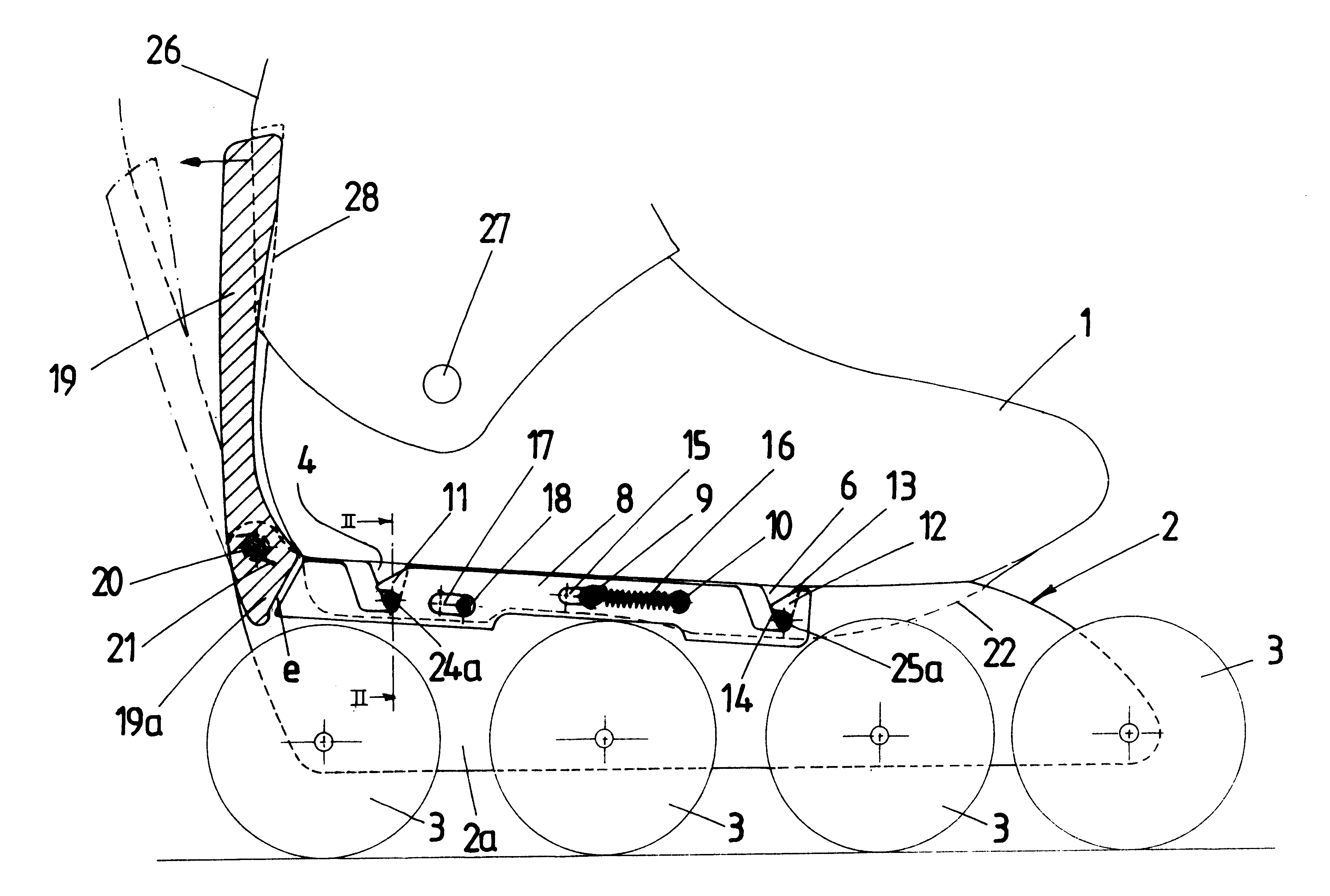

Roller skate with removable boot

Roller skate comprising a chassis (2) equipped with rollers (3) and a boot (1) attached removably to the chassis at four points by catching and locking. Catching and locking are achieved automatically and simultaneously at all of the attachment points using a common element (8) subject to the action of an elastic means (16). Unlocking is achieved using a lever (19) articulated to the rear of the chassis and which can be used as a handle when putting the chassis on.

Owner:SKIS ROSSIGNOL

Tubular medical instrument

The invention relates to a tubular medical instrument having a hollow shaft, a handle equipped with at least two gripping members and positioned on the proximal end of the shaft, and at least one push-pull rod that is mounted in the hollow shaft and has a tool consisting of at least two jaw members. For opening and closing at least one jaw member of the tool, said push-pull rod can be coupled with at last one rotatable gripping member of the handle, and the hollow shaft and handle can be releasably connected to one another by means of a coupling mechanism. To create a coupling mechanism that is simple to operate, it is proposed with the invention that the coupling mechanism should be configured as a combined clamping and snap-on device.

Owner:KARL STORZ GMBH & CO KG

Mechanism for bedding a receiver frame and/or a barrel in a stock of a firearm

The present invention relates to a mechanism for bedding a receiver frame (3) and / or a barrel (1) in a stock (2) of a firearm, the mechanism having a bearing component (8) which can be attached to the stock (2) and which, on its upper surface, has a bearing surface (10,11) for bearing the receiver frame (3) and / or the barrel (1). To ensure permanent and reproducibly accurate positioning, the lower surface of the bearing component (8) comprises a guide profile (9) for seating the bearing component (8) free from play in the stock (2).

Owner:BLASER FINANZHLDG

Wearing parts system for detachable fitting of wearing parts for the tool of a cultivating machine

ActiveUS20060143953A1Reduce wearGood stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention relates to a wearing parts system (1) intended for the tool of a tilling machine of the type which comprises a holder part (3), having a front end part (8), and an exchangeable wearing and / or replacement part (2), arranged over this end part and comprising a hood-shaped (6) hollow (7) which, when the wearing part (2) is fitted in place, is designed to grip over the end part and is fixed thereto by means of at least one locking device (27) placed through interacting openings (28), the end part and the hollow having front, rear and collateral contact zones (9, 22, 23), each comprising contact faces (10, 25, 26), disposed one on the holder part and one on the wearing part, for the absorption of acting vertical, horizontal and collateral forces Fx, Fy and Fz. The contact faces (25, 26) are designed to interact so as, on the one hand, to limit the pushing-on of the wearing part over the holder part and, on the other hand, to ensure that the contact between the contact faces will be made, primarily, at the common centre M0, of the two radii (of a recess and a projection) essentially in the horizontal plane YZ and secondarily, as the wear has progressed, symmetrically about this mid contact point as an increasingly large contact zone (22′, 23′).

