Polycrystalline diamond composite sheet with extensions

A technology of polycrystalline diamond and composite sheet, which is applied in diamond, drilling equipment, earth-moving drilling and mining, etc., can solve the problems of indigestion, slow machine speed, etc., so as to reduce thermal damage, reduce grinding heat, and improve cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

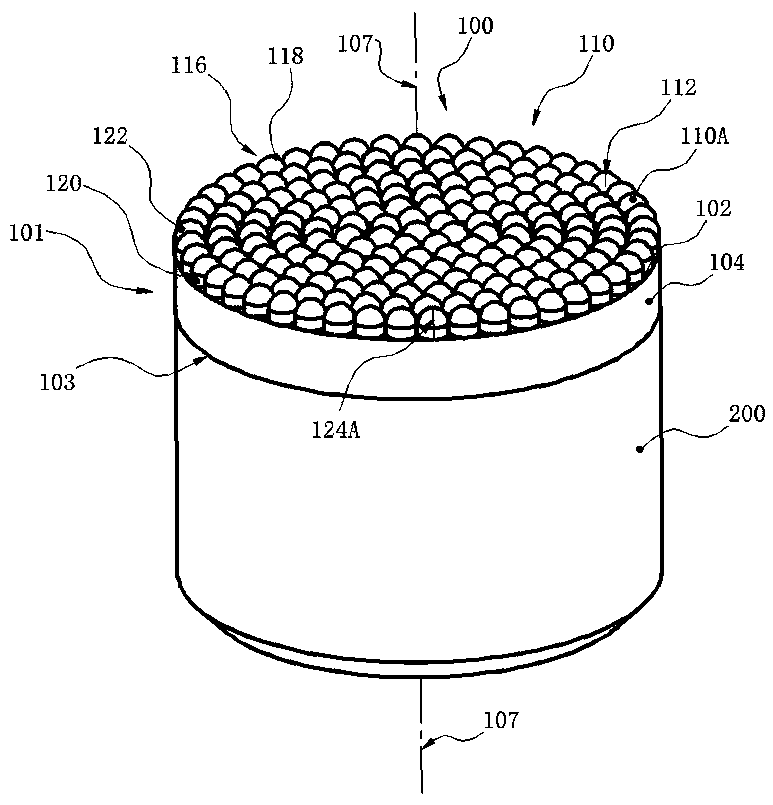

[0099] like figure 1 As shown, in this embodiment, the composite sheet includes a polycrystalline diamond layer 101 and a cemented carbide substrate 200, which are vertically grown on the first surface 102 of the polycrystalline diamond layer 101 in the form of annular arrangement and distribution of the central axis 107 of the first surface. The first surface extension 110A is divided into two parts, wherein the first part 120 is hemispherical, the second part 122 is cylindrical, and the height 124A of all the extensions 110A is the same and perpendicular to the first surface 102, the side 104 has no extend. The spaces between adjacent extensions form annular alternating coolant passages.

