Roof drilling improvements

a technology for roofs and drilling holes, applied in drilling machines and methods, cutting machines, mining structures, etc., can solve the problems of fracturing the cutting element, pcd cutting inserts may even shatter, and the cutting element of superabrasives can fail, so as to achieve the effect of faster drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

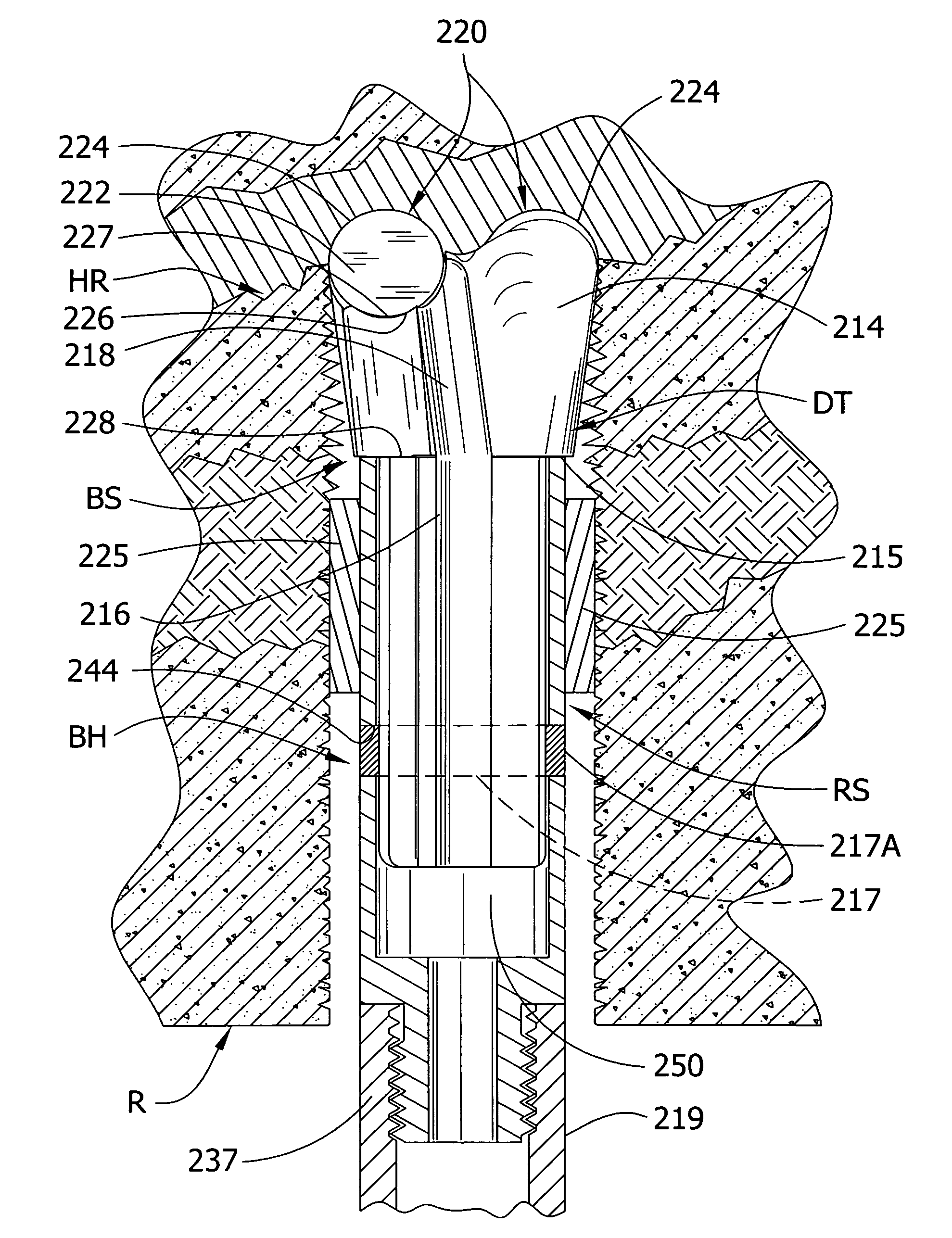

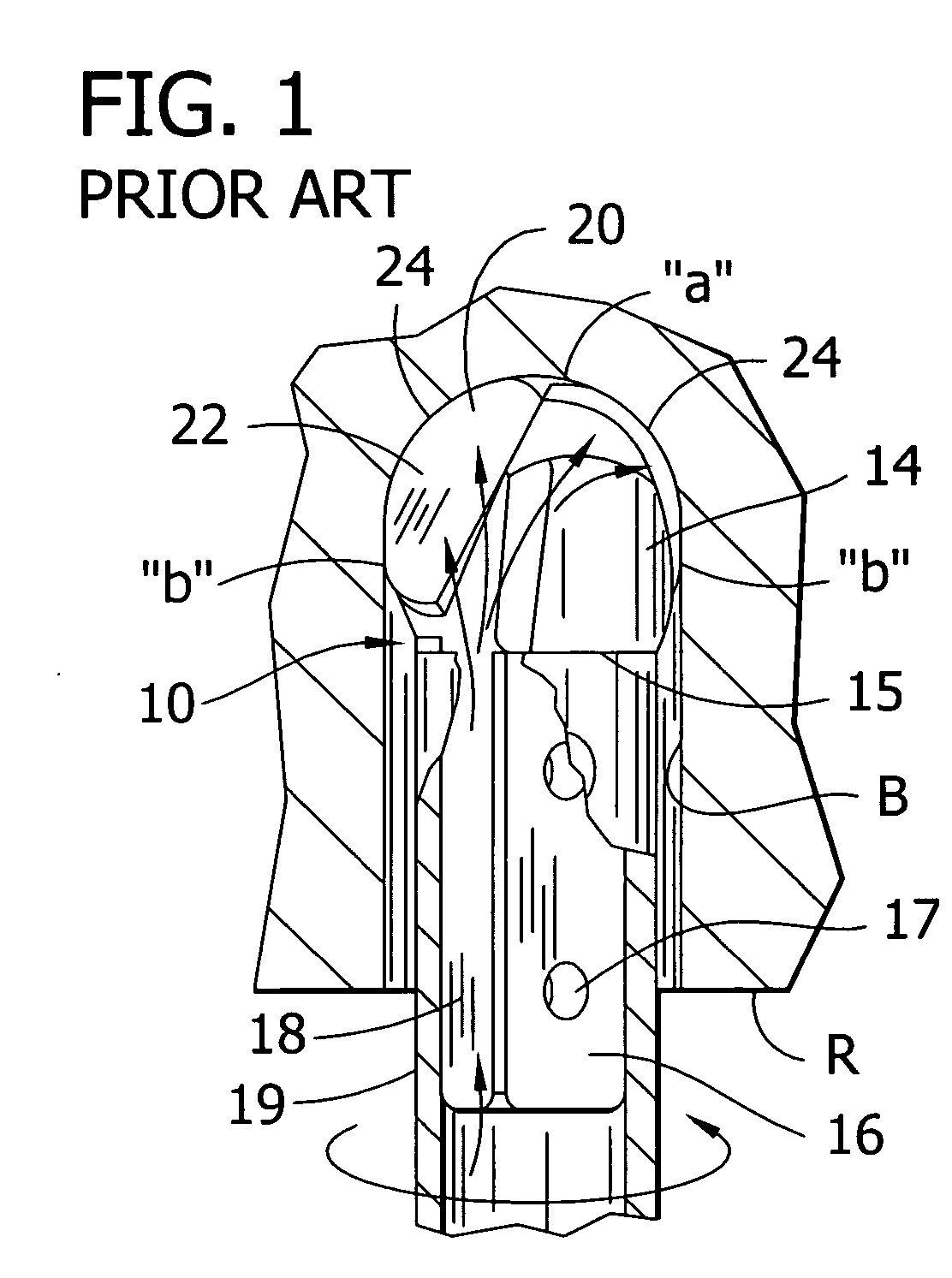

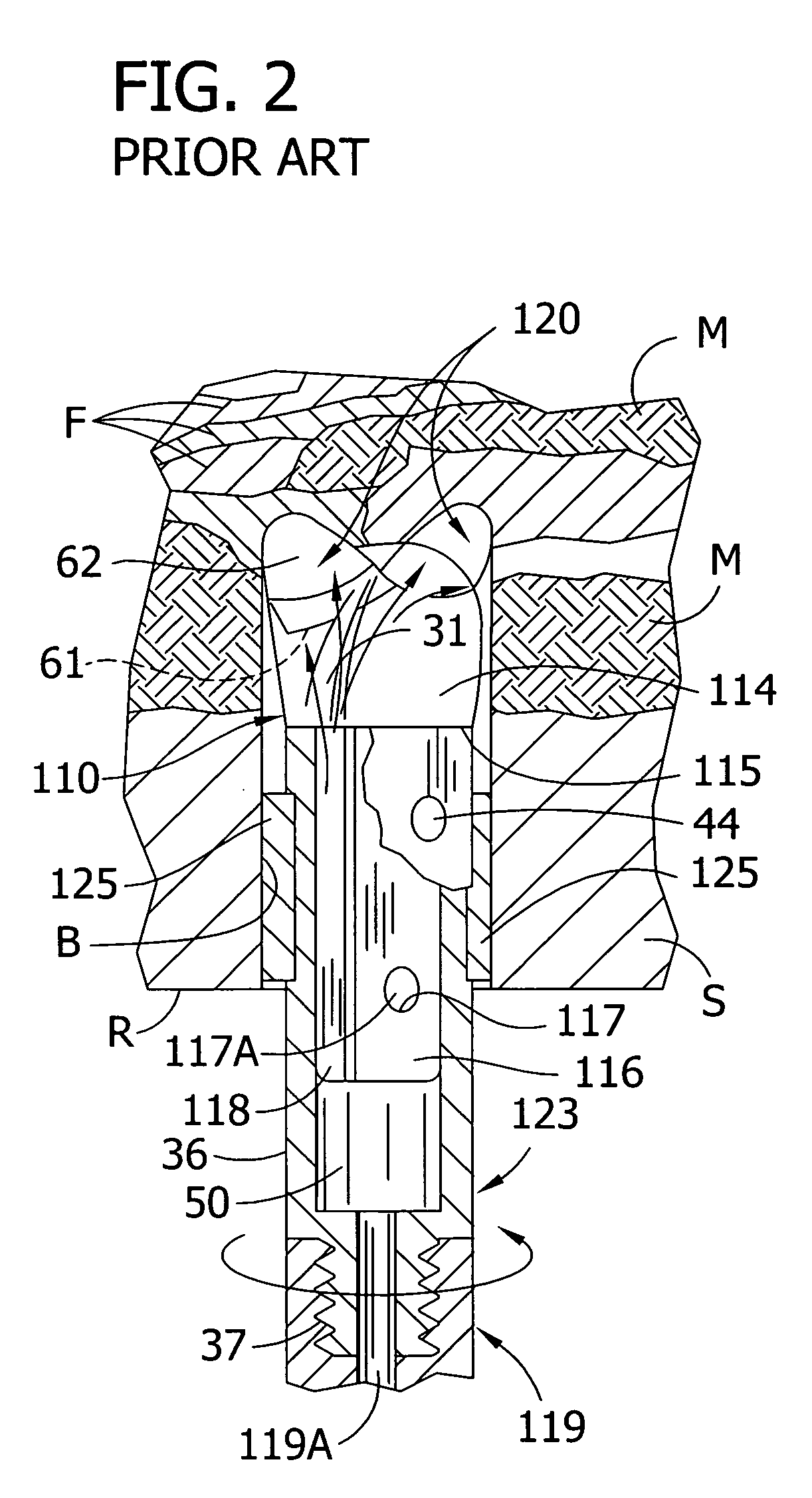

[0024] The present invention relates to improvements in rotary drag bits, particularly roof drill bits for boring and drilling operations in metal / non-metal mining and construction, and to methods for carrying out such metal / non-metal mining operations. The following definitions will be useful for a fuller understanding of the scope of the invention disclosed:

[0025]“Metal / non-metal mine” or “metal / non-metal mining” is used herein as a generic or comprehensive term to mean any type of underground mine or tunnel and encompasses ore mining, hard rock mining and coal mining operations.

[0026]“High-fatigue resistant” and / or “high alloy” are used herein with reference to the material strength of steel having a tensile strength in the range of 209,000 to 211,000 psi (typically 209,500 to 210,000 for 4340 steel) and a fatigue yield strength in the range of 135,000 to 145,000 psi (typically 141,000 psi for 4340 steel).

[0027]“Hard / soft rock” is used to designate earth formations that are ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com