Owner:COMBI WEAR PARTS AB

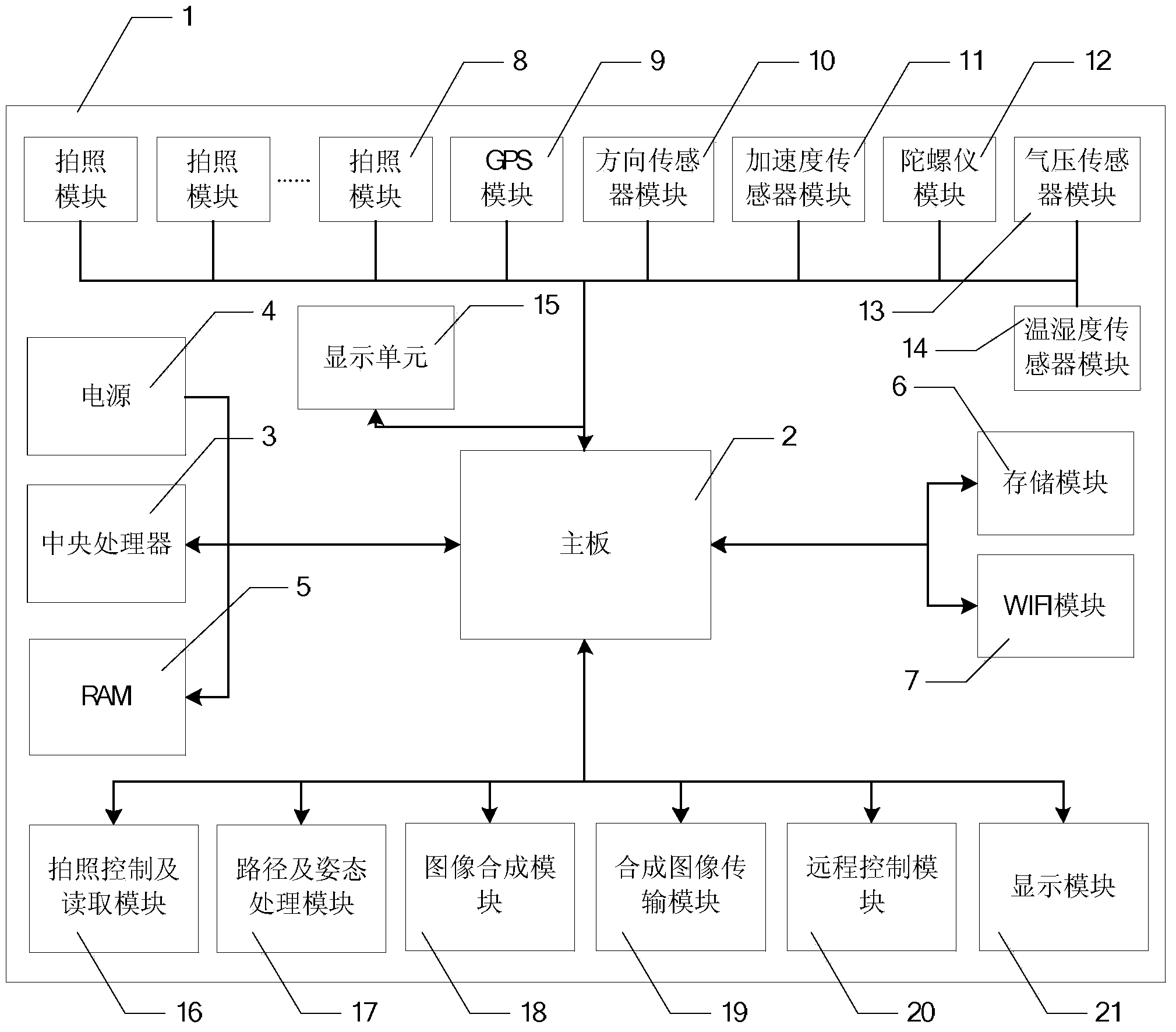

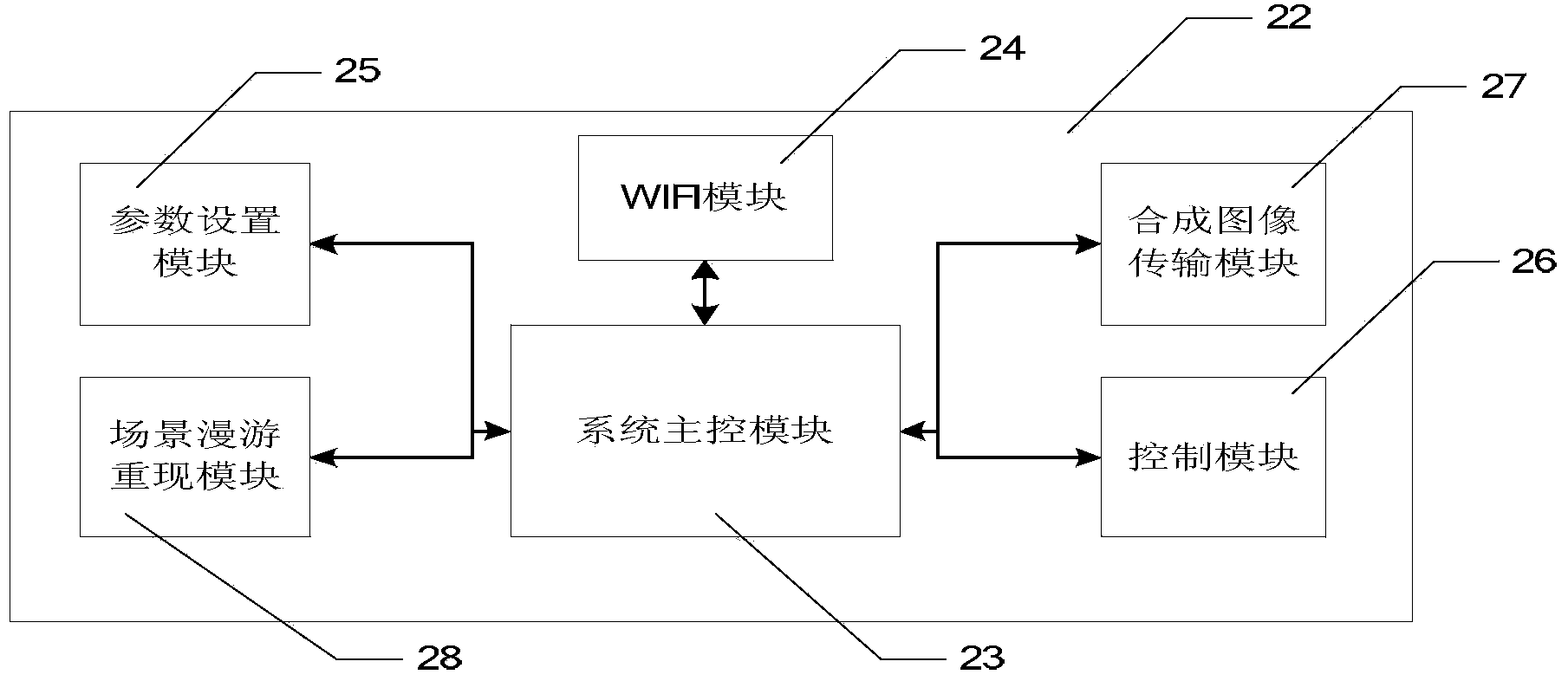

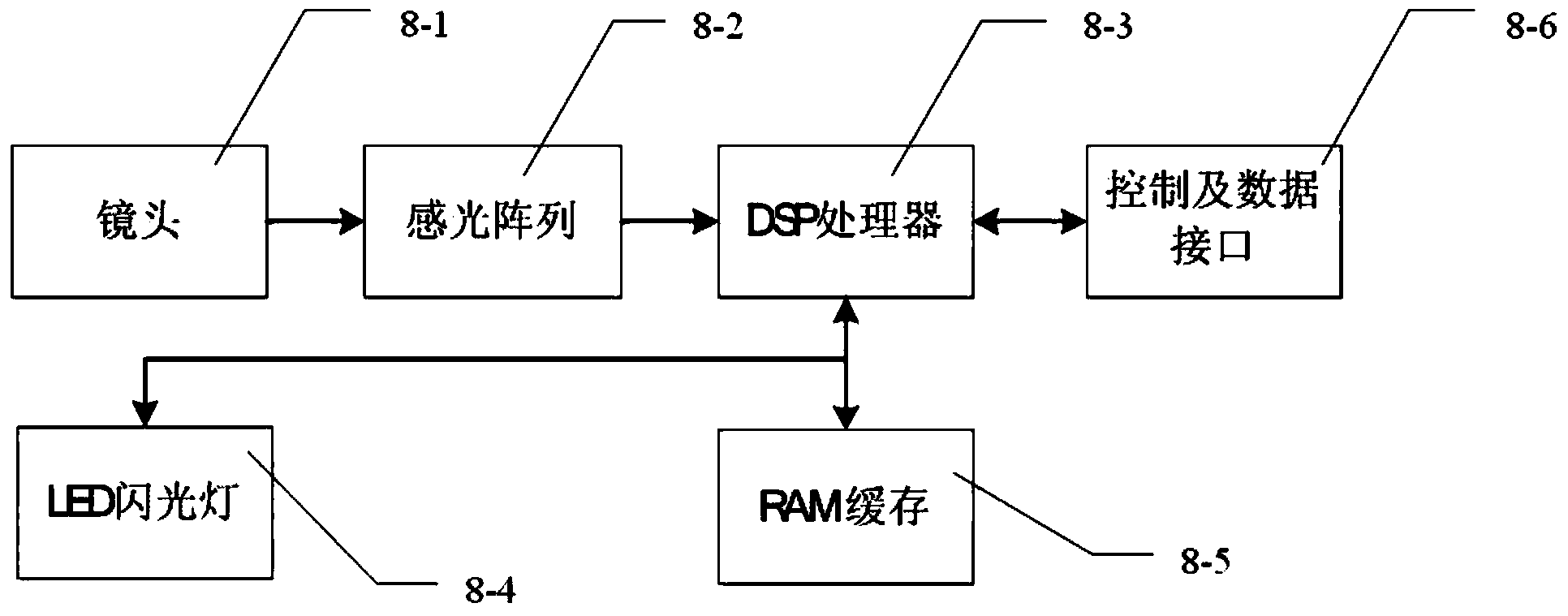

Portable scene shooting device

InactiveCN103763470AEasy accessFree playTelevision system detailsColor television detailsGyroscopeMoisture sensor

The invention discloses a portable scene shooting device. The portable scene shooting device comprises at least two shooting modules for carrying out scene shooting, a mainboard, a central processing unit, a power module, an RAM, a storage module, a WIFI module I, a GPS module, a position measurer, an air pressure sensor module, a temperature and humidity sensor module and a display unit (15), wherein the mainboard is connected with the shooting modules, and the central processing unit, the power module, the RAM, the storage module, the WIFI module I, the GPS module, the position measurer, the air pressure sensor module, the temperature and humidity sensor module and the display unit (15) are all connected with the mainboard. The position measurer comprises a direction sensor module, an acceleration sensor module and a gyroscope module. The power module is used for supplying power to the mainboard. The portable scene shooting device has the advantages of being convenient to carry, small in size, low in cost, free of restriction of the GPS, and easy and convenient to use.

Owner:CHONGQING LUWEI SCI & TECH DEV

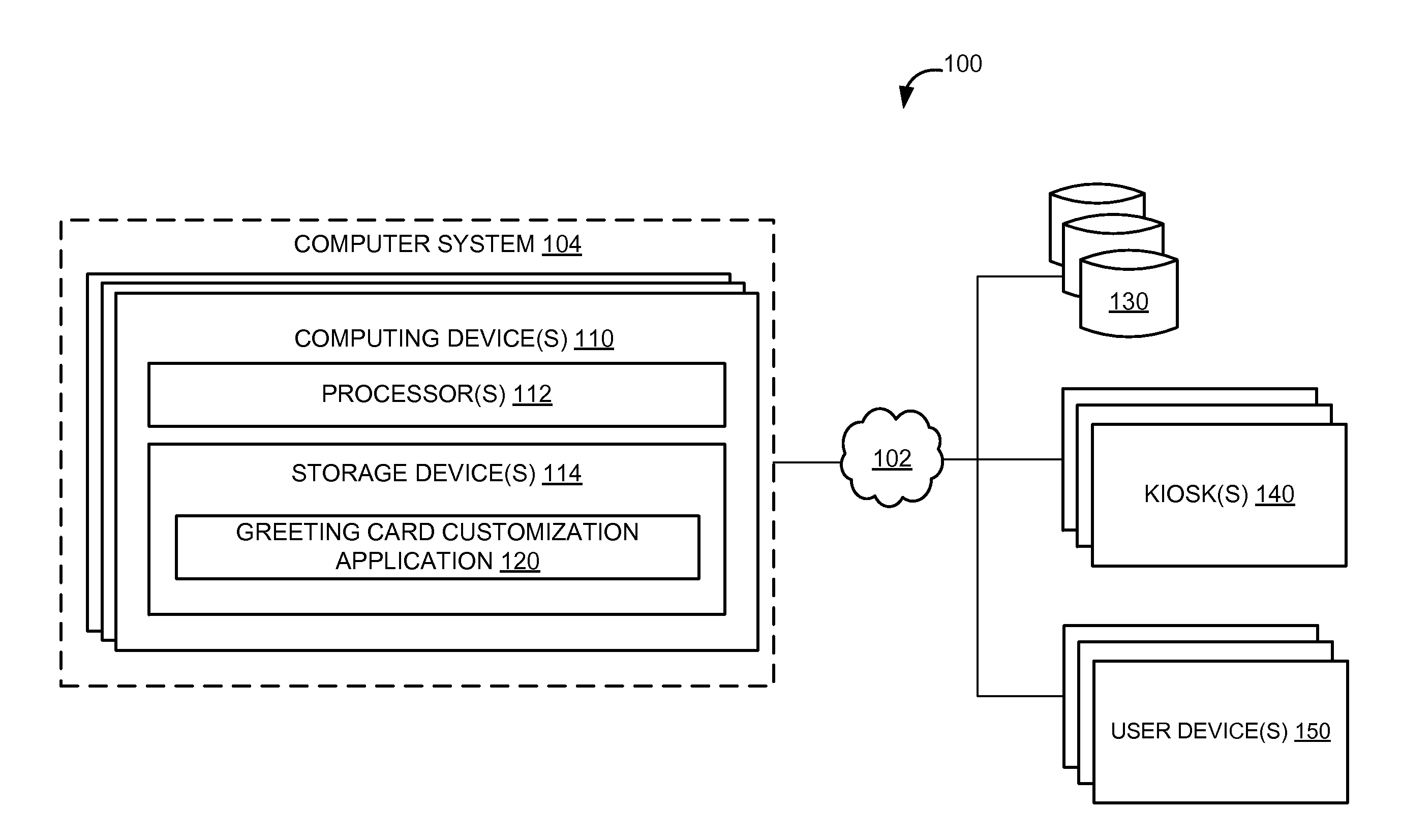

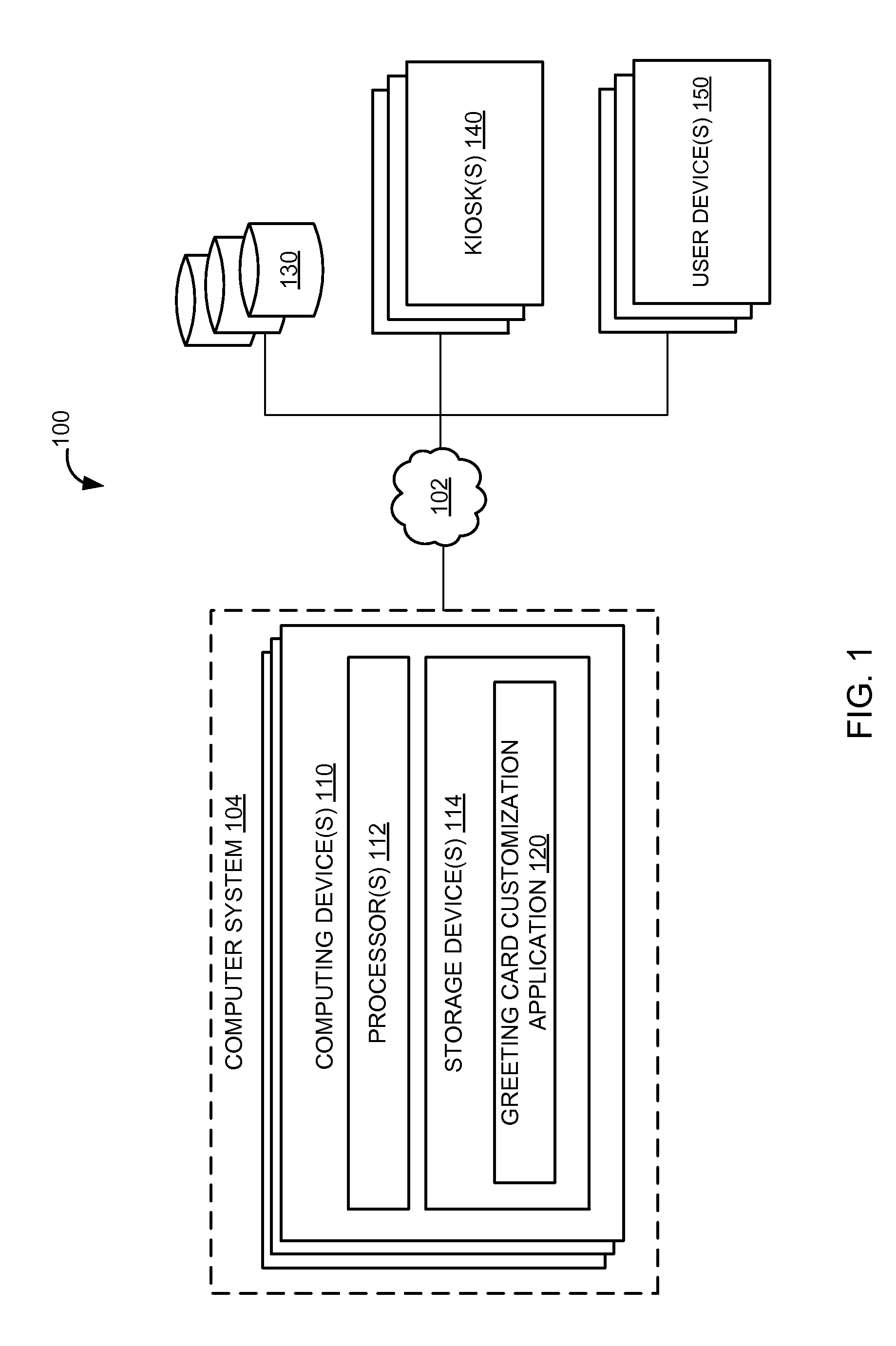

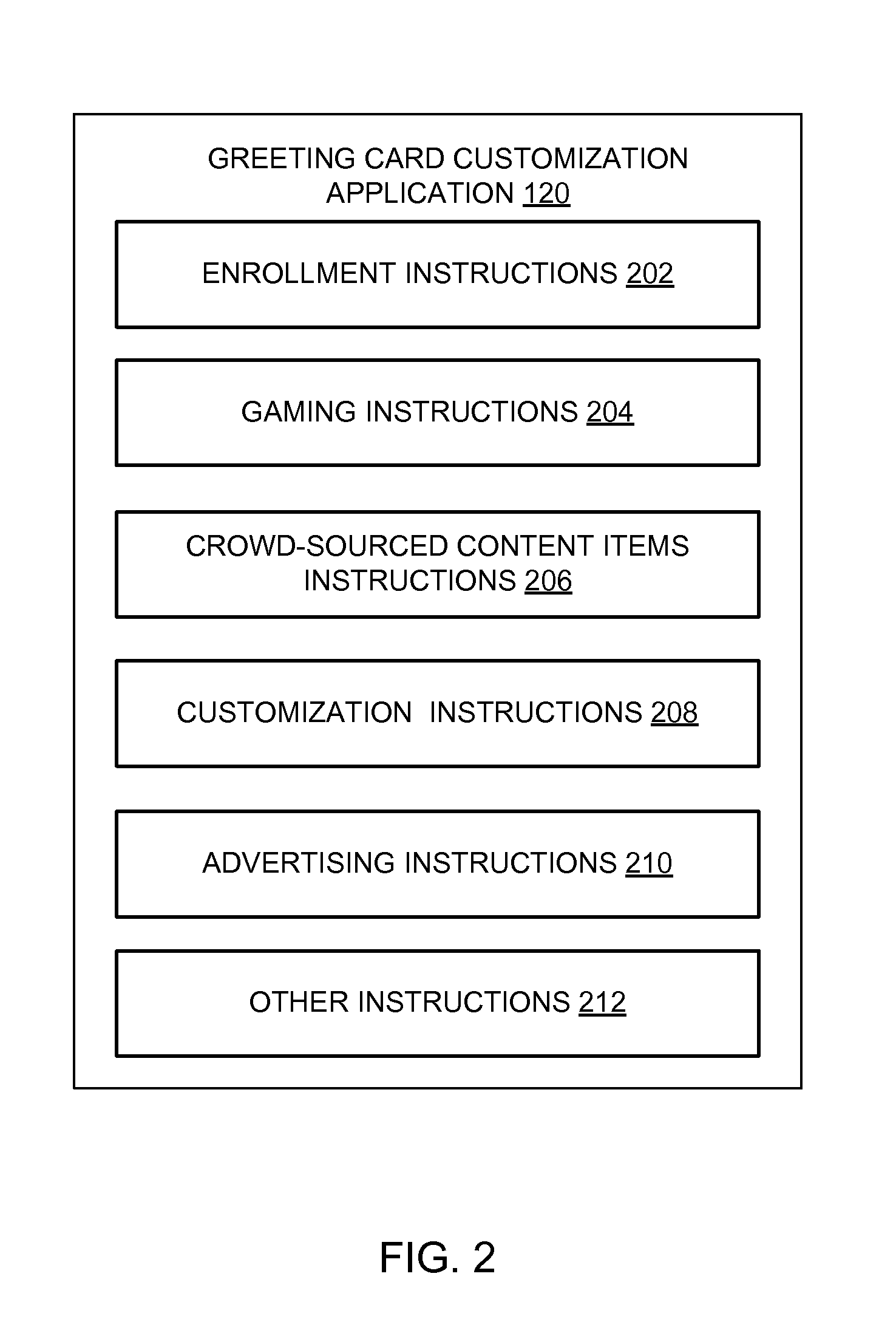

User customized greeting card design system with portal for crowd-sourced artwork

ActiveUS20150310520A1Minimize waiting timeFree playOther printing matterDiscounts/incentivesCrowd sourcingCrowds

The invention relates to systems and methods of providing a user customized card design system with a portal used to receive crowd-sourced artwork that users may select to include in customized greeting cards, games for bonuses that can be applied to customized greeting cards, and greeting card kiosks that may have different portions each having a dedicated functionality. The crowd-sourced content items may include items that are provided by various entities so that others may use the items in their own greeting cards. The crowd-sourced content items may be localized such that crowd-sourced content items within a proximity of a given location may be used to customize greeting cards at or in association with the given location. The bonuses may be won during gameplay and may include free or discounted customized greeting cards, free or discounted customization options, and / or other value.

