Play-free rotary mounting

a rotary mounting and rotary technology, applied in the direction of instruments, mechanical devices, optical elements, etc., can solve the problems of insufficient space, insufficient wall thicknesses available on the housing and in the drive roll, and the inability to adjust, so as to achieve the effect of low production cost of mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

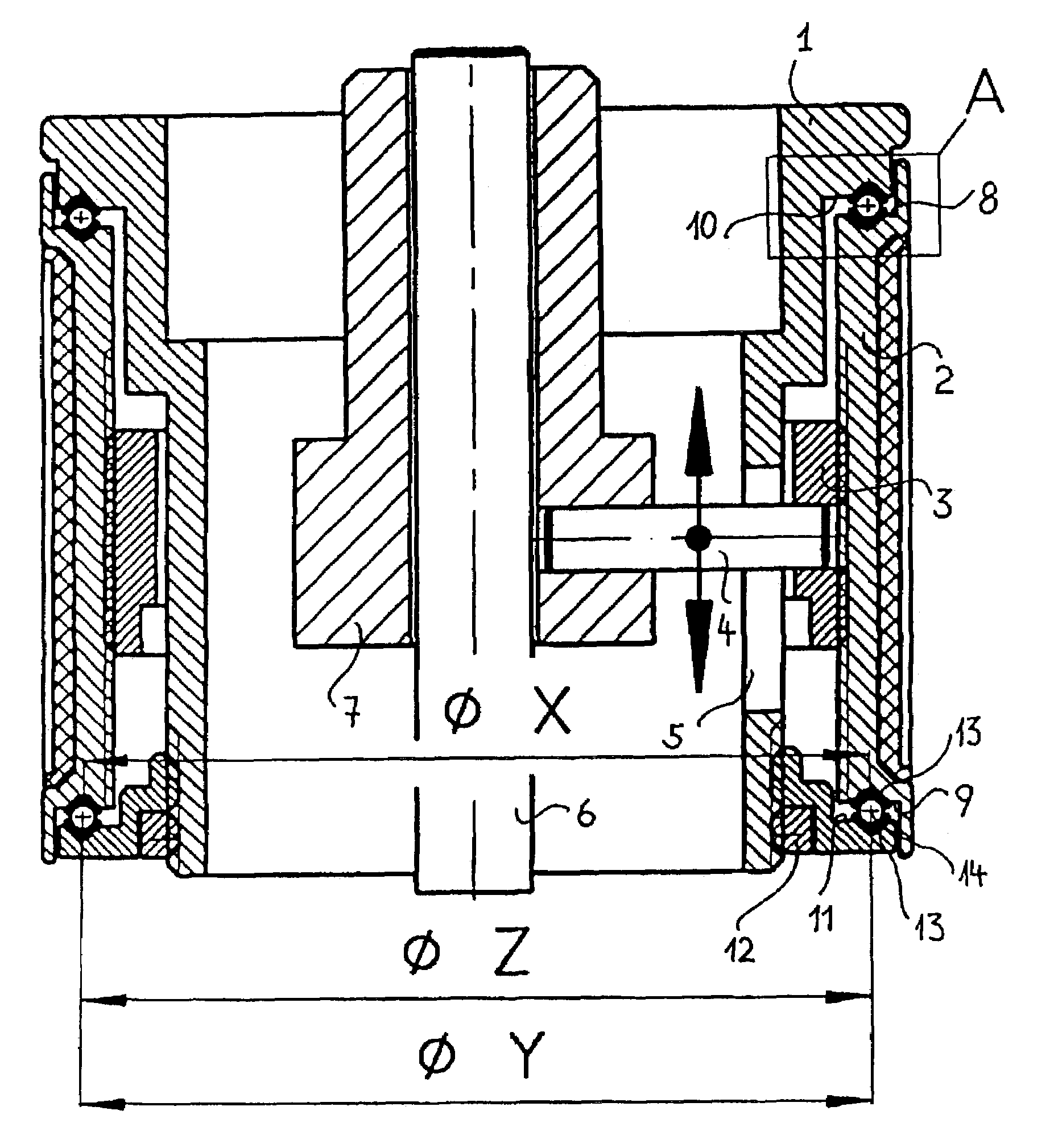

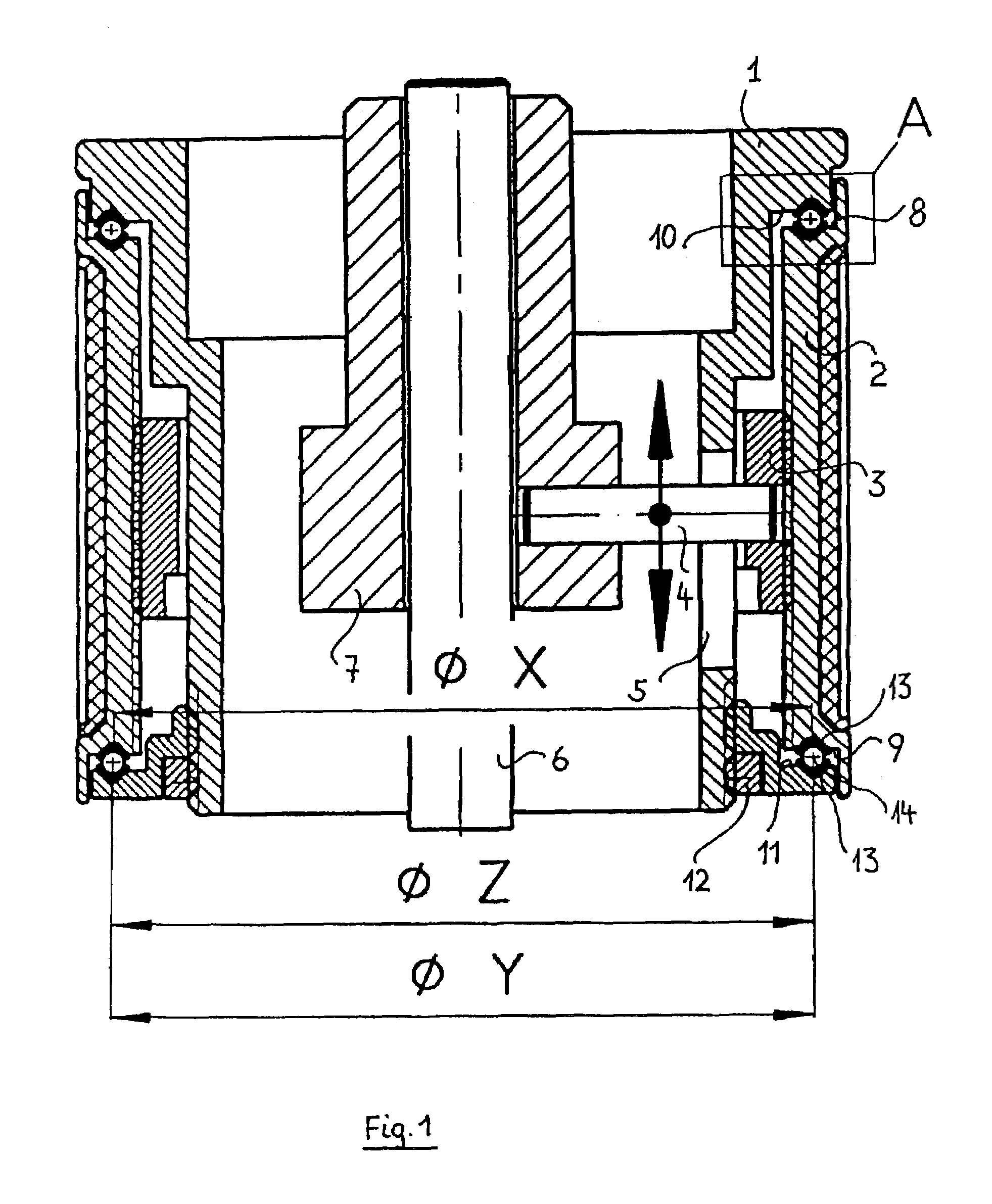

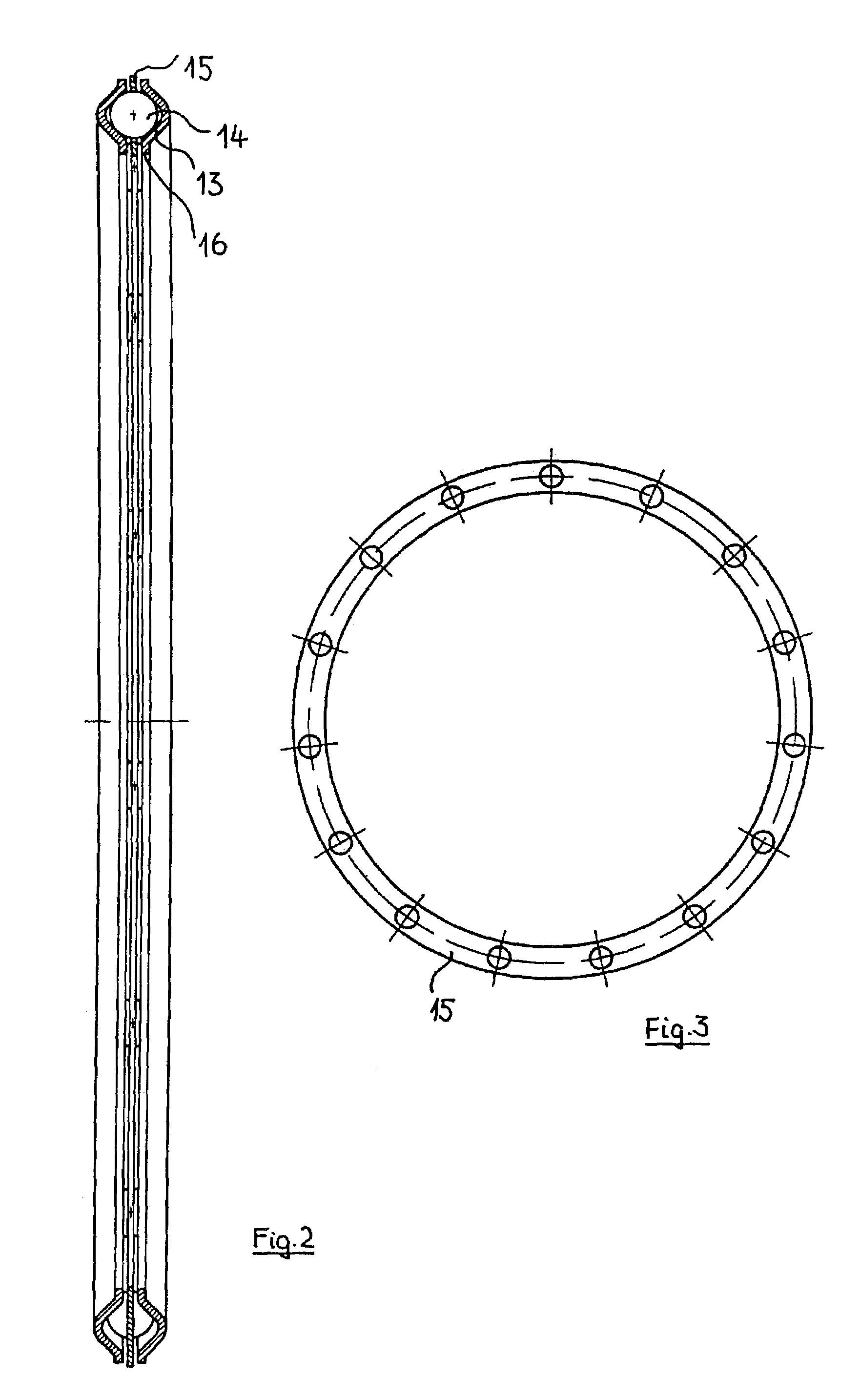

[0022]In FIG. 1, a drive roll 2 is rotatably mounted on a cylindrical body 1. The body 1 is, for example, part of the hinge bridge of a pair of binoculars, and the drive roll 2 is the drive knob for setting the focus. For this purpose, a screw ring 3 is mounted in a thread in the drive roll 2. Inserted into the screw ring 3 is a pin 4 which is guided in a longitudinal slot 5 in the body 1. A sleeve 7, which is coupled to the pin 4, is mounted such that it can be displaced longitudinally on a stationary shaft 6 belonging to the body 1. In the event of rotation of the drive roll 2, the sleeve 7 is displaced in the direction of the arrow on the shaft 6 in a known way. Adjusting elements, not further shown, belonging to the pair of binoculars, are coupled to the sleeve 7. The transmission of the adjustment forces from the drive roll 2 is to take place without play and without any backlash at the points of reversal. As a result of the mounting of the drive roll 2, no additional frictiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com