Unit plant and solid electric heat storage unit of combined structure

A technology of unit unit and combined structure, which is applied in the direction of fluid heaters, heat storage equipment, heat storage heaters, etc., can solve the unfavorable heat exchange efficiency of solid heat storage boilers, improve heat storage capacity, and do not consider the convenience of equipment maintenance and maintenance Problems such as internal thermal storage heat exchange and ventilation air path are too long, so as to simplify the process and difficulty of design and construction, reduce personnel and costs, and improve system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

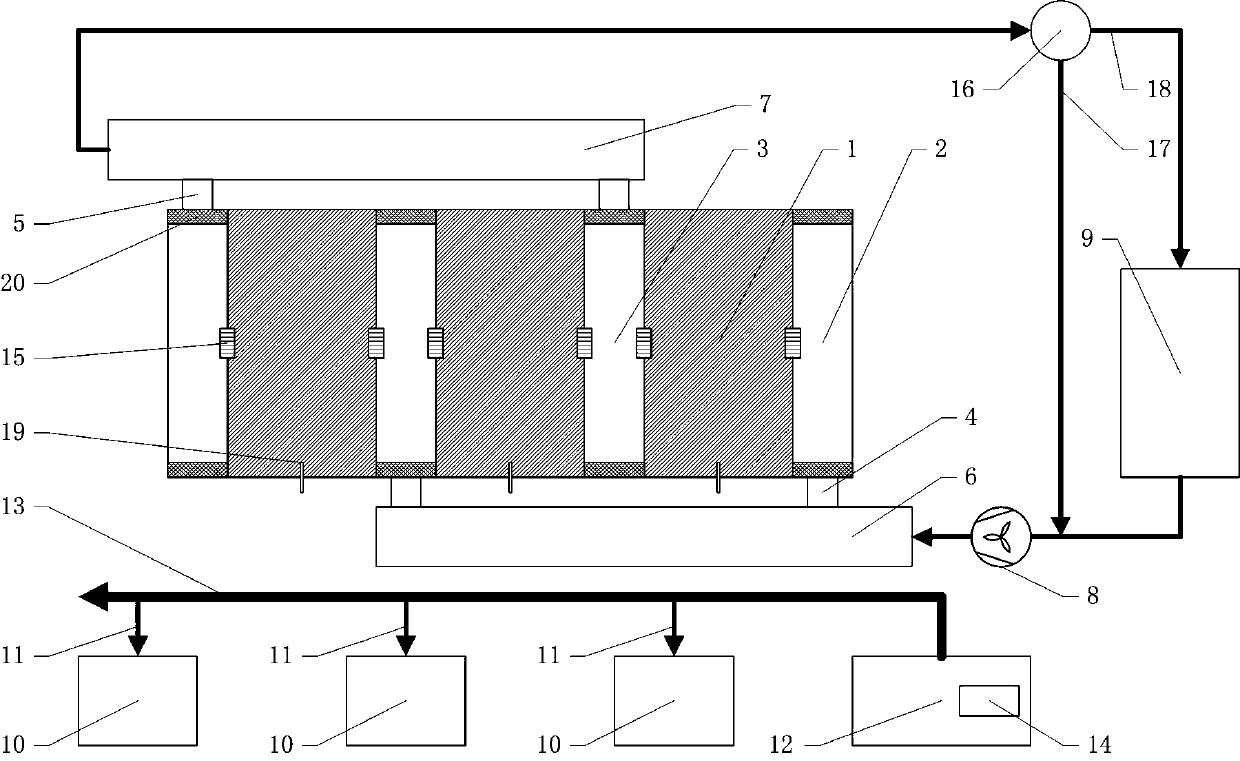

[0029] Such as figure 1 Shown is the top schematic diagram of the solid heat storage unit system structure. The unit unit and the solid electric heat storage unit with combined structure include a unit unit (1), a unit air inlet chamber (2), a unit air outlet chamber (3), an inlet Air outlet (4), air outlet (5), air inlet main pipe (6), air outlet main pipe (7), fan (8), heating equipment (9), unit power distribution cabinet (10), unit inlet line (11 ), main distribution cabinet (12), main busbar (13), intelligent measurement and control device (14), connection mechanism (15), air volume distribution device (16), bypass pipe (17), working pipe (18), temperature Sensor (19), plane insulation wall (20).

[0030] figure 1Among them, there are three unit units (1), which can be numbered sequentially as unit units (1) 1, 2, and 3 from left to right. Unit No. 1 unit (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com