Owner:CARD ISLE

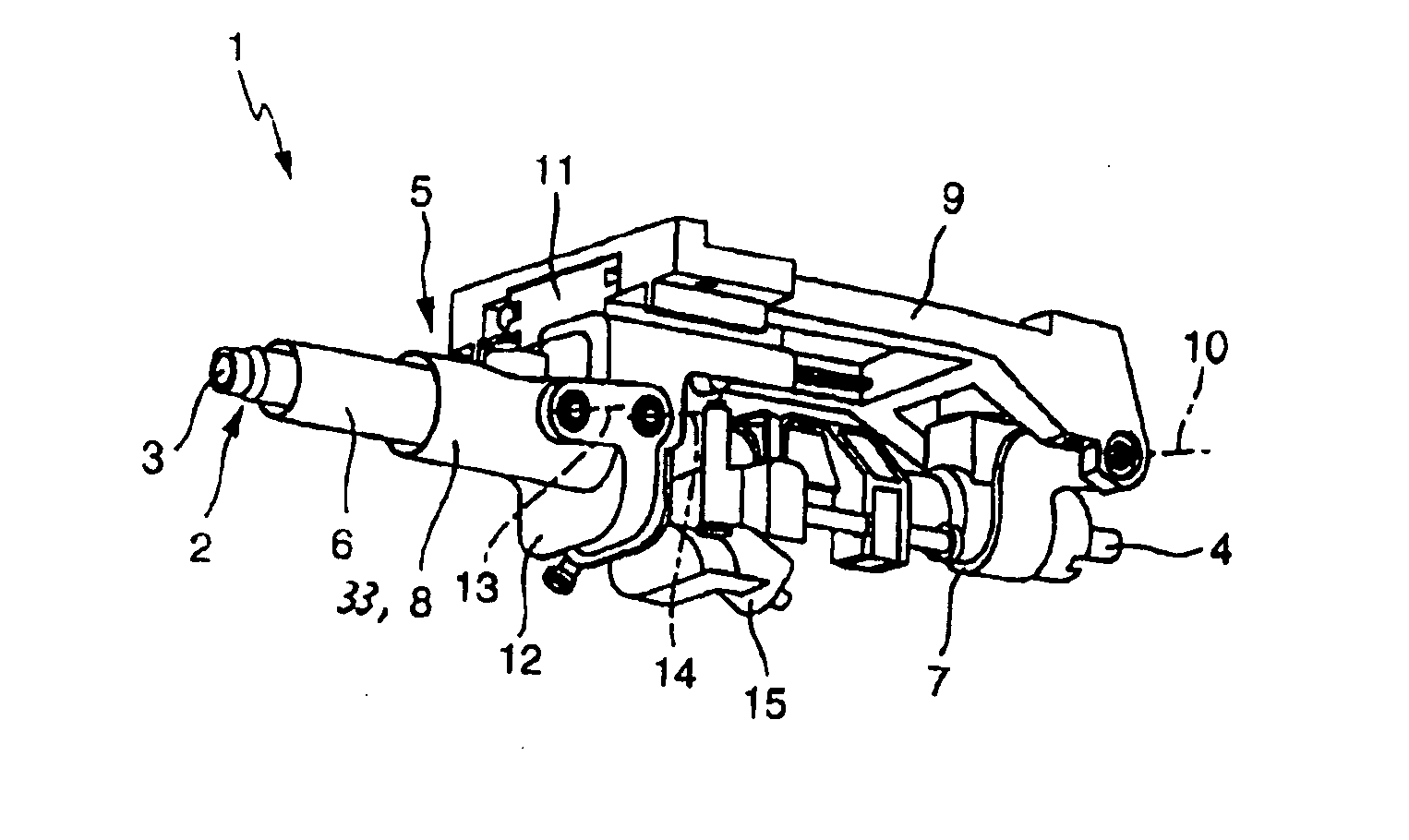

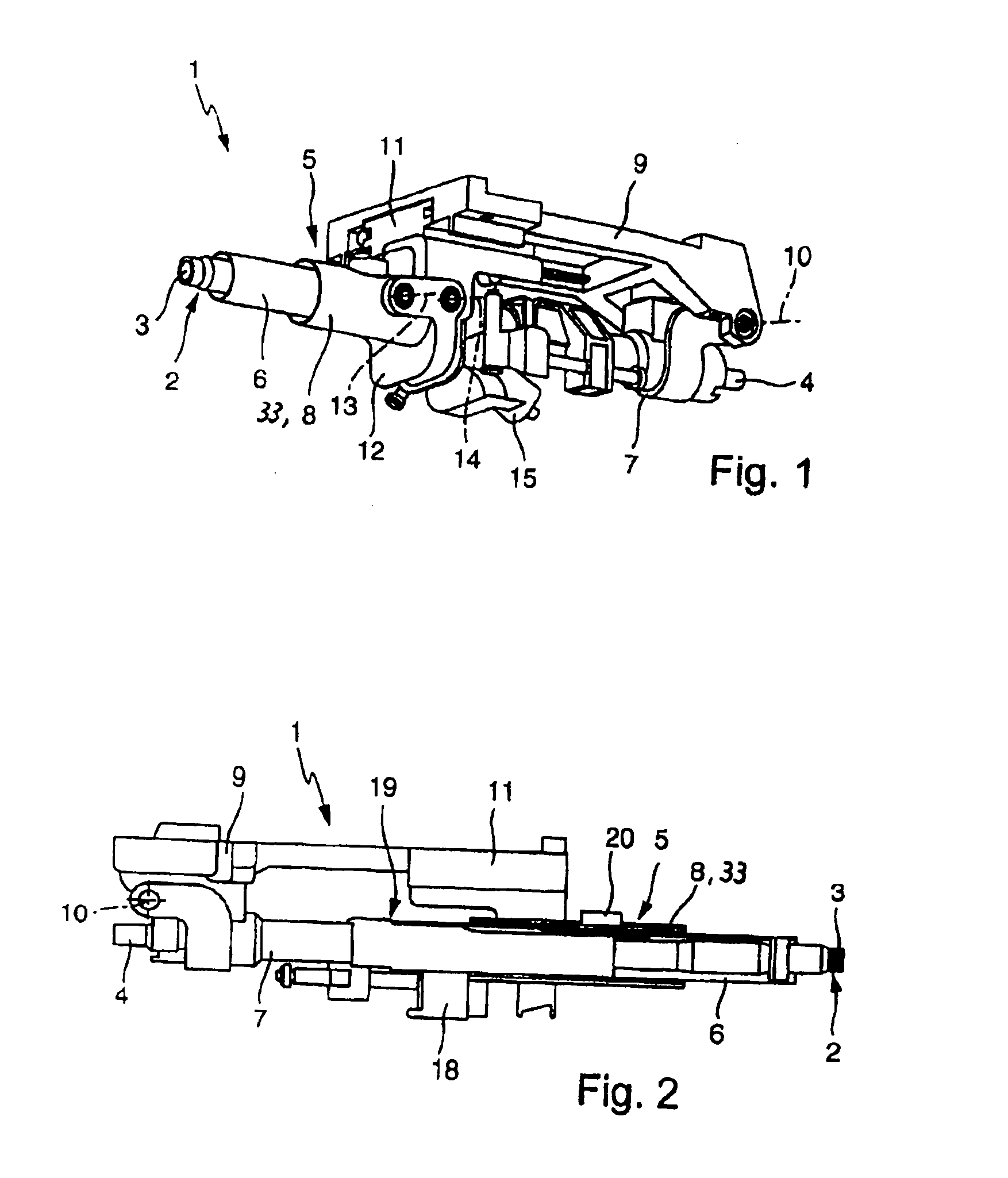

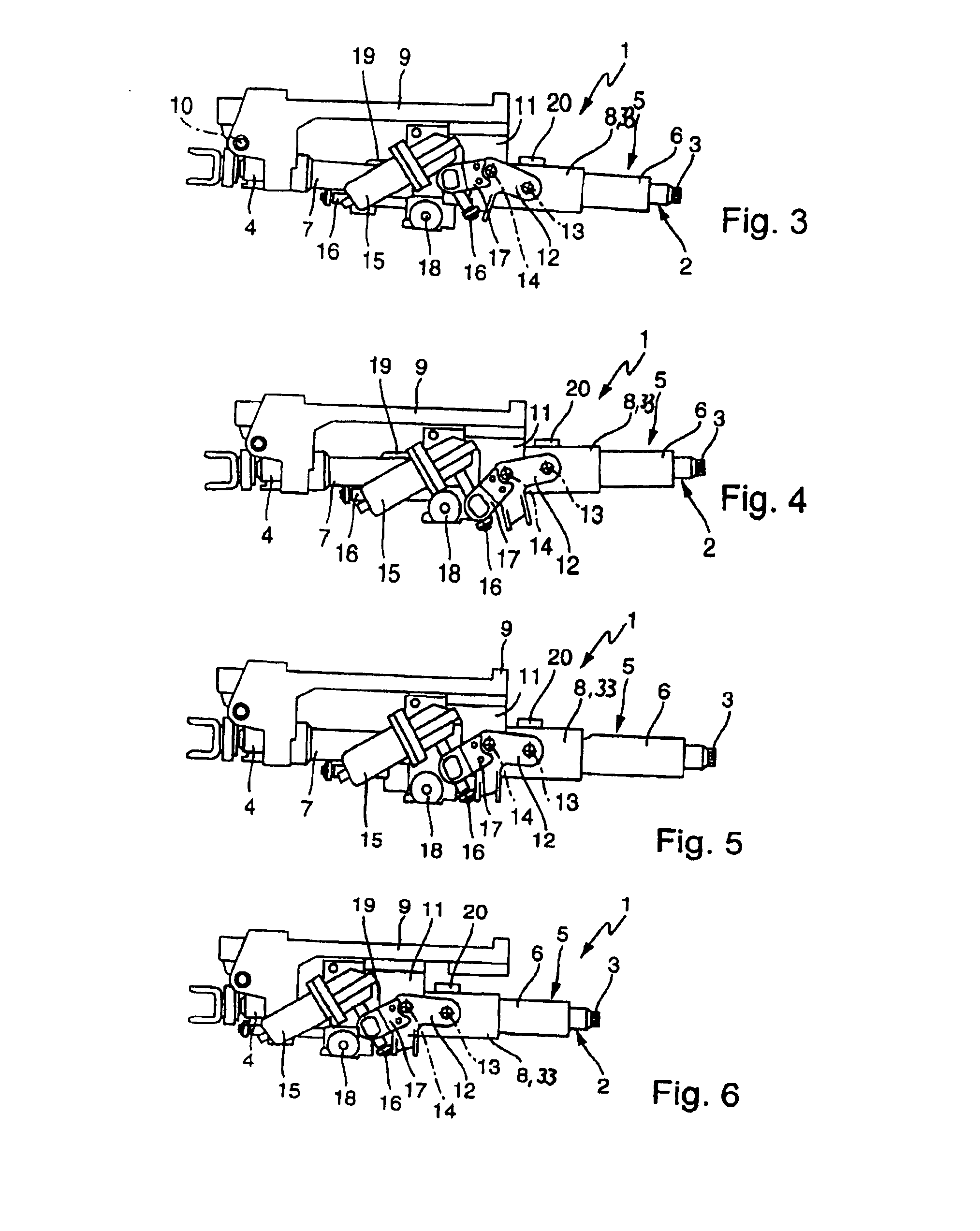

Safety Steering Column for a Motor Vehicle

A safety steering column (1) is provided for a motor vehicle, which has a telescopic steering spindle (2) with an upper spindle part (3) which is near to the steering wheel and a lower spindle part (4) which is remote from the steering wheel, and is rotatably mounted in a jacket tube (5). The jacket tube (5) is of telescopic design and has an upper tube part (6) which is near to the steering wheel and a lower tube part (7) which is remote from the steering wheel, the lower tube part (7) being mounted so as to be pivotable about a first axis (10) on a bracket (9) which can be arranged fixed to the vehicle. In addition, an adjustment device which serves to vertically adjust the safety steering column (1) and has an actuating element (12) which is mounted so as to be pivotable about a second axis (14) is provided. The safety steering column (1) is distinguished by the fact that the actuating element (12) is coupled to the jacket tube (5) by means of a force transmitting element (33) which can be adjusted in a translatory fashion in the axial direction relative to the jacket tube (5).

Owner:DAIMLER AG

Back rest for a chair

InactiveUS7490901B2Simple configurationIncrease stiffnessStoolsAdjustable chairsRotational axisPull force

A back rest for a chair with a back support and a back surface secured to the back support and able to swivel about a two-axis joint. The joint has a joint plate connected to the back surface, an element made of an elastic material that supports the joint in a ground position, and a chamber to accommodate the elastic element, connected to the back support. The joint plate is arranged in the receiving chamber between two elements made from an elastic material, holding the joint in a ground position and each being supported against the receiving chamber, and it can swivel about the two swivel axes. When the joint is placed under load, the two elastic elements are only subjected to compression. There are no tension-loaded connections which break under loading and can result in the joint falling apart.

