Non-planar polycrystalline diamond composite piece and drill bit for oil drilling

A polycrystalline diamond, non-planar technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of lack of entry ability and drilling efficiency, difficult entry, and slow drilling, so as to improve entry capability. and machine speed, reduce grinding heat, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

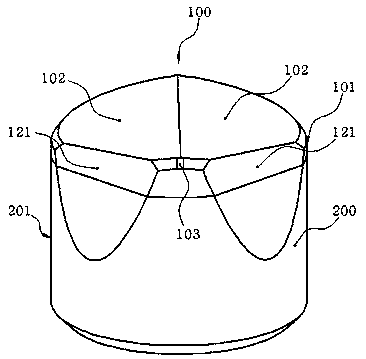

[0042] Such as figure 1 As shown, a double-edged non-planar polycrystalline diamond composite sheet, the composite sheet includes a polycrystalline diamond layer 100 and a cemented carbide substrate 200 compositely wrapped at the bottom of the polycrystalline diamond layer, and the polycrystalline diamond layer 100 is exposed The top surface to the outside is composed of two surface structures 102 , the surface structures 102 are inclined planes, and the two inclined planes are connected to form a roof-like structure of the polycrystalline diamond layer 100 . The surface structure 102 and the peripheral surface 101 of the polycrystalline diamond layer form two cutting edges 103 extending radially along the polycrystalline diamond layer, and the polycrystalline diamond layer and the cemented carbide substrate are distributed on both sides of one cutting edge 103 There is an integrally extending non-horizontal structure 121, the two non-horizontal structures 121 are oblique plan...

Embodiment 2

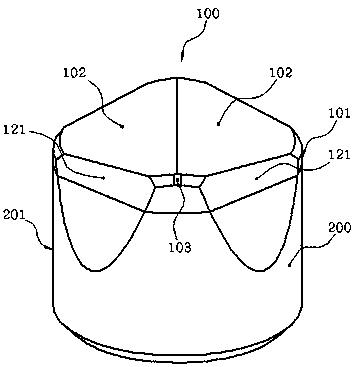

[0044] Such as figure 2 As shown, a double-edged non-planar polycrystalline diamond composite sheet, the composite sheet includes a polycrystalline diamond layer 100 and a cemented carbide substrate 200 compositely wrapped at the bottom of the polycrystalline diamond layer, and the polycrystalline diamond layer 100 is exposed The top surface to the outside is composed of two surface structures 102 , the surface structures 102 are inclined planes, and the two inclined planes are connected to form a roof-like structure of the polycrystalline diamond layer 100 . The surface structure 102 and the peripheral surface 101 of the polycrystalline diamond layer form two cutting edges 103 extending radially along the polycrystalline diamond layer, and the polycrystalline diamond layer and the cemented carbide substrate are distributed on both sides of each cutting edge 103 There is a non-horizontal structure 121 extending integrally. The non-horizontal structures 121 on both sides of ea...

Embodiment 3

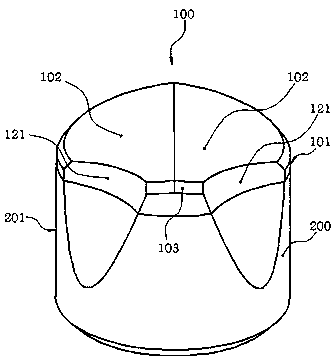

[0046] Such as image 3 As shown, a double-edged non-planar polycrystalline diamond composite sheet, the composite sheet includes a polycrystalline diamond layer 100 and a cemented carbide substrate 200 compositely wrapped at the bottom of the polycrystalline diamond layer, and the polycrystalline diamond layer 100 is exposed The top surface to the outside is composed of two surface structures 102 , the surface structures 102 are inclined planes, and the two inclined planes are connected to form a roof-like structure of the polycrystalline diamond layer 100 . The surface structure 102 and the peripheral surface 101 of the polycrystalline diamond layer form two cutting edges 103 extending radially along the polycrystalline diamond layer, and the polycrystalline diamond layer and the cemented carbide substrate are distributed on both sides of one cutting edge 103 There is an integrally extended non-horizontal structure 121, the two non-horizontal structures 121 are concave curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com