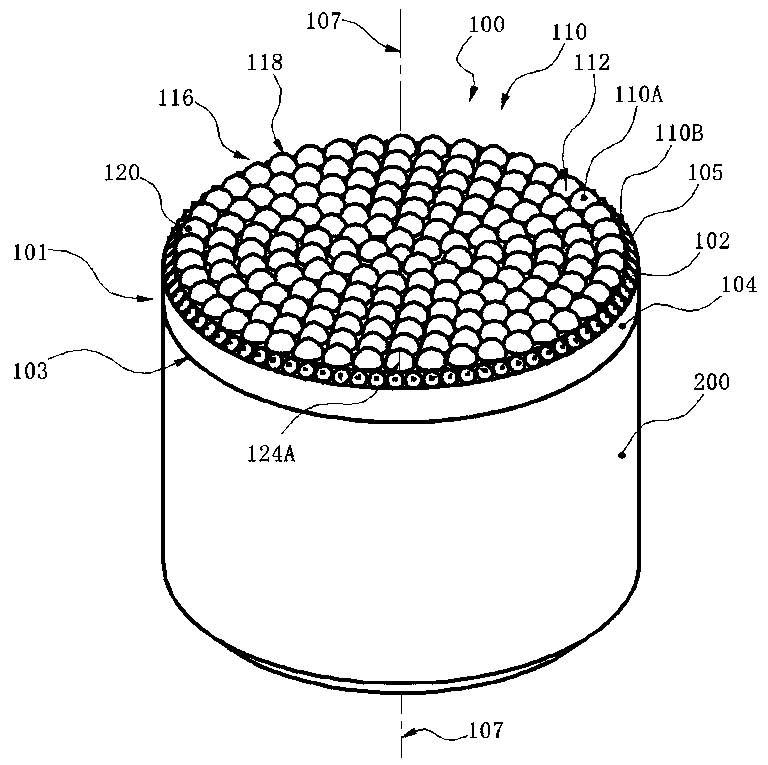

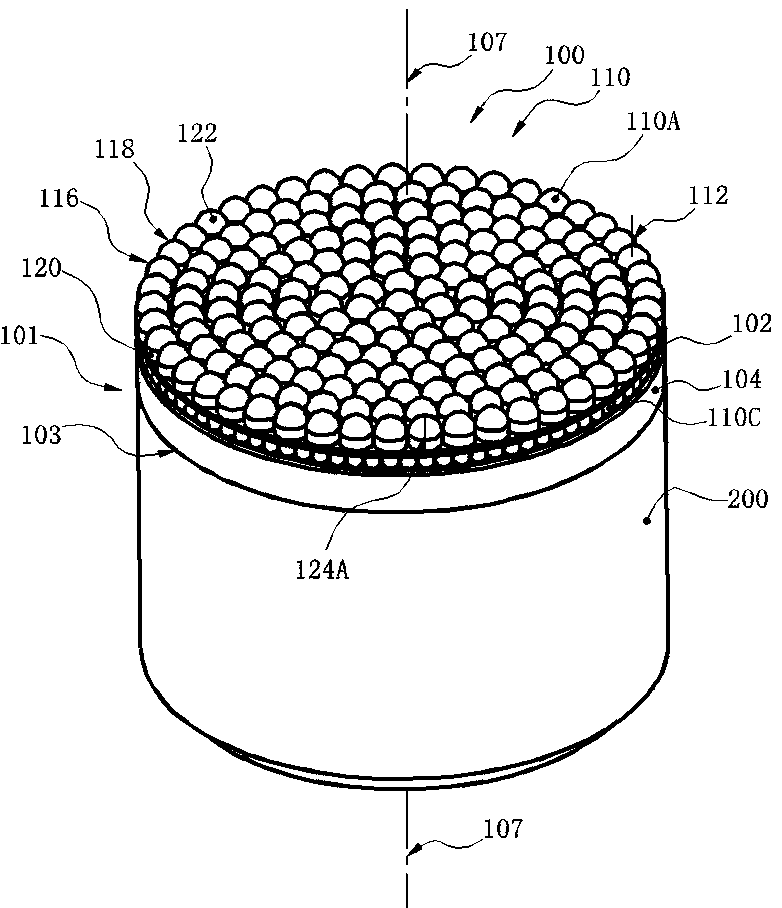

[0100] like figure 2 shown, it is the same as figure 1 The only difference is that there is no second portion of the first surface extension 110A, leaving only the figure 1 A chamfered surface 105 is provided between the first surface 102 and the side surface 104, and a chamfered surf...

Embodiment 2

[0105] like Figure 4 to Figure 8 , Figure 49 As shown, the present embodiment includes five similar products, all of which are vertically grown on the first surface 102 of the polycrystalline diamond layer 101 with the first surface extensions 110A arranged in the radial distribution lines 108, and between the first surface extensions 110A A radial distribution channel is formed, and the contour line 130 formed between the farthest point 119 of the extension 110A on the same straight line from the first surface 102 is a radial broken line, such as Figure 49 As shown, the height of the extension is low inside and outside and high in the middle, and a chamfered surface 105 is provided between the first surface 102 and the side surface 104, and a chamfered surface extension 110B of various shapes is grown on the chamfered surface 105. The face extension 110B is monolayered and completely spreads over the chamfer face 105 .

[0106] Figure 4 The shape of the first surface e...

Embodiment 3

[0108] like Figure 8 to Figure 11 , Figure 50 As shown, this embodiment includes four similar products, all of which are provided with a circular boss 126 in the center of the first surface 102 of the polycrystalline diamond layer 101, and the extensions 110 grown vertically on the first surface 102 are distributed radially The first surface extensions 110A arranged by the lines 108 are evenly distributed around the circular boss 126, and the heights 124A and 124B of the first surface extensions 110A gradually decrease from the outside to the inside, such as Figure 9 As shown, the height ratio is 5:4.5:4:3.5 from the outside to the inside, and a chamfered surface 105 is provided between the first surface 102 and the side surface 104, and the shape of the chamfered surface 105 is grown on the first surface 102. The extension 110 has the same shape as the chamfered surface extension 110B, which is single layered and fully covered on the chamfered surface 105 .

[0109] in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com