Owner:SEDUS STOLL

Toothed tool coupling for rotating a rotary tool

A driven tool includes a driven part which is rotatably driven by a drive part. The driven part and the drive part are coaxially arranged one inside of the other. The drive part and the driven part are conical as viewed in a longitudinal section plane containing the axis. The driven part includes driven teeth projecting generally radially with respect to the axis and received in respective radially-open recesses formed in the drive part. Each of the driven teeth makes contact with a wall of the respective recess at first and second contact places which are respectively situated on opposite sides of a generally radial line of symmetry of the driven tooth. The contact places are operable to transmit a drive force from the drive part to the driven part in respective directions of rotation. A driving angle in the range of -5° to +45° is formed at each contact place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

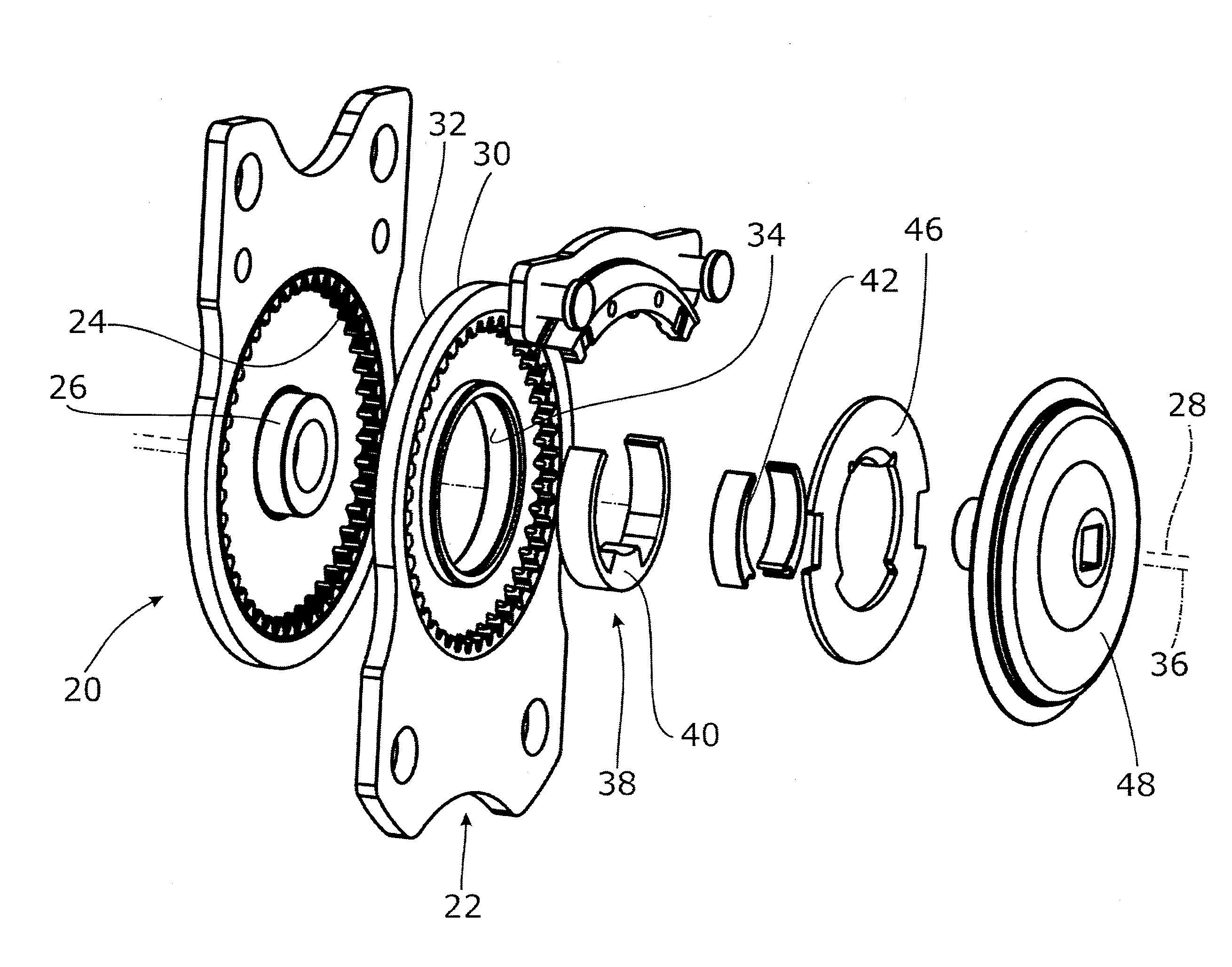

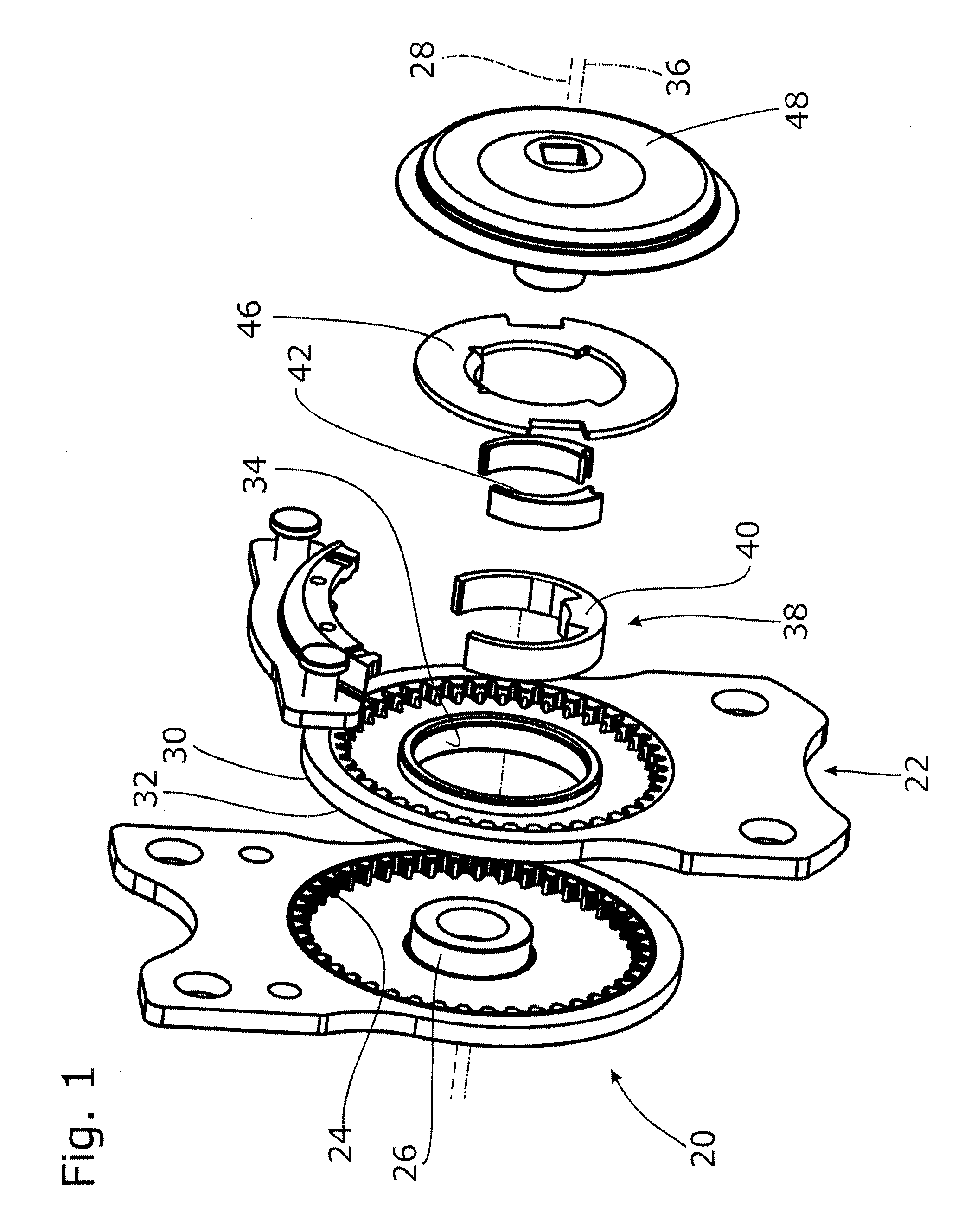

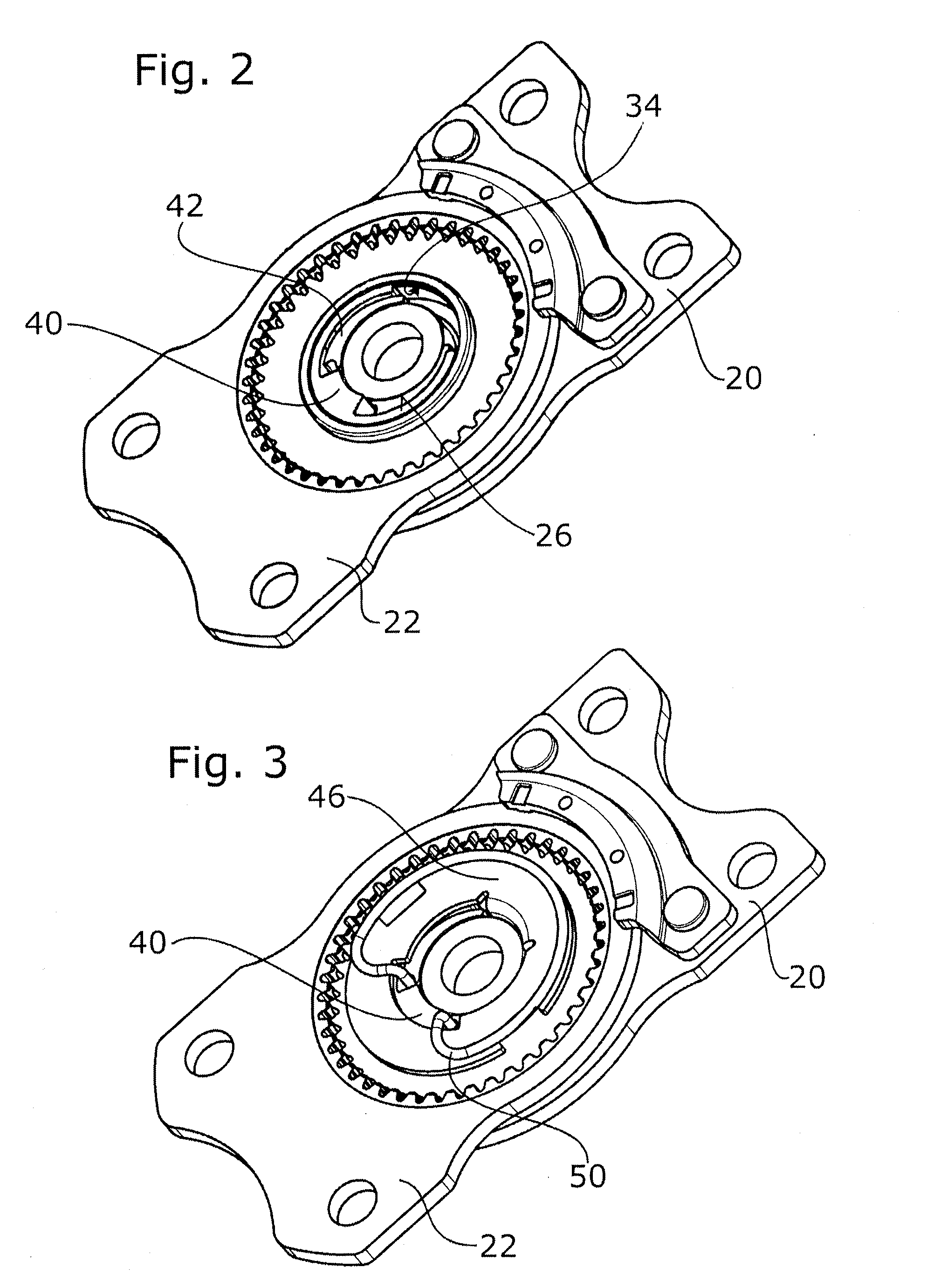

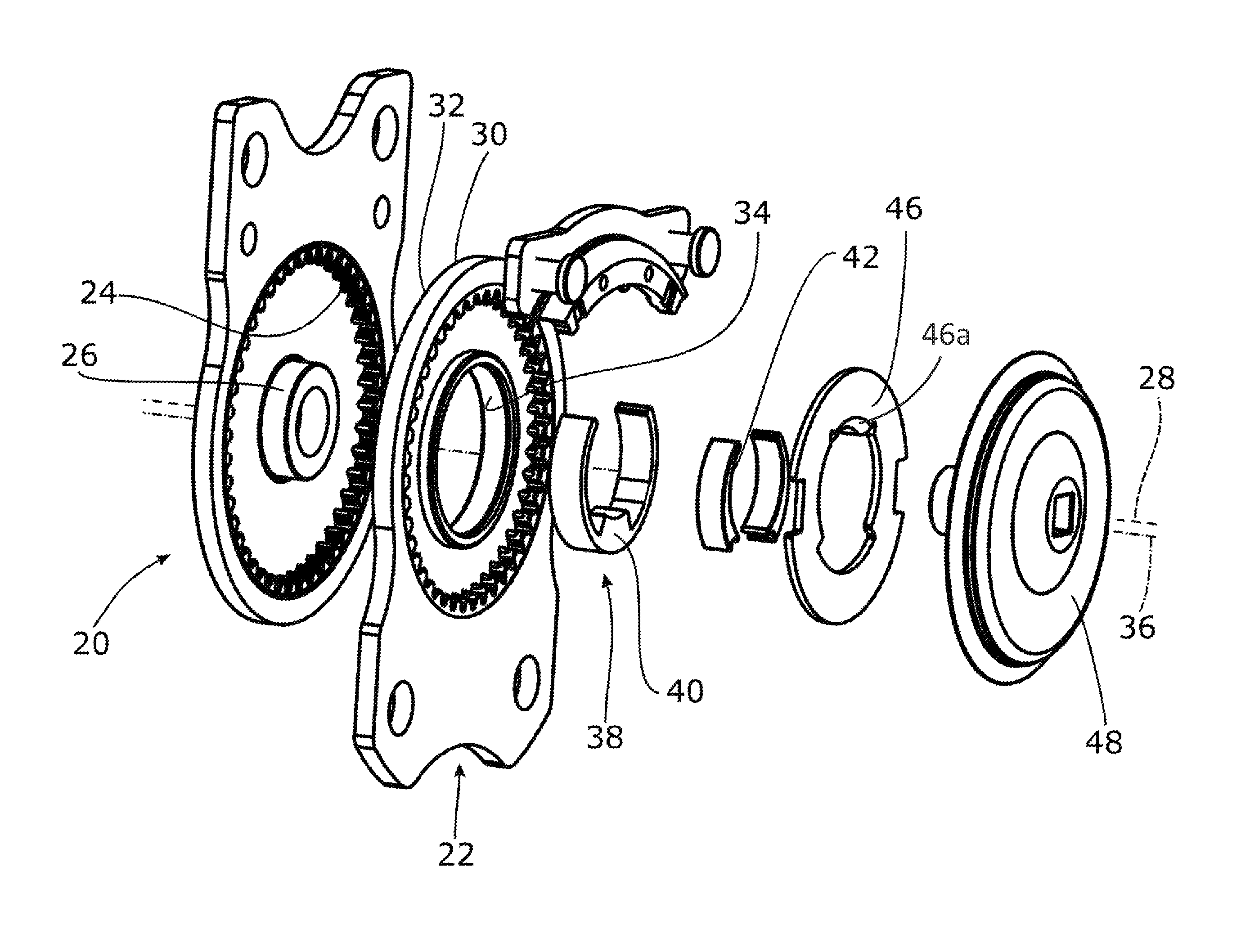

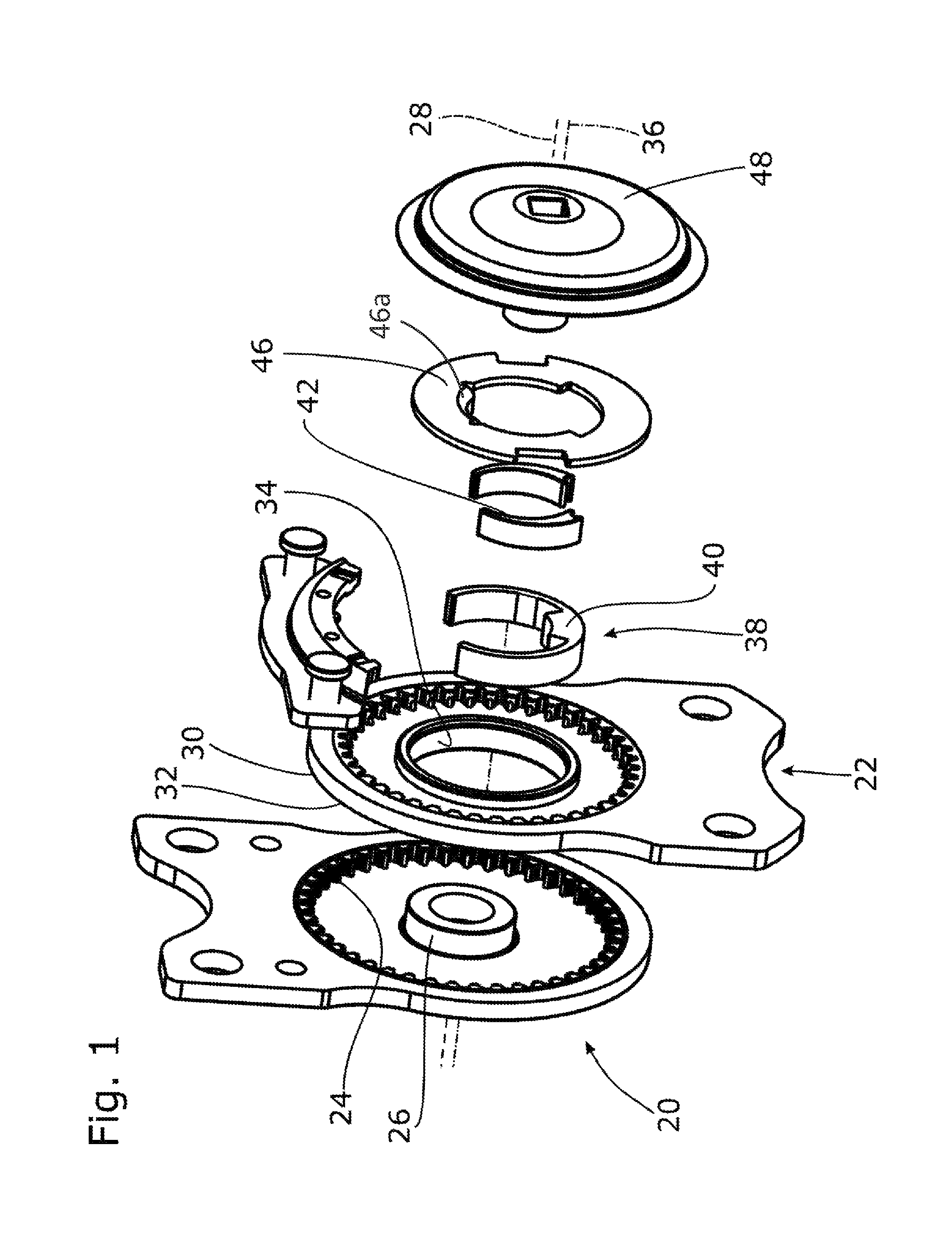

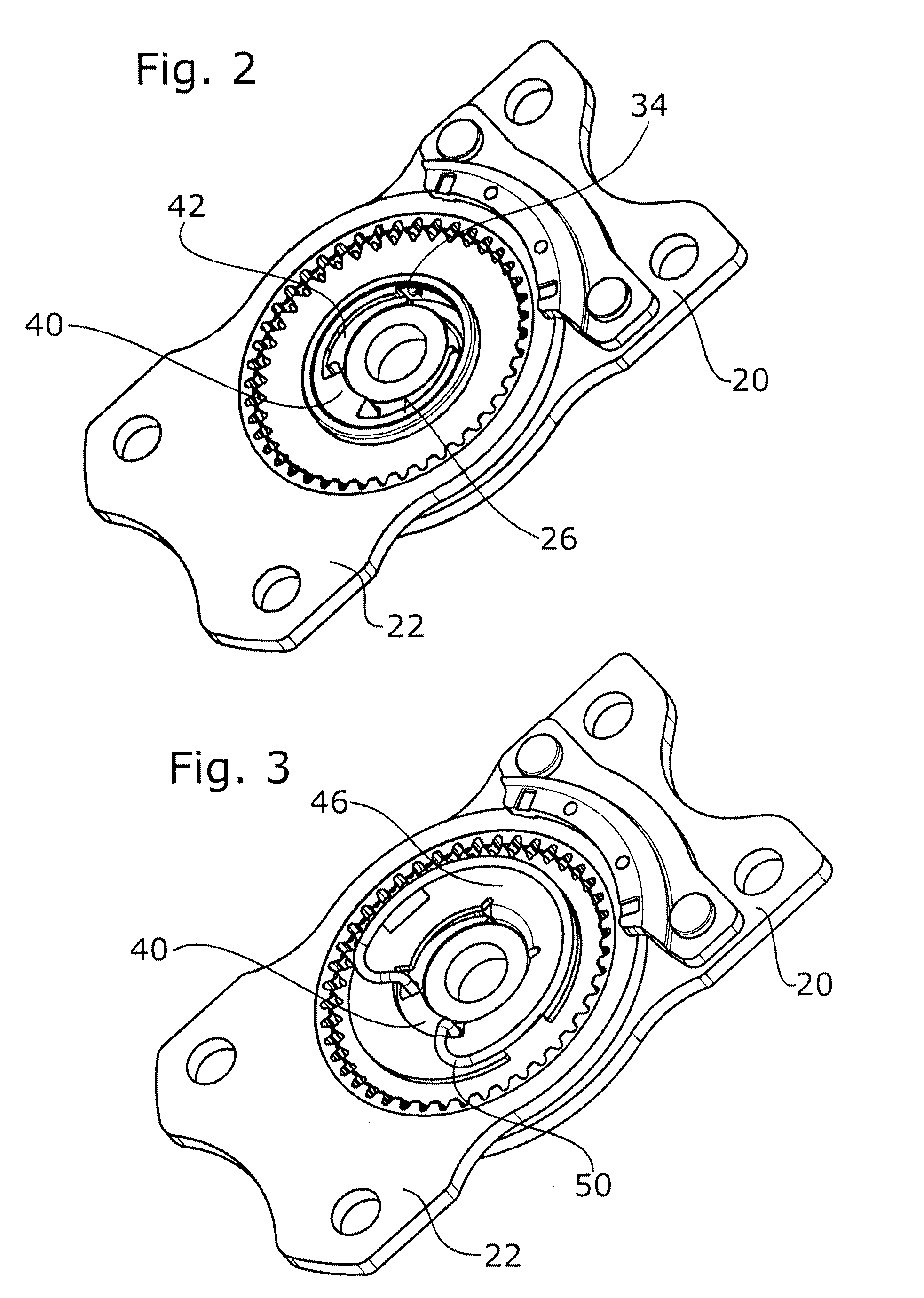

Eccentric joint fitting for a vehicle seat

A wobble joint fitting for a vehicle seat has a first joint arm, which carries an internal gear and forms a first bearing surface, which are central to a main axis, and a second joint arm to which an eccentric gear is allocated, which comprises an externally toothed pinion and a second bearing surface. The pinion and the second bearing surface are central to an eccentric axis. An eccentric driving part is disposed in the area between the first bearing surface and the second bearing surface. Clamping parts, in a clamping state, displace the eccentric axis relative to the main axis. The eccentric driving part defines the eccentric. The rotary drive of the eccentric driving part causes a rotation of the pinion relative to the internal gear even without the clamping parts being present, wherein only play compensation is not obtained without the presence of the clamping parts.

Owner:KEIPER SEATING MECHANISMS CO LTD

Guidance of an optical scanning device

InactiveUS7216354B2Eliminate fitReduce vibration sensitivityDriving/moving recording headsRecord information storageRelative displacementData storing

An optical scanning device for reading data stored on a rotating recording medium having a scanning head; at least one guide device for guiding the scanning head along a predefined track; at least one bearing device connected to the scanning head for supporting the at least one guide device and having at least one elastic prestressing device to provide a static prestress on the at least one guide device to prestress the same and the at least one bearing device connected to the scanning head against each other to eliminate a relative displacement.

Owner:ROBERT BOSCH GMBH

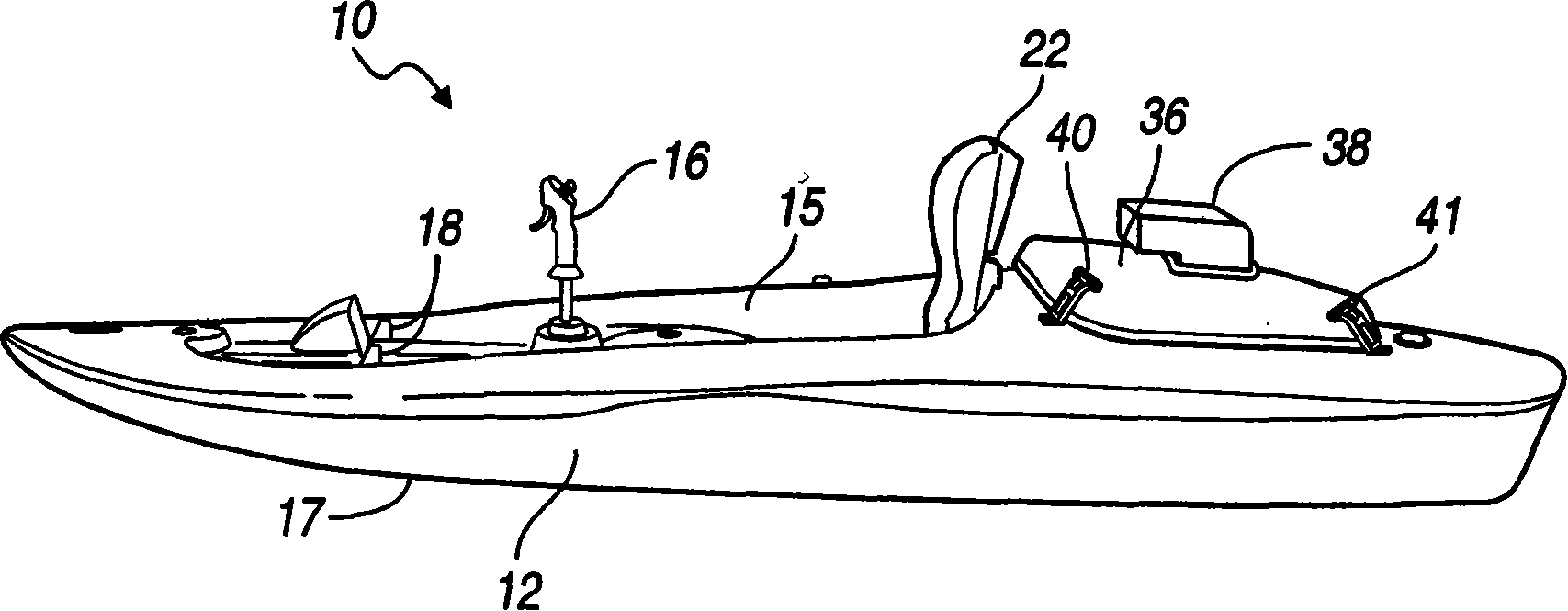

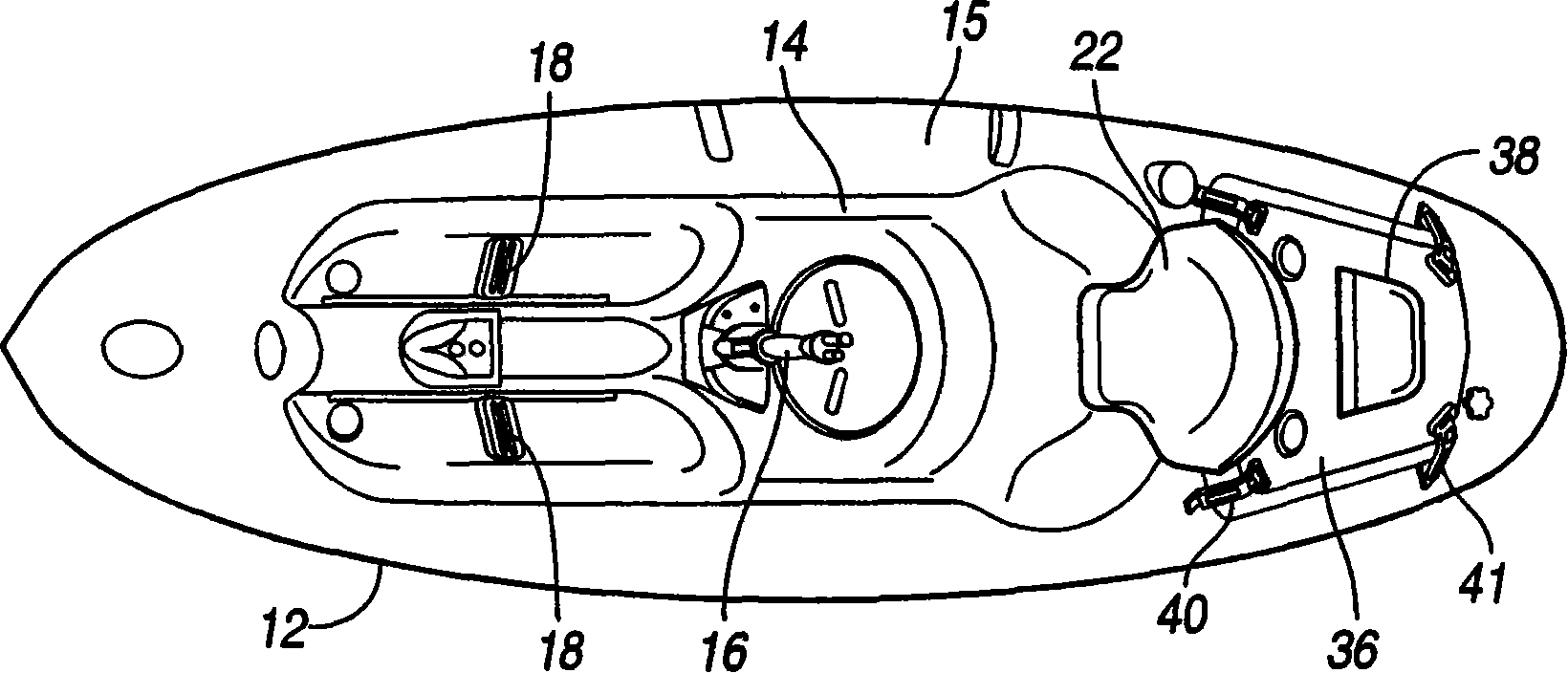

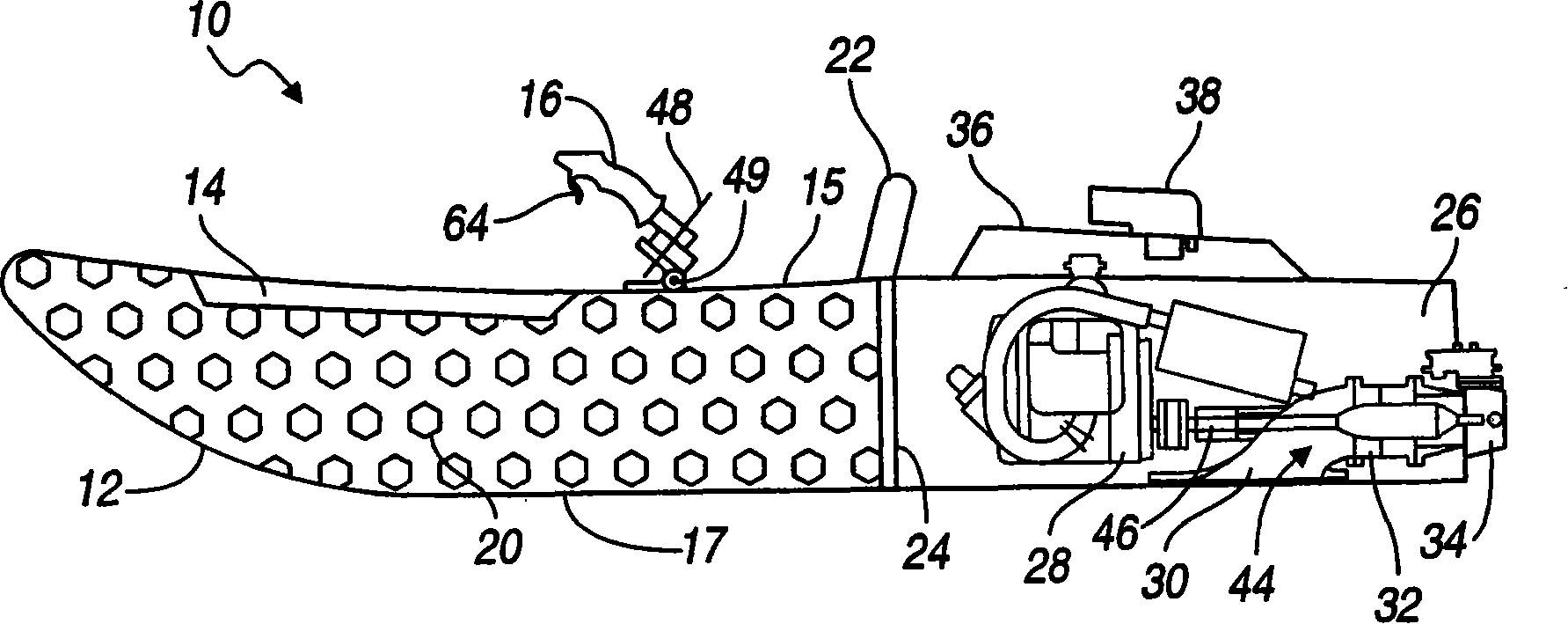

Water-spray type propulsion boat

InactiveCN101244761AEasy to start againImprove playbackNon-magnetic metal hullsPower plants being motor-drivenWater flowPropeller

The invention discloses a water jet propelled ship, comprising a sealed ship hull, an engine cabin and a control lever; wherein, the sealed ship hull comprises an upper surface and a lower surface; the engine cabin with a propelling and operating system is behind the sealed ship hull; water is introduced by a blade propeller of an engine of the system from a water inlet and ejected through the pressure applied by a direction-adjustable jet pipe; the control lever on the upper surface is used for controlling an engine accelerator and the direction of the jet pipe. With an engine propeller system of a kayak provided by the invention, drivers can conveniently, freely and leisurely drive the ship for amusement; the ship hull is sealed, the buoyancy is strong and the vibration is low; water can not enter into the engine cabin in case the ship is straightly sunk in the water or overturned, thereby ensuring normal operation of the engine when the ship is turned to upright or normal position and floated on the water.

Owner:芮应睿

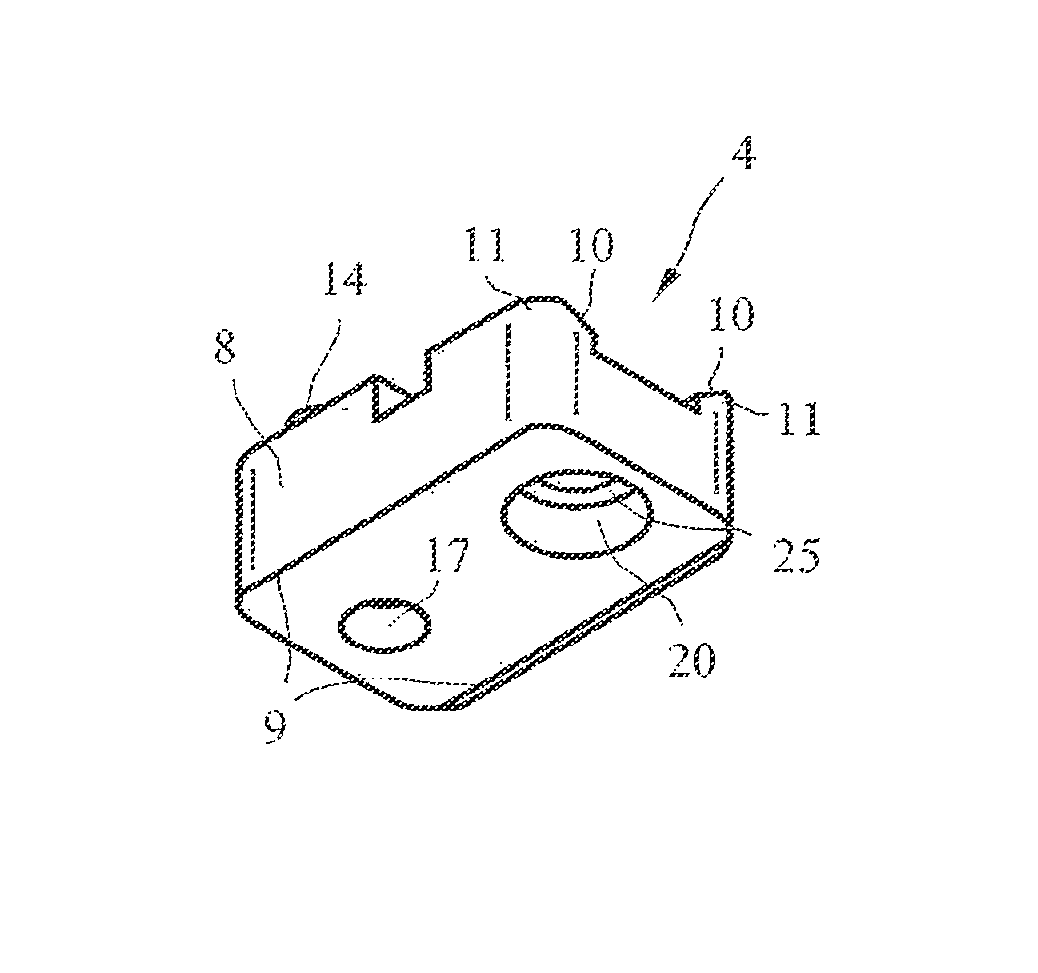

Mechanism for bedding a receiver frame and/or a barrel in a stock of a firearm

The present invention relates to a mechanism for bedding a receiver frame (3) and / or a barrel (1) in a stock (2) of a firearm, the mechanism having a bearing component (8) which can be attached to the stock (2) and which, on its upper surface, has a bearing surface (10,11) for bearing the receiver frame (3) and / or the barrel (1). To ensure permanent and reproducibly accurate positioning, the lower surface of the bearing component (8) comprises a guide profile (9) for seating the bearing component (8) free from play in the stock (2).

Owner:BLASER FINANZHLDG

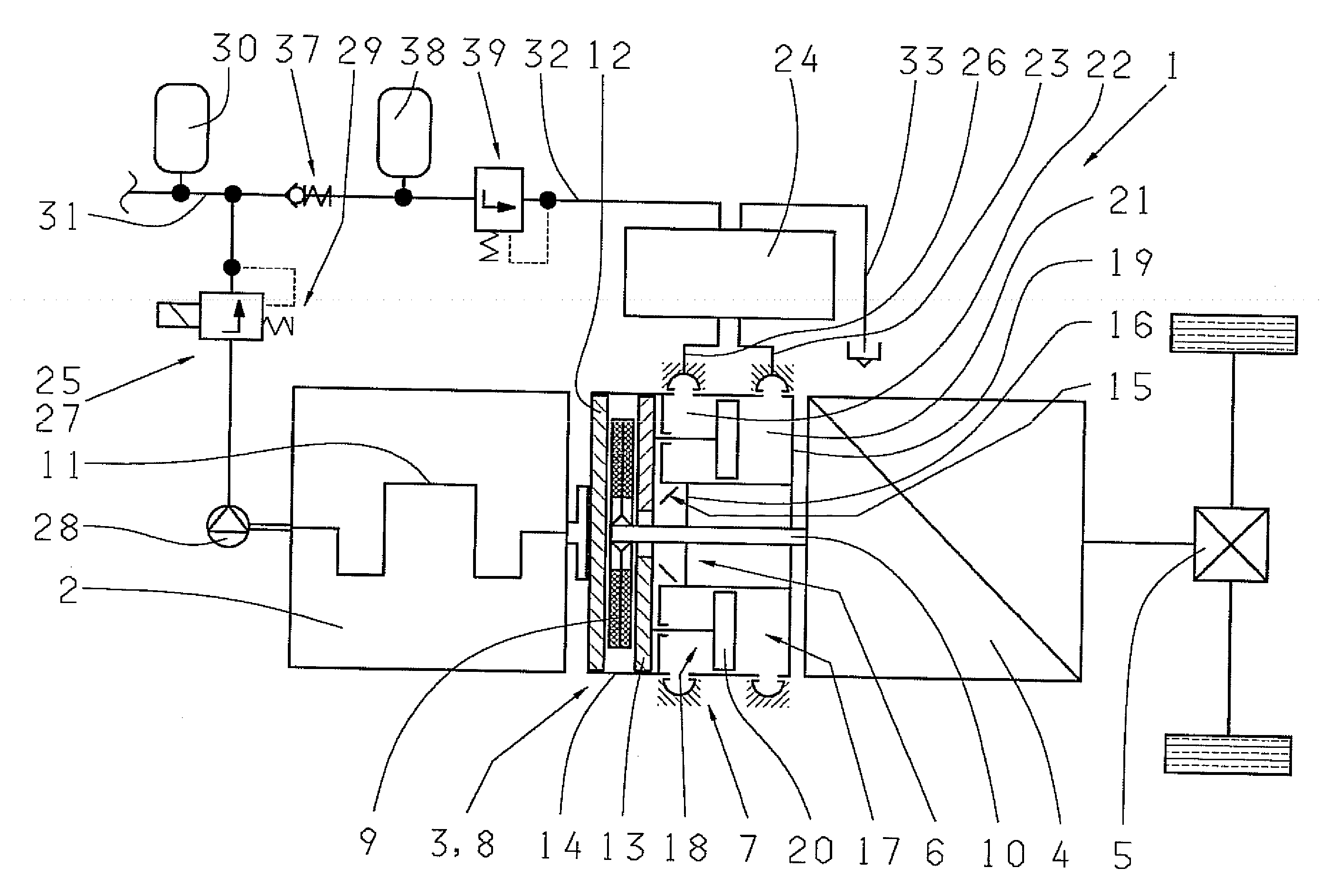

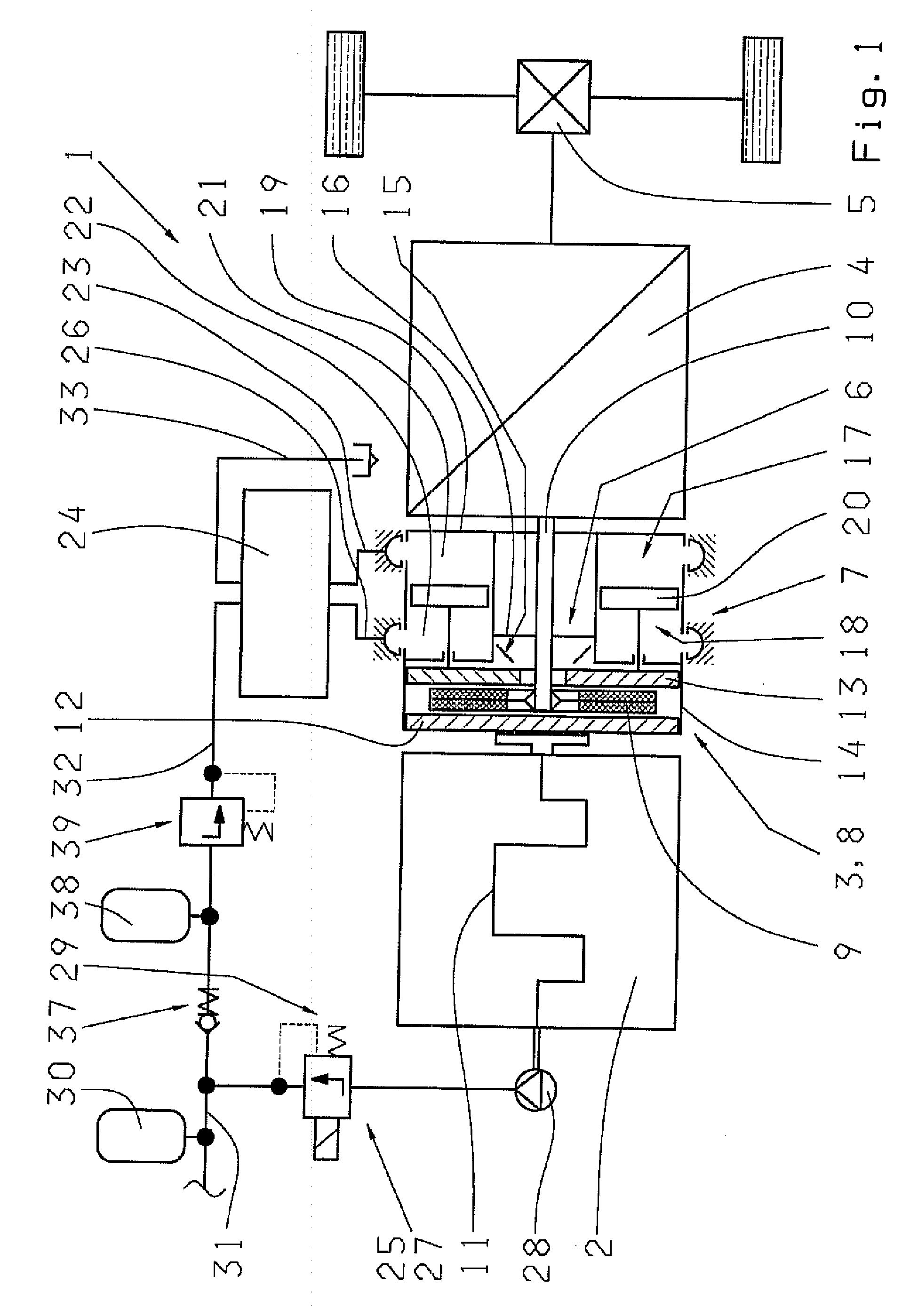

Motor Vehicle Driving Train and Process For Controlling an Automated Engine Clutch

InactiveUS20080194382A1Mount inexpensivelyConstruct relatively simply and economicallyClutchesEngine controllersClutchMotor vehicle driving

A power train of a motor vehicle with a drive motor (2), a transmission (4) with variable transmission ratios connected to an axle drive (5), and an automatic motor clutch. The automatic motor clutch is a passively lockable friction clutch actuated by a spring-loaded pressing device (6) and whose transferable rotational toque (coupling torquet) is adjusted using a clutch actuator (7), and is located in the flow of power between the drive motor (2) and the transmission (4). Improved controllability and a more rapid response of the motor clutch (3) is achieved by the spring-supported pressing device (6) to produce a basic coupling torque below the maximum rotational torque of the drive motor (2) and, a second pressing device (17) regulates a higher coupling torque by way of an effective connection with the clutch actuator (7).The invention involves a power train of a motor vehicle with a drive motor (2) constructed as a combustion engine, a transmission (4) with variable transmission ratios connected to an axle drive (5), and with an automatic motor clutch, which is constructed as a passively lockable friction clutch by means of a spring-loaded pressing device (6) and whose transferable rotational moment (coupling moment) is adjusted using a clutch actuator (7), located in the power flow between the drive motor (2) and the transmission (4). To achieve an improved controllability and a more rapid response of the motor clutch (3) the spring-supported pressing device (6) is designed to produce a basic coupling moment lying below the maximum rotational moment of the drive motor (2) and to regulate a higher coupling moment a second pressing device (17) is provided in an effective connection with the clutch actuator (7).

Owner:ZF FRIEDRICHSHAFEN AG

Eccentric joint fitting for a vehicle seat

A wobble joint fitting for a vehicle seat has a first joint arm, which carries an internal gear and forms a first bearing surface, which are central to a main axis, and a second joint arm to which an eccentric gear is allocated, which comprises an externally toothed pinion and a second bearing surface. The pinion and the second bearing surface are central to an eccentric axis. An eccentric driving part is disposed in the area between the first bearing surface and the second bearing surface. Clamping parts, in a clamping state, displace the eccentric axis relative to the main axis. The eccentric driving part defines the eccentric. The rotary drive of the eccentric driving part causes a rotation of the pinion relative to the internal gear even without the clamping parts being present, wherein only play compensation is not obtained without the presence of the clamping parts.

Owner:KEIPER SEATING MECHANISMS CO LTD

Connecting device for the articulated connection of a wiper blade to a wiper arm, and an adaptor

Owner:ROBERT BOSCH GMBH

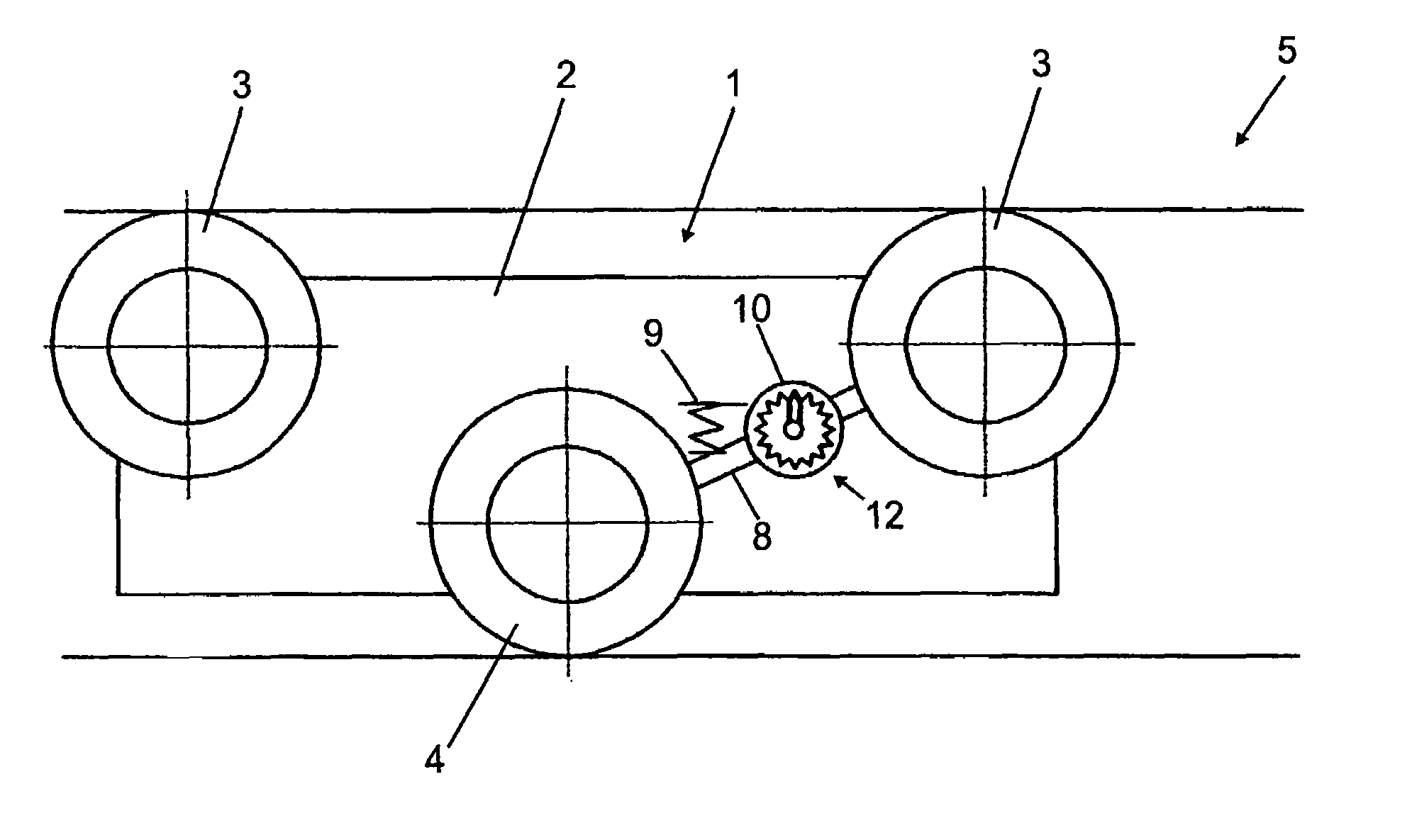

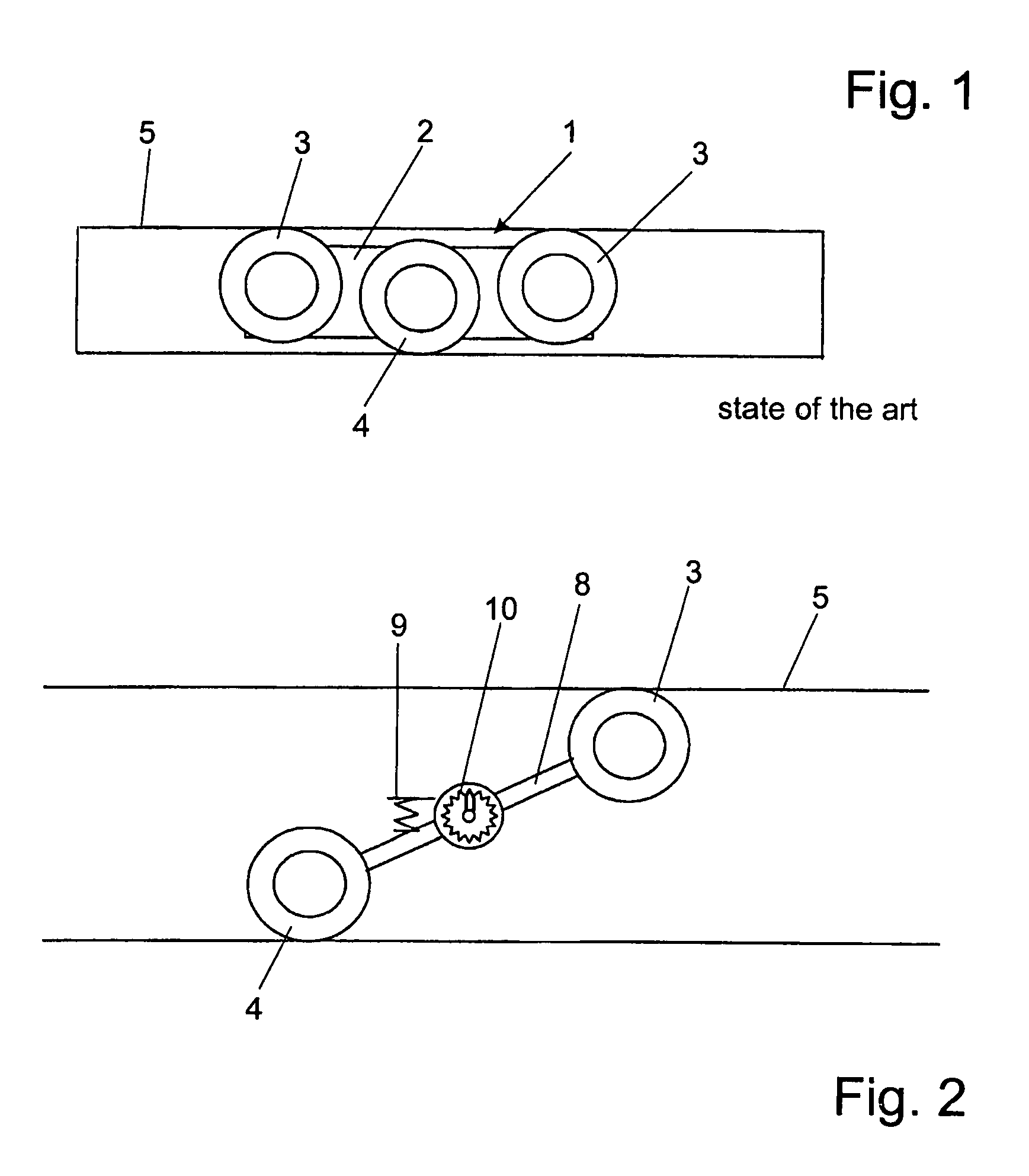

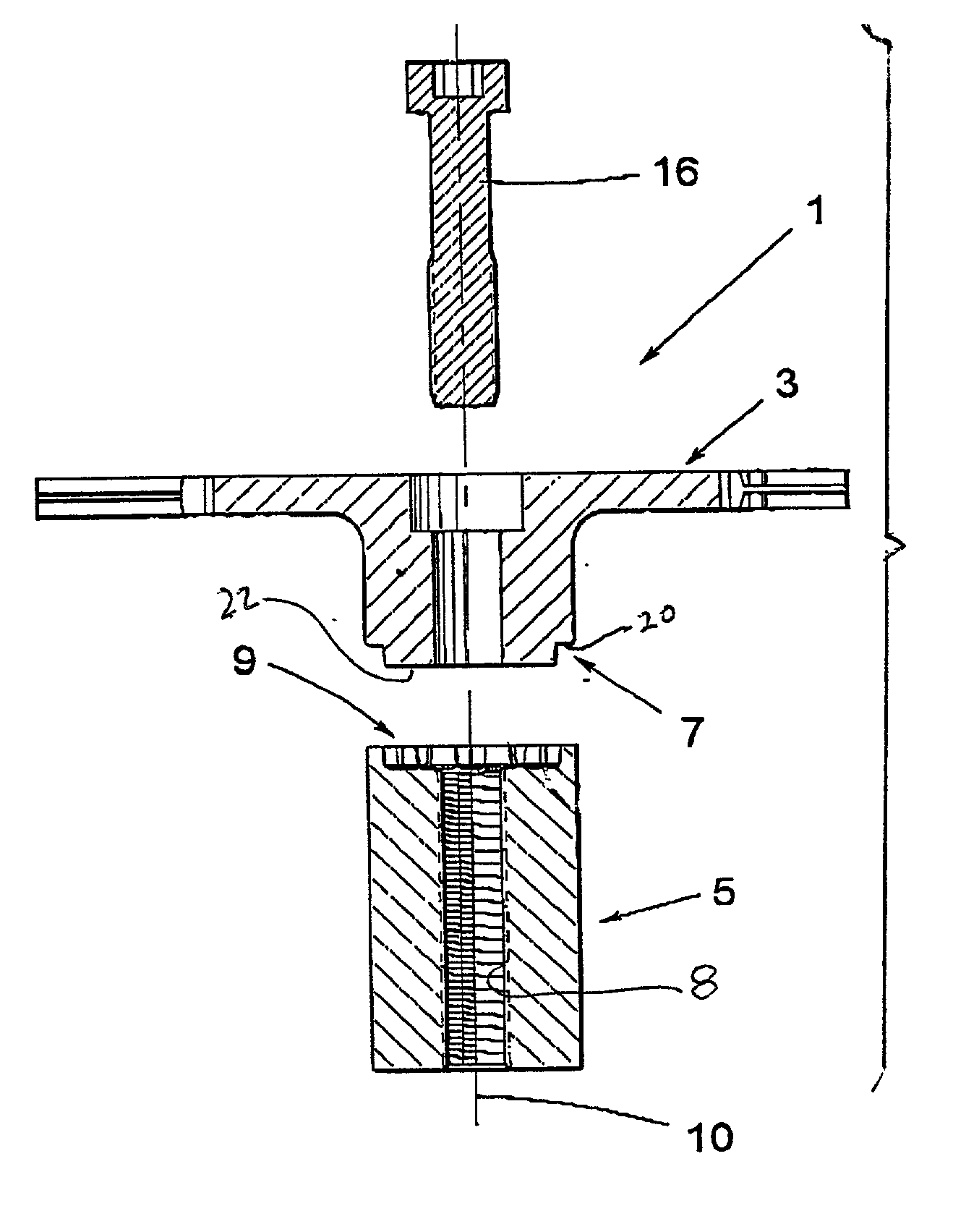

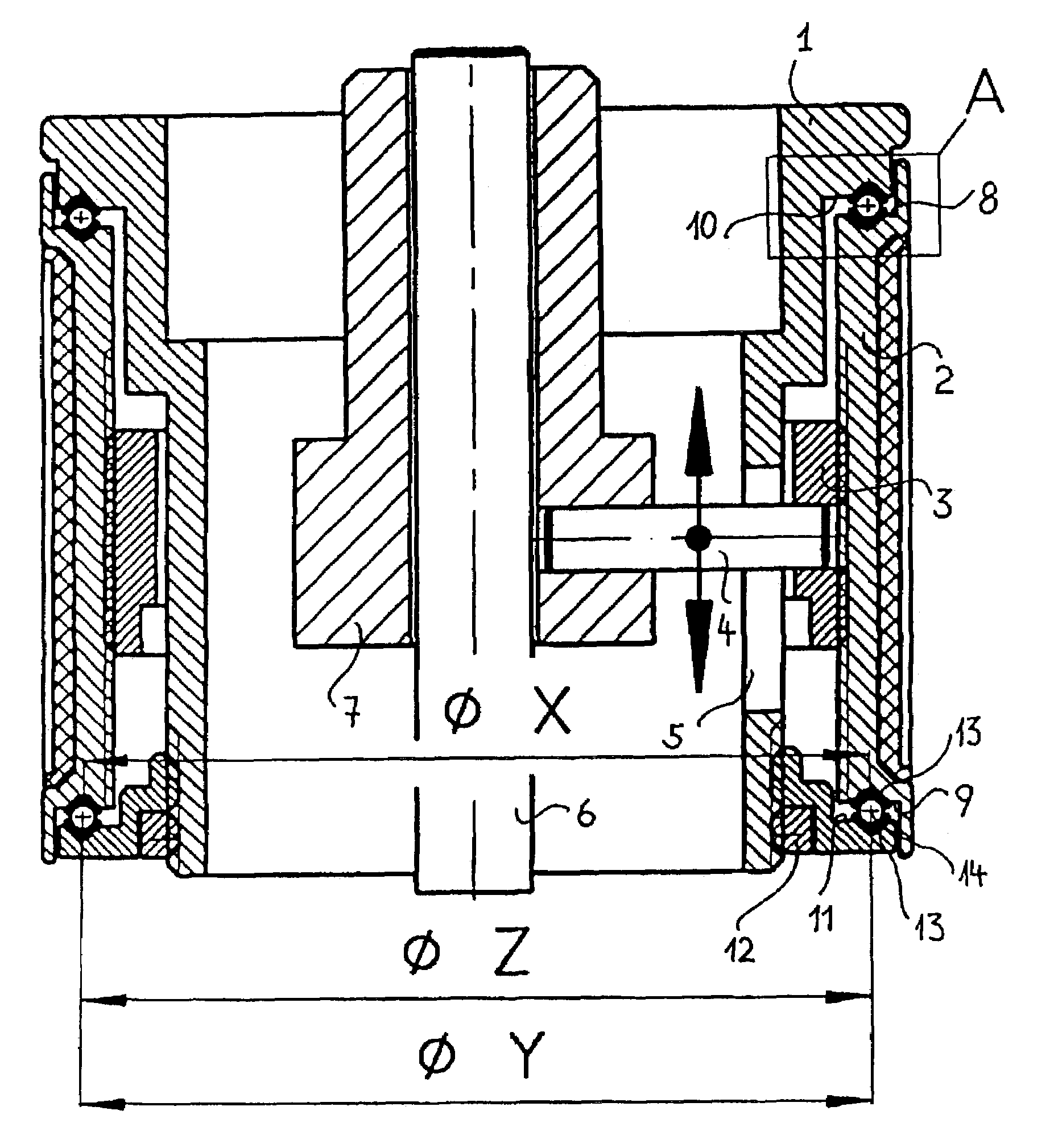

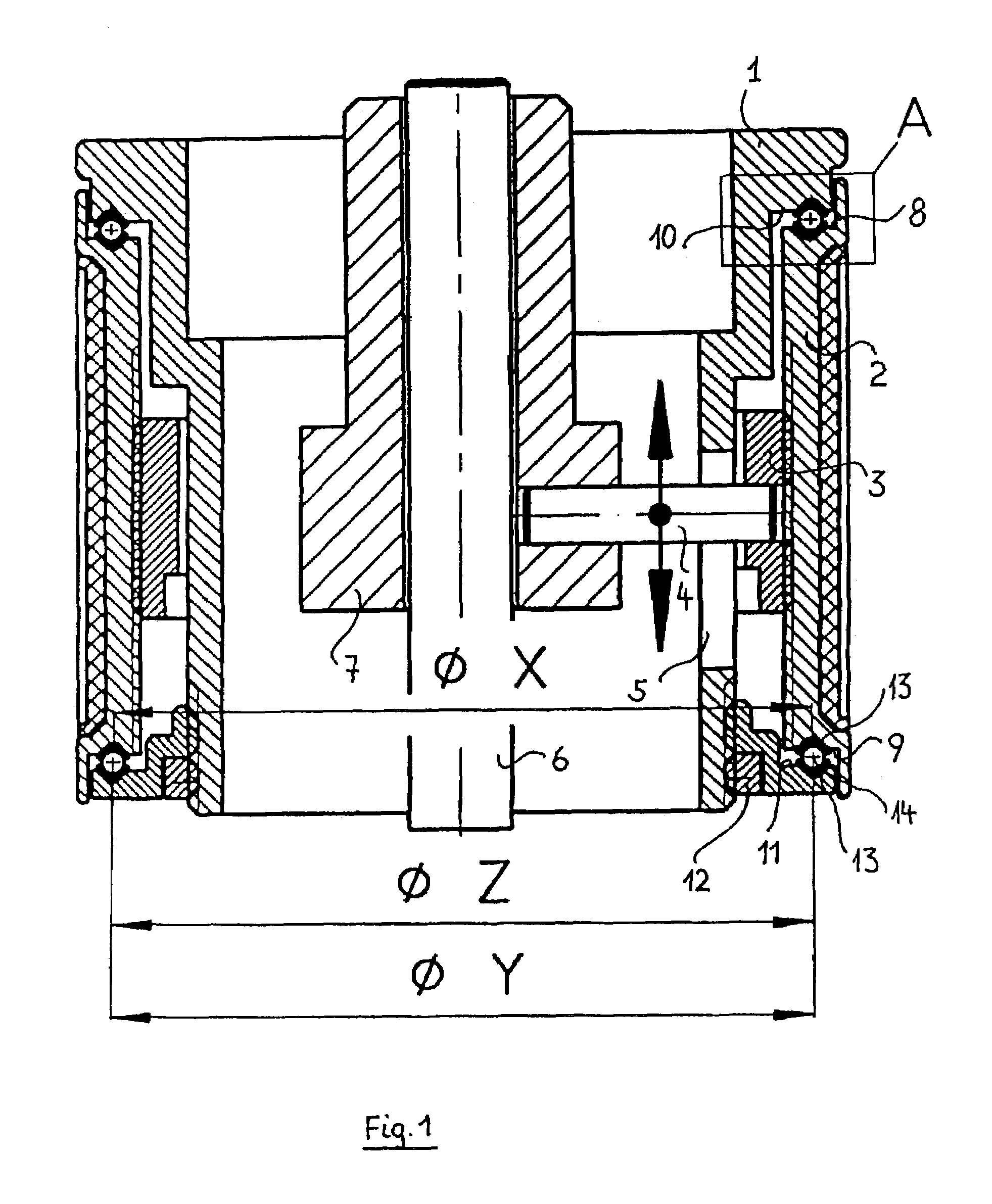

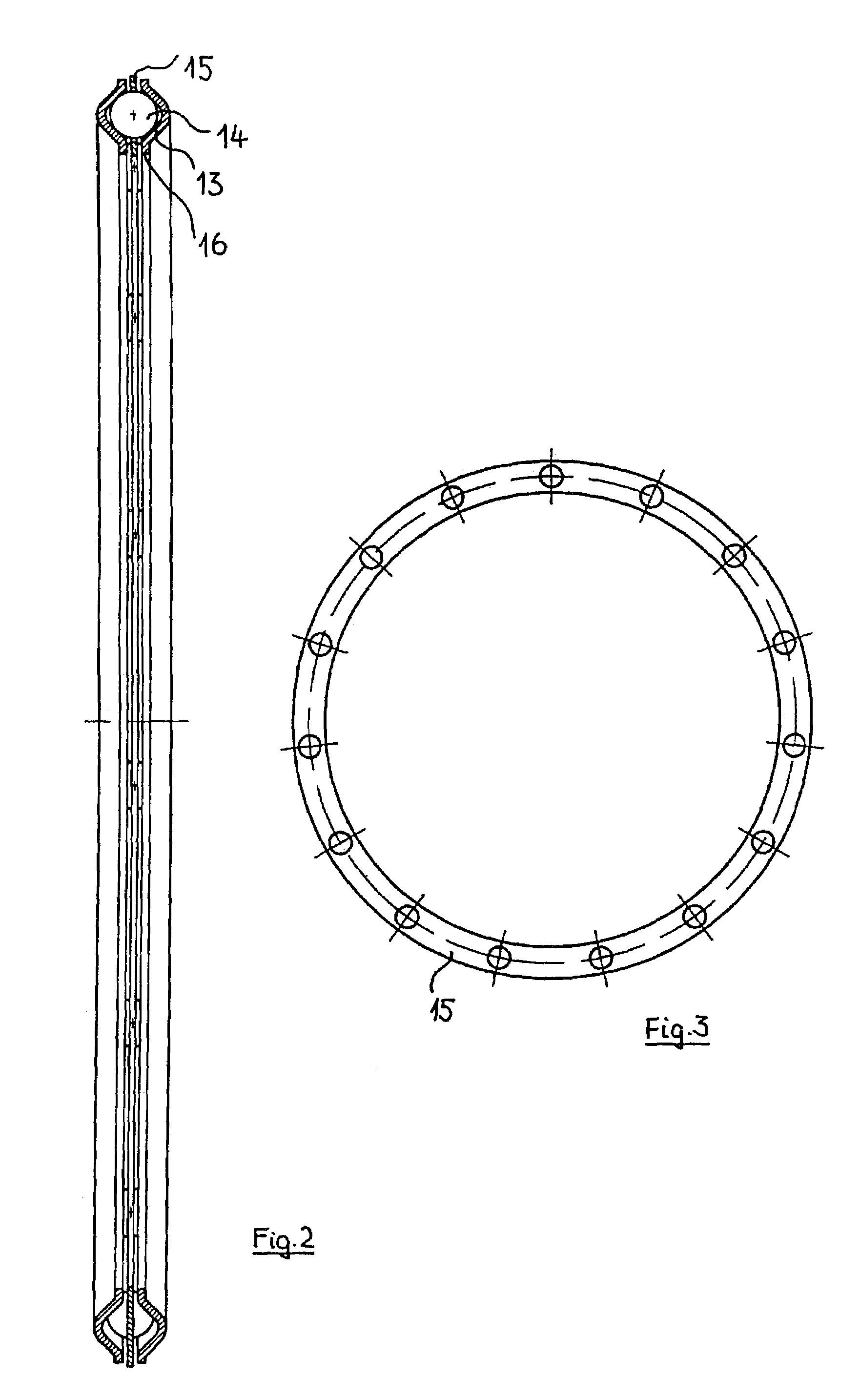

Play-free rotary mounting

InactiveUS7050226B2Low production costRun freelyBall bearingsBearing componentsLeg lengthEngineering

A play-free rotary mounting for a drive roll held on stop surfaces in the axial direction on a cylindrical body, wherein V-shaped annular grooves with an opening angle V are provided at least in one of the end faces of the drive roll and the stop surface located opposite them on the body, V-shaped bearing shells with at approximately identical opening angles and approximately identical leg length are inserted into the annular grooves, the vertex diameters of the annular grooves differ from the vertex diameters of the bearing shells. Balls with a diameter matched to the opening width of the bearing shells are inserted into the bearing shells. At least one of the stop surfaces can be adjusted in the axial direction in order to clamp the drive roll in. Instead of different vertex diameters, different opening angles can also be provided for the annular grooves and opening angles for the bearing shells.

Owner:LEICA GEOSYSTEMS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com