Grinding type anti-drop rock sampling device and use method thereof

A technology for rock sampling and anti-dropping, which is used in the extraction of undisturbed core devices and earthwork drilling, etc., can solve the problems of low core cutting rate, etc., and achieve the effects of avoiding core breakage, low failure rate and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

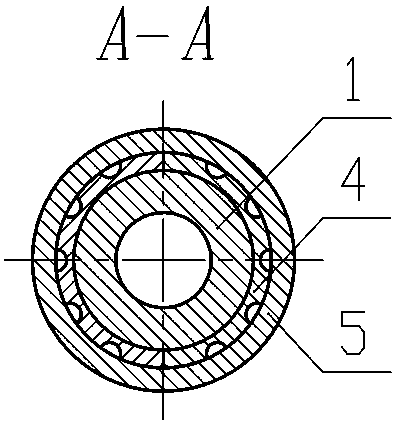

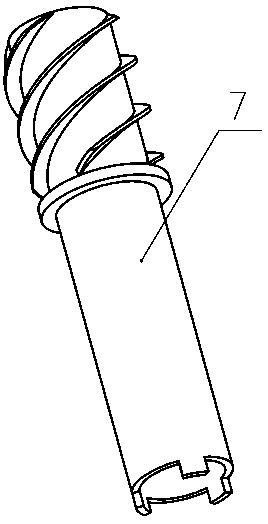

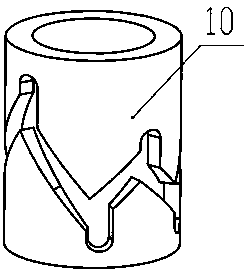

[0020] like figure 1 and figure 2 As shown, a kind of grinding type anti-dropping rock sampling device of the present invention is made of upper joint 1, thrust bearing a2, bearing seat 3, snap ring 4, outer cylinder 5, inner cylinder 6, rotor 7, thrust bearing b8, slide Pin 9, limit cylinder 10, spring a11, claw 12, sliding sleeve 13, spring b14 and guide head 15 constitute; Its structural feature is: the upper end of outer cylinder 5 is connected with the outer rock core cylinder screw thread of coring tool, and outer The lower end of the barrel 5 is connected to the coring drill with a threaded thread, and the upper end of the upper joint 1 is connected to the inner core barrel of the coring tool with a threaded thread; the middle of the outer barrel 5 is evenly provided with two flow holes in the circumferential direction, and the middle of the outer barrel 5 has two flow holes. A pin hole is set under the hole, a circle of raised steps is set at the lower part of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com