Drill jumbo

A technology of drilling rig and assembly, which is applied to drilling equipment, drilling equipment and methods, and earth-moving drilling and mining, etc., can solve the problems of high equipment cost and inability to construct hard rocks, and achieve the effect of rapid modular installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

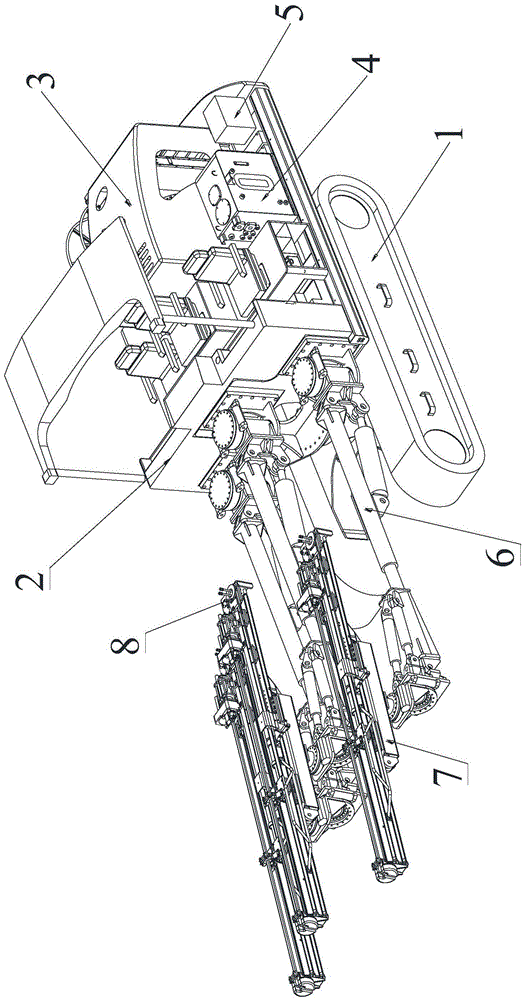

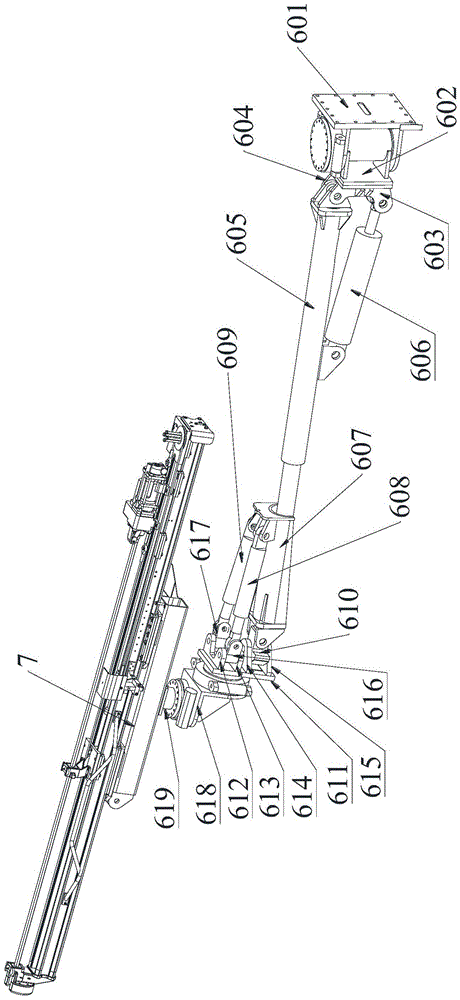

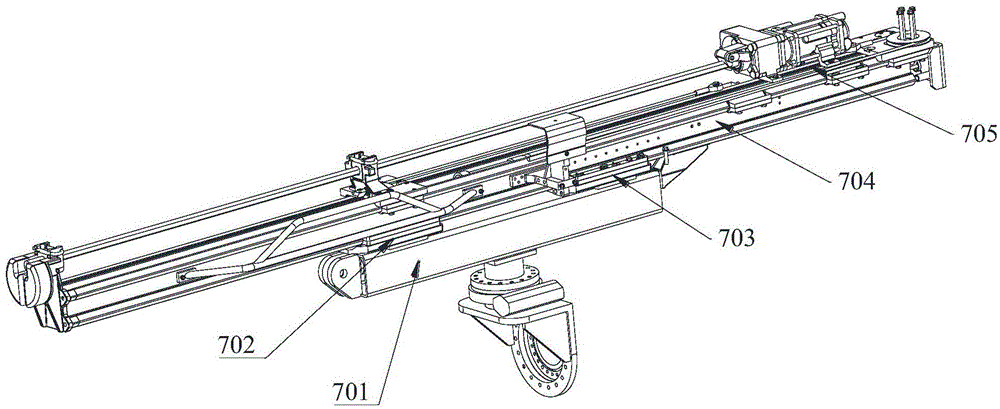

[0046] This embodiment provides a rock drilling jumbo, which includes a walking system 1, a frame 2, a power system 3, a hydraulic system 4, an electrical system 5, a drilling boom assembly 6, a propulsion beam assembly 7 and a replaceable rock drilling Working component 8.

[0047] The walking system is a crawler vehicle, and the frame is arranged on the crawler vehicle, so as to move the position of the frame and other parts installed on the frame by the crawler vehicle, and adjust the frame and Other components mounted on the frame provide effective support.

[0048]The frame includes a front frame and a rear frame, and the front frame and the rear frame are all fixed on the chassis of the tracked vehicle, refer to figure 1 , the front frame is fixed on the left side of the tracked vehicle, and the rear frame is fixed on the right side of the tracked vehicle.

[0049] The power system, hydraulic system, electrical system and wireless remote control system are